3D Printed cars make all the headlines… but what about 3D printed motorcycles? Let’s take a look at some of the most fascinating recent projects.

As you probably know, rapid prototyping (and 3D printing) are used extensively in car manufacturing. Many industrial 3D printing techniques used there can of course be applied to motorcycles. Likewise, some of the 3D printing technologies we described when we wrote about 3D printed bicycles can also be implemented in motorcycle production.

So without further ado here are three of the most interesting 3D printed motorcycles.

Ducati’s Desmosedici Zooms Out of the Factory

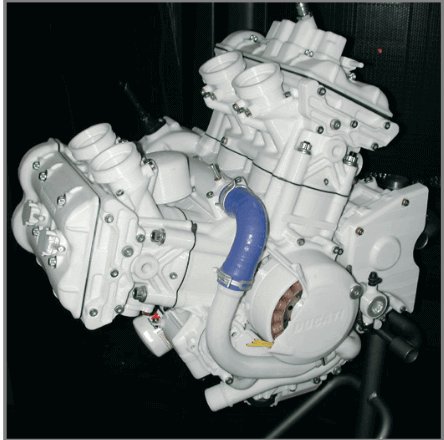

One of Ducati’s key challenges when turning to 3D printing was to reduce time-to-market for by reducing the design cycle for new products such as its Desmosedici race bike.

To help meet this challenge, they turned to industrial Fortus 3D printers by Stratasys. These are machines that work like your average desktop 3D printer. Except they guarantee the quality and repeatability necessary for large manufacturers.

Ducati bought two Fortus Series 3D printers. By bringing all prototyping activities in-house, the company cut 20 months from the development process of the engine designed for its Desmosedici race bike. It was designed and assembled in only eight months while the company’s previous engine had taken 28 months to design and build.

“Prior to purchasing the prototyping systems, our service-bureau expenses totaled approximately 1 million euros per year. That was much higher than the cost of purchase, maintenance, and materials for the two FDM machines. Not only can we produce higher quantities of parts at a fraction of the cost, but we are also able to forecast costs for each project much more accurately,” said Piero Giusti, R&D CAD Manager for Ducati Motor Holding Spa.

Energica Ego: Energizing the Two Wheels

Another incredible 3D printed motorcycle success story is the Energica Ego by CRP Group, a small international company based in Modena. CRP has specialized in offering 3D printing services to the nearby companies of Italy’s Motor Valley and has even developed its line of advanced 3D printable materials called Windform.

Using SLS 3D printing technology and different types of Windform, CRP was able to prototype, build and launch the Energica Ego electric super bike win just two years, from 2013 to 2015. The whole 1:1 scale master model of the Ego was built for testing the assembly, overall dimensions, space optimization, raceways, and verification of different parts, both static and partly dynamic, and electronic equipment.

The functioning “proto zero”, which was tested on several thousand kilometers of road, consisted of several 3D printed parts: The hulls, the frame of the dashboard mount, the windshield, the under-saddle, and saddle (including the rubbery part). Other 3D printed parts included covers, electronic insulators, cable clamps, front and rear fender, in addition to other components less subject to stress such as the chain cover and headlights.

Easy Rider, 3D Printing Style

TE Connectivity is a very large manufacturers of highly engineered connectors, sensors and electronic components. Like many large companies, it decided to undertake a 3D printing challenge in-house. The goal was to assess better the potential of this technology. The result is a Harley Davidson lookalike motorcycle. It demonstrates the ability to design a motorcycle on a computer; 3D print it using FFF technology, add tires and a motor, and ride it.

As reported by Gizmag, the TE motorcycle measures 2.4 m and weighs 113.4 kg. The frame was 3D printed and can support a total of 181 kg. Other non-3D printed part included the braking system, electrical wiring, battery, belt drive, mirrors, side stand and some bolts. A small one hp (750W) electric motor can power a 24 km/h ride for several minutes, which is not exactly breakneck speed. But it’s a start, and 3D printing evolution goes very fast.

Compared to the previous examples, this motorcycle was manufactured using regular ABS materials and desktop 3D printing technology. So if you have a large 3D printer, some good mechanical skills and about 1.000 hours to spare, you can make one at home as well.

License: The text of "3D Printed Motorcycles You Should Know About" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.