New research identifies a potentially serious breach in 3D printer security, where recorded sounds can enable reverse engineering of digital models.

Previously, we’ve made light about the noise of a fused deposition modeling (FDM) 3D printer. The stepper motors controlling the XYZ axes are known to emit a constant whirring, whining and buzzing, and sometimes this can be employed to comedic effect. The Imperial March from Star Wars, anybody?

But now comes the revelation this very same aspect of 3D printing on an FDM machine is a potentially serious security breach when handling sensitive data.

According to new research published by the University California in Irvine, the acoustic signals emitted by a 3D printer that can be used to reveal the motion and location of the print-head. And by recording these sounds — discreetly or otherwise — scientists reckon it’s possible for industrial saboteurs to identify design details and even reverse engineer the blueprints for a printed object.

While the STL files for a 3D printed object can be protected and encrypted via regular means, once it’s been uploaded to a 3D printer and the object has commenced fabrication, that sensitive information has effectively been compromised.

The fact that intellectual property is even more vulnerable than previously thought can only cause alarm among industrial designers and makers.

How to Improve 3D Printer Security?

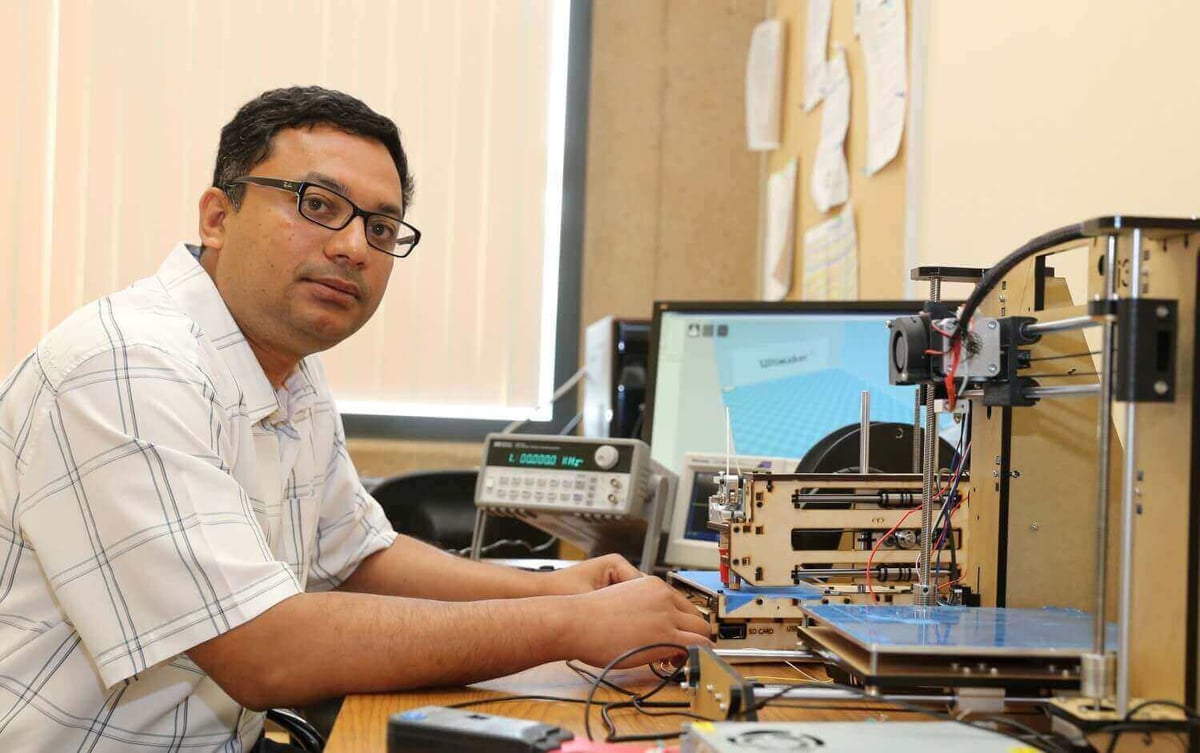

Mohammad Al Faruque is the director of the Advanced Integrated Cyber-Physical Systems lab at UCI. Al Faruque and his team found that by placing a smartphone alongside a Printrbot Simple as it printed objects layer-by-layer, they were able to capture the acoustic signals in sufficient quality.

Studying these recordings revealed information about the precise movement of the nozzle; so much so that they were able to reverse engineer the designs for several items where audio was captured as they were being printed. In one example using this technique, Al Faruque and his team were able to reproduce the STL file for a 3D printed key with almost 90 percent accuracy.

Al Faruque is concerned about the implications of this discovery:

“In many manufacturing plants, people who work on a shift basis don’t get monitored for their smartphones, for example. If process and product information is stolen during the prototyping phases, companies stand to incur large financial losses. There’s no way to protect these systems from such an attack today, but possibly there will be in the future.”

But all is not lost. One of the possible safeguards for 3D printer security in the future would be to mask the acoustic signals through the layering of white noise. Another would be to dampen the noise emitted by an FDM printer, using upgraded components. And indeed, research will be extended to see whether stereolithography (SLA) 3D printers or other additive manufacturing processes have a similar vulnerability.

This discovery has attracted interest from other researchers at UCI, and at various government agencies. The team are preparing to present their findings at the International Conference on Cyber-Physical Systems in Vienna this coming April.

License: The text of "3D Printer Security: Designs Reverse Engineered by Sound" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.