Why Do It?

Laser cutting is just one of many ways to produce a leather design. Let’s explore some pros and cons of laser cutting leather to see how it stacks up to other methods, such as manual cutting, machine cutting, punching presses, and water jetting, among others:

Advantages

- The precision of laser cutters makes it much easier to produce intricate designs compared to using manual cutting.

- There’s no risk of physical damage or abrasion to the leather since the cutting tool is literally light.

- Laser cutters are also equipped to cut a wide range of materials, such as cardboard, wood, MDF, fabric, acrylic, and even metal, depending on their power.

Disadvantages

- Laser cutting leather requires some trial and error. Due to natural variances in material composition, experimentation and experience is necessary to operate these machines successfully.

- Fumes are inevitably produced since the laser vaporizes and burns the material to make cuts, thus machines need to be placed in a well-ventilated area with a dedicated exhaust system.

Note: Never use laser cutters on synthetic leather and chrome-tanned leather as they contain chemicals capable of producing toxic fumes when burned.

Choosing a Machine

Laser cutting has been growing in popularity in recent years, so the choice and quality of consumer machines has also improved. Here are some factors to consider when picking one for cutting leather:

- Power: Leather, a flexible and durable material, needs a significant amount of power to be vaporized and pierced using a laser. CO2 lasers are the most popular in the general community for this reason. They typically have a power of 40 W and above, the recommended minimum for cutting leather of various kinds.

- Working Area: Larger laser cutters are much more expensive, but in the long run, they can save you more leather since it’s possible to strategically arrange cuts to get the most possible “objects” from one sheet of material. With a small cutter, the raw material must be cut in order to fit the working area before you can cut your designs, potentially wasting more trimmings.

- Speed: This depends on the power of the laser, the type of material, and its thickness. A high-powered laser can increase cutting speed in direct proportions (double the power, double the speed). As for the material and thickness variation, the impact on speed varies.

If you need to find a laser cutter for leather, start with our 2019 laser cutter guide.

Let's Get Cutting!

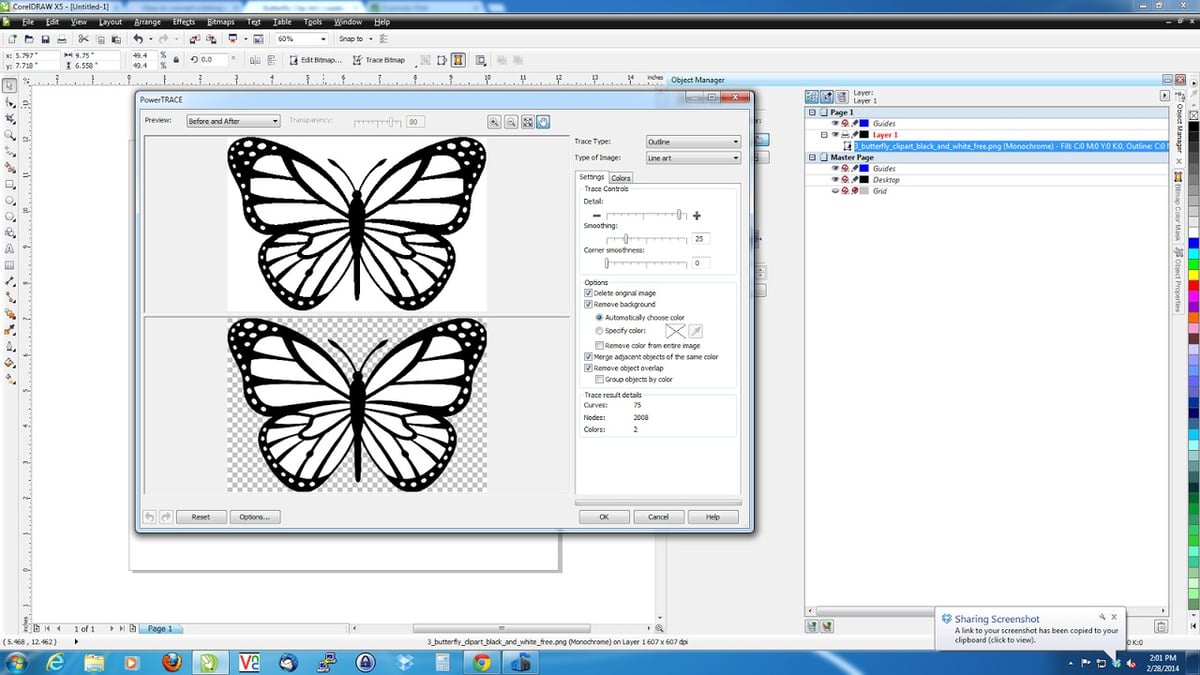

1. Prepare the file

When creating your design for leather cutting, you can use any application that outputs vector images. Vector graphics are versatile and come in many formats:

- DXF and DWG (Autodesk AutoCAD)

- CDR (CorelDRAW)

- AI (Adobe Illustrator)

- EPS (Adobe Illustrator)

- SVG

When creating your vector files, try to make them as simple as possible. Simpler designs with less lines save time and money, since the laser won’t need to trace so many lines. In addition, prevent overlapping lines in your design for the same reason.

2. Test the cut on cheap materials (e.g. cardboard)

Once you have selected the design you want for your leather piece, make sure the file is scaled to the right dimensions. To check this (and other settings), use cardboard first as a tester and cut the design. (It’s easier to spot errors when you have a physical sample.) Then, you can adjust the layout and improve the design for the real cut.

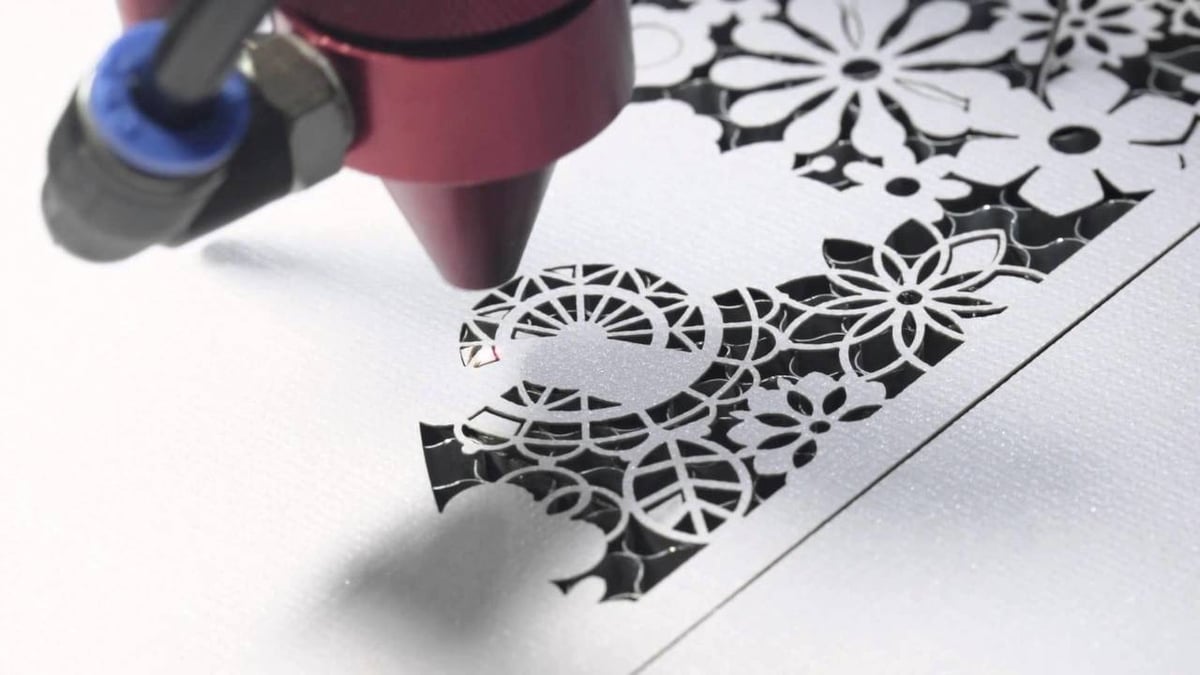

3. Cut the leather

The leather piece should first be cut into the appropriate size of your working area. Leather sheets are normally flat on the surface so there won’t be much of a problem straightening them before the real cutting job begins.

4. Finish

Finishing improves the look of the finished product, and the removal of burnt edges may be necessary for some cuts.

Plan B: Services

Want a laser-cut leather design without the hassle of using a machine yourself? You’ve got options:

- Makerspaces: Laser cutters and engravers aren’t uncommon in makerspaces, especially since all-in-one machines are becoming more and more common.

- Online Services: From a single personalized design to batch production, online services have you covered. Here are some options:

- Ponoko: This site caters to designers, Etsy and Kickstarter entrepreneurs, business owners, and creative agencies. They’re capable of producing thousands of units of your design.

- LaserCut Finland: A laser cutting company based in Helsinki, they provide service for creators in Finland and the rest of Europe.

- Lasercuts: This US-based company is focused on laser cutting with different materials, namely acrylic, plastic, vinyl, wood, rubber, ceramic, foam, and leather.

- American Laser Cutter: This LA-based company is capable of producing various laser-cut leather products such as awards, signs, and gifts.

Feature image source: threadlounge.com