Patient-specific neonatal manikins, created using 3D printing and 3D printed molds, help surgeons practice before heading into surgery.

3D printing offers a broad scope for improving on medical training. The latest example of this is mannequins with functional organs and intelligent sensor feedback.

At the Eindhoven University of Technology, Mark Thielen is a Ph.D. candidate and also a Healthcare Flagship Program participant. Thielen is modernizing neonatal mannequins. Currently, these objects used by surgeons are very basic.

However, Thielen is using 3D printing to create ”manikins”. These small devices offer surgeons the ability to measure every aspect of their practice. To do this, the major internal organs are both simulated and equipped with sensors.

These sensors can measure pressure, impact, and stress. Thielen believes that this could lead to an increase in surgical and procedural success for neonatal patients. He goes on to explain why he chose to use 3D printing: “Without 3D printing, this work would have been impossible. The sheer complexity of human anatomy is very hard to recreate realistically with any other production method, not to mention the cost and time differences.”

He goes on to explain why he chose to use 3D printing: “Without 3D printing, this work would have been impossible. The sheer complexity of human anatomy is very hard to recreate realistically with any other production method, not to mention the cost and time differences.”

The Process of Creating a Manikin

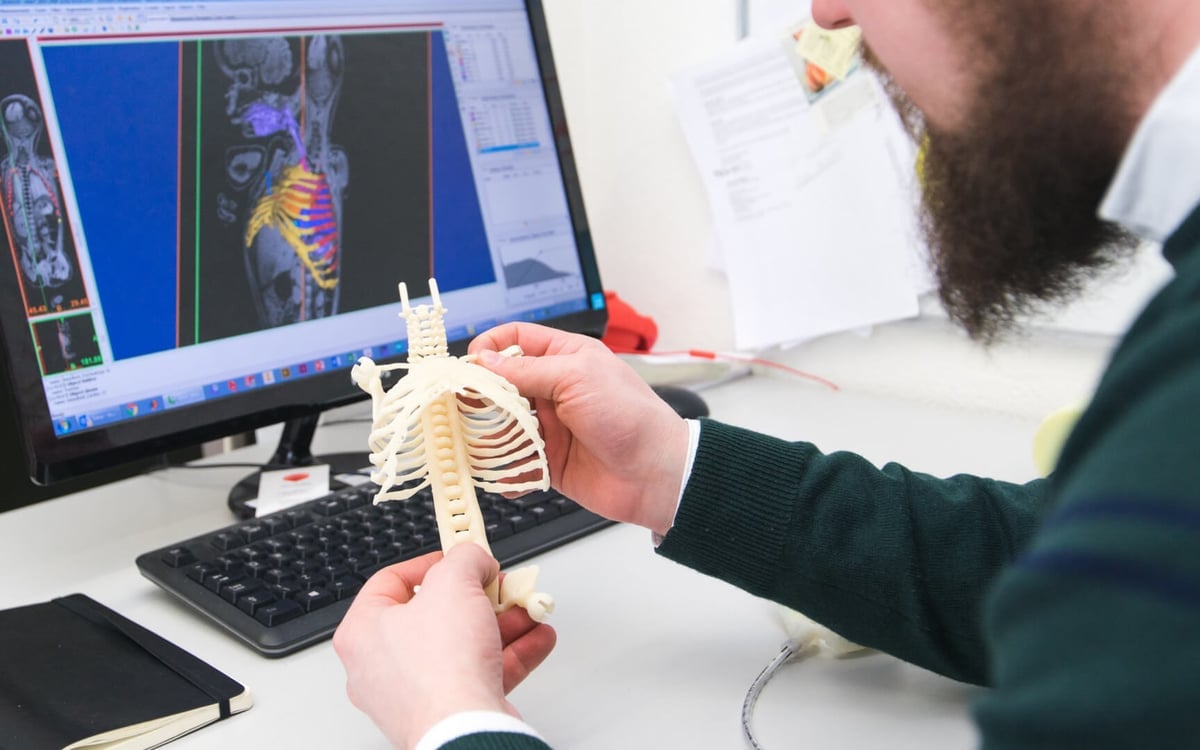

In order to create a baby manikin, Thielen first receives an MRI scan of the neonatal patient. Then, he uses Materialise Mimics software to segment specific organs and creates STL files of them. As it is extremely difficult for surgeons to operate on such small scale, a realistic representation of the organs is crucial to success.

Thielen imports the organ scans into Solidworks to make them functional and for mechanical reconstruction. The final stage before printing is using Materialise Magics software to optimize the design.

Finally, Thielen prints the files or creates 3D printed molds. So far, Thielen has tested Fused Deposition Modelling (FDM), Laser Sintering (SLS) and Multi-Material Jetting (MJ). He has also used 15 different 3D printing materials to find which has the best properties under stress.

Some aspects of the manikin are printed, while others — including the heart — are developed using 3D printed molds. Thielen explains: “3D printing helped this research by enabling the synthesis of models for testing in a swift and detailed manner. As this research focusses on the physical realm, it is important that we work with physical models rather than just virtual ones.”

Cameras and sensors are finally added to the manikin before testing. Thielen is pleased with the final manikins and believes that the technology can be used for wider applications. For example, creating surgical training models for emergency procedures and pregnancies. Watch this space.

Source: 3D Hubs

License: The text of "3D Printed Neonatal Manikins with Simulated Organs Improve Surgical Success" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.