What Is PolyJet 3D Printing?

PolyJet is the trademarked name for a particular type of material jetting, a 3D printing technology, by US-Isreali-based company Stratasys. Although not technically a distinct category of 3D printing, PolyJet has several unique features that set it apart from other processes. The most distinguishing, of course, is full color.

There are only a handful of full-color, multi-material 3D printing processes on the market, and PolyJet is likely the most popular. It’s offered by dozens of 3D printing service bureaus, including Craftcloud, and it’s the go-to method for full-color product prototypes for a long list of manufacturers. Looking at some of the PolyJet product photos in this article, it’s almost hard to believe that these are not assembled, dyed, or painted — they pretty much come out of the printer this way (after you take off the support layers).

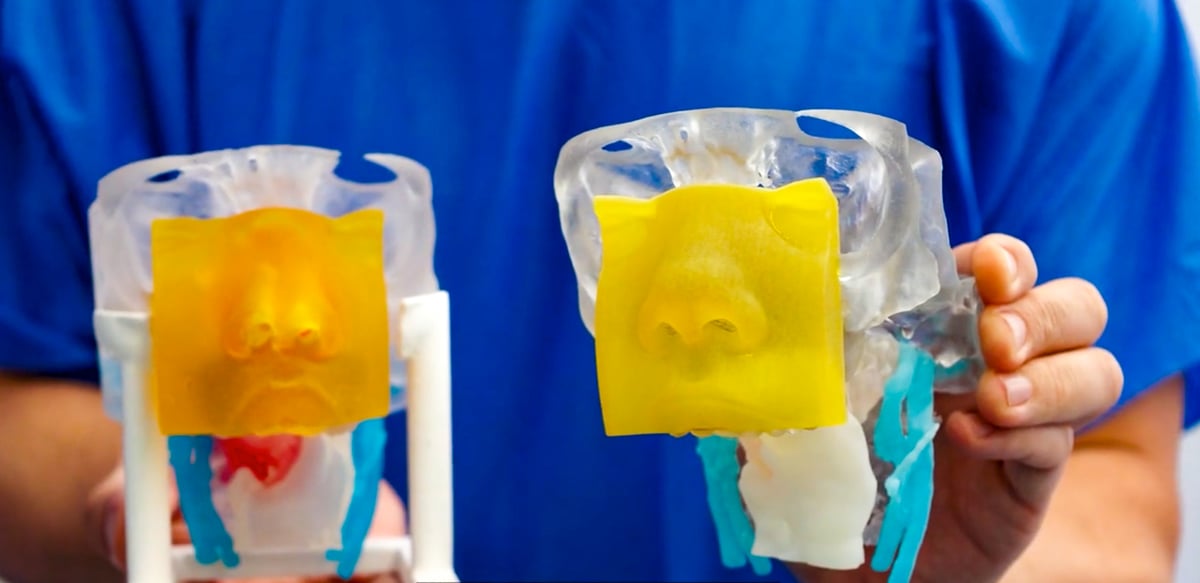

But PolyJet isn’t just about color. Although it’s easy to be dazzled by the colors and textures of PolyJet prints, the technology is used for rugged industrial parts and biocompatible dental products.

We go into the techy details below, but the bottom line is multi-material, finely detailed, durable, and life-like parts from your 3D printer for use as product prototypes, medical models, fashion products and apparel, molds, manufacturing tools, dentures, surgical guides, and much more.

Let’s dive into PolyJet!

The Technology Behind PolyJet

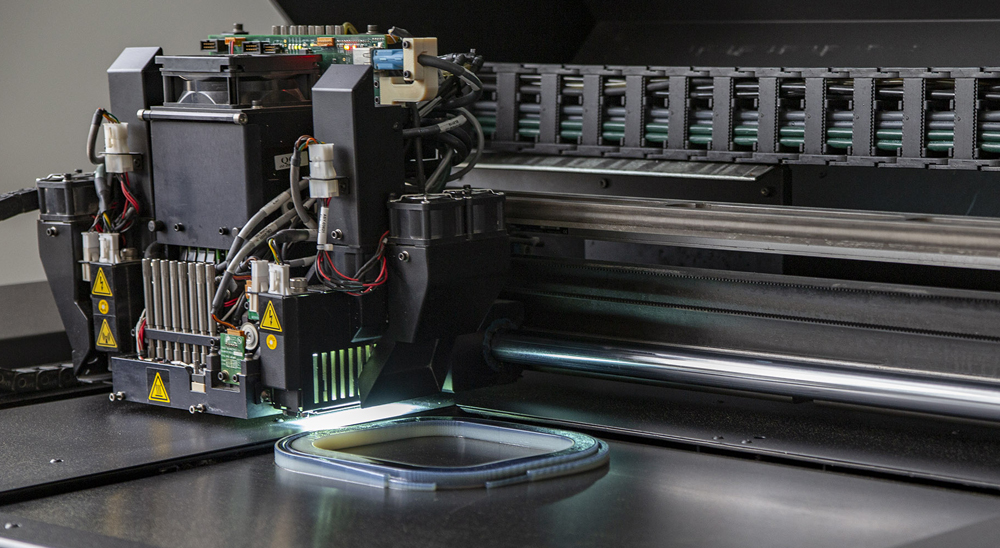

In a nutshell, Stratasys PolyJet 3D printers (there are several) deposit tiny droplets of resin that solidify almost instantly under UV light so that parts are produced layer by layer.

The first 3D printer that jetted photopolymer droplets and cured them with UV light was developed by a company called Objet-Geometries in 2000. They called it PolyJet. In 2011, Stratasys acquired the company and has further advanced the technology and expanded its application possibilities, and launched several new PolyJet 3D printers (see below). There are now 16 PolyJet printers in the Stratasys family.

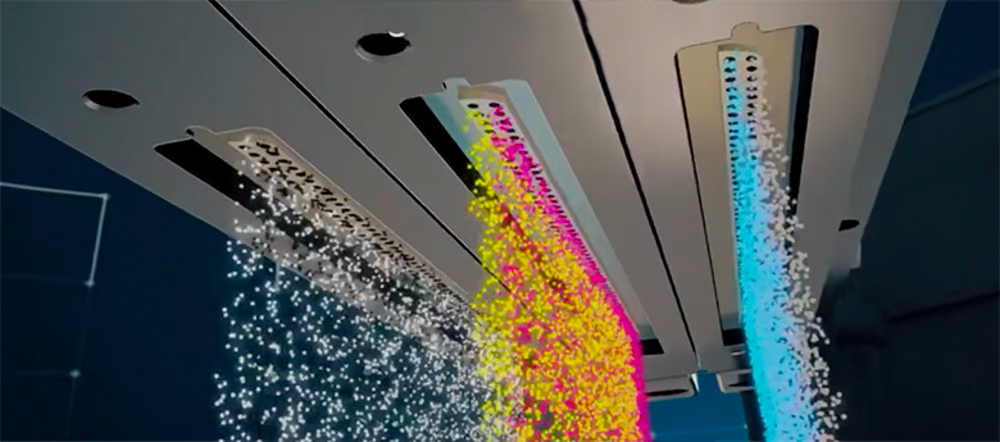

PolyJet falls under the 3D printing technology category called material jetting, which is just like it sounds: material (typically liquid resin) is deposited or “jetted” from an array of nozzles onto a surface. PolyJet jets thousands of material droplets at a time precisely placed according to a digital model of the part uploaded to the printer.

Although not all PolyJet printers are full color, the ones that are can achieve more than half a million unique colors resulting in highly realistic objects, including wearable dentures and product prototypes. The level of fine detail is achieved by the tiny layers, as fine as 16 microns (0.0006″ inches), but more commonly in the 14 to 55 micron range.

PolyJet printers have multiple independent printheads, which allow them to print multi-color and multi-material parts. After the droplets are deposited on the build platform, a UV light source passes over the layer to solidify it. The build platform moves down by one layer, and the next layer is deposited on top of the previous one. PolyJet printers can blend two to seven model materials to obtain an array of features in one print to produce not only different colors but also various textures.

PolyJet printers are fast (depending on how many materials you’re using at once) and accurate (depending on the machine and the print speed). The highest levels of accuracy are achievable at the slowest print speeds.

On PolyJet 3D printing systems, the support material is printed simultaneously with the modeling material.

After printing, there are post-process steps necessary to remove the support material that can completely encase the part. Pressurized water can remove as much support material as possible without dissolving it. Afterward, the parts are submerged in a chemical solution, in which the rest of the supports dissolve, leaving a clean part. In 2022, Stratasys introduced water-soluble support material for its J35 Pro and J55 Prime PolyJet 3D printing systems that on require a water bath to remove supports.

Polishing and coating are other optional steps depending on your required part quality.

As far as software is concerned, PolyJet printers use the Stratasys GrabCAD, which enables you to print directly from this CAD software without the need to convert and fix STL files. The J55 also supports the 3MF file format so you can directly 3D print in full color and multi-material textures directly from KeyShot 3D rendering software. This technology can save a lot of time.

PolyJet Materials

PolyJet 3D printers only print with Stratasys PolyJet materials. You can pour just any type of photocurable resin into your PolyJet machine. Still, Stratasys makes dozens of materials, including biocompatible materials for dental applications and high-temperature materials for industrial applications.

If you’re familiar with the cost of resins for other types of 3D springing, such as SLA, you may experience a bit of sticker shock when it comes to Polyjet resins, they average about $400 per kilo. Below we detail the most common but you can see the full list on the Stratasys material menu page.

Stratasys PolyJet General Materials

Stratasys PolyJet Dental/Medical Materials

Who's Using PolyJet?

The potential of PolyJet has been recognized by many industries, which implement the technology to enhance their workflow and save money, and create products not possible with any other technology

Because PolyJet is a technology that can produce highly detailed parts in hours, it’s especially ideal for making realistic prototypes, lifelike medical models, and more. Let’s take a look at some of the latest applications.

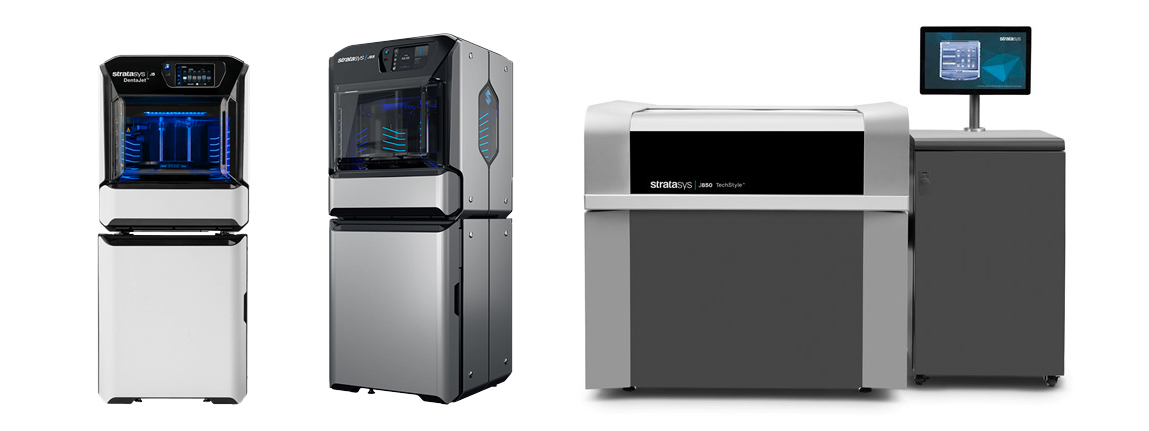

Stratasys PolyJet 3D Printers

Stratasys offers PolyJet technology in 14 3D printers and variations ranging in size from desktop to massive production-level machines. The differences between these models include size, which materials they are compatible with, how many materials they can print at a time, and speed.

Get PolyJet Parts Printed

As we mentioned, PolyJet is an expensive technology starting at about $50,000 with some pricy materials. For many applications, the machines pay for themselves by boosting productivity, getting products to market faster, delivering patient-specific dental products, and creating potentially life-saving models for surgical planning.

That said, if you are not ready to invest in PolyJet there are many service providers available le to print your PolyJet products for you. Ordering directly from the Stratasys parts-on-demand service, aptly named Stratasys Direct, is a top option.

There’s also Craftcloud by All3DP, which isn’t a PolyJet 3D printing service, per se, but it will help you find one that’s right for you. Craftcloud is a marketplace of 3D printing services that helps you compare prices and technologies from different services near you to find ones that fulfill your needs at a price you’re comfortable with.

Craftcloud has a good collection of PolyJet resins available. The material range covers everything from high-detail and tough resins to flexible, multicolor, and transparent materials.

For alternatives, check out our guide to the top PolyJet 3D printing services below.

License: The text of "PolyJet 3D Printing – The Ultimate Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.