Air New Zealand is the next airline which is adopting 3D printing and making big changes to the way parts and tools are manufactured. It joins the likes of Emirates and Airbus.

The latest from the airline is that it’s partnering with Zenith Tecnica. This company is also New Zealand based and specializes in Additive Manufacturing of titanium parts.

Through Zenith Tecnica, Air New Zealand will be able to 3D print titanium and use the company’s equipment from GE Additive – Arcam’s Electron Beam Melting (EBM) process.

A major benefit of 3D printing parts is the ability to save time, money and produce complex designs. All of which are necessary when designing metal aircraft components and tools.

Bruce Parton, Air New Zealand Chief Operations Officer, said:

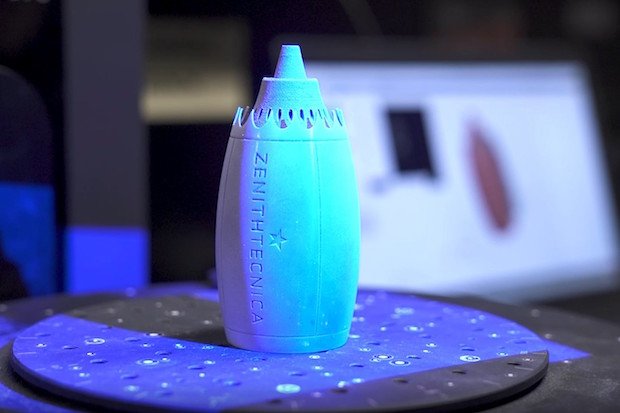

“It’s fantastic to be able to team up with and support local operator Zenith Tecnica and work with GE Additive to learn and collaborate in this space… While the aerators, made to look like replica aircraft engines, are a bit of fun, we’re really excited by the possibility they represent as 3D printing is both cost and space effective… Aircraft interiors are made up of tens of thousands of parts, and the ability to 3D print on-demand lightweight parts we only require a small number of, rather than rely on traditional manufacturing methods, is of huge benefit to our business, without compromising safety, strength or durability.”

3D Printing Metal Aircraft Parts

This change is likely to result in a significant change in the way the airline creates parts. But, it’s not the first time Air New Zealand has worked with 3D printing.

In fact, since 2016, the airline has been testing polymer 3D printing technologies and working with New Zealand based universities and companies to develop 3D printing processes. It has also been using laser 3D scanning to create tools and part designs.

But, first tests using Zenith Tecnica’s equipment include developing novelty wine aerators (see below) and prototypes of metal framing for Business Premier cabins.

But, the plan is to go further with 3D printing technology. It’s likely that while working with Zenith Tecnica there are going to be bigger changes and applications seen in future.

Martyn Newby, Zenith Tecnica Managing Director added: “This is a good project to demonstrate the strength, versatility and utility of titanium 3D printed parts for aircraft applications and it’s very exciting to be working alongside Air New Zealand on this journey. We are in a very good position to support the local adoption of 3D printing for aviation applications and welcome Air New Zealand’s enthusiasm to embrace this emerging technology and help it take it to the mainstream.”

Source: tct Magazine

License: The text of "Air New Zealand Starts to 3D Print Airplane Parts and Tools" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.