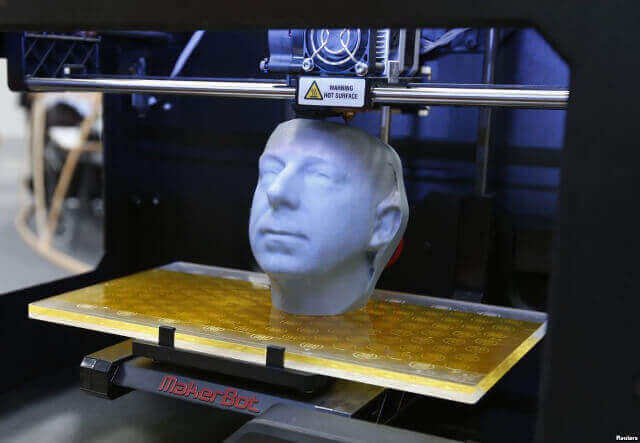

Guns, printed organs, disrupted logistics: There are way too many myths surrounding 3D printing. Here’s what‘s true – and what’s not.

There are quite a few untenable myths that surround 3D printing. As it combines several different technological trends (electronics, mechanics, robotics, 3D modeling software, programming, open source and online sharing, material science), 3D printing has even more confusion surrounding it.

These myths are causing a mix between enthusiasm and down phases – as a massive bipolar syndrome – that potentially slow the wider adoption and development of the technology.

Here is a list of the ten most widespread myths on 3D printing.

1. 3D Printers Cost Too Much

Like in every product category, there are both expensive and cheap 3D printers that consumers can choose to acquire. In the past, there was very little choice. Almost all of the printers were too pricey for non-professional use.

But as technology progressed, adequately capable 3D printers became cheaper to build. Online crowdfunding platforms are now literally filled with high-quality models that cost under $500.

The same issue is true at an industrial level, on scales of thousands and millions of dollars. But any unique product that costs several hundred dollars to 3D print would usually cost even more using traditional formative technologies. And sometimes (more and more) 3D printing is simply the only way to make it.

2. 3D Printing Is Only For Plastics

It is only natural to connect 3D printers with ABS and PLA plastics. Those are the materials that witnessed the most prominent use in the field for quite some time.

But times have changed. 3D printers can now comfortably print metals, wood, resins, bio-materials, and even carbon fiber. It all comes down to filament technology, and this is a field that is developing in parallel to 3D printers. In fact, at an industrial level, metal 3D printing is the fastest growing segment. Not to talk about bioprinting with real cells. The real issue is multi-materiality.

3. 3D Printers Can Massively Produce Guns

This is somewhat misleading. Yes, 3D printers can produce guns. Yes, for gun controlled countries these 3d printed guns are a horror scenario.But some facts: 3D printed guns will only last for a few shots (or one if you use plastic) with real bullets before breaking apart. Also, won’t exactly get a very powerful shot either.

While it is practically possible to do, the cost to effectiveness rate is nowhere close to buying a real gun. After all, if you consider the practically possible ways to produce a gun, there are thousands and include much more common equipment and components than a 3D printer.

As someone wisely said, you are much better off bringing a 3D printed knife to a 3D printed gunfight.

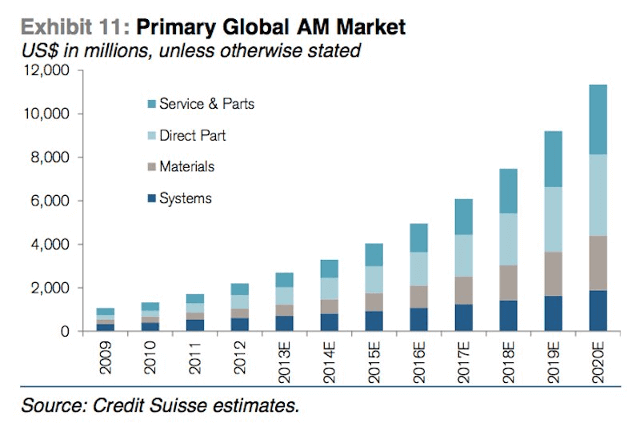

4. 3D Printing Market Is Still Not Stable Enough

That’s a myth to discourage investors to put their money into 3D printing. Analysts tell a different story, though. The market seems to have stabilized by now, and the prospects for 3D Printing will only get obvious in the near future.

The mentioned “up and down” syndrome materialized in a 3D printing stock bubble and the subsequent collapse. Currently, stocks are at three-four year minimums. So it is the time to buy, since Gartner predicted that organic, real growth is starting.

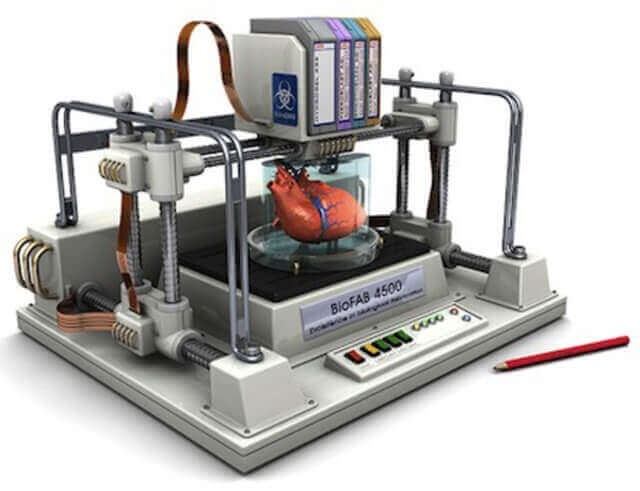

5. 3D Printers Can Print Human Organs

If you follow All3DP.com, you must have read articles that are dedicated to innovative bio-printers and pioneering bio-medical teams that managed to successfully blend additive manufacturing with human physiology and biology. The truth, however, is that we’re still on the first tentative steps and no real human organ has been printed yet.

Scientists are currently testing relatively simple organs in much simpler organisms of animals, so as far as this myth is concerned, we should hold our horses for now. The issue with organs, even more than with every other product, is the inability to effectively 3D print multiple materials at the same time.

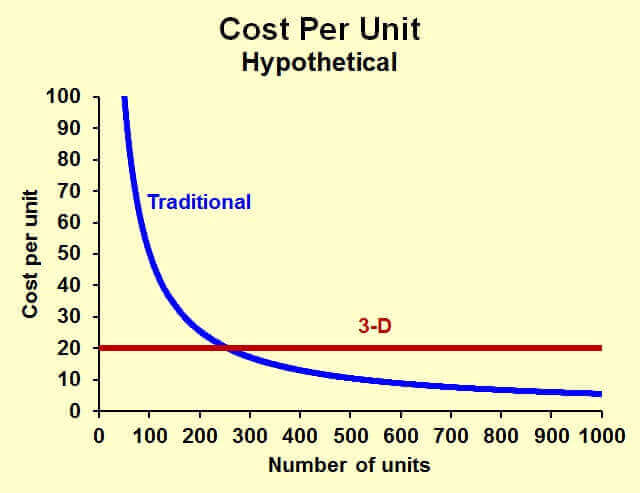

6. 3D Printing Is For Large-Scale Manufacturing

While there have been some products aimed at massive manufacturing, 3D printing is generally suitable for customized production. Maybe both categories will be covered by additive manufacturing technologies in the future. But for the time being, it seems that traditional manufacturing methods are here to stay and to produce massively at rates that are not achievable through 3D printing. This does not mean things won’t change, as some argue that on certain highly complex geometries (for example earring aids) it is already more convenient to 3D print up to 10,000 parts than to produce them with other methods. Also, 3D printing is starting to prove feasible for manufacturing of objects as large as cars and houses.

7. Soon, Every Home Will Have a 3D Printer

Ok, I must admit that this one sounds logical, but still it seems like it won’t happen anytime soon. 3D printers may get ridiculously cheap and easy to use, but so will the online printing services.

Why buy and operate a 3D Printer when you can order whatever you want at a very competitive price? (All3DP offers a free price comparison service for you, by the way). Maybe we will never see a 3D printer in every home after all. It took 15 years for personal computers to reach an installed base of 1 billion. Personal 3D printing has only been around for around three years so who knows?

8. Things Are Quicker to Make on a 3D Printer

3D Printers have become very fast in the last few years, significantly decreasing the manufacturing times to a much more logical spectrum. Still, 3D printing takes a lot of time. And if something goes wrong. you have to restart from scratch. Once again it all must be contextualised: if you are making a single unit of something with a very complex shape, then 3D printing is super fast.

9. Some Things Are Cheaper To Make on a 3D Printer

You may have heard that there are things that are cheaper to produce with a 3D printer than with molding or milling, etc. The truth, however, is that 3D printing makes the prototyping phase cheaper. End products are still not cheaper to build on a 3D printer. It makes no sense to use 3D printing to make products that already exist. This technology is ideal for making products that do not exist yet. The limit is the imagination.

10. 3D Printers Will Save Humanity

This one is a socio-political one, but important nonetheless. This exciting technology may pose as the humanity savior for some, and it is easy to see the reason why. Many may think that with 3D printing people will have better and cheaper access to high-quality and readily available products and goods.

The truth is that 3D printing will only work to the benefit of the people of this world if everything becomes open source. This way, we will be allowed to reap the full benefits of this technology instead of being constrained by user licenses and over-priced proprietary parts, materials. and equipment. 3D printing does have the potential to help humanity produce in a more sustainable way and make the world a better place. However, just like everything else, it depends on the use we make of it.

License: The text of "10 Common 3D Printing Myths Dispelled" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.