Engineers and small businesses have increasingly adopted 3D printing technology as the primary tool for tackling industrial applications, but there are still several areas where most professional 3D printers just don’t bridge the gap.

There are several requirements that professional users need from their 3D printer, some more important than others – depending on the task at hand. Size and quality are two of the most obvious attributes, but one factor that typically gets overlooked is the ability to print with engineering-grade materials while maintaining both print quality and mechanical properties.

INTAMSYS, a renowned industrial 3D printer manufacturer, has developed its Functional Materials (FUNMAT) 3D printer series with this in mind. This fleet of FDM 3D printers, which includes the FUNMAT HT, the FUNMAT PRO 410, and FUNMAT PRO 610HT, were designed with high-temperature 3D printing capabilities and a large build volume.

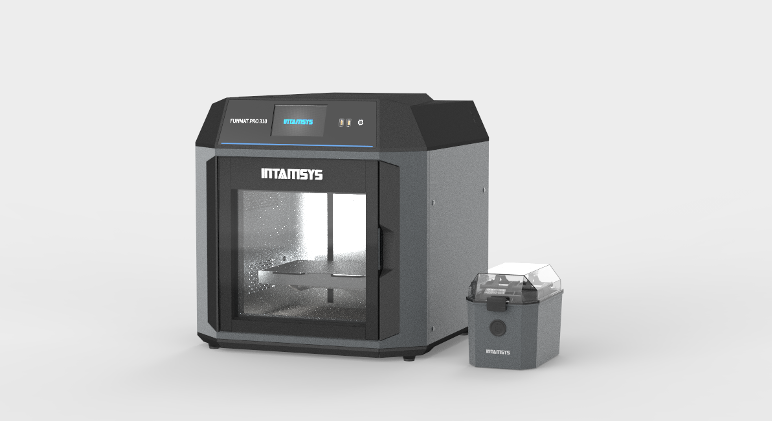

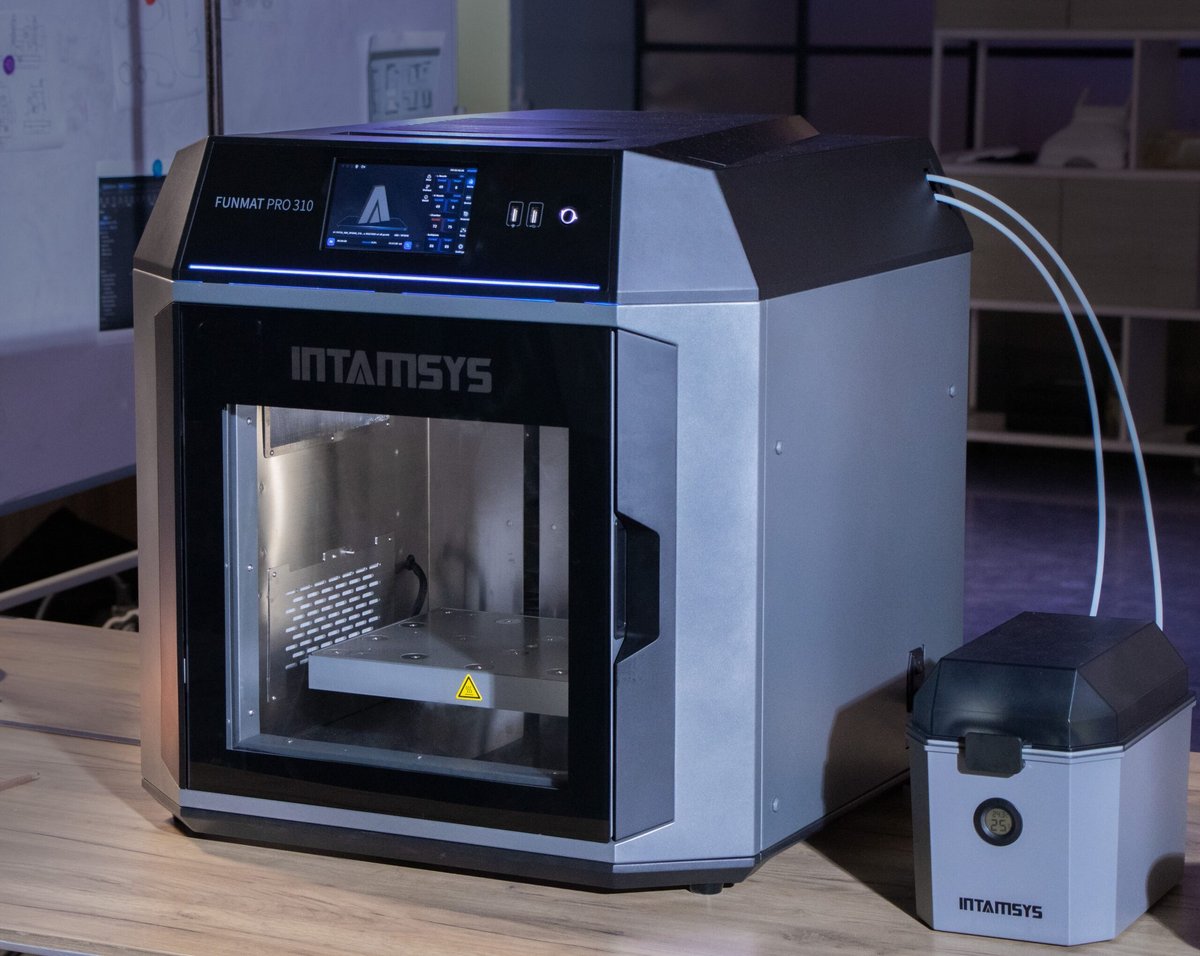

This week, at Formnext 2022 in Frankfurt, INTAMSYS unveiled its latest and greatest addition to its FUNMAT series: FUNMAT PRO 310. Like its predecessors, this new professional FDM 3D printer is engineered to flawlessly print with engineering-grade materials, delivering flexibility and ease of use to engineers and small businesses.

Aside from material compatibility, FUNMAT PRO 310 also offers some cutting-edge features that make it even better than previous iterations. INTAMSYS developed the FUNMAT PRO 310 based on the growing needs of engineers and other customers, aiming to improve print quality and production capabilities.

For those who couldn’t see the FUNMAT PRO 310 in person at Formnext 2022, let’s take a quick tour of the latest 3D printer from the INTAMSYS team.

FUNMAT PRO 310: More Materials, Greater Quality

The most noteworthy improvements integrated into the FUNMAT PRO 310 include the new thermostatic print chamber and larger build volume. In fact, FUNMAT PRO 310 can print larger parts than almost any other desktop 3D printer in its class. These two features work in tandem with one another to generate incredible print quality while reducing potential errors or flaws.

Sizable build volume is almost always a requirement for industrial 3D printing applications, as engineers and businesses need to print whole parts as a single print. While there’s no shortage of large-format 3D printers on the professional market, there are several challenges that users will face when utilizing a large build area.

When utilizing difficult-to-print materials on an FDM 3D printer, large print areas are prone to issues such as warpage, delamination, and cracking. Additionally, once an extruded material is reduced after extrusion, internal stresses are created when the material is cooled down and solidified, resulting in poor interlayer bonding. Heated print beds attempt to solve this problem, but fail to maintain stable temperatures throughout the entire print process.

Offering a sizable 305 x 260 x 260mm build volume, FUNMAT PRO 310 is able to overcome these issues with its thermostatic chamber. This fully closed chamber provides a uniform and stable temperature within a controlled environment, ensuring better melding and mechanical properties. The thermostatic chamber, which can reach up to 100 °C, is supported by the printer’s sealed thermal insulation that prevents heat from escaping.

FUNMAT PRO 310 is compatible with a wide range of engineering plastics, such as ASA, ABS, PC, PC-ABS, PA, PA-CF, and others.

The combination of a large build volume and stable high-temperature print environment makes FUNMAT PRO 310 ideal for many applications, including aerospace, automotive, electronic manufacturing, consumer goods, healthcare, researching and others. Nearly limitless compatibility with engineering-grade filaments enables professional users to print functional prototypes and even end-use production parts.

INTAMSYS has shared a few examples of functional components printed on the FUNMAT PRO 310 using engineering-grade materials:

There are numerous other features found in the FUNMAT PRO 310 that are worth mentioning, some of which further complete the ability to print with engineering-grade materials. The printer is equipped with an independently sealed drying filament box with a reusable molecular sieve, keeping humidity from impacting the quality of filament. This is especially useful for hygroscopic materials such as nylon-based filaments.

Boasting a dual-material IDEX design, FUNMAT PRO 310 offers a variety of printing modes that enable users to print support structures, print with multiple materials, and even mirror or duplicate their designs during a single print operation. Users will greatly benefit from utilizing water soluble support solutions when printing with engineering materials.

The sturdy, high-rigidity frame design of the machine works to reduce vibrations from interfering with the print process, while the high-precision motion control system promotes continuous stability and print quality.

Users are also granted full control and management over the print process all from the FUNMAT PRO 310’s 7-inch full-color touch screen. From this intuitive interface, users can control the automatic bed leveling function, automatic task and print queue management, access standard API interfaces, integrate with MES, and fully access the benefits of Industry 4.0.

Finally, INTAMSYS has developed new process control software that provides algorithm-driven path planning for different applications, rich material process profiles, and printability detection to ensure a higher success rate. Network printing functionality generates a more seamless and intelligent printing process, providing remote monitoring, traceability of historical data, online diagnosis and maintenance, and control over the printing process.

INTAMSYS has launched a limited pre-order sale for the FUNMAT PRO 310, which will be widely released sometime in the first half of 2023. For more information on INTAMSYS and its new FUNMAT PRO 310, visit the manufacturer’s website here.