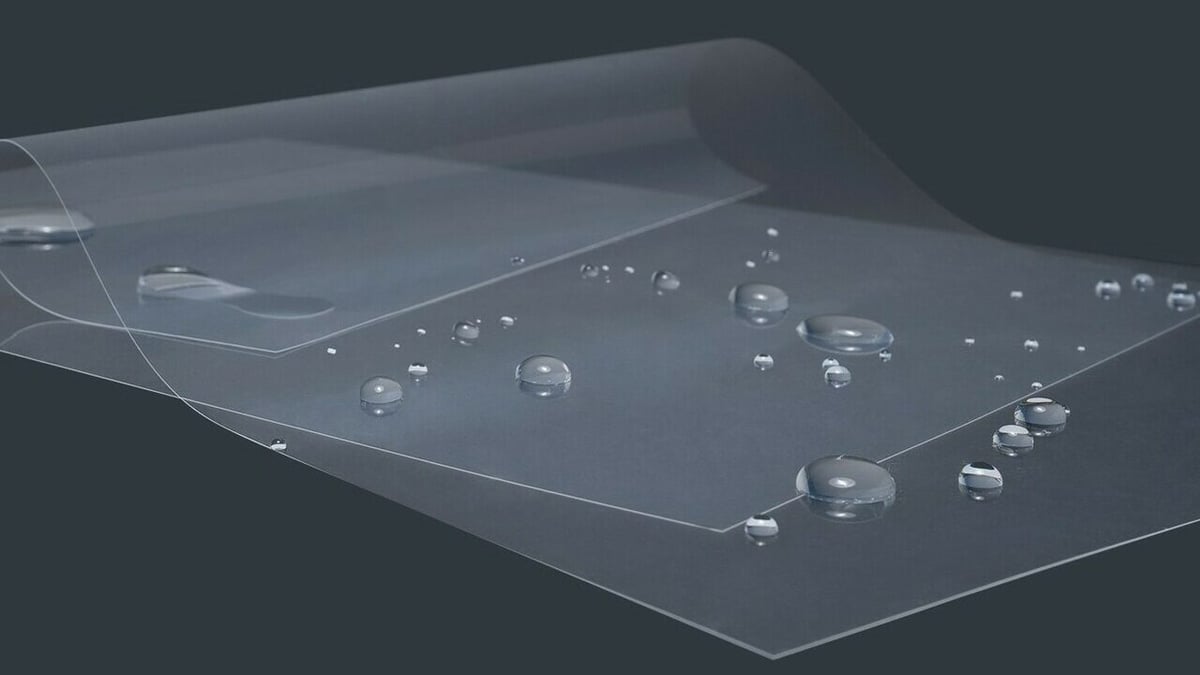

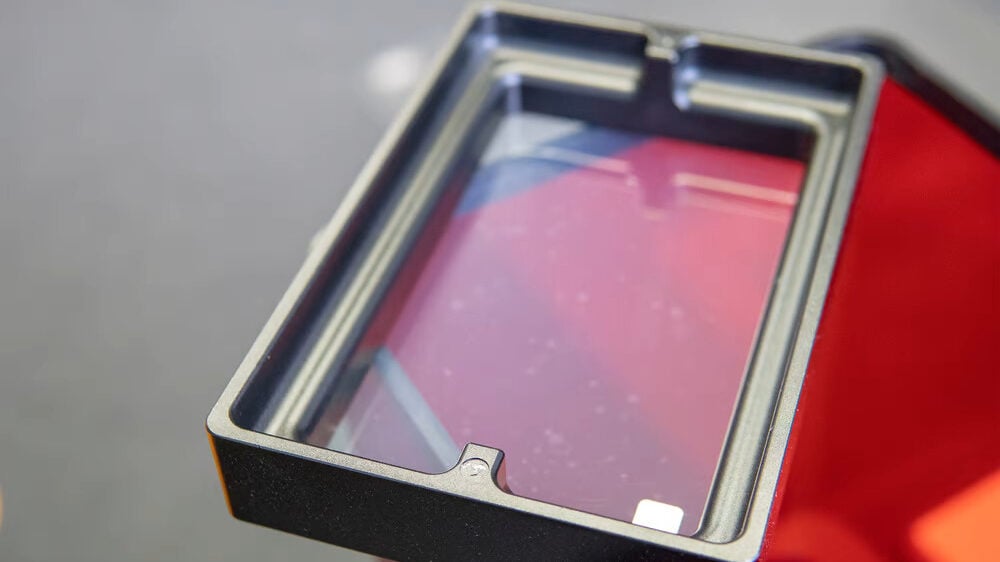

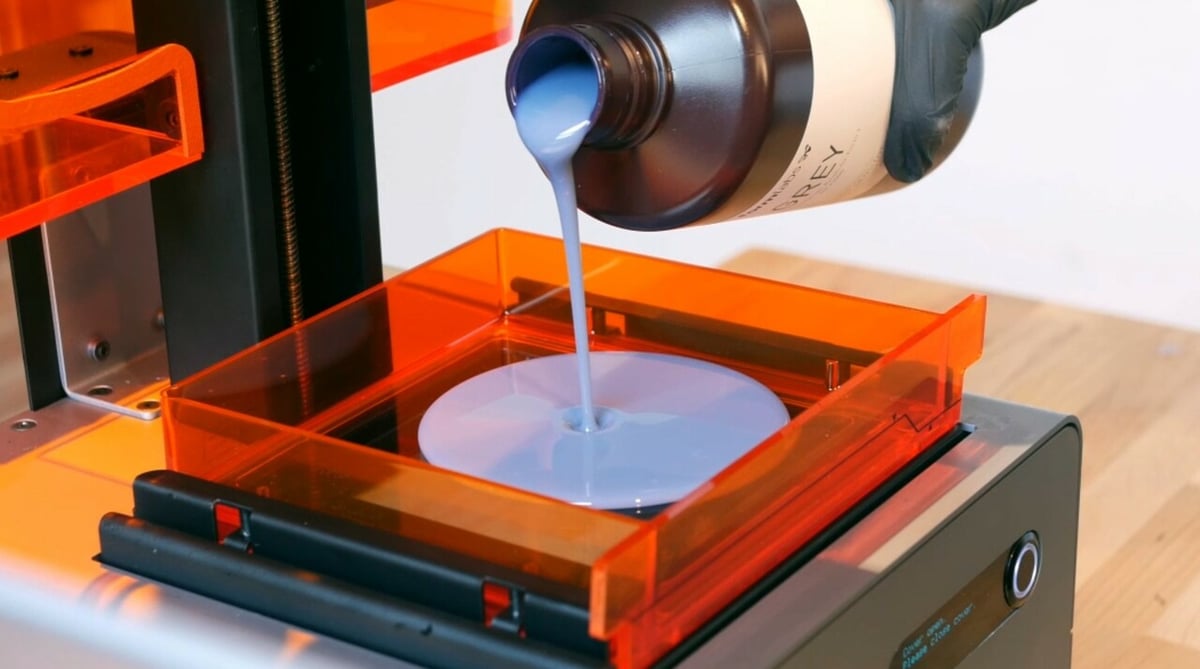

Resin printing films are an essential part of vat polymerization, used by every resin 3D printer on the market. The film separates the liquid resin and build plate from the light source in the base of the machine. It holds the resin until the print bed moves upwards, peeling the newly cured resin away from the film and starting the process all over again. This peel creates the specialized need for a film instead of something like a glass sheet. The interface layer needs to be flexible with a low suction force so that the newly cured layer can be easily removed by the pull from the build plate, preventing failed prints.

As resin 3D printing becomes more accessible and affordable, new film materials are becoming available. Between nFEP, FEP, and PFA, the varying levels of flexibility and tensile strength are just a few of the differentiating factors. Let’s go through their differences in more detail to find the perfect match for you.

FEP

FEP, also known as fluorinated ethylene propylene resin, is the most common material of choice when it comes to resin 3D printer films. With a tensile strength of 14-21 mPa – a value that describes the strain a material can take while being stretched before breaking – the film achieves a balance between rigidity and the needed stretch when peeling a new layer away. (For reference, marble, rubber, and pine wood have tensile strengths of 15, 16, and 40 mPa, respectively.) FEP is also quite cheap and easy to buy, making it a sensible choice.

Unfortunately, the advantages in price and flexibility also create some downsides. For example, a coarser surface than the other film materials combined with a high stretch factor can lead to an increase in failed prints. These failures come in the form of the cured layer having too much adhesion with the film rather than the build plate and detaching from the plate, blocking the next layers from properly printing. The increased stretch level also decreases the film’s lifespan due to a higher chance of micro-cracks developing on the film surface.

FEP Options

FEP sheets can be bought everywhere nowadays, being much cheaper and of higher quality as the market becomes more saturated. Most filmmakers market their sheet to one specific printer, but luckily, any sheet can be used for any resin printer as long as the sheet can cover the whole vat. Below are two high-quality options that have been tried and tested by the community with great results, but for more, check out our complete list of the best FEP brands.

Phrozen

From popular resin 3D printing company Phrozen, this FEP sheet is the classic workhorse for any resin printer. This specific example is A4 size, with a variety of other sizes available.

- Cost: ~$15 for 1 sheet

- Sheet dimensions: 210 x 297 mm

- Where to find: Phrozen

Elegoo

These FEP sheets from 3D printing company Elegoo are specifically made for their Mars lineup of printers. Yet, they’ll work on any similar-sized machine, providing good quality at a very affordable price.

nFEP/PFA

Recently, a new film called “nFEP” was introduced to the 3D printing world, boasting better print reliability and a longer lifespan. With these improvements, the price of traditional FEP sheets increased. The actual material behind nFEP was unknown for some time, as the abbreviation simply stands for “non-FEP”. However, it’s now known that the films are made of a material called PFA, standing for perfluoroalkoxy. PFA is much cheaper than FEP, so it was simply rebranded and sold as a specialized 3D printing product.

Looking past the rebranding, however, nFEP films are indeed an improvement over traditional FEP sheets. The most beneficial feature of PFA is that it has a higher tensile strength rating of 29 mPa. This means that, while a cured layer is being peeled up by the print bed, the film will flex less and provide better layer separation.

This lower resistance, combined with the material having a low suction force, means that layers are rarely stuck to the film, which is one of the most common causes of printing failures. The lower tensile strength and flex also mean that the film will last longer. This is due to the reduced elasticity, which results in less strain on the film and fewer micro-cracks.

nFEP/PFA Options

As nFEP (or PFA) films are newer to the market, less reliable options currently exist. There are of course still trusted manufacturers selling the sheets like the first example below. An advantage of nFEP being a rebranded PFA sheet means that the cheaper PFA can be bought in bulk from some industry supply stores for a much more economical price like the second option listed.

Phrozen

Phrozen was one of the first companies to create a 3D printer-specific nFEP sheet. The A4 version is for their Sonic Mini printer, but it will work for any machine with a similar film size.

- Cost: ~$21 for 1 sheet

- Sheet dimensions: 210 x 297 mm

- Where to find: Phrozen

McMaster-Carr

This PFA sheet from industrial supplier McMaster-Carr is more expensive than other options, but it’s also much larger. For the best value, this large sheet can be cut to the correct printer size to offer maximum sheet-per-dollar value.

- Cost: ~$37 for 1 sheet

- Sheet dimensions: 305 x 610 mm

- Where to find: McMaster-Carr

Which One's Right for You?

Now to the all-important question, which film is the right one for your printer? The simple answer: nFEP (or PFA). The advantages of using nFEP versus a traditional FEP film greatly outweigh the price difference. nFEP provides better print reliability, lasts longer, and improves your print flow and user experience. All of these advantages should make the decision to switch an easy one, but try it out for yourself to see!

The sheets all have the same installation procedure, which you can find in our article on replacing Anycubic Photon FEP film.

License: The text of "nFEP vs FEP vs PFA Films (3D Printing): The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.