Digital Metal, the Swedish metal binder jet 3D printer maker, just launched a machine that doubles the maximum speed of its older binder jet technology.

The new DMP Pro has twice the maximum productivity (1,000 cm3 /h) compared to the company’s older DMP2500 metal binder jet printer in the same build volume (250 × 217 × 186) and the same maximum resolution (35 µm in z-direction).

Binder jetting is the fasted method of metal 3D printing and a favorite among manufacturers looking to produce significant volumes of small parts for industry, medical manufacturing, and consumer products. Because the method doesn’t require heat, there’s no lengthy cool down or heat up, no inert gas environment, and the time between batches can be as little as 15 minutes, Digital Metal says.

The DMP Pro has 70,400 nozzles to precisely deposit binding material on the metal powder. It’s not typical for binder jet printer makers to boast about the number of nozzles or how it makes a difference, but perhaps this will become a point of differentiation in the future.

Consumers are increasingly looking to move away from any 3D printing technology involving the need to handle loose metal powder. Printer makers, like Digital Metal, are introducing cartridge or powder magazine solutions to make changing materials faster, cleaner, and easier.

Built on Siemens MindSphere cloud IoT OS the software system ensures that future IoT integration and connections will be reliable and secure. The system is intuitive and easy to use, and optimized for production environments. New support structure minimization increases productivity and reduces part cost. Higher power utilization means that now 100% of excess powder can be reused. This environmental gain also reduces part costs.

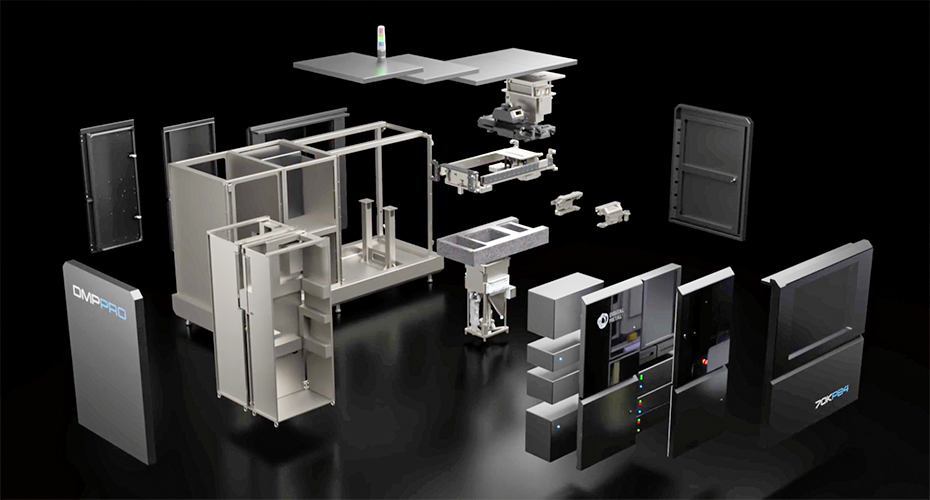

According to Digital Metal CEO Christian Lönne, DMP Pro is not just a machine in isolation; “We have a true platform optimized to work in concert with debinding, sintering, and post-processing equipment. This platform is modular, extensible, and a stepping stone for Industrialization.”

By “extensible,” Lönne is referring to the idea that, in the future, the current DMP Pro systems can be extended by adding automation modules or other updates. Currently, though, the company’s debinding, sintering, and post-processing equipment is sold separately.

On the software side, the machine’s OS is built on Siemens MindSphere cloud IoT. A new support structure minimization algorithm is touted as another way to reduce material usage and overall costs. The custom software also enables remote monitoring of status, performance, and KPIs, plus full-part traceability and production data backups.

As part of the Höganäs Group, the world’s largest producer of iron and non-ferrous metal powders, Digital Metal has a pedigree in metals, sintering, and everything else related to industrial metal parts production.

Specifications

- Machine footprint: 2,700 x 1000 x 1,700 mm (L x W x H)

- Build volume: 250 × 217 × 70 mm or 250 × 217 × 186 mm (L x W x H)

- Typical productivity: 500 – 1,000 cm3 per hour

- Resolution: 8000 x 1600 DPI

- Changeover time between prints: 15–25 min

- Materials: copper, D2 tool steel, 316L steel, TI6AL4V titanium, 17-4PH steel, and superalloys 625, 718, and 247

- Price: Not officially announced, but All3DP’s estimate is above $500,000

Lead image source: Digital Metal DMP Pro

License: The text of "Digital Metal Launches Higher Productivity Metal Binder Jet 3D Printer" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.