A 3D printed artificial ice which replicates bad weather conditions is being made to help Boeing test an aircraft’s ability to shed this dangerous hazard.

Boeing filed a patent application which explores the possibility of using a 3D printed plastic ice to simulate icing on a plane.

A build up of ice crystals on a plane can increase chances of a crash as it hinders the plane’s aerodynamic shape which is crucial for a safe flight.

Boeing’s new idea is to create artificial ice in order to test the aircraft. 3D printing has been chosen as the best way to make the ice ideal for ground testing.

How Can Boeing Substitute Ice With 3D Printing?

Currently, testing protocols require a plane to be outfitted with artificial ice shapes of fiberglass resin which are then bolted to the aircraft.

Boeing have found that using 3D printing, rather than this previous method, is far less time consuming and, as the ice can be made in the exact right shape, it is less likely to damage the aircraft too.

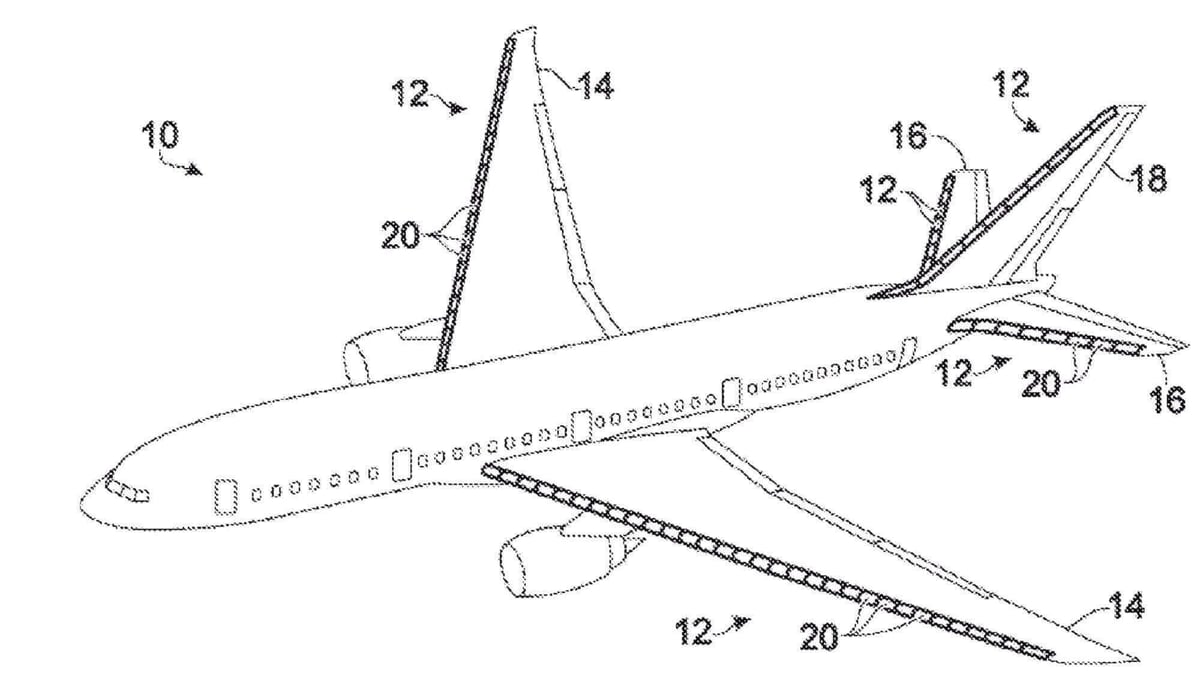

The company is using a material which can be printed into different shapes that fit exactly onto a plane’s wings, flaps and the engine – just like real ice. These “ice pieces” are printed in a testing facility and then applied using a double-sided adhesive foam.

By using 3D printing, a variety of different shapes can be removed and placed on the aircraft depending on the testing conditions, for a fraction of the cost, too.

Researchers are able to monitor changes in the plane’s aerodynamics and test the aircraft’s de-icing capabilities a lot more easily as the amount of ice that is formed can be controlled with precision.

License: The text of "3D Printed Ice to Weather Test Boeing Planes" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.