The European Space Agency shares the first results of their 3D printing experiments with simulated Mars soil. The results are… unusual.

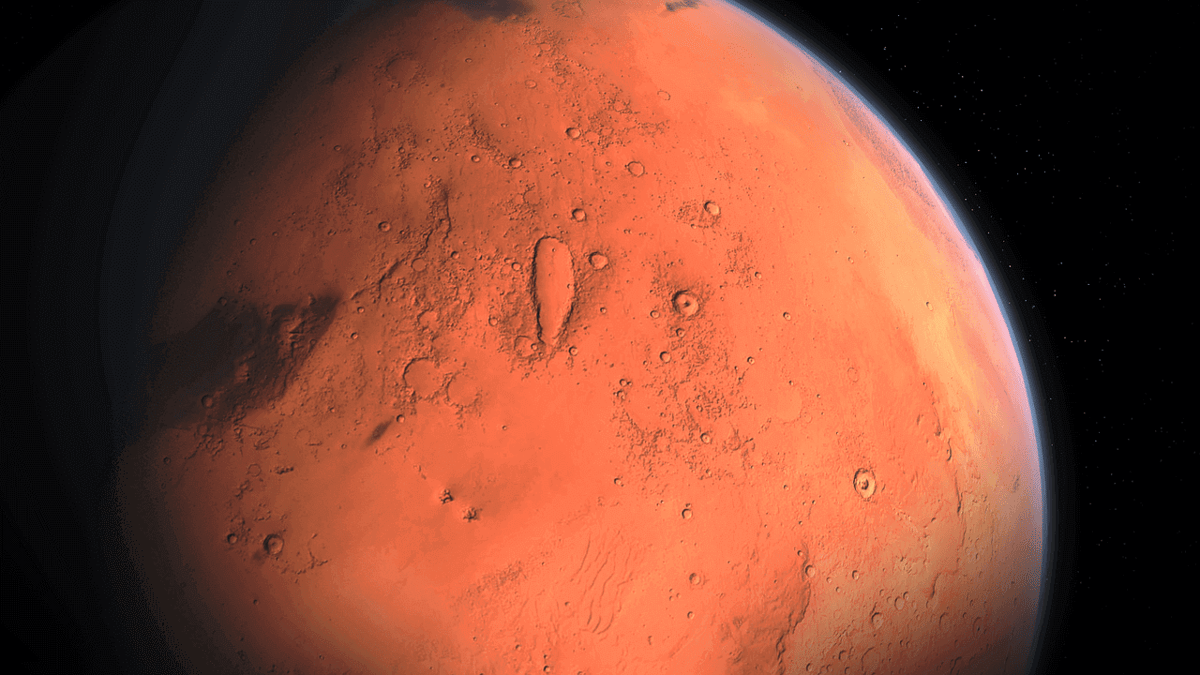

Humanity is getting their collective ass to Mars. President Trump has given $19.5bn funding for NASA to send people to the Red Planet by 2033, so it’s pretty much guaranteed. But there’re also the tricky question of how we’ll survive when we get there.

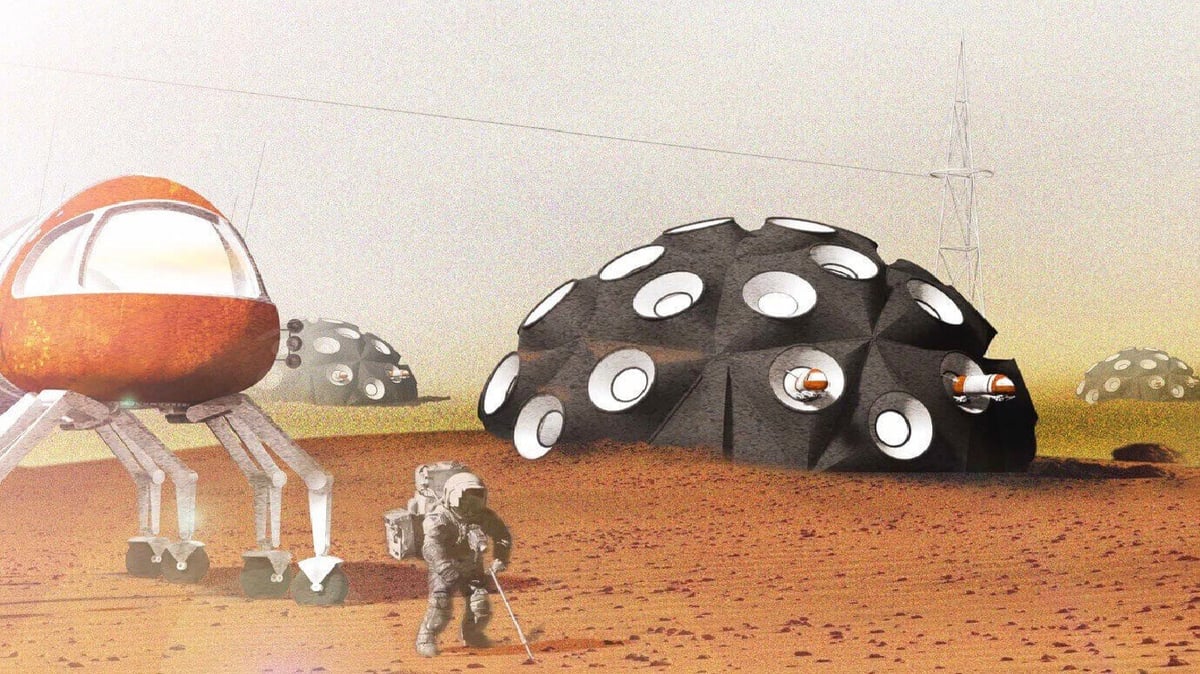

One idea gaining traction is to leverage local resources to minimize the epic transport burden. And Mars has one resource in abundance — soil. Scientists have been exploring methods to convert them into useful objects with additive manufacturing technology.

Most recently, ALL3DP reported how University of Central Florida and NASA were researching how astronauts could 3D print habitats and tools using Martian soil.

Elsewhere, the European Space Agency (ESA) has also been looking at methods to do the same. They’ve shared the results of a 3D printing test using simulated Mars soil, and the results are rather intriguing.

They’ve 3D printed two items — an igloo and a wall corner — which have the color and texture of brown clay. Aesthetically pleasing they are not. And they’re so small that only a mouse could comfortably make use of them. But they prove that constructing a sturdy form of shelter is definitely within reach.

Simulated Mars Soil Looks Like Dog Poop

The igloo and corner wall are good examples for fabrication because they’re structures a colonist is likely to need. The name of the material used is ‘JSC-Mars-1A’. This is volcanic soil which has undergone careful processing to match the known composition and characteristics of martian soil.

“The material was mixed with phosphoric acid serving as a binding ‘ink’, then extruded through a nozzle and deposited in successive layers,” explains Christoph Buchner of Fotec, the research arm of the University of Applied Sciences in Wiener Neustadt, Austria, which performed the test project for ESA.

“The hardened results demonstrate the technique has potential for hardware and structural manufacturing on a variety of planetary bodies – it does not depend on the destination. So this is a promising step towards ‘in-situ resource utilisation’ – the concept of using as much local materials as possible during a planetary mission, to cut down on the launch mass and cost.”

Tommaso Ghidini, Head of ESA’s Materials and Processes Section, is happy with the outcome.

“This is an encouraging result which complements a number of activities ESA is undertaking to provide the technologies for long-distance robotic and manned exploration,” he says. “For such missions, in-situ manufacturing will be key, so we are developing a wide variety of capabilities.”

So what will the explorers of tomorrow make of their new home on Mars? They’re the ones who have to live in a dog-poo colored igloo, after all. Our advice is to bring along a nice rug that really ties the room together.

License: The text of "ESA Shares Results of 3D Printing with Simulated Mars Soil" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.