Anycubic’s expanding their 3D printer repertoire. The popular 3D printer manufacturer known for hits like the Photon and i3 Mega is now offering a desktop metal 3D printer.

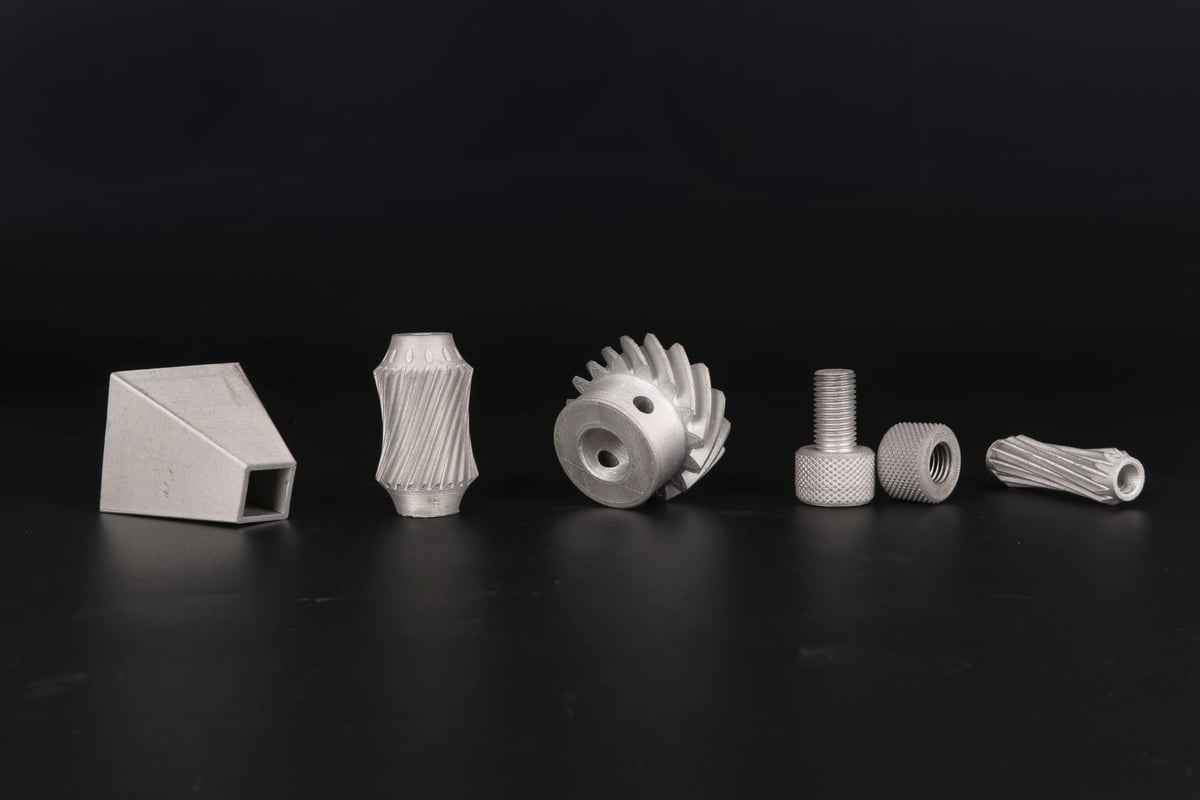

Metal 3D printing can get products to market quickly and improve the efficiency of supply chains. But, if you want a functional metal part, the cost of industrial metal 3D printers can be prohibitively high and the production can also take up quite some time.

There’s a simpler way to 3D print in metal – with the 4Max Metal. The metal 3D printing process boils down to four simple steps:

- Slice your part in Cura or any other slicing software.

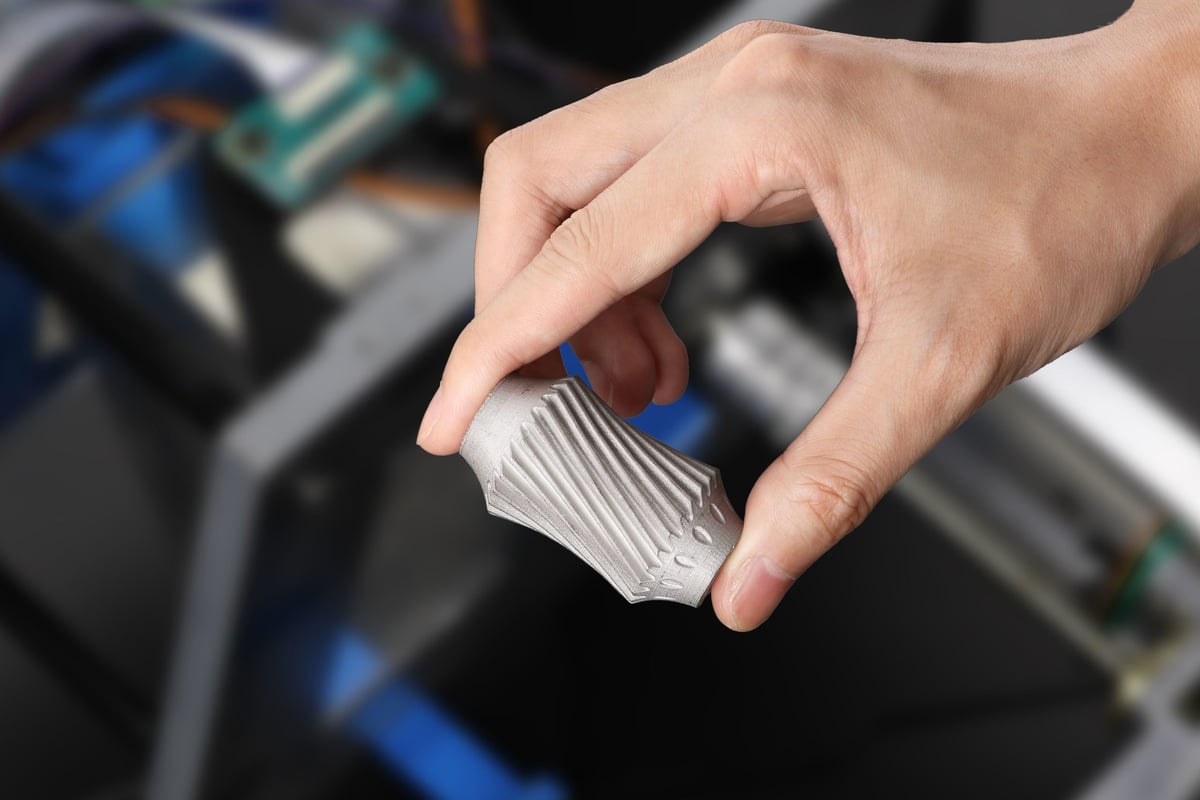

- Print your object on the Anycubic 4Max Metal. The metal powder is bound in the plastic filament and it will be printed layer by layer. Parts will be scaled up to compensate for shrinkage during the sintering process.

- The third step is debinding. In this process, the printed “green” part is transformed into a dense metal piece.

- The last step is sintering. The now “brown” part is placed in a furnace, where the remaining binder is burned away and the metal powder gets sintered. The result is a dense metal part.

The 4Max Metal comes with many thoughtful features to make the metal printing process a smooth one.

The machine has an enclosed build chamber to maintain a constant temperature throughout the printing process, while its hotend heats up to a maximum temperature of 260°C and its heated bed can reach up to 100°C. It also comes with a 0.5 mm steel nozzle to handle stainless steel filament and its short distance extruding provides stronger torque and smoother extrusion.

The printer boasts a 270 x 210 x 200 mm build volume, which is roomy enough for small-batch printing and a power-loss recovery feature, so you can continue your print even after a power cut – just press one button to resume.

In order to enhance safety, fire retardant material has been added to the shell of the print head. The printer also comes with an in-chamber air-filtration unit.

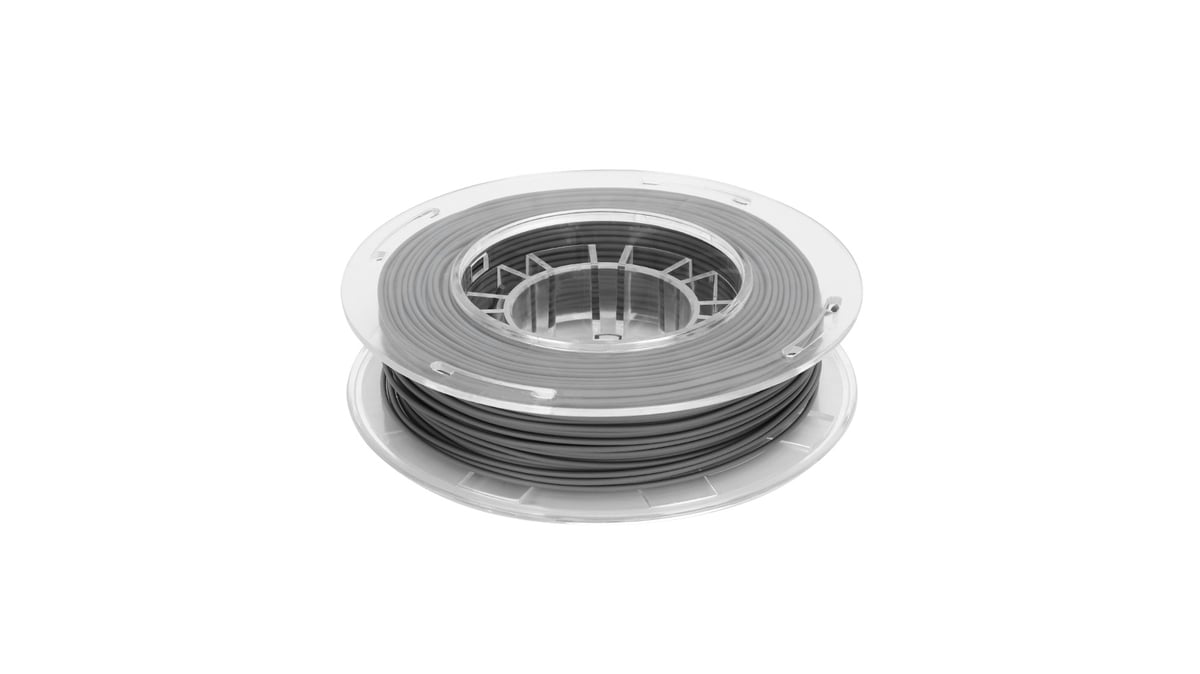

Designed for the 316L Metal Filament

Developed by Uprise3D and Anycubic, the 316L metal filament is a metal-polymer composite for desktop FFF 3D printers. Its main features consist of:

- A high metal content so your prints are rigid.

- No odor or smoke while printing.

- The ability to produce metal parts with high strength after the sintering process.

Technical Specifications

Here are the technical specifications for the Anycubic 4Max Metal 3D printer:

General Specifications

- Printing Technology: FDM (Fused Deposition Modeling)

- Build Volume: 270 × 210 × 200 mm

- Layer Resolution: 0.05 – 0.3 mm

- Positioning Accuracy: (X/Y/Z) 0.01/0.0125/0.00125 mm

- Extruder Quantity: Single

- Nozzle Diameter: 0.5 mm

- Print Speed: Suggested 30 mm/s

- Supported Materials: Metal 316L

Software

- Slicer Software: Cura

- Software Input Formats: STL, OBJ, JPG, PNG

- Software Output Formats: G-code

- Connectivity: SD card, USB cable

Electrical

- Input rating: 110V/220V AC, 50/60Hz

Where to Get the Anycubic 4Max Metal

Anycubic will provide after-sales service to help customers with parameter settings or other operational problems.

The Anycubic 4Max metal is on sale here.

—

This content is sponsored and the views and opinions expressed within it do not necessarily reflect All3DP’s editorial stance.

For more information, please see our Terms of Use.

License: The text of "Anycubic 4Max Metal: Affordable Solution Provider for Metal 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.