An all-liquid device was 3D printed by researchers at the Department of Energy (DOE) Lawrence Berkeley National Laboratory. The device can carry out complex chemical reactions on demand, such as screening drug candidates and making battery materials.

“What we demonstrated is remarkable. Our 3-D-printed device can be programmed to carry out multistep, complex chemical reactions on demand… What’s even more amazing is that this versatile platform can be reconfigured to efficiently and precisely combine molecules to form very specific products, such as organic battery materials,” said the leader of the study, Brett Helms who works as a staff scientist in Berkeley Lab’s Materials Sciences Division and Molecular Foundry.

The researchers have previously been working on a number of experiments which fabricate all-liquid materials using 3D printing. For example, Helms worked on an investigation last year which developed a technique for printing liquid structures in other liquids using a 3D printer.

After the success of this experiment, Helms explains that a group of researchers began pondering how liquid printing could be used to develop a functioning device.

“Then it occurred to us: If we can print liquids in defined channels and flow contents through them without destroying them, then we could make useful fluidic devices for a wide range of applications, from new types of miniaturized chemical laboratories to even batteries and electronic devices,” he explains.

Developing a 3D Printable Fluidic Device

Following this breakthrough, a postdoctoral researcher in Berkeley Lab’s Materials Sciences Division, Wenqian Feng, began creating a patterned glass substrate to make the 3D printable fluidic device.

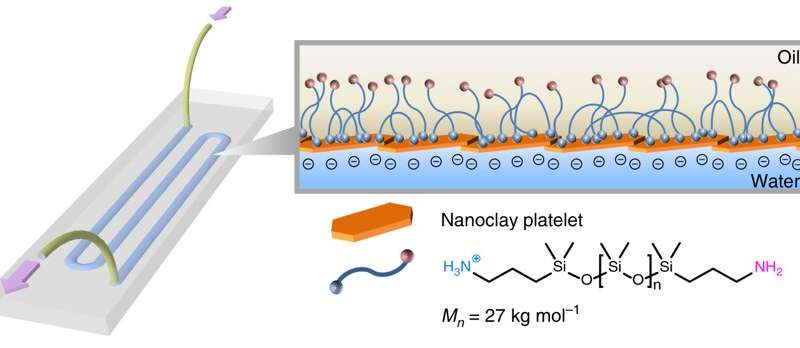

Two liquids are then 3D printed onto the substrate; one contains nanoscale clay particles, and the other contains polymer particles. These liquids form narrow channels, with catalysts placed within.

From here, the researchers 3D print bridges between the channels, connecting them. Chemicals flow through the bridges and encounter the catalysts in a specific order which triggers the reactions, creating chemical compounds.

The process of building liquid bridges, placing catalysts in the right place, and running reaction sequences to make molecules can be automated when controlled by a computer.

The next step in the researcher’s work is to use conductive nanoparticles to electrify the walls of the device. This will increase the number of types of reactions which the researchers can explore.

Helms explains: “With our technique, we think it should also be possible to create all-liquid circuitry, fuel cells, and even batteries. It’s been really exciting for our team to combine fluidics and flow chemistry in a way that is both user-friendly and user-programmable.”

The researcher’s most recent work was published in the journal Nature Communications.

Source: Berkeley Lab

License: The text of "Researchers 3D Print All-Liquid Device Capable of Carrying Out Chemical Reactions on Demand" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.