Researchers have used 3D printing to develop a long lasting bioreactor. This new yeast-wrangling contraption could offer lengthy and continuous ethanol production, and could be a new, efficient step in brewing beer.

We’re raising a glass to the news that researchers from Seattle’s University of Washington have developed a method that could make one of the world’s most popular beverages, quicker and cheaper than before.

The key to creating beer, wine and any other alcoholic beverage for that matter, is fermentation — the conversion of sugars (from fruits and grains) to ethanol. Typically yeast — a catchall name for a group of micro-organisms — is responsible for this process.

Under optimal conditions, such as temperature, moisture and the like, yeast can convert sugars like glucose with machine-like regularity. To encourage the micro-critters to do so, we make bioreactors.

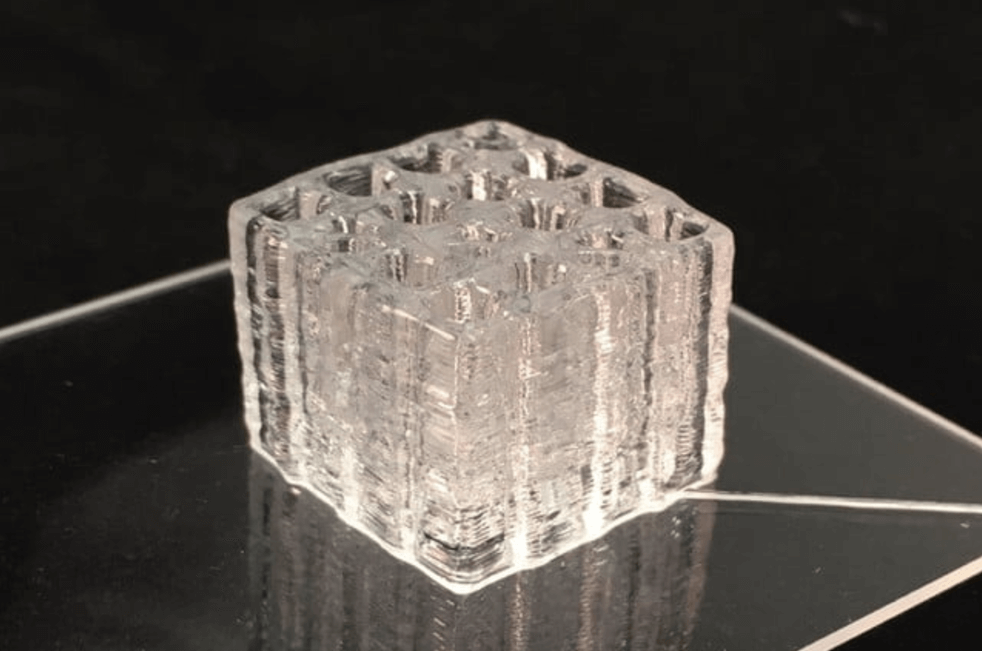

And an experimental new bioreactor is just what Dr. Alshakim Nelson and team from the University’s Organics, Materials and Polymer Chemistry department have created. Indeed, using a custom built FDM 3D printer, the team prints a yeast-laced hydrogel into a cube-like arrangement.

Usable for months, it opens up new possibilities for brewing beer. However, that’s not all – the researchers believe it may also open doors for the development of drugs too.

Dr. Nelson is the lead researcher on the project. He told Digital Trends:

“We have developed the materials and a process to 3D print hydrogels embedded with yeast cells… Hydrogels are materials that are comprised of a significant volume of water, Jell-O. Our hydrogels are about 70 percent water by weight, and the yeast cells appear to exist quite comfortably inside the hydrogel. Not only are the yeast cells viable within the hydrogel, but they are also metabolically active for extended periods of time. We are excited by the fact that we can use the yeast residing within the 3D printed structures to actively convert glucose into ethanol for months and months at a time.”

The Sweet Taste of Additive Manufacturing

The bioreactor’s construction comprises of square lattice layers that, like other FDM 3D prints, build up over time. At to 1 cubic centimeter, the researchers cure it with ultraviolet light to prevent it from collapsing.

Next, the researchers submerge the cube into a glucose solution. Surrounded by this sugary goodness, the trapped yeast gets to work converting the solution to ethanol — with remarkable efficiency. In fact, tests of the process have seen the printed hydrogel steadily convert the solution for some four months.

Current production methods for beer rely upon batch processing for fermentation. However, the researchers believe that their new bioreactor and method may be a more useful alternative in the future. Nelson adds:

“We believe that our 3D printed structures can help improve the efficiency of fermentation processes — for example, keeping the yeast cells trapped inside the hydrogel may simplify their removal at the end of the fermentation process.”

The technology’s potential lies not only in brewing beery goodness. Others applications, such as the production of pharmaceuticals and vitamins are a possibility. However, the researchers still have a lot of work to do and Nelson explains that they’re currently speaking to potential partners before moving onto the next stage.

Source: Digital Trends

License: The text of "Researchers 3D Print a Hydrogel Bioreactor" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.