Researchers say counterfeits and product piracy can be prevented by innovative security features like 3D printed microstructures.

A new technique called 3D microprinting can provide additional security for branded goods, passports, and money. Developed by researchers at the Karlsruhe Institute of Technology, counterfeits and product piracy can be prevented using innovative fluorescent 3D structures.

Losses caused by product forgery and counterfeiting are potentially massive. According to the German Engineering Association, the damage to their industry alone amounted to 7.3 billion euros in 2016.

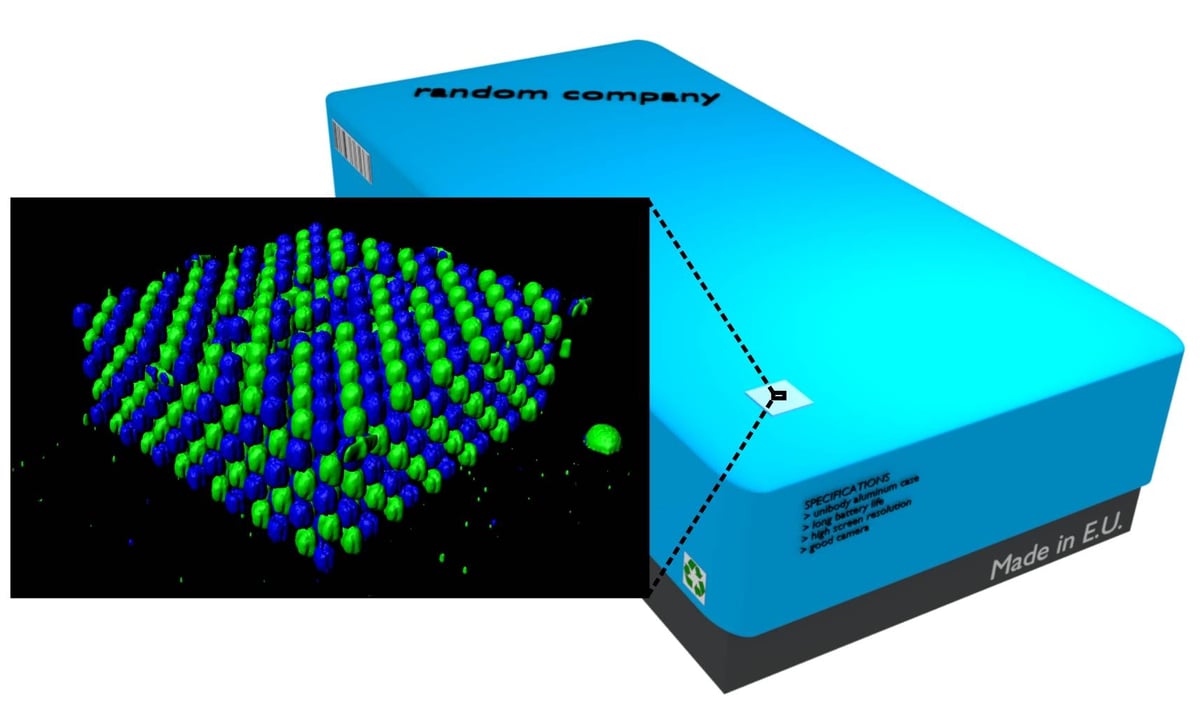

In the Advanced Materials Technologies journal, researchers of Karlsruhe Institute of Technology (KIT) and the ZEISS company have published a paper proposing to use 3D printed microstructures instead of 2D structures — such as holograms — for added security against counterfeits.

“Today, optical security features, such as holograms, are frequently based on two-dimensional microstructures,” says Professor Martin Wegener, expert for 3D printed microstructures at the Institute of Nanotechnology of KIT. “By using 3D printed fluorescent microstructures, counterfeit protection can be increased.”

The new security features have a side length of about 100 µm and are barely visible to the human eye. For their production and application, Wegener and his team developed a new method that spans the entire process from microstructure fabrication to the readout of information.

3D Printed Microstructures Deployed in War on Piracy

The microstructures consist of a 3D cross-grid scaffold and dots that fluoresce in different colors. They can be arranged variably in three dimensions within this grid.

To produce and print such microstructures, the experts use a rapid and precise laser lithography device. It was developed and commercialized by the Nanoscribe company, a spinoff of KIT. It enables highly precise manufacture of voluminous structures of a few millimeters edge length or of microstructured surfaces of several cm² in dimension.

The special 3D printer produces the structures layer by layer from non-fluorescent and two fluorescent photoresists. A laser beam very precisely passes certain points of the liquid photoresist. The material is exposed and hardened at the focus point of the laser beam. The resulting filigree structure is then embedded in a transparent polymer in order to protect it against damage.

“Security features produced in this way are not only of individual character, but also very complex in manufacture.”

“Security features produced in this way are not only of individual character, but also very complex in manufacture. This makes life difficult to forgers,” says Frederik Mayer of the Institute of Nanotechnology of KIT.

The new process can be extended easily and is extremely versatile. The 3D features may be applied as an embedded foil in security tags to protect pharmaceuticals, car spare parts, or mobile accumulators against counterfeiting. They may also be integrated into the transparent windows of bank notes.

For later authentication checks at the supermarket checkout or in the production hall, special readout instruments are required to detect the fluorescent 3D structures.

Source: KIT

License: The text of "3D Printed Microstructures Can Prevent Counterfeits and Fakes" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.