Eplus3D, a top manufacturer of metal, polymer, and sand 3D printers, has added a new metal 3D printer to its menu of 11 laser powder bed fusion machines.

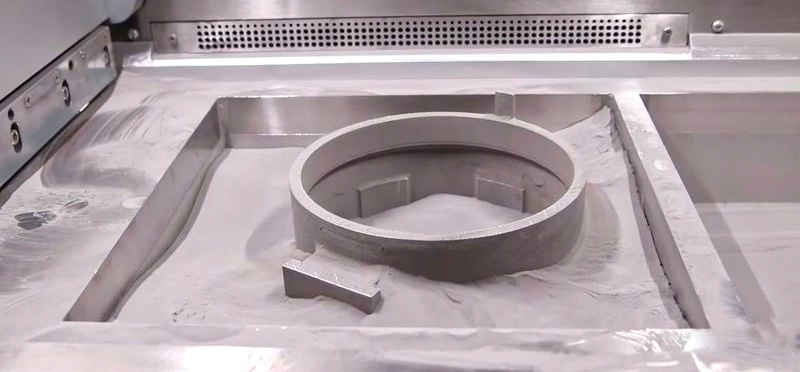

The new EP-M400, which features variable single, dual, or quad-laser configuration and a 405 x 405 x 450 mm build volume, is a size smaller than the company’s M450, which only has a dual laser. The company’s other quad-laser is the much larger M650.

Eplus3D’s Deputy General Manager, Enis Jost says that Eplus is aiming for the sweet spot in both size and power. The M400 is twice as fast as the M450 (120 cm3 per hour vs 55 cm3 per hour) but offers the size and front-loading structure customers prefer. If you’re comparing quad-laser machine speed, the M400 is as fast as the SLM Solutions SLM 500.

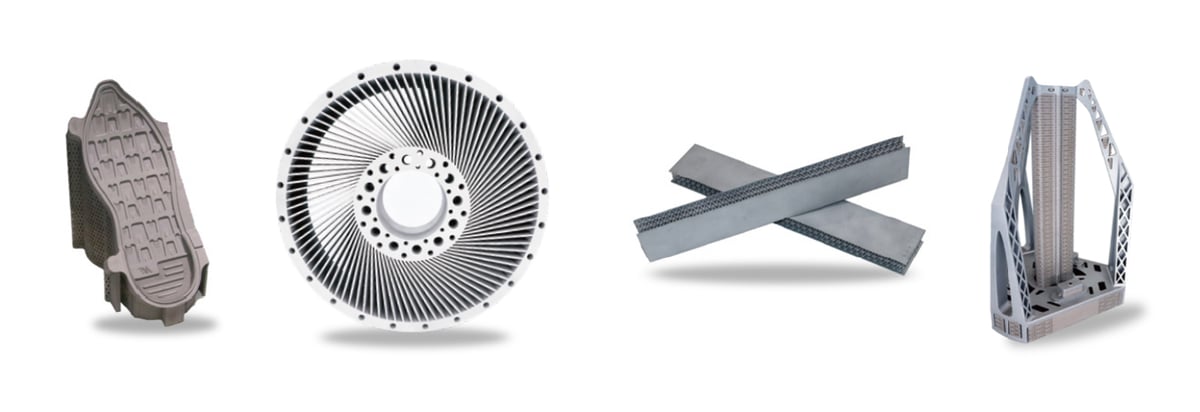

Eplus3D hopes the M400 will expand the application of multi-laser metal 3D printing in multiple industries. Although the company calls the M400 an entry into metal 3D printing, the newest machine is tailored to customers who are expecting to expand their business through large metal printing with quad-laser power at a lower cost than machines with similar technology (without sharing the printer’s price tag).

As you’d expect from laser powder bed fusion with quad lasers, the final part density is 99.9% with high accuracy, the company says.

The build chamber can hold 70 liters of powder, and the machine features components from well-known suppliers, such as water-cooled IPG Lasers, Scanlab scanners, and F-Theta lenses, all made in Germany.

The variable layer thickness perimeter can make for faster part production. In fact, the processing software, EP-Hatch, lets you adjust and optimize the scanning strategies to achieve the production rate you require.

Despite the ability to adjust perimeters, including laser powder and scan speed, and direction, Eplus3D says the Hatch software is user-friendly and has one-click printing options.

Typically, machines that are open materials and open perimeters are aimed at more experienced users, but Jost says every M400 system can be pre-set with certain material perimeters depending on the customers’ needs. “Therefore, anyone can use it, and no experience is required,” he says. “Our engineers will train the users for several days to ensure they can use the systems well.”

As an open material system, users can choose among a wide range of metal powders available in the market.

EP-M400 Tech Specs:

Technology: Laser Powder Bed Fusion (LPBF)

Build Volume: 405 x 405 x 450 mm

Laser: 1, 2, or 4, 500 -W Fiber lasers

Laser Spot Size: 80 – 120 µm

Max Scan Speed: 8 m/s

Layer Thickness: 20 – 120 μm

Materials: Open. Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, and more.

Gas Supply: Ar/N₂

Software: Eplus3D EPHatch

Price: not yet available

License: The text of "Eplus3D Launches Another Quad-Laser Metal 3D Printer" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.