Researchers from University of California, Riverside developed a 3D printed LEGO style modular system for chemistry and biology instruments.

LEGOs and scientific research make the perfect match. Just ask this team from the University of California, Riverside, who have invented a modular system of 3D printed LEGO style blocks for experiments on the fly.

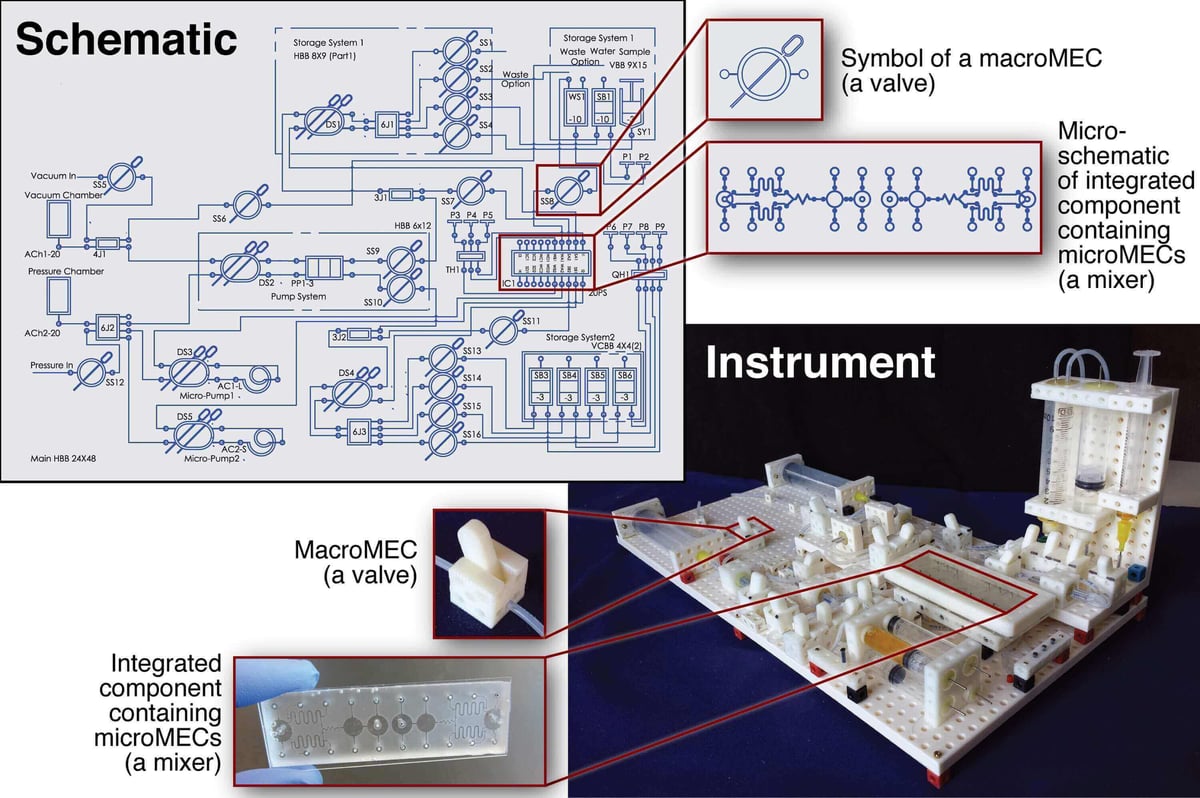

The blocks are called Multifluidic Evolutionary Components, or MECs for short. The 3D printed blocks can be quickly assembled to make custom chemical and biological research instruments. The system is fast, simple and cheap, and their intended use is for university labs, schools, hospitals, and field trips.

The project is led by graduate student Douglas Hill, together with assistant professor of bioengineering William Grover, and is funded by the National Science Foundation.

Grover explains that part of the inspiration came from the time it took for bioengineers to build new instruments:

“When Doug came to UC Riverside, he was a little shocked to find out that bioengineers build new instruments from scratch. He’s used to putting together a few resistors and capacitors and making a new circuit in just a few minutes. But building new tools for life science research can take months or even years. Doug set out to change that.”

The way the MECs work is that each individual unit performs a basic task found in a typical lab instrument, e.g. pumping fluids, taking measurements, or a user interface.

But because the blocks are designed to snap together, that’s where the real fun begins. Users can rapidly and efficiently build complex apparatus for more sophisticated functions. Examples include bioreactors for making alternative fuels, or acid-base titration tools for high school chemistry classes.

The 3D printed LEGO style blocks are especially handy for locations where resources are limited; a small library of blocks can be used to create a huge range of research and diagnostic equipment.

See a set of MECs being put together in the video below (with apologies for the irritating soundtrack):

3D Printed LEGO Science Tools are Perfect for Limited Resources

The development and invention of the MECs are described in detail in the journal PLOS ONE. Because the blocks are designed and packaged to interface together, virtually any material or fabrication technique can be employed to make them.

As a proof-of-concept, the team used rapid prototyping and CNC machining to fabricate larger-scale “macroMECs”.

Two different 3D printers were used. The first was a fused deposition modeling (FDM) printer, a Stratasys Dimension Elite which fabricated parts in ABS filament. The second was a stereolithography (SLA) printer, the Formlabs Form 1+, for delicate parts requiring finer detail.

For the next stage of the project, Grover and Hill will pilot the MEC system in two California school districts. There it will support recently introduced Next Generation Science Standards, a new initiative to improve science education in US schools.

Hill is optimistic about their success:

“As 3D printers become more mainstream, we’ll see them being used by schools and non-profits working in underserved communities, so ultimately we would like people to be able to use those printers to create their own MEC blocks and build the research and educational tools they need.”

What do you think? Would you like to see a MEC in your local school or classroom? Sound off in the comments.

License: The text of "3D Printed LEGO System for Chemistry & Biology Labs" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.