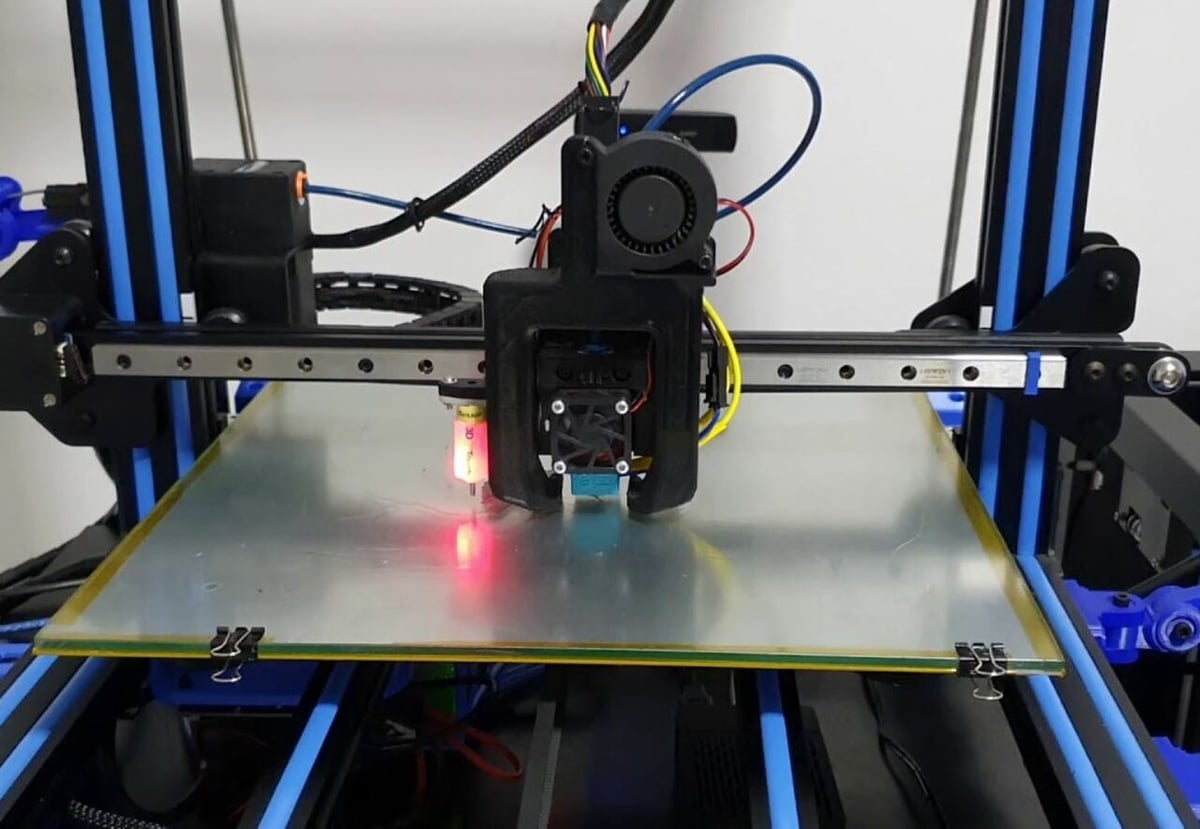

Linear rails, also referred to as linear motion guides or linear slides, are common motion components used to achieve smooth sliding movements. They can be found in 3D printers, CNC mills, waterjet cutters, and the like.

A linear rail consists of a stiff steel rail, along which a carriage slides. Most commonly, the carriage contains recirculating ball bearings that provide contact points between the carriage and the rail. This enables a smooth sliding motion as the balls roll between the surfaces. The shape of the shaft enables the carriage to stay locked on with tight tolerances, restricting the motion to strictly linear directions.

Linear rail 3D printers utilize the numerous advantages of these linear rails supposedly to achieve better motion. So, how plausible are these claims? Let’s take a look.

Advantages

Most 3D printers sport hardened-steel linear rods, used in tandem with linear ball bearings. This combination has worked well for thousands of printers and users, so what more do linear rails bring to the table?

- Linear rails are stiffer. Linear rails flex significantly less than linear rods, due to factors such as shape and metal stiffness. Not convinced? Try bending one yourself, then compare it to a typical linear rod. Any decent rail will have far less give. In terms of 3D printing, this leads to greatly reduced backlash and ringing artifacts, yielding cleaner print surfaces and edges.

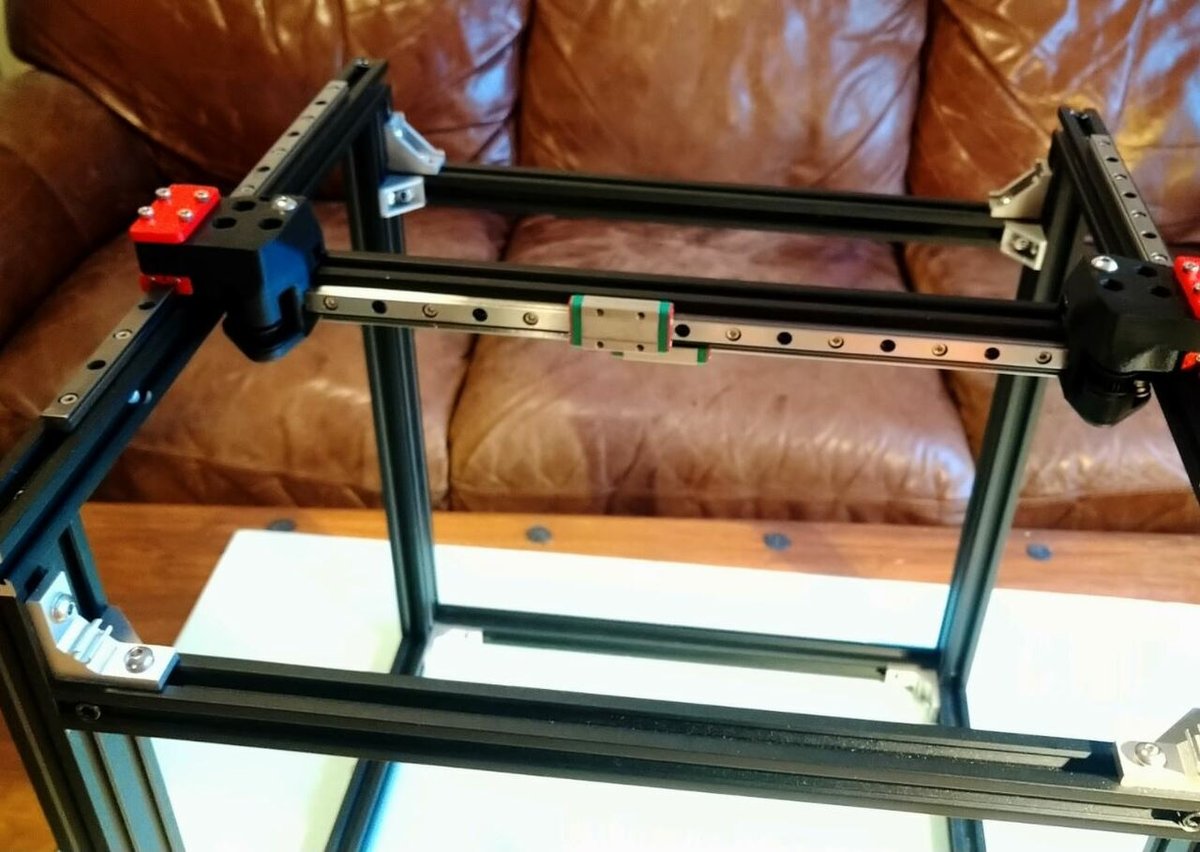

- You can get away with one linear rail. Unlike linear rods, linear rails don’t allow for any rotation of the carriage. This means that, when setting up a motion system, a single rail can achieve strictly linear motion on its own, as shown above. With linear rods, at least two are necessary to prevent rotation, leading to complications with proper alignment and introducing weight considerations. Using a linear rail can create a simpler, lighter, and more nimble assembly, which will also reduce 3D print ringing.

- Higher precision, smoother motion. Linear rails are also usually manufactured to much tighter tolerances than linear rods. This higher precision translates to reduced play and binding (when the bearings catch and don’t roll smoothly), yielding smoother, more consistent motion.

- Easier, more precise mounting. Linear rails are much easier to mount than rods. The rails and carriage both have regularly spaced mounting holes, so a couple of bolts will have everything locked down. This contrasts sharply with linear rods and bearings, whose round shapes require more creative and often less precise mounting solutions in 3D printers.

Disadvantages

Of course, nothing is perfect. In a few areas, linear rails fall short of rods in 3D printer applications.

- Linear rails are expensive. There’s no getting around that. Any decent linear rail will easily cost several times more than a comparable combination of linear rod and bearing. The premium precision, stiffness, and smooth motion come at an equally premium price.

- Linear rails must be handled with care. Unlike round linear bearings, the ball bearings in linear rail carriages aren’t usually capped and locked in. If the carriage accidentally falls off the rail, some ball bearings may roll out, leading to inconsistent motion.

Popular Linear Rail 3D Printers

Overall, if you’re willing to spend some extra money and desire smooth and precise motion, purchasing a 3D printer with linear rails isn’t a bad idea. Unfortunately, because of their cost, there aren’t too many commercially available printers with integrated linear rails. Most machines use V-slot rollers, which are significantly less expensive.

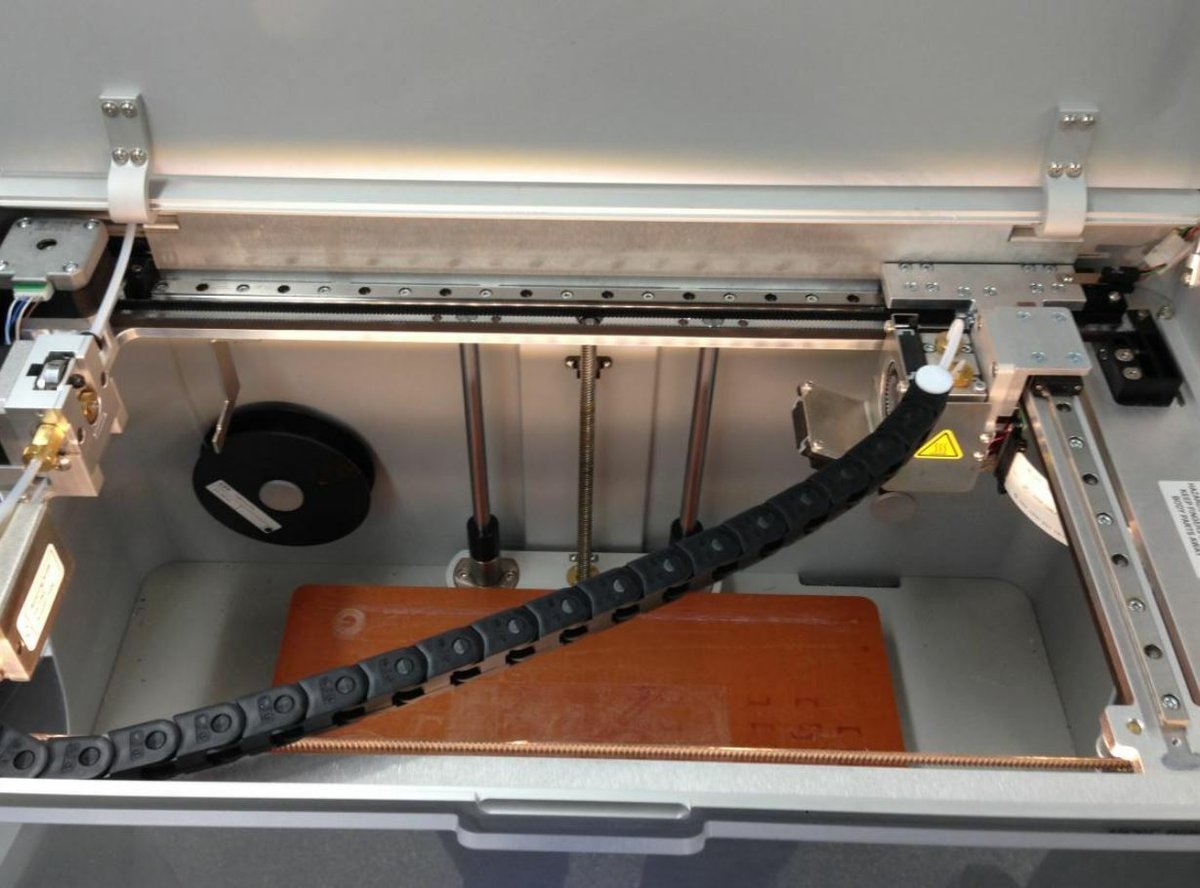

Tiertime, a manufacturer of consumer and professional-grade FDM printers, has a few machines with built-in linear rails, such as the Cetus MK3, UP Mini 2, and Cetus2. Atom, another 3D printer developer, has the Atom 3.5, which has linear rails and is a Delta-style machine rather than Cartesian. Some other popular examples of printers with linear rails include Prusa’s Prusa XL, the Markforged Mark Two, and the E3D Toolchanger.

Although there aren’t many purchasable machines with linear rails, a handful of DIY 3D printer projects use them. Of course, you have to build these 3D printers yourself, but if you’re an experienced maker, you may be up for the challenge. Popular options include the Voron (2.4, Switchwire, etc.) and the BLV mgn12, which are both open-source and use linear rails on at least one axis.

Lastly, if you already have a 3D printer but still want to take advantage of linear rails, you can upgrade an existing machine with this motion system. For popular consumer printers, like the Ender 3, you can buy linear rail kits that come with everything you need for the installation and follow a guide online. Alternatively, if a kit isn’t available, you can purchase all the hardware individually and use 3D printed mounts to install the upgrade.

Verdict

Linear rail 3D printers have a lot going for them. But are they really better?

From a pure performance perspective, yes, linear rails are superior. They offer greater precision, better mounting, and smoother motion, improving print quality and printer reliability. With good design choices, weight and cost savings are also possible, as demonstrated by the Cetus 3D printer.

There is, however, an elephant in the room: the price. Traditional linear rods and bearings are perfectly usable at just a fraction of the cost, making linear rails difficult to recommend to everyone. If you’re on a tight budget and don’t need the best possible performance, linear rails may not be the best choice.

Thus, we have our verdict: Linear rails are better. They’re just not for everyone.

License: The text of "Linear Rail (3D Printer): Really Better or Just a Hype?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.