Stereolithography (SLA) is the formal name of the technology behind liquid 3D printers. Traditional SLA printers consist of a build platform in a vat of liquid photopolymer resin. A UV laser focused on the surface of the resin precisely draws each layer. Then the build platform is lowered, and a blade spreads the resin over the top of the previous layer so that the next layer can be drawn.

Other liquid 3D printer versions now exist, including inverted SLA printers and digital light processing (DLP) printers.

Traditional vs. Inverted SLA

One disadvantage of traditional SLA printers is that the volume of resin in the vat must be a bit larger than the maximum build volume. Thus a large quantity of resin is required even for smaller prints.

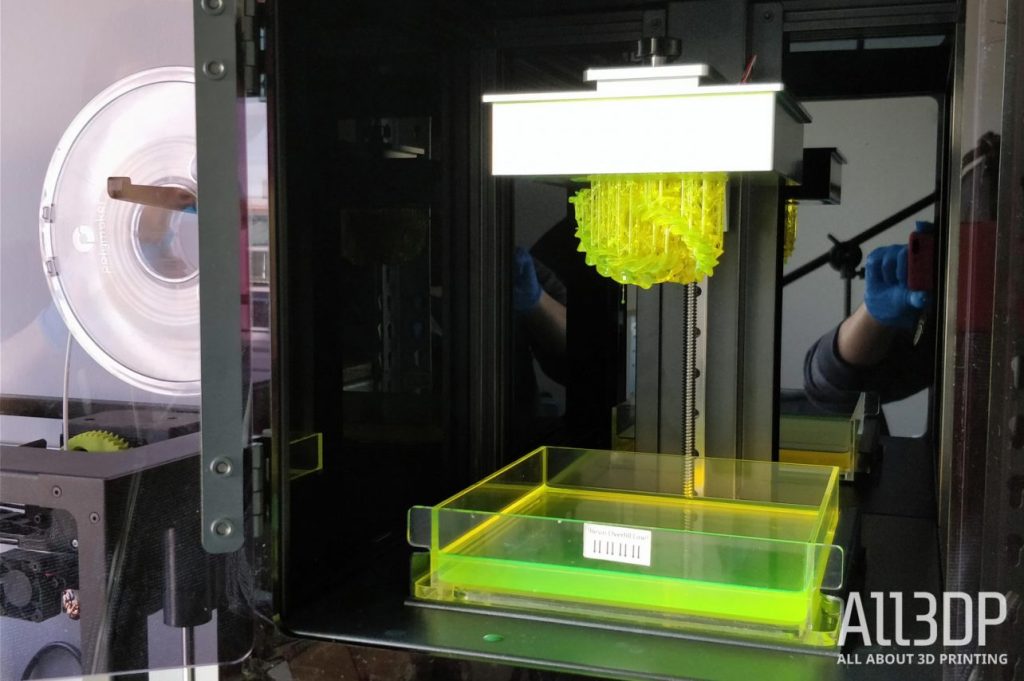

The vast majority of today’s liquid 3D printers are inverted SLA printers. They address the problem of large vats by printing “upside down”. The laser focuses up through the bottom of a resin tank, which has a transparent bottom, and the build plate lifts up out of the resin tank one layer at a time. This makes it possible to print with only a small volume of resin in the tank.

The primary disadvantage of inverted SLA printers compared with traditional SLA printers is that the laser is directed through the bottom rather than the top of the resin tank, gradually clouding the bottom of the resin tank, requiring periodic replacement of the tank.

Pros & Cons of SLA printers

Since a laser beam controls the geometry of the printed object, SLA printers are capable of much finer resolution than FDM printers, in which the resolution is limited by the diameter of the nozzle. With a liquid 3D printer, resolutions can be as high as 20 microns, whereas an FDM printer will typically linger around 50 to 100 microns. That means fewer layer lines and a high amount of detail.

There are several disadvantages of SLA printers, traditional or inverted, when compared to FDM printers:

- Photopolymer resin is significantly more expensive than filament. For example, resin for the Nobel 1.0A is $120/kg. Also, SLA printers often require or recommend proprietary resin.

- An FDM printer with multiple nozzles can print with multiple materials, something that’s not possible with an SLA printer.

- The model must be rinsed with isopropyl alcohol or some other solvent after printing, to clean off the uncured resin. For optimum print quality, the prints should be cured using UV light after rinsing.

- SLA prints tend not to be as strong or sturdy as FDM prints, making the latter technology better for functional parts and prototypes.

- Changing materials requires draining and cleaning the resin tank, a time-consuming process that inevitably results in some loss of resin.

- SLA printers may require the use of proprietary slicing software that may be slower or have fewer features than the slicing software you use for FDM printers.

Final Thoughts

Consider using a liquid 3D printer if you appreciate the exquisite detail that an SLA printer provides and don’t mind the disadvantages listed above.

Related articles:

License: The text of "Liquid 3D Printer & 3D Printer Ink – What Is It?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.