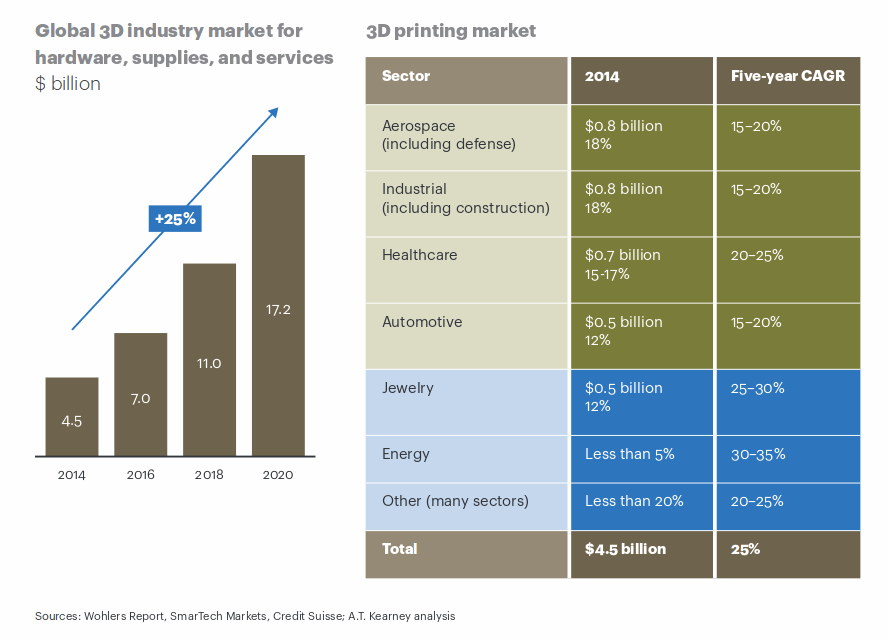

Research by consultancy firm A.T. Kearney finds that the global market for the 3D printing industry will grow to $17.2 billion by 2020.

Thanks to key benefits like mass customisation, waste reduction and improved speed to market, the global market for 3D printing is predicted to grow from $4.5 billion today to $17.2 billion by 2020, according to a study by A.T. Kearney. In particular, the jewellery and the energy sectors will see strong growth, as the technology introduces significant changes to manufacturing.

The report, titled ‘3D Printing: A Manufacturing Revolution’, looks at the current status of the 3D printing industry, and spotlights growth areas over the next five years. According to their analysis, the market for hardware, supplies and services is looking very positive indeed. The question is not if, but when companies need to start considering 3D printing.

The market today is worth approximately $4.5 billion, with the Aerospace sector accounting for 18% market share, Industrial also at 18%, followed by Healthcare at around 16%. The Automotive and Jewellery sectors both represent a 12% market share, while Energy holds at 5%, and the remainder accounting for 20% of the share.

5 Factors Driving 3D Printing Industry Growth

So what are the factors driving this boom in the 3D printing market? The benefits of 3D printing technology over traditional forms of manufacturing can be summarised across five different impact areas.

1. Mass Customization

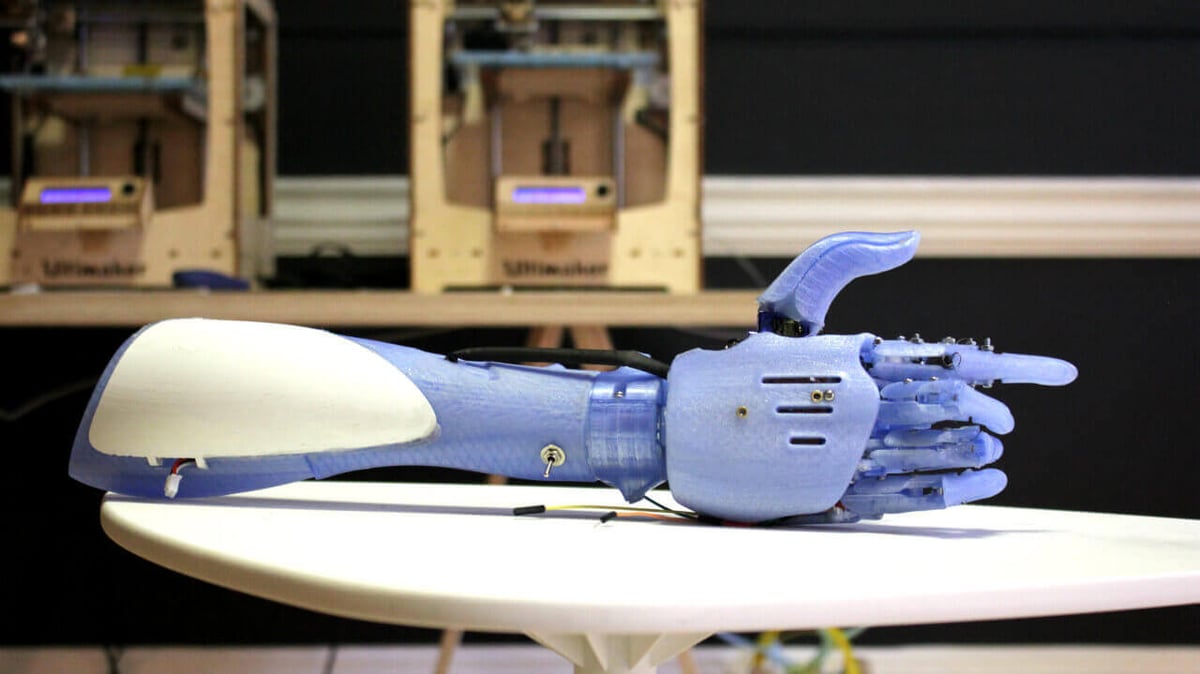

3D printing allows allow people to create items built to their precise specifications, with custom-built designs opening up a wealth of possibilities. A great example are personalized medical implants and prostheses, like those developed in collaboration between Reddit users and Wevolver.

2. New Capabilities

Items can be now be mass produced without high-fixed capital costs related to their specific design. Jet engine components frequently require complex assembly and have high fly-to-buy ratios, but these obstacles are removed with 3D printing. Read our Vulcan-1 story for example.

3. Lead Time & Speed

3D printing allows for rapid prototyping, or even real-time prototyping, in a wide range of mediums on the basis of data templates. This benefits the whole design and production process, ultimately leading to reduced lead time and speed to market. The Coolest Cooler is but one recent example.

4. Supply Chain Simplification

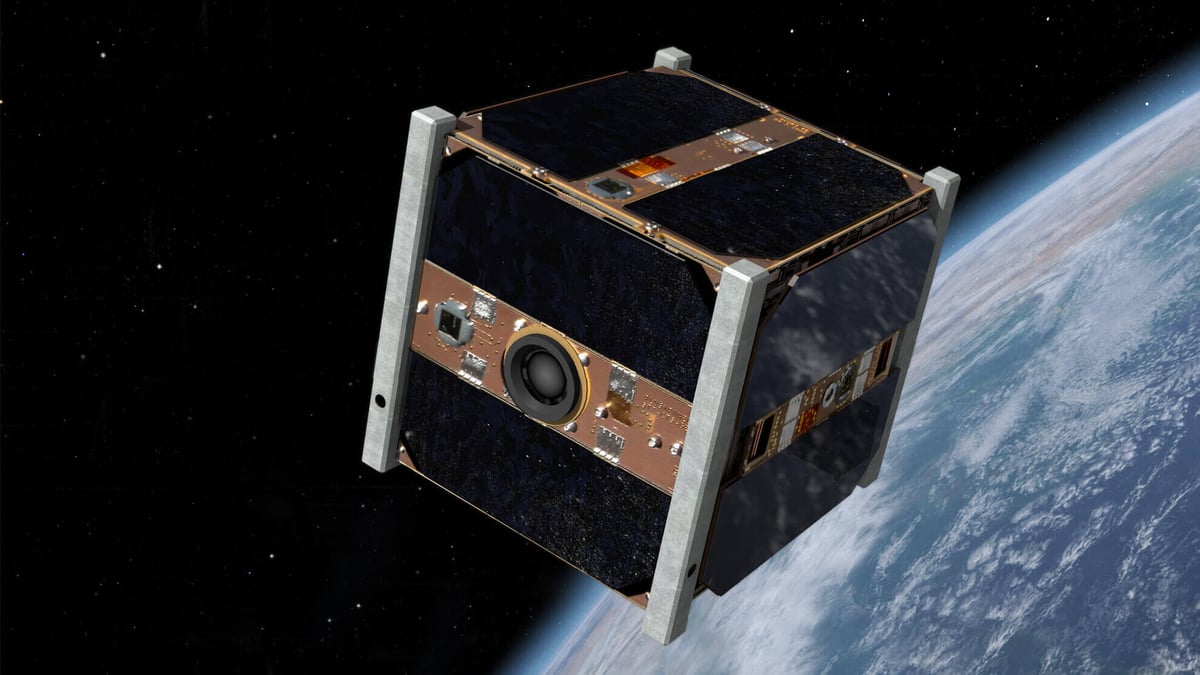

With 3D printers easily deployable and moveable, the whole process can be enacted close to markets, thereby requiring less inventory. The most spectacular example of this principle are 3D printed satellites that can be manufactured in outer space and launched directly into orbit.

5. Waste Reduction

Unused base material can be used in a variety of other products, and only what is needed is used, thereby reducing the waste of offcuts, among others. Moreover, the filament itself is both recyclable and made from recycled materials.

Challenges Ahead

But, the report concludes, while the outlook is sunny there are still challenges ahead.

Traditional forms of manufacturing will continue to have a place in the wider production value chain, and 3D printing hardware is at least 5 years away from achieving the technical and cost benchmarks to go beyond its current role from prototyping into supporting production processes across broad categories.

Plus, new software platforms and ecosystems are crucial to support a wide range of 3D printing applications.

But perhaps most importantly, mass adoption by consumers and businesses are hindered by poor design choices for hardware and software. Simply put, better design and education capabilities would give 3D printing a dramatic boost.

License: The text of "5 Reasons Why 3D Printing Industry Will Boom by 2020" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.