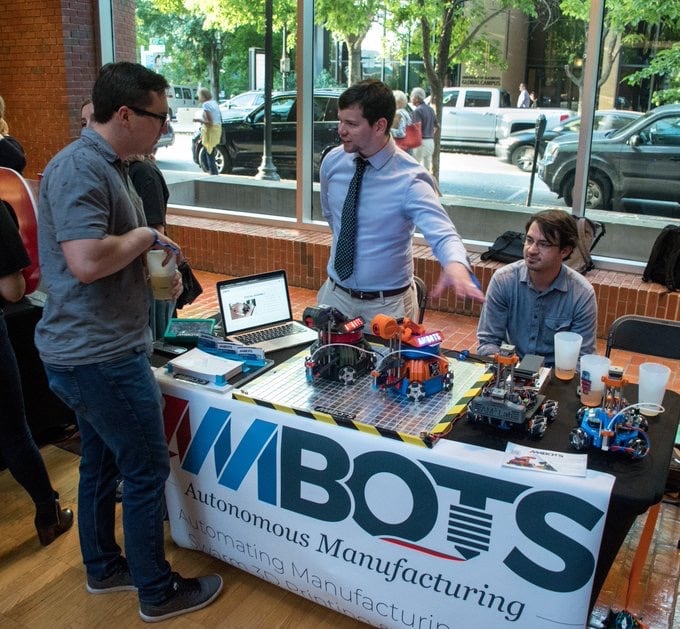

AMBOTS, a small US-based company is on its way to creating a future “where manufacturing is fully … automated with a swarm of advanced manufacturing robots.”

The company, created in the Mechanical Engineering Department of the University of Arkansas, released videos of its prototypes on Twitter this week to demonstrate an early realization of this vision

Essentially, their approach to efficient, large-scale manufacturing involves many mobile robots. Each is armed with an extruder and works on producing the final model in unison with its companions.

It’s just as cool as it sounds, and fortunately, we don’t have to do much imagining, either. AMBOTS has released several videos on their Twitter feed demonstrating the system in action.

The benefit of such an approach is that larger prints are completed faster and more efficiently. You don’t need a meter-long gantry to complete a meter-long print, just the space for the robots to travel that distance.

How does it all work?

Judging from the footage AMBOTS has released thus far, each printing robot has an extruder mounted on a SCARA arm, and its own filament spool – it’s essentially an independent printing node.

The robots move around to complete different parts of the print, which requires some degree of accuracy. Omniwheels help in this department, but each robot also uses a guidance system involving black lines and light sensors, as seen in the video.

The impressive element of AMBOTS’ system is really the coordination of each robot. SCARA printers and omniwheel robots aren’t new – the innovation here is the coordination of the system as a whole.

Each robot is assigned sections of the print to complete in a way that optimizes production time, and that’s a process that presumably involves two big steps.

First of all, in software. Behind the scenes of every video, some clever program divides up different sections of the print in a way that makes maximum use of each robot in the swarm to reduce printing time.

Then, these instructions are actually carried out, and nothing crashes or gets misaligned.

Is Swarm Manufacturing the Future?

The distributed, collaborative swarm assembly model could be applied to other processes that normally require significant time or manpower. It’s quite intuitive: split up the work among nodes in the network that work at the same time, and the task is done faster.

But the time cost involved in setting up AMBOTS’ system also needs to be taken into account. The company has not released much information about the preparation stage of their swarm prints,

Swarm manufacturing is certainly a promising concept that could create many opportunities in the future, and we already have a working early prototype. It’s only a matter of time before the initiative advances and we can see for sure what real-world applications this novel technology really has.

For more on innovations in 3D printing, check out these stories:

Source: AMBOTS

License: The text of "AMBOTS Brings Autonomous Collaboration to Manufacturing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.