Introduction

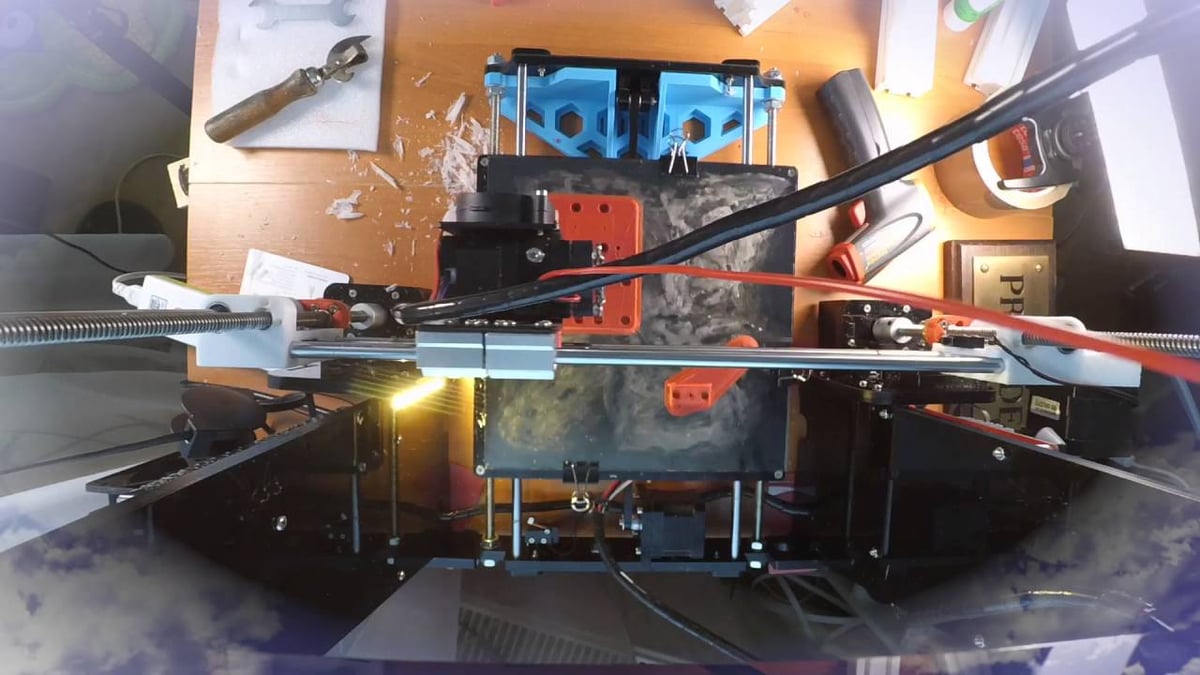

The Anet A8 is an extremely popular 3D printer because of its affordability and hackability. This machine is a fun project to put together and is an excellent kit for amateurs who are eager to learn about FDM printing.

Owing to its hackability, the prints it makes can have a difference like night and day when the right upgrades are implemented. And most importantly, these upgrades can be done without having to break the bank.

For example, in its stock format, this 3D printer does not come with a duct fan, which helps in directing air from the Anet A8 extruder fan to the nozzle. The air is needed to cool the extruded plastic and to keep the printer in proper working condition. The good news is that there are plenty of 3D printable duct fans on Thingiverse. Here is an example by a user named Arjjck.

Perhaps the most basic upgrade is adding an extruder button to make the printer easy to use. This 3D printed button is always a better replacement for the stock extruder screw that hurts the fingers. Here is a 3D printed Anet A8 extruder button by a user named dryas. It prevents the pain on your fingers when you want to make a filament replacement.

Check out All3DP’s extensive list of Anet A8 upgrades and mods here.

One improvement that may significantly improve your print quality is upgrading the Anet A8 extruder.

Here are some of the best extruders for your Anet A8:

E3D Titan Extruder

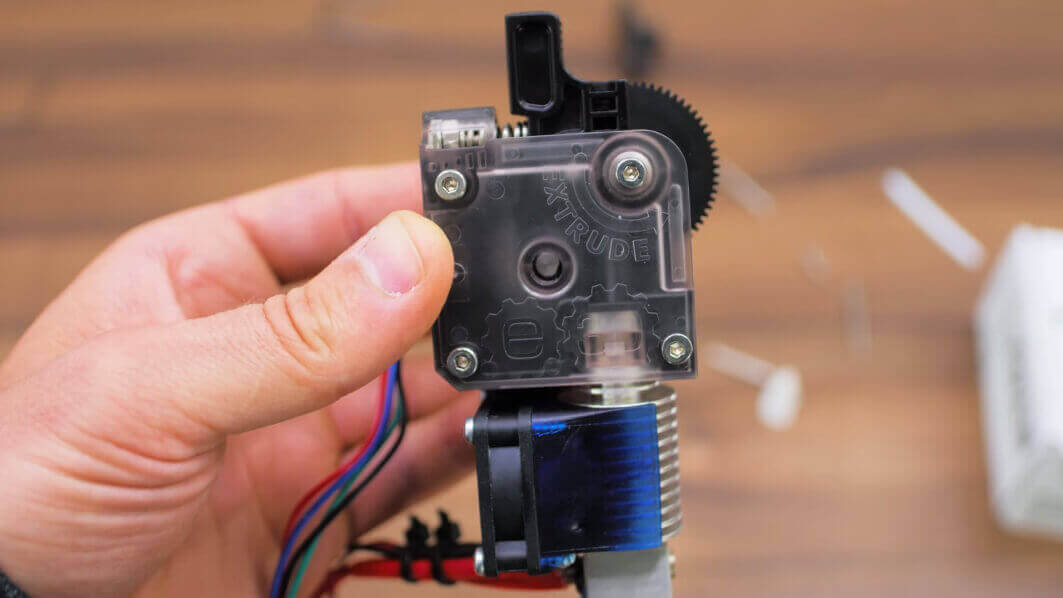

The E3D Titan extruder is perfect for designers who want to 3D printing using materials beyond PLA. The lightweight E3D Titan reduces clogging and has custom machined teeth that are curved to grab filaments at the right angle. The teeth enhance filament grip and increase precision.

This extruder has been manufactured to increase torque, reduce clogging, and print in higher resolution. It’s designed to match with the E3D v6 hotend, allowing for printing in higher temperatures while the 3:1 gear ratio enables more precise movement.

According to the manufacturer, this specific ratio gives the extruder the best performance in terms of accuracy and speed. Apparently, lower ratios are too slow while higher ratios run too fast. Therefore, the manufacturer found 3:1 to be a sweet spot that enables the extruder to keep up with the right amount of extrusion. The gear ratio increases resolution and facilitates smooth printing at lower layer heights.

The extruder supports the printing of both 1.75mm and 3 mm filament diameters, including other filaments like abrasive carbon fiber, TPU, TPE and a range of other harder plastics. The Titan also comes with a constrained path to enable it to print a full range of flexible printers.

The E3D Titan has a solid construction owing to its injection-molded parts. The parts eliminate cases of wiggling and increase precision, unlike other clunkier extruders. Apart from its lightweight design giving it more torque, the E3D Titan was manufactured in a way that makes it easy to put together or disassemble.

LulzBot Taz Single Extruder Tool Head v2

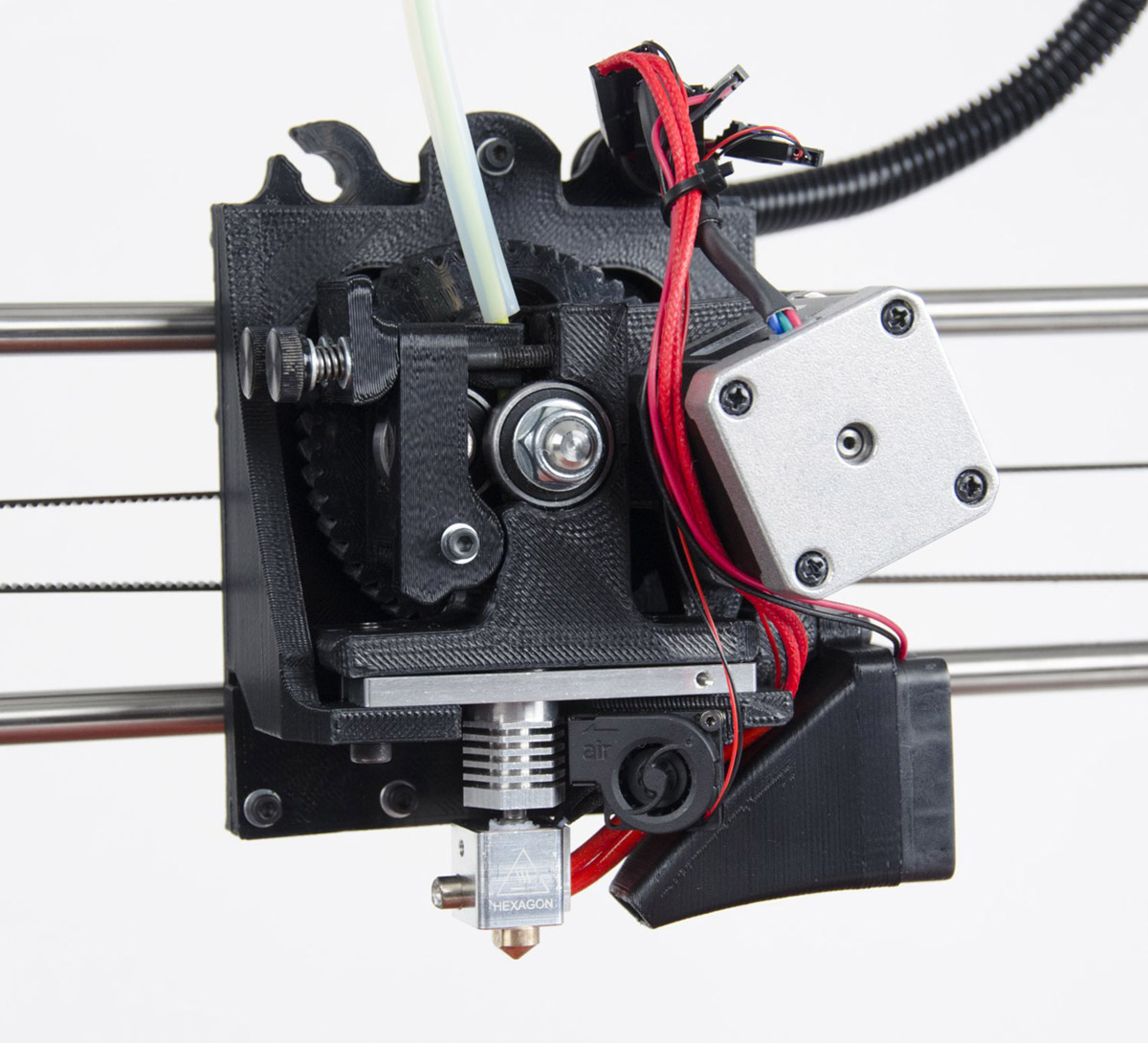

The LulzBot TAZ Single Extruder Tool Head v2 comes with an all-metal hexagon hotend and can sustain temperatures of up to 300°C (572°F). Therefore, you will have no problems with filaments like ABS, PLA, and HIPS. You can also use other types of filaments like T-Glase, Polycarbonate, Nylon, and varieties of stone and wood-filled filaments.

The extruder comes installed with two fans, one for the nozzle, which helps to accomplish high detail prints, and the other for the heat sink. The LulzBot Taz has undergone countless hours of testing and makes a suitable Anet A8 extruder replacement; drawing knowledge from the Open Source Hardware community and RepRap Discount.

Single Flexion Retrofit Kit for Single Extruder

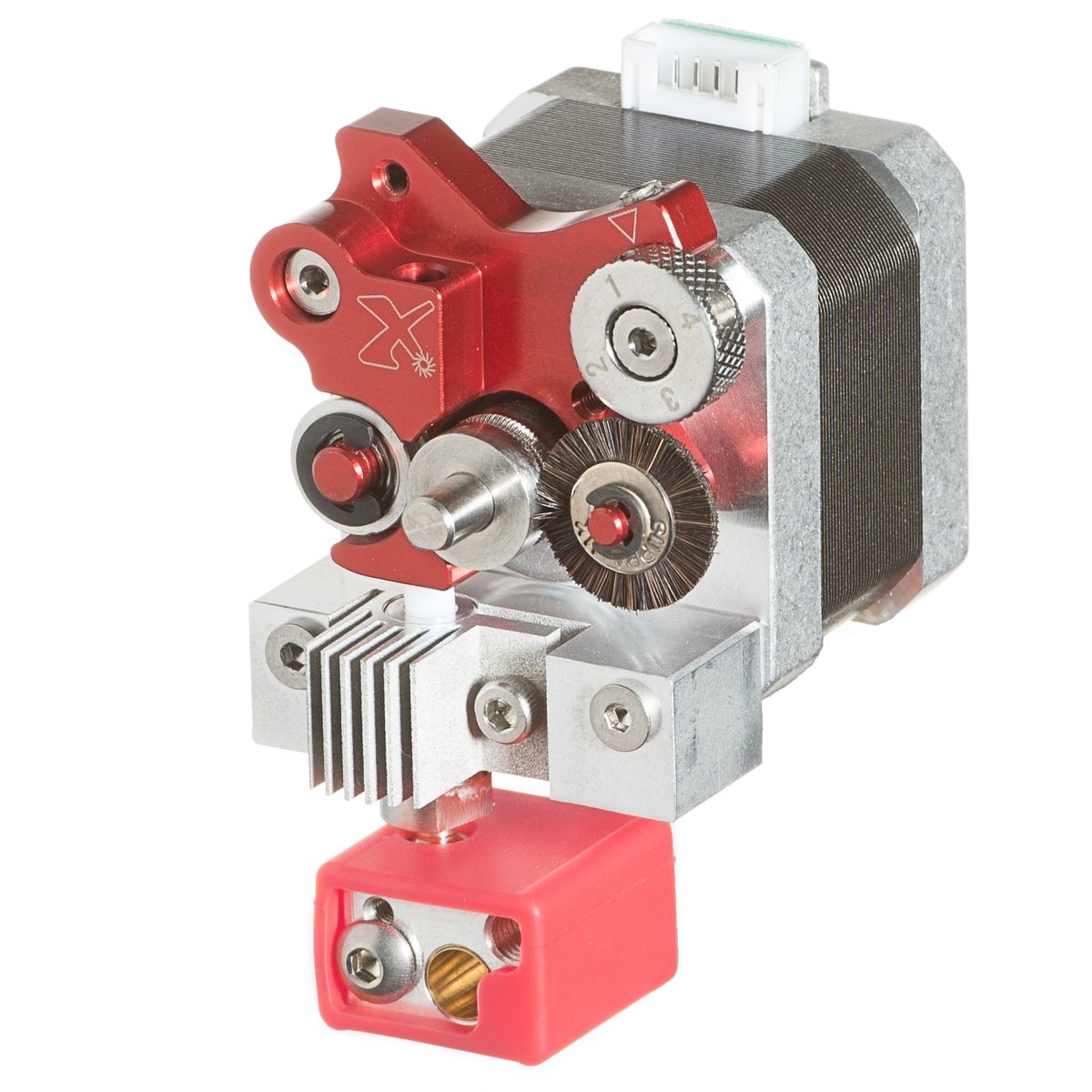

It is far better than your stock Anet A8 extruder and will guarantee high resolution and fewer failures. The Flexion Extruder Retrofit Kit has precision machined components that give you the ability to full-speed print flexible filaments while applying adjustable, precise tension on your filament to maintain high accuracy in your print.

It pushes filaments harder, and the self-cleaning drive will guarantee your time-consuming prints don’t fail due to clogging. The extruder relies on a high-stiffness lever for compressing the filament and an adjustable screw and cam are used to control the compression – to precisely control tension. This Flexion Extruder will work with TPU, TPE, flexible PLA, Filaflex, and Ninjaflex, in addition to the standard rigid filaments.

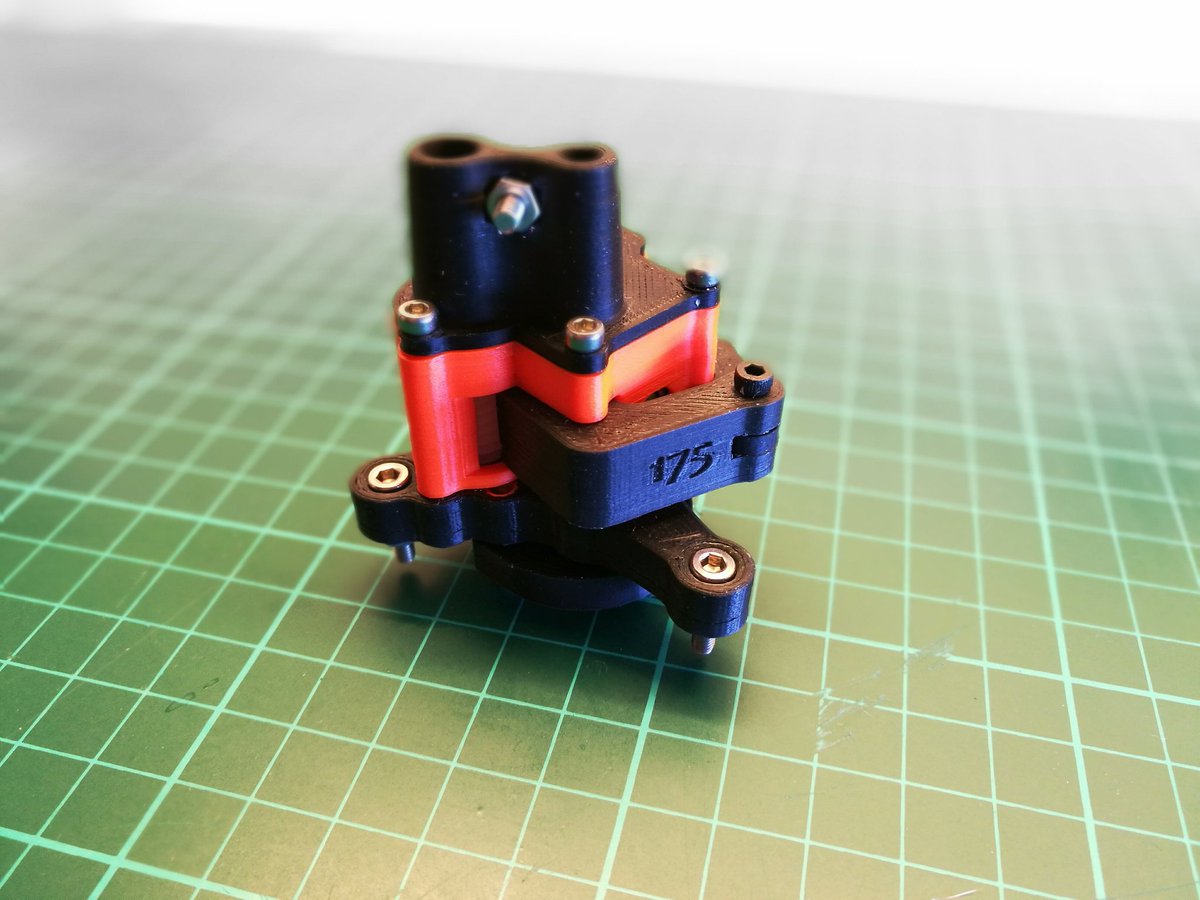

Flex3Drive Extruder

The Flex3Drive extruder is compatible with a wide range of hotends and has a 40:1 gear ratio. It will print remarkable first layers because of this ratio, the motor doesn’t have to do much work. It allows for direct feeding into the hotend, but the motors are remotely located to reduce moving mass and make the extruder lightweight. This translates into a smoother movement of the print head and reduces vibrations.

This shaft driven extruder is compact, and it is manufactured to be small and lightweight, while also highly effective. The extruder has cam lock tensioners for consistent filament tension without the need for springs or screws. This is especially suitable for rigid filaments, but there is an adjustable tension arm for the filaments that don’t require a hard grip.

The tight filament path means the printing of flexible filaments has been made easier. In addition, filament loading is made much simpler with the easy filament loading that allows a filament to be loaded without removing the tension arm. This means filaments can be changed without the need to pause the printing process.

Installing the Flex3Drive hotend at the bottom of the extruder can be a headache, but it’s worth it. This extruder is powerful for the widest nozzle diameter or the thickest layers and will print at lower layer heights. The drive gears are CNC machined and make it adaptable for custom machines because of durability.

Bowden Extruder

We are adding a Bowden extruder to this list with caution because it is always lambasted for its apparent unreliability. The Bowden style of extruder will mean the hotend is physically separated from the extruder. Typically, the extruder is mounted on the interior or back of your Anet A8 3D printer and works as a “remote” extruder the same way a direct extruder works: grasping the filament and pushing it. The main difference, however, is that your filament will need to travel over a tube before it reaches the hotend.

The nature of a Bowden extruder significantly reduces weight that needs to be carried around while printing and reduces wobbling, backlash, and overshoots. This is because when the extruder (with its mounts and motor) is kept away, only the hotend is left to move around. Therefore, there is less momentum to be overcome, and this makes the Bowden approach the best choice when printing intricate details.

But this type of extruder also has its downside. The separation of the hotend and the extruder typically causes a lag or hysteresis. The longer filament path means a prolonged contact and increases friction that your extruder needs to counter. Therefore, the motors will require higher torque to deliver the filament to the hotend. This makes Bowden extruders challenging to use with flexible filaments. The longer path means the filament could deform, warp, compress, or stretch, and lead to inconsistency in the printing.

While a Bowden extruder may work well with an Anet A8 printer, it could require a bit of technical knowledge because certain adjustments may need to be made on the printer firmware to overcome the aforementioned issues. Therefore, going for a Bowden extruder might be asking for trouble if you are not a true 3D printing enthusiasts.

On the other hand, if you are confident with your skills and don’t have a problem tweaking your printer settings, then a Bowden extruder may serve you right. You will get cleaner and smoother prints at a shorter time.

Bowden extruders do present a number issues, but those issues can usually be solved if you are keen and you have some time to tinker.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.