Imagine you could apply the same artificial intelligence behind photo and speech recognition technology to manufacturing parts with 3D printing. You’d have multiple sensors spot defects too small for the human eye to notice and then instantly or even preemptively adjust the printing process to fix them, improving reliability and part quality. It would be the end of failed prints.

No, we’re not quite there yet, but one company was just granted another patent in this area, getting them even closer to commercializing the technology.

Nano Dimension, a US-based company specializing in additively manufactured electronics (AME) and micro-scale polymer, metal, and ceramic 3D printing, yesterday secured a patent related to the neural network that supports its cloud-based additive manufacturing platform.

This patent and the technology around it enable AI solutions to run more effectively on a distributed network of 3D printers deployed around the globe. AI, by nature, is very computing intensive, which is a challenge when it comes to having it where it’s needed the most, like operating across a distributed network. The decentralized manufacturing model is becoming more critical as a method to alleviate supply chain disruptions and print locally for environmental reasons.

The company’s latest patent adds to the existing library of patents (20 granted and 25 pending) under the company’s AI learning engine called DeepCube, which improves performance on additive manufacturing hardware.

DeepCube’s algorithms increase the speed of data analysis tenfold, according to Nano Dimension, making it the only hardware performance accelerator of its kind. Considering how fast 3D printers operate, decisions are needed in fractions of seconds – similar to the decision-making speed required by autonomous vehicles. Memory usage reduction is achieved by overcoming the infrastructure, energy, and memory limitations of previous AI models for low-cost deployment, the company says.

Publicly traded Nano Dimension acquired DeepCube, a deep learning pioneer, in 2021.

“When we acquired DeepCube, it was under the premise that 3D printing was ripe for disruption with AI,” says Yoav Stern, chairman and CEO of Nano Dimension. “These patents, and the others like them, are clear examples of the hard work that is coming to fruition. Our customers are noticing the difference that these technologies enable.”

As additive manufacturing moves towards higher volumes, success may hinge on unit economics. AI is critical to improving both quality and speed for high yields.

Nano Dimension says its DeepCube solution for hardware and 3D print error corrections is installed in specific models of their printers but not in all of them. The company says it will make its AI-led capabilities a core component of its next-generation systems.

Promising AI Advances in 3D Printing

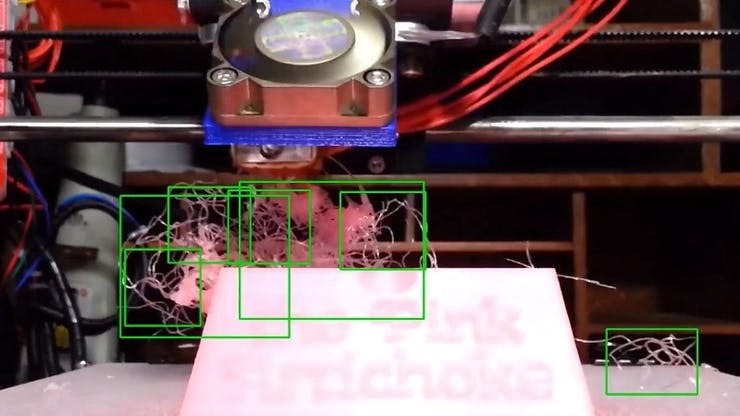

DeepCube isn’t the only tool in the works to bring AI to 3D printing. Several initiatives are underway that aim to combine data and AI to improve the quality and reliability of additive manufacturing. Most of them succeed in monitoring the printing process and collecting data, including visual, thermal, x-ray, and ultrasonic data. Some even interpret the data to predict the quality of the final print. However, the ability for AI to intervene autonomously during a printing process and correct for errors remains mostly elusive.

Working on fixing the printing process in real-time, MIT researchers recently used AI to develop a machine-learning system that uses computer vision to watch the manufacturing process and then correct errors in how it handles material in real time. They used simulations to teach a neural network how to adjust printing parameters to minimize error and then applied that controller to a real 3D printer. Their system printed objects more accurately than all the other 3D printing controllers they compared it to.

University of Cambridge researchers are also developing technology for “driverless” 3D printers that can learn from the experiences of other machines to detect and correct errors while fabricating objects, even when working with new designs or unfamiliar materials.

“We’re turning our attention to how this might work in high-value industries such as the aerospace, energy, and automotive sectors, where 3D printing technologies are used to manufacture high-performance and expensive parts,” says Douglas Brion, from the university’s Department of Engineering. “It might take days or weeks to complete a single component at a cost of thousands of pounds. An error that occurs at the start might not be detected until the part is completed and inspected. Our approach would spot the error in real time, significantly improving manufacturing productivity.”

Detection Solutions Available Now

If you can’t wait for the advent of driverless 3D printers, several current print failure detection solutions will help you stop a doomed print before you’ve wasted too much time and materials.

Sigma Additive Solutions’ PrintRite3D uses machine learning and AI to detect defects at the part level and can flag a lack of fusion or abnormal porosity in metal and polymer powder bed fusion 3D printed parts. Another solution from London-based AI Build called AISync has advanced simulation capabilities to catch errors before you hit print, as well as error detection during the printing process.

The growing category of additive manufacturing workflow software, such as the Authentise MES Platform, boasts several solutions with in-process monitoring and print failure detection that uses machine learning to predict maintenance. Even on the hobby end of 3D printing, there are AI solutions, such as the free Nexus AI OctoPrint plug-in that captures images from your OctoPrint setup (a camera is necessary) and checks these photos for print failures using machine learning on the service server. You then receive a notification of the print failure, including a photo, in any mailbox. Similar solutions include PrintWatch and Obico.

License: The text of "New AI Tool Aims To Watch & Fix Your 3D Prints in Real Time" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.