During the recent NBA All-Star Weekend, which featured the hugely popular All-Star Game pitting the likes of Kyrie Irving and Donovan Mitchell against Stephen Curry and LeBron James, you’d be forgiven for not noticing the odd black ball that player Kenyon Martin Jr. used for his second attempt in the Slam Dunk Contest Saturday night. It took three tries, but he slam-dunked it with style.

The prototype basketball was from Wilson Sporting Goods, which has produced the standard, leather official NBA basketball since 1946, until being replaced by rival Spalding for 30 years, but winning back the title in 2021.

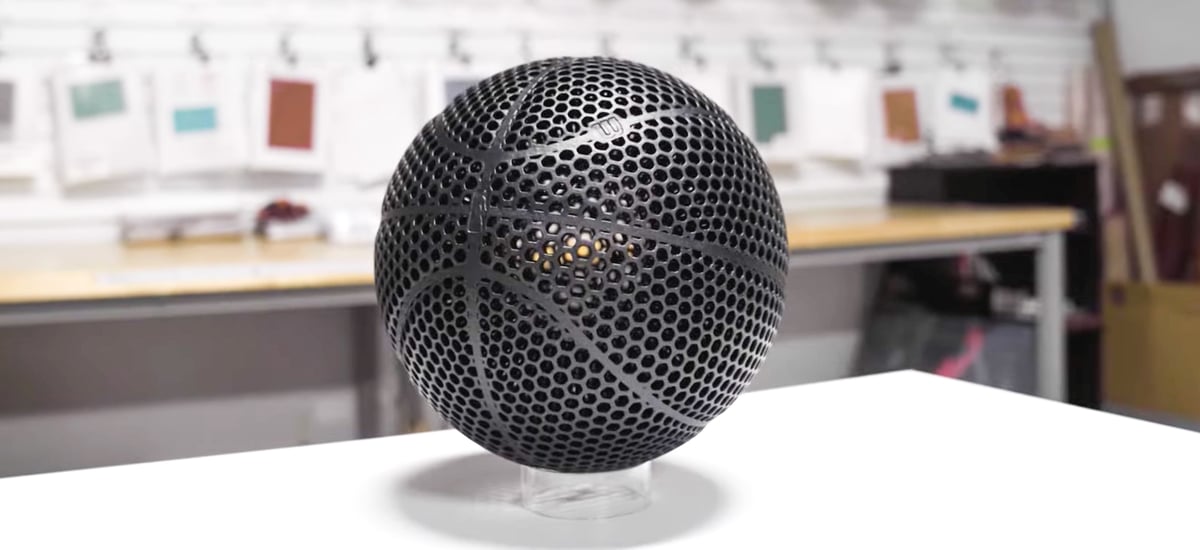

The 3D Airless Prototype Basketball, as it’s called, “nearly” fits the performance specifications of a regulation basketball, including its weight, size, and rebound (bounce), according to the company. The ball does not need to be inflated because it comprises a solid see-through lattice with eight panel-like lobes.

The prototype debut was designed to display the sports company’s “continued commitment to sport innovation,” Wilson says, but will not replace the Wilson NBA official game ball anytime soon.

Why 3D Print a Basketball?

Whether or not the 3D Airless Prototype Basketball was publicity in front of millions of sports fans or a preview of a product in the works, Wilson may have difficulty selling a material change and a shape change to NBA players.

In 2006, the then-official ball maker Spalding introduced a synthetic basketball that testing showed produced a better grip and more consistent rebound than the leather standard. Despite its advances, it was soundly rejected by NBA players and replaced halfway through the season. It didn’t have the same feel, players said.

What the new Wilson prototype ball does nicely is show off the technical abilities of 3D printing and the materials it uses. The ball is printed in one piece using selective laser sintering (SLS) technology on an EOS 3D printer and has flexibility many consumers don’t associate with 3D printed products.

The Wilson Labs team created the design for the 3D Airless Prototype Basketball at the brand’s Innovation Center in Chicago. General Lattice provided computational design services, and DyeMansion provided color and finishing solutions.

“This is only a dot on the development path,” says Bob Thurman, VP of innovation at Wilson. Will this become the core of a leather basketball or a puncture-proof consumer product that will never deflate? Time will tell.

“There’s still work to do before it’s ready for courts around the world,” Wilson said in a statement, “but we’re thrilled by the possibilities this ball represents. Possibilities for other sports and future Wilson products, revolutionary sustainability through additive manufacturing … This is an innovation made to push boundaries and open imaginations.”

License: The text of "3D Printed Basketball Debuts at NBA All-Star Weekend" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.