Cubicon, a 3D printer manufacturer from South Korea, is ushering in a new standard for low-cost 3D printers with its latest machine: Cubicon Prime M22Z. This DIY 3D printer comes equipped with a dual Z-axis and auto-leveling capabilities.

Low-cost DIY FDM 3D printers target entry-level users, but does that mean the Cubicon Prime is built with cheap, entry-level features? Is it possible for an affordable DIY machine to be user-friendly and frustration-free?

Cubicon Prime, a DIY 3D printer priced at just $399, includes advanced functions and components such as auto-leveling, Wi-Fi functionality, and new motor drivers and boards.

At first glance, the minimalistic design of the Cubicon Prime isn’t flashy, but it’s very modern. With basic colors and a simple look, this 3D printer reflects that it’s “faithful to the basics.” The simplicity is also represented in the assembly process. After connecting the black frame to the printer base, along with the extruder and other accessories, the 3D printer is ready to get to work.

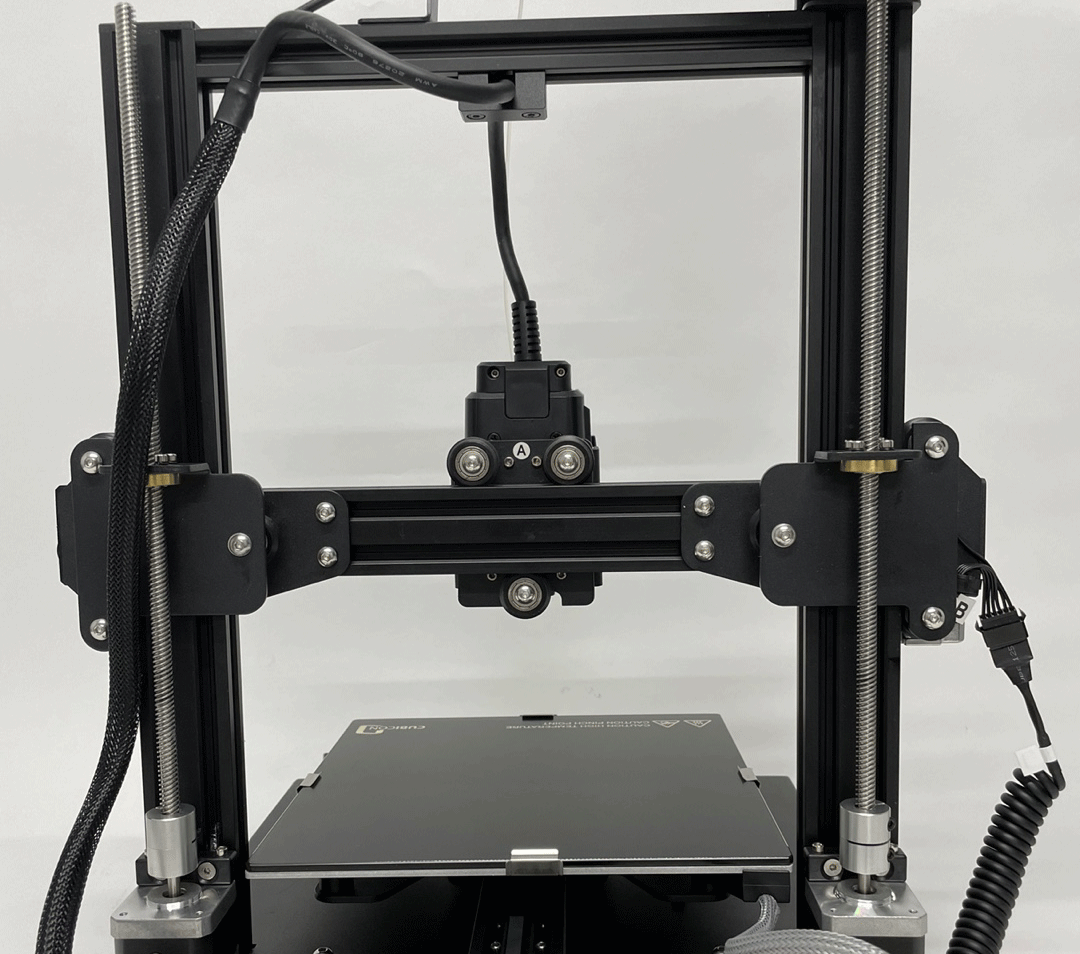

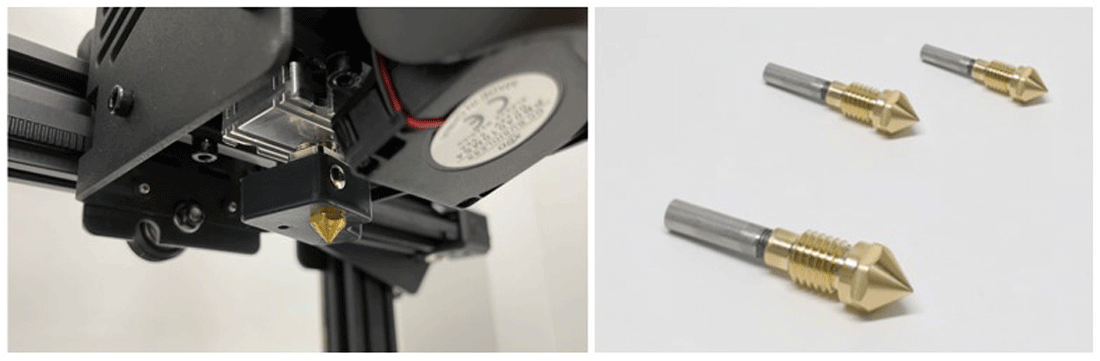

Cubicon Prime offers an auto-leveling system that functions differently than the auto-leveling found in other low-cost DIY 3D printers. While this feature is starting to become more common with low-cost 3D printers, most competitors usually utilize BL touch leveling. Cubicon Prime uses its own nozzle to detect the 16 points on the bed instead of using BL touch.

This means the tip of the nozzle itself is the probe. A flat map of the print bed is created using the 16 values that are recorded by the load cell in the nozzle, leveling the print bed.This mechanism removes the tedious manual bed leveling process using a piece of paper. This is definitely a welcomed feature for both entry-level and experienced users.

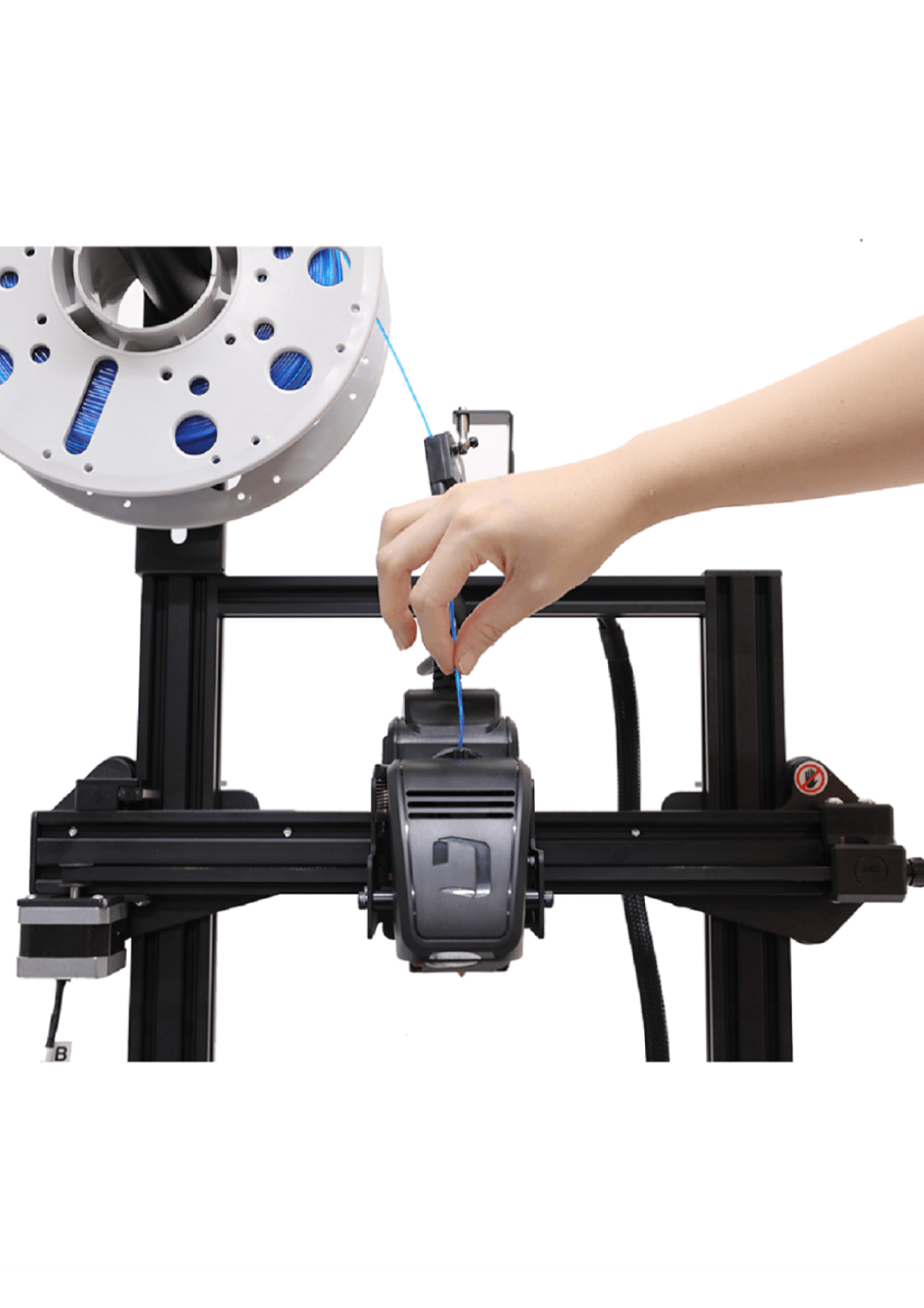

In general, mendel-styled FDM 3D printers use a bowden extruder setup. Cubicon Prime, on the other hand, features a direct type extruder. Entry-level 3D printer users who purchase the Cubicon Prime will be very happy about the choice to implement a direct drive extruder. While the bowden-type extruder is light and offers a faster printing speed, it is also known to have issues with oozing and stringing. Because controlling the filament feed is not an instant process, oozing may not stop even when the nozzle is moving to a different coordinate. That is why you may find unwanted cobwebs or stringing in your final print.

Even though the print speed of a direct type extruder may be slower, the ability to precisely control the filament feed is the reason why entry-level users will find this exturder to be more appealing. The Bowden extruder can set entry-level users up for repeated failure. Cubicon’s decision to use the direct extruder seems to be an excellent solution to this common problem.

When trying to ABS, smaller objects could be successfully even with an open environment and for bigger objects, the corners could shrink a little due to the mechanical properties of ABS filament. To overcome this potential issue, Cubicon recommends that users create a temporary chamber with a cardboard box to protect the print from external conditions. Overall, users who like to print with ABS will be pleased with this 3D printer’s ability. Based on the ABS filament exclusively sold by Cubicon, the default setting is 230 degrees Fahrenheit for the nozzle and 100 degrees Fahrenheit for the bed.

Cubicon Prime is supported by two long Z-axis rods. Thanks to these rods, the X-axis profile parallel to the print bed smoothly moves up and down and stays level throughout the printing process. The Z-axis rods are firmly assembled to the X-axis profile by Cubicon so users only need to connect the profile to the printer base upon opening the box. Cubicon recommends measuring the height of both Z-axis with a leveling paper, just to be safe.

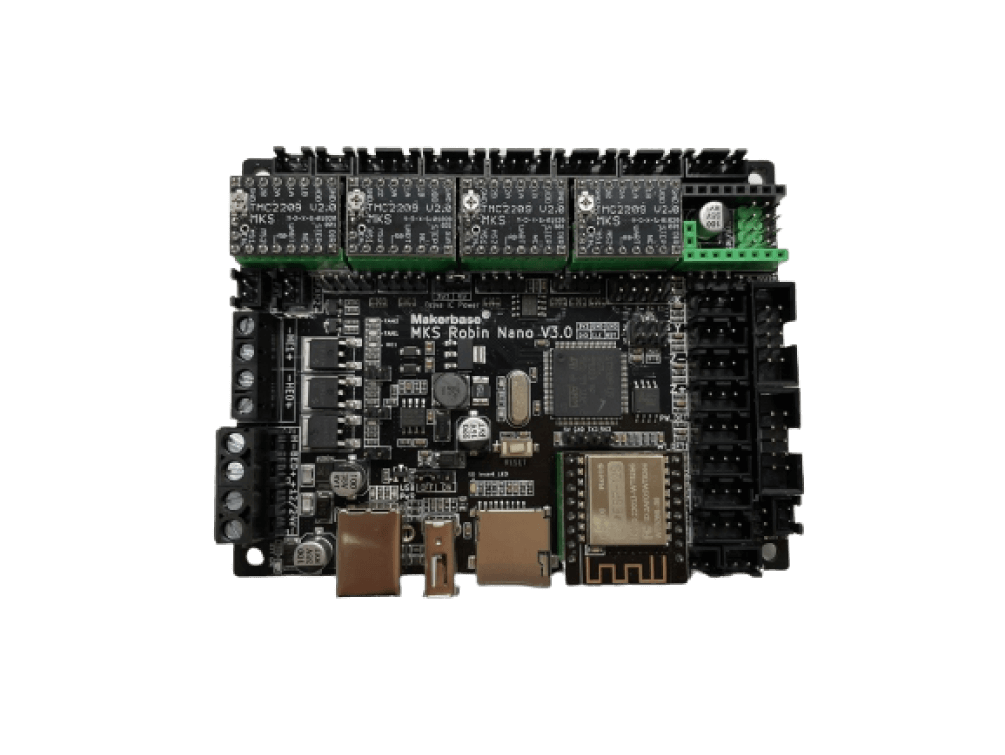

If users have only used printers with one rod, they will experience enhanced stability with this dual rod system. Cubicon Prime is also equipped with a TMC2209 motor drive that syncs the two rods.

Cubicon Prime is an ideal low-cost 3D printer for those who value a high-performance motor driver. For its latest 3D printer, Cubicon selected the TMC2209 stepper motor driver and the 32-bit MKS Robin 3.0, both of which are optimized for 3D printers. The TMC2209, which regulates the current that is supplied to the motor, generates smooth movements that result in improved print quality. The operating noise of the TMC2209 motor driver is almost completely silent, producing the same amount of noise that a household fan would make.

There may be users who are concerned about the stainless-steel nozzles becoming clogged, but thankfully, Prime users do not have to take the entire extruder assembly apart to clean out the nozzle. The toolbox that is shipped with the product has every tool needed to make this process as simple as possible. Detaching the nozzle from the extruder can be done in a few seconds with the provided box wrench, allowing users to quickly remove the clog with the supplied cleaning tool. Some users may remember using DIY 3D printers that required them to disassemble the entire extruder to clean the nozzle. Because the nozzle can be easily removed, cleaned, and assembled alone, maintenance of the Cubicon Prime is a breeze.

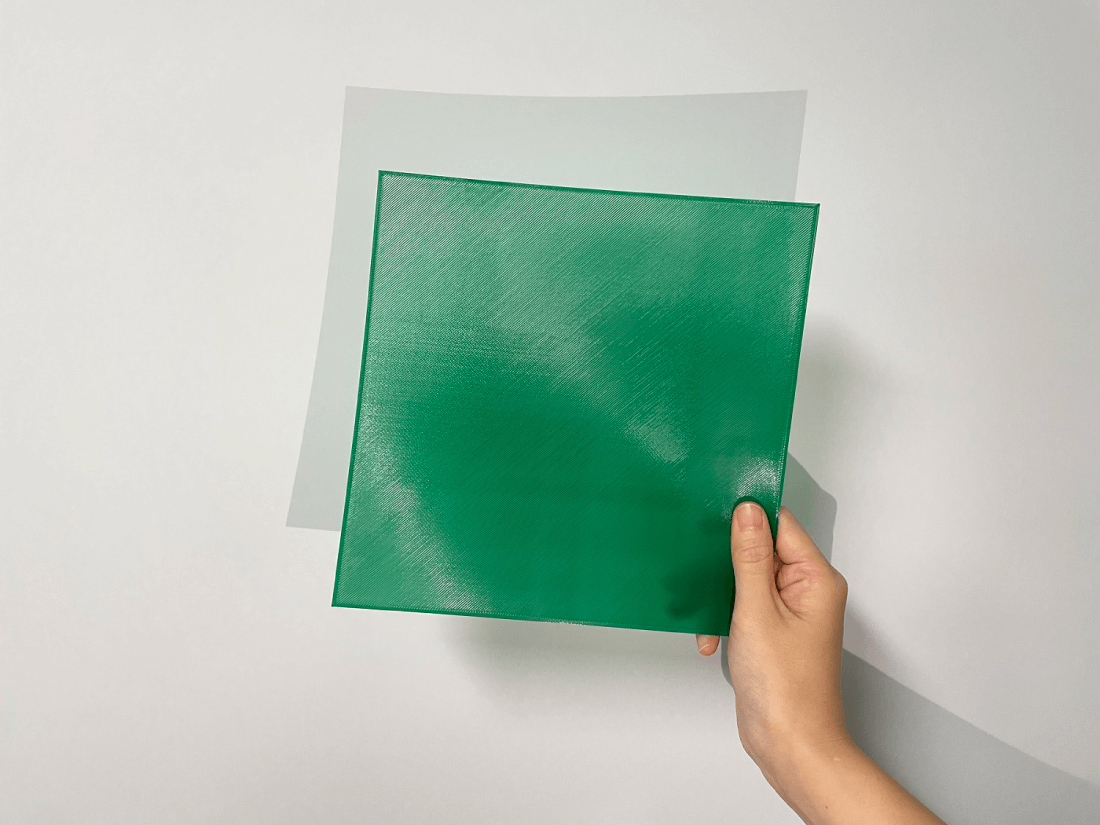

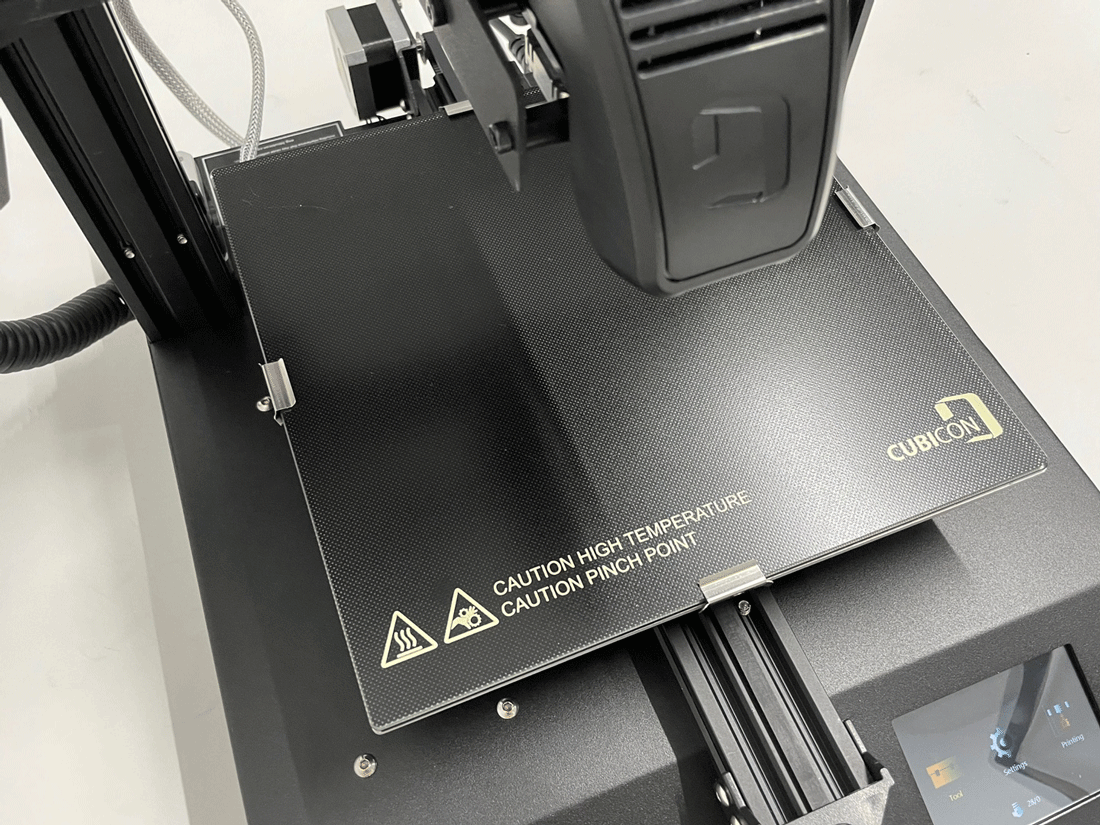

Cubicon Prime’s print bed is made from carborundum glass. It’s able to reach 65°C in about 3 minutes and 110°C in about 9 minutes. Cubicon recommends starting the print with the initial temperature being approximately 10°C higher than the ideal temperature to improve first layer adhesion. The supports that are inserted on all sides of the bottom of the print bed keeps the heat away from other parts of the 3D printer. Furthermore, the attached heat insulation prevents thermal deformation in other areas, such as the printer base.

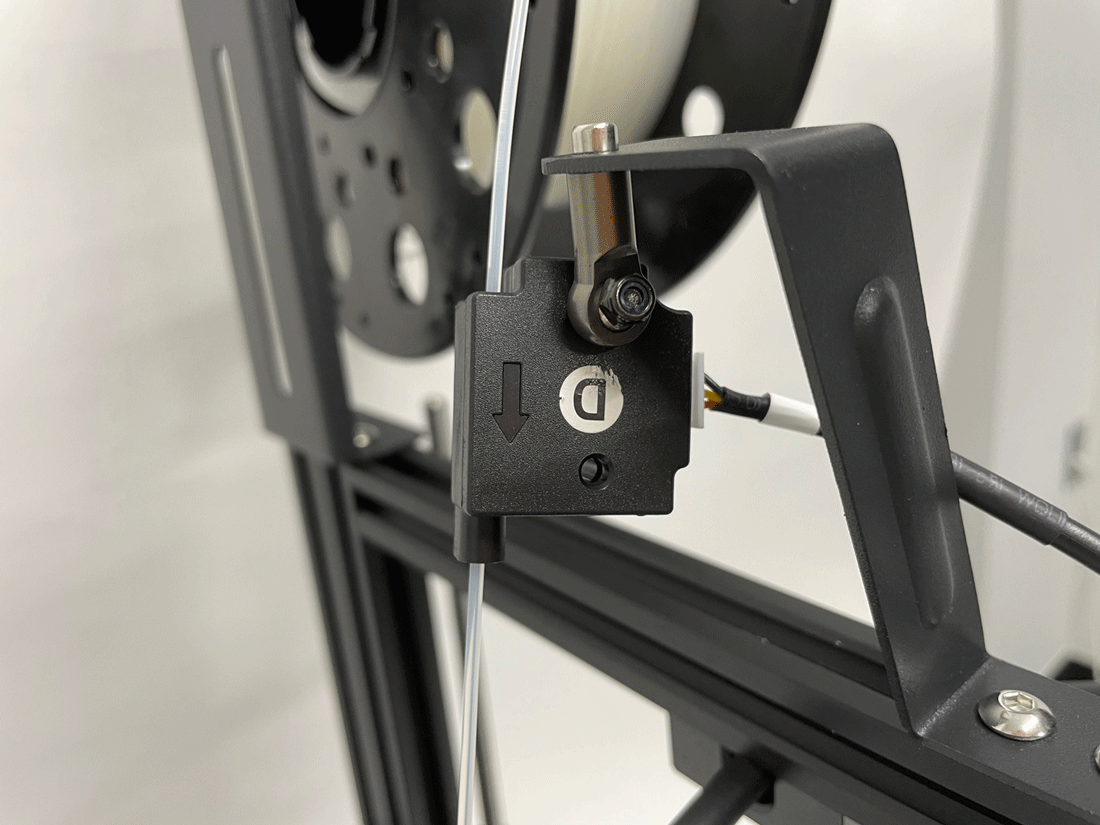

When the filament runs out, Cubicon Prime automatically stops the printing process and waits for the user to replace the empty spool. The sensor is not fixed and moves with the extruder. Because of that, the filament connected to the extruder through a hole will not be tugged, making this detector a delicate solution to improving print quality and user experience.

The 3.5-inch display screen acts as the user interface of Cubicon Prime. It has a different feel than most UIs made from open-source projects.

Users will enjoy the clean and intuitive look. Cubicon implemented both touch screen operation and a smooth wheel that you can use in the event that the touch screen malfunctions. These two options ensure that the user always has full control of the operation.

Cubicon Prime supports Wi-Fi connectivity, granting users with remote access to the printer. The WiFi connectivity makes it easy to control the bed and the nozzle temperature, and also check the print progress.

At the end of the day, what most users really want to know is the print quality that will be produced by the Cubicon Prime. How does this 3D printer work with various materials, from basic PLA to more advanced filaments. Even in the case of TPU, a notoriously difficult-to-print material, the Cubicon team found that its 3D printer handled it surprisingly well. The TPU print was smooth and well done, with no scratches or ripple patterns. Every layer was printed perfectly, and there was no skew or warp. Surface quality, shrinkage, and uniformity were all excellent in their test print.

Cubicon Prime is now available on Amazon. If you’re interested in adding this DIY 3D printer to your home office or makerspace, take a look at the Cubicon Prime.

Note: This article was written by the Cubicon team, and does not represent the experience or opinions of All3DP’s editorial team.