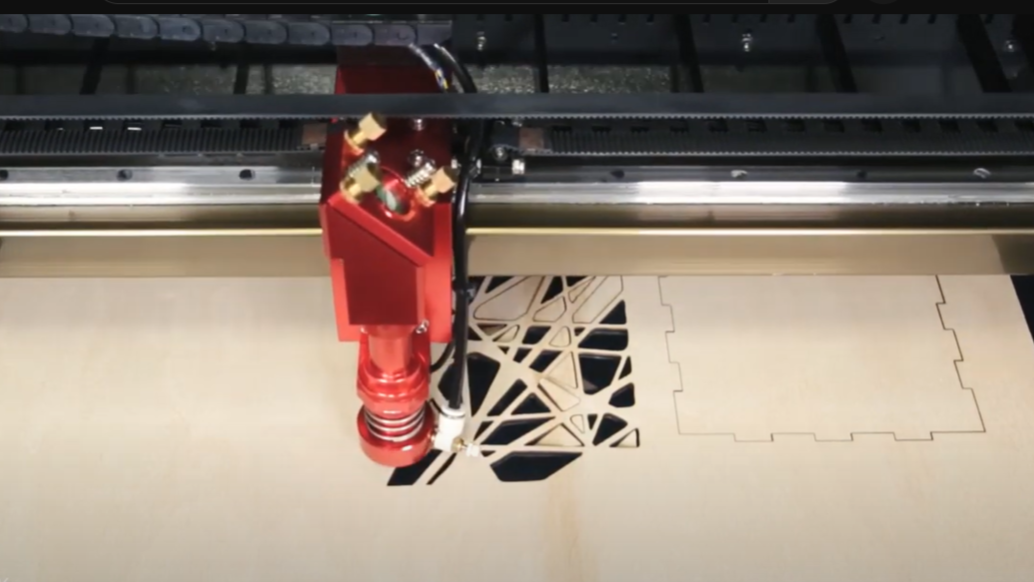

Laser cutting is an amazing technology that’s widely used to make precise cuts on flat materials. It cuts, marks, or engraves materials like wood, acrylic, and metal by emitting a concentrated beam of light through a movable head.

This subtractive machining process is great for cutting simple and intricate designs into flat sheets of material. While there are some laser cutters that can cut material as thick as 20 mm, most machines work on materials closer to 0.5-12 mm thick, depending on what’s being cut.

In this article, we’ll focus on cutting wood with laser cutters, but if you want to cut wood thicker than 20 mm, it’s best to consider using a CNC router, as it will take multiple passes for a laser to cut through thick materials and won’t produce a clean cut. A CNC router can easily handle thicker materials and carve wood, but it’ll produce a larger kerf (width) in exchange.

When cutting wood, plywood, or MDF with a laser, there are two primary options to choose from: CO2 and diode lasers. We’ll dig deeper into both types of lasers, including what they can cut and how much they cost.

Let’s dive in!

Choosing the Right Machine

When using or investing in a laser cutter, it’s important to know which kind to use for your project. Any laser cutter can cut wood, but not every laser is necessarily meant to. It’s always best to choose the right tool for the job.

Diode

Diode laser cutters are known for their compact size, high efficiency, and reliability, and they use laser diodes to generate the cutting beam. These diodes are based on semiconductor technology and emit laser light when excited by an electrical current. Electrons within the diode transition between energy states, emitting photons to create a focused laser beam for cutting.

In relation to power wattage, they are much weaker when compared to CO2 machines, which we’ll get to below. For reference, semiconductor diode lasers come in a range of strengths from 6 to 15 W, which isn’t very powerful compared to other lasers.

When working on wood, it’s best to use these laser cutter machines for etching and marking because of their power constraints. Some diode lasers can cut wood, but they’re usually limited to cutting thin and soft woods, as they’re generally more suited to paper or thin sheets of acrylic.

The upside to this kind of machine is its relatively compact size and affordable nature, with prices typically ranging from $200 to $1,000.

CO2

These types of laser cutters come in a multitude of sizes and powers. CO2 laser cutters produce the laser beam by exciting a mixture of carbon dioxide gas. This excitation process occurs within a sealed tube, and when an electric current is applied, it stimulates the carbon dioxide molecules, causing them to emit photons and generate a high-energy laser beam. The light generated is infrared, so you can’t see it with the naked eye. This laser beam is usually directed through mirrors toward a lens that converges the light beam pointed to the material.

CO2 laser cutters are available in a range of power wattages, typically ranging from a few to several hundred watts. The glass tubes come in different lengths that correspond to power ratings. For hobby and professional use, you’ll be looking at a range of 60 to 150 W – plenty more than what can normally be expected from semiconductor diode lasers.

When it comes to working on MDF, plywood, and wood, these machines are capable of marking, engraving, and cutting with amazing results. Any wattage should be able to mark, engrave, or cut wood. Choosing a higher power wattage simply means that the machine can cut thicker or denser wood faster.

Since it’s more powerful, the CO2 laser will work faster than a diode laser. However, CO2 laser cutters tend to be much bigger compared to diode options, and they tend to be more expensive, with prices ranging from $500 to $10,000 or more.

These laser cutters often benefit from additional equipment or accessories to enhance performance and safety. Common helpers include an exhaust system to remove smoke, fumes, and debris, a cooling system to maintain optimal temperatures, laser optics for precise cuts, and a worktable or fixtures to ensure stability and accuracy during the process.

Another thing to consider is what sort of laser cutter projects you’re interested in working on. If you plan to primarily burn pictures or imagery on wood, you may want to consider sticking with an affordable diode laser. If you want to mark, engrave, and cut thicker wood, it’s best to think about committing to a CO2 laser cutter.

Safety Considerations

While certain machines aren’t as powerful as others, they all come with potential dangers. Always remember these lasers could possibly blind or burn you, so use proper personal protective equipment when necessary. You should read the safety concerns provided by the manufacturer, but in general, the safety concerns for both CO2 and diode laser cutters are as follows:

Ventilation

Both types of laser cutters produce smoke, fumes, and potentially hazardous airborne particles during the cutting or engraving process. Adequate ventilation is necessary to remove these byproducts and maintain good air quality in the workspace. Proper air circulation and the use of exhaust systems or fume extractors are important for creating a safe working environment.

Fire Hazards

Laser cutters generate intense heat, which can pose a fire hazard. It’s important to have fire safety measures in place, such as fire extinguishers and fire-resistant materials. In addition, always ensure that flammable materials are kept away from the laser cutter.

Eye & Skin Protection

Laser beams emitted by CO2 and diode lasers can cause serious eye and skin injuries. It’s crucial to wear proper laser safety goggles or glasses that are specifically designed for the wavelength of your laser. Operators should avoid direct exposure to the laser beam and ensure that others in the vicinity are also protected.

Electrical Safety

Laser cutters require a high-power electrical supply, so electrical safety precautions should be followed. Proper grounding, protection against electrical surges, and adherence to electrical codes and regulations are important to prevent accidents or damage to the equipment.

Operator Training

Operators should receive proper training on the safe operation of laser cutters. This includes understanding the machine’s controls, safety features, and emergency shutdown procedures. Adequate training ensures that operators are aware of potential hazards and know how to handle the equipment safely.

Maintenance & Inspections

Regular maintenance and inspections are essential to ensure the safe and proper functioning of laser cutters. This includes checking the laser components, cooling systems, ventilation systems, and other critical parts to identify any potential issues or wear that could compromise safety.

By prioritizing safety and implementing appropriate measures, the risks associated with CO2 and diode laser cutters can be minimized, creating a safer working environment. Additionally, remember that laser cutters should not be left unattended. Someone should always be present to allow for immediate response in case of any issues, such as material ignition, unexpected movement, or malfunctions. An operator’s presence helps ensure that potential problems are addressed promptly, minimizing the risk of accidents or damage.

How to Cut Wood

When it comes to laser cutting, certain materials offer unique properties and present distinct challenges. Wood, plywood, and MDF (medium density fiberboard) are popular choices for laser cutting due to their versatility, natural aesthetic, and availability.

Each material has its own characteristics that affect the laser cutting process, making it essential to understand their properties and considerations for achieving optimal results. In this section, we will explore the specific attributes of soft and hard woods, plywood, and MDF.

Soft Woods

Soft woods are great if you have a less-powerful laser. Woods that are less dense aren’t nearly as strong or durable as harder woods, but they’re much easier to work with. They’re light, easy to cut, and typically easy to find. On the downside, they burn easily and aren’t very strong and durable.

Pine, cedar, alder, basswood, poplar, balsa, and aspen are popular choices, all of them cutting easily. If you have a more powerful laser, wood as thick as 19 mm can still be cut without much trouble.

Hard Woods

Not surprisingly, harder woods are best used with more powerful lasers. Denser woods are harder to cut but are much more durable and reliable. Keep in mind that they can be more expensive and require more heavy-duty machines.

Birch, maple, cherry, mahogany, walnut, and oak are all beautiful materials to work with and are favorites for laser cutters. They require more powerful lasers because of their density, but thick sheets can still be cut with the right power.

Plywood

Plywood is a material manufactured from layers of thin plies of wood veneer. Each layer is glued perpendicular to the last to make one solid, strong piece.

Plywood is great for laser marking and engraving because of its light and clean surface. It’s also great for assembly projects because of its lightweight material, and it has a relatively low chance of snapping. A primary drawback of plywood is that it can fracture if put under too much stress.

It’s readily available and post-processing is easy. Keep in mind that plywood can be difficult to cut and prone to splintering.

MDF

MDF, which as mentioned stands for “medium density fiberboard”, is like particle board but denser and made from wood wastage fibers compressed and held together with resin and glue.

MDF is great for cutting and engraving because the material is perfect for creating depth. When creating assemblies, it’s best to use MDF for larger projects. This is because smaller project parts are more likely to crumble and break. With topographic projects, size doesn’t matter.

MDF is strong, readily available, and affordable. In addition, it cuts cleanly and smoothly, without knots or a tendency to warp. Post-processing is easy and includes staining, painting, fireproofing, waterproofing, and more. On the downside, MDF tends to break unevenly, and it’s susceptible to moisture.

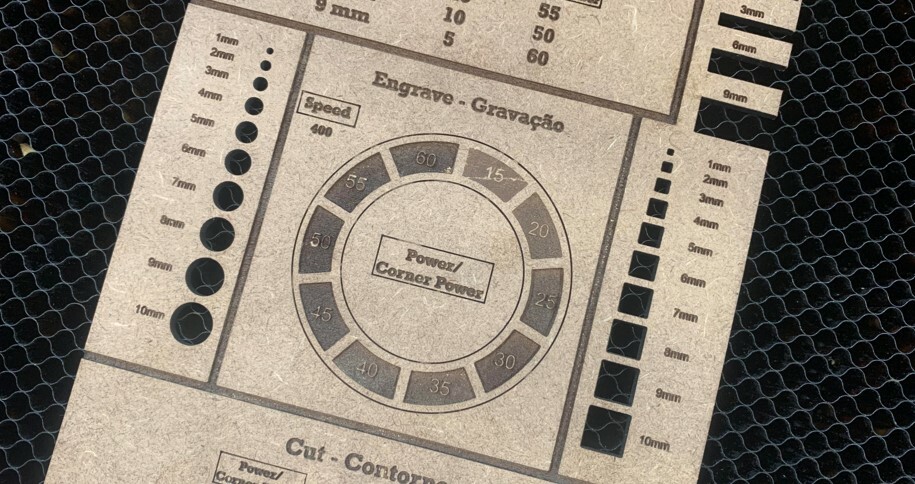

In conclusion, soft and hard woods, plywood, and MDF offer a world of possibilities for laser cutting, each with its own unique characteristics. While we have explored some general guidelines and considerations for laser cutting these materials, it’s important to remember that no configuration parameters for the machine are absolute. Laser cutting is a dynamic process that requires experimentation and testing to achieve the best results.

Every laser cutter, material batch, and project may have slight variations, necessitating adjustments to the speed, power, and focal length settings. By conducting test cuts and iterating on your parameters, you can fine-tune your laser cutting process to obtain the desired precision, edge quality, and efficiency.

By understanding the properties of soft and hard woods, plywood, and MDF, along with diligent testing and a willingness to adapt, you can unlock the full potential of laser cutting and unleash your creativity on these versatile materials.

Troubleshooting

Laser cutting is an incredibly useful and versatile manufacturing process, offering excellent results for product prototyping and design. However, achieving the best outcome requires careful attention before and after the laser cutting process.

It all starts with the CAD file. To create a CAD file for laser cutting, ensure that your design is vector based, with clean and properly closed shapes, accurate dimensions, and appropriate line colors or layers to indicate different cutting or engraving operations.

In addition to the CAD file, you’ll also need the correct software for laser cutting before you can start cutting. One of the more popular software tools used by many is LightBurn.

Beyond that, when cutting wood, plywood, or MDF, there are a few simple tricks to use to get a clean cut:

- Keeping the workpiece elevated helps prevent molten sap from sticking to the bottom of the piece. This can be achieved with a honeycomb bed or using pins to hold the workpiece up.

- Cutting wood with a laser can leave scorch marks. Applying painter’s tape to both the top and bottom of the workpiece helps protect the edges of the cut from burning. Using air assist can also help prevent flare-ups.

- After the piece is cut, any burn marks can easily be sanded away with high grit sandpaper.

- If a cut didn’t make it all the way through, X-acto blades are perfect for finishing the job.

- Staining the wood or adding another type of finish can make a job look more professional.

When You Don't Own a Laser Cutter

Just because you don’t have direct access to a laser cutter doesn’t mean that you can’t utilize this powerful tool for your projects. Here are a few popular options to consider:

Makerspaces

Makerspaces, also known as hackerspaces or fabrication labs, are community-oriented workshops that provide shared access to a wide range of tools and equipment, including laser cutters. These spaces typically offer membership or rental options, allowing you to use their facilities and pay for machine hours. Makerspaces provide access to laser cutters and the opportunity to collaborate with other like-minded individuals, share knowledge, and gain valuable insights into different techniques and projects.

Online Cutting Services

If you prefer a more convenient approach, online cutting services can be a viable option. Many companies specialize in laser cutting and offer their services through online platforms. These services often have user-friendly interfaces where you can upload your design files, select your preferred materials, and specify your desired cutting parameters. The service provider will then laser cut your design and ship the finished parts to you. This option is particularly useful if you don’t have immediate access to a local makerspace or if you require professional-grade precision or specialty materials. There are several options available, some good examples of which include Ponoko, Sculpteo, and Sendcutsend.

Buying a Laser Cutter

If you find yourself frequently in need of laser cutting capabilities, investing in your own machine might be a good long-term solution. Purchasing a laser cutter gives you the freedom and convenience of using it whenever you need it, without the limitations of rental times or service providers. However, it’s important to consider the upfront costs, maintenance requirements, and the learning curve associated with operating a laser cutter. Researching different models, consulting with experts, and considering your specific needs will help you make an informed decision. There are several options out there, including popular picks like the Flux Beamo, Glowforge Plus, and the Gweike Cloud.

Regardless of the approach you choose, it’s crucial to ensure you have a well-prepared design file that meets the specifications of the laser cutter you will be using. This typically involves creating a vector-based file with properly closed shapes, accurate dimensions, and appropriate line colors or layers to indicate different cutting or engraving operations.

By utilizing makerspaces, online cutting services, or investing in your own laser cutter, you can harness the power of this technology to bring your ideas to life. Whether you prefer the hands-on experience of a makerspace, the convenience of online services, or the independence of owning your own machine, laser cutting can be accessible and transformative for your creative endeavors.

License: The text of "Wood Laser Cutter: How to Laser Cut MDF, Plywood & More" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.