Correction: A previous version of this story claimed the Ultimaker S3 came with the CC print core as standard. This is not the case – it is available separately.

Ahead of the TCT Show in Birmingham, UK, Netherlands-based 3D printer manufacturer, Ultimaker, has crystallized its vision of the future of professional printing with the release of the S3 3D printer, plus system add-ons for its existing S5 printer.

The new Ultimaker S3 is the second machine to release for the company’s modish Studio line. It continues the design language established with the S5, featuring a glass door enclosure, dual extrusion print head utilizing Ultimaker’s print core tech, and a removable glass bed underpinned with an aluminum base plate for advanced auto-calibration.

Priced at $4,395 and available as of today’s announcement, the S3 is slightly smaller than the S5, with a print volume of 230 x 190 x 200 mm compared to the S5’s 330 x 240 x 300 mm.

Speaking to All3DP ahead of the announcement, Paul Heiden, Senior Vice President of Product Management at Ultimaker, explains, “what we want to achieve with the S3 is that people in a professional environment can really start using 3D printing. It’s far more accessible than the Ultimaker 3. That has predominantly to do with, whether we like it or not, the touchscreen.”

New Hardware, Expanded Possibilities

Accessible touchscreen UI aside, the new S3 uses the interchangeable print cores that are compatible with the S5 and Ultimaker 3 3D printers that came before. Slight hardware improvement can be found in the use of tougher extruder feeder wheels, which improve the durability of the machine with abrasive composite filaments, helping make it, Ultimaker claims, the ideal jumping-on point of its range of professionally-oriented hardware.

It’s a far cry from the company’s beginnings developing open-source hardware back in the formative years of desktop 3D printing. Where an Ultimaker was once a wood panel kit for hobbyists and tinkerers the machine has evolved rapidly into a (figuratively) well-oiled machine outputting ever closer to turnkey solutions for business and enterprise.

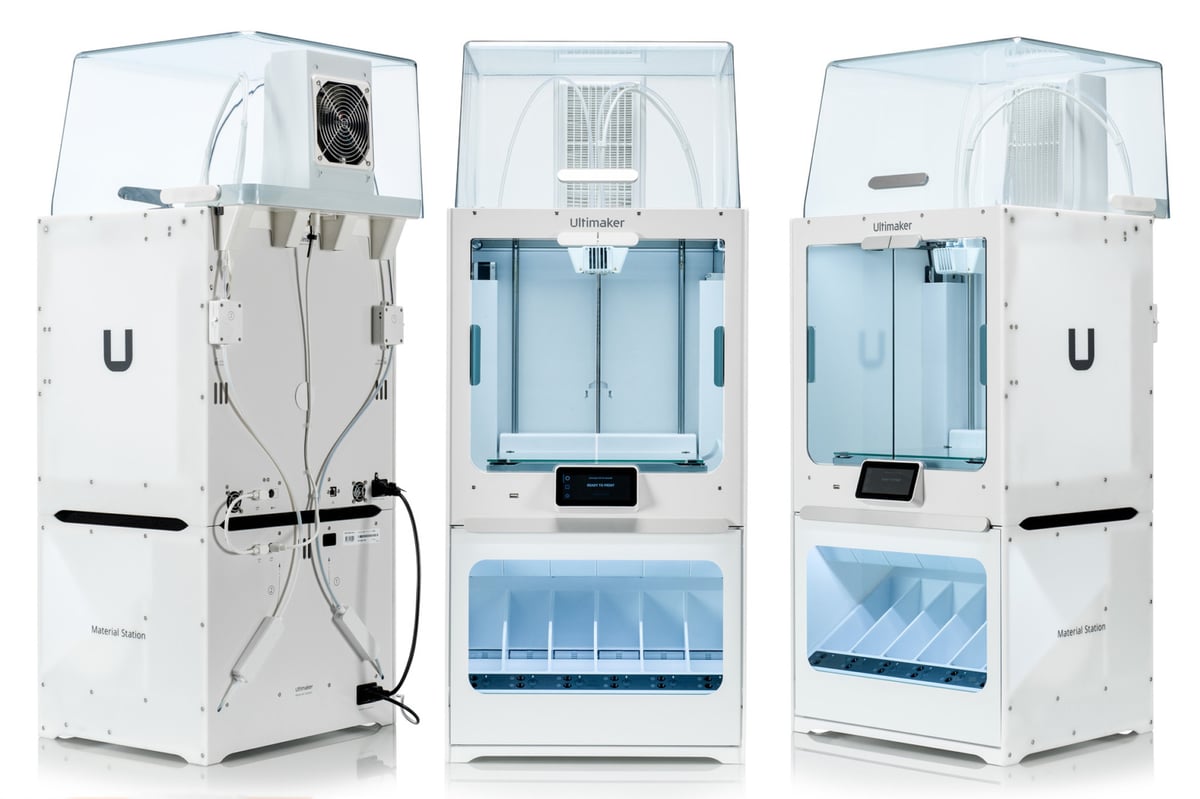

The latest step toward Ultimaker’s current corporate vision is present in the company’s other big announcement at TCT Show, the S5 Pro bundle. Pairing the 2018-released S5 3D printer with all-new Material Station and Air Manager units, the package, Ultimaker claims in a release, “is tested to be left unattended 24/7 and significantly improves the 3D printing workflow and productivity.”

A top-to-bottom solution aiming to make the S5 a better fit in the professional workplace, the new units speak to two important considerations in modern enterprise: efficiency and safety. Where the Material Station tackles material distribution and expands the uptime and flexibility of the printer, the Air Manager pulls double duty of creating a stable temperature and airflow inside the printer while filtering out the majority of harmful emissions from a print.

“What we did here with the S5 Pro Bundle is really put in a baseline” says Heiden, adding “(this) makes sure that people can use the printer without being around the printer at the time.” Informing this direction during the development of the Material Station and Air Manager, was what Heiden describes as ‘utilization rate’ – how to ensure that the printers can be used as intensively as is possible.

Near Continuous Printing

Perhaps the biggest boon to this is the Material Station. Standing as a base unit that slots in beneath the S5 printer, this new integrated unit takes over material extrusion duties from the S5’s normally rear-mounted spool mounts and extruder motors and allows (finally) the front-loading of filament, eliminating the need to access the rear of the printer.

We suspect as Ultimaker continues to professionalize its offerings to appeal better to the workshop or factory floor, we’ll see more of these minor irritants get ironed out. Efficiency is key, and the less the engineer has to futz with the machine, the better.

More than just a front-loading solution though, the Material Station has been designed to address two other limitations of the workflow of Ultimakers past: uptime, and material management. Using the Material Station, Ultimaker claims six spools of filament can be loaded for “24/7” printing, with spools automatically loading in succession to continue a print that would otherwise have paused for the operator to add more material.

As with the S3 detailed above, the Material Station will benefit from hardened material feeders, allowing it to withstand prolonged printing of abrasives, carbon composites and other tough to print materials.

Process Stability and Safety

The addition of a reservoir of material for longer-term operation is not without its own challenges. In exacting conditions humidity becomes an issue, denaturing material and negatively impacting on a print. The Material Station is said to address this using desiccant that keeps the air inside the sealed station below 40 % relative humidity, in theory maintaining the S5’s ability to print extremely hygroscopic materials such as water-soluble PVA over the long term, too.

As one might expect of a lid-style enclosure for a printer, the Air Manager is designed to close the S5’s largest opening – the open top – trapping heated air in the print chamber and helping to maintain a steady ambient temperature for printing materials that are prone to warping when cooling unevenly.

Packing an air filtration unit to reduce the harmful emissions released to the atmosphere when printing some materials, the Air Manager is a sensible upgrade to develop, but apparently not a simple one to design. Treating it as more “than just another top cover”, which Ultimaker users have often done concedes Heiden, it was necessary for the presence of the Air Manager to influence print settings, given the changes in temperature and pressure it introduces around the material.

Through collaboration on adjusted print profiles with material manufacturers in Ultimaker’s Material Alliance Program, and no small amount of firmware fine-tuning, all facets of the S5 Pro appear to be seamless drops-ins, expanding on the recent advances the company has made in printer management and general simplification and automation of the workflow.

Heiden continues: “the user profile is so fundamentally changing where people really want to use it as a mature production method, really delivering on the potential digital distribution and not local manufacturing. That’s literally what this is all about. It’s not just about the parts of the S5 Pro Bundle. It’s really about this vision.”

The S5 Pro bundle, which includes S5 printer, Material Station and Air Manager units, is set to release on October 18, 2019. It will retail for $9,100 – an eye-watering figure on first glance, but for the farmability the Studio line is already capable of using Cura Connect, and the possibilities the new add-ons give to what we found to be the ultimate printer, it’s perhaps not all that surprising.

License: The text of "Ultimaker Announces New S3 3D Printer and 24/7 Printing Solution for S5" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.