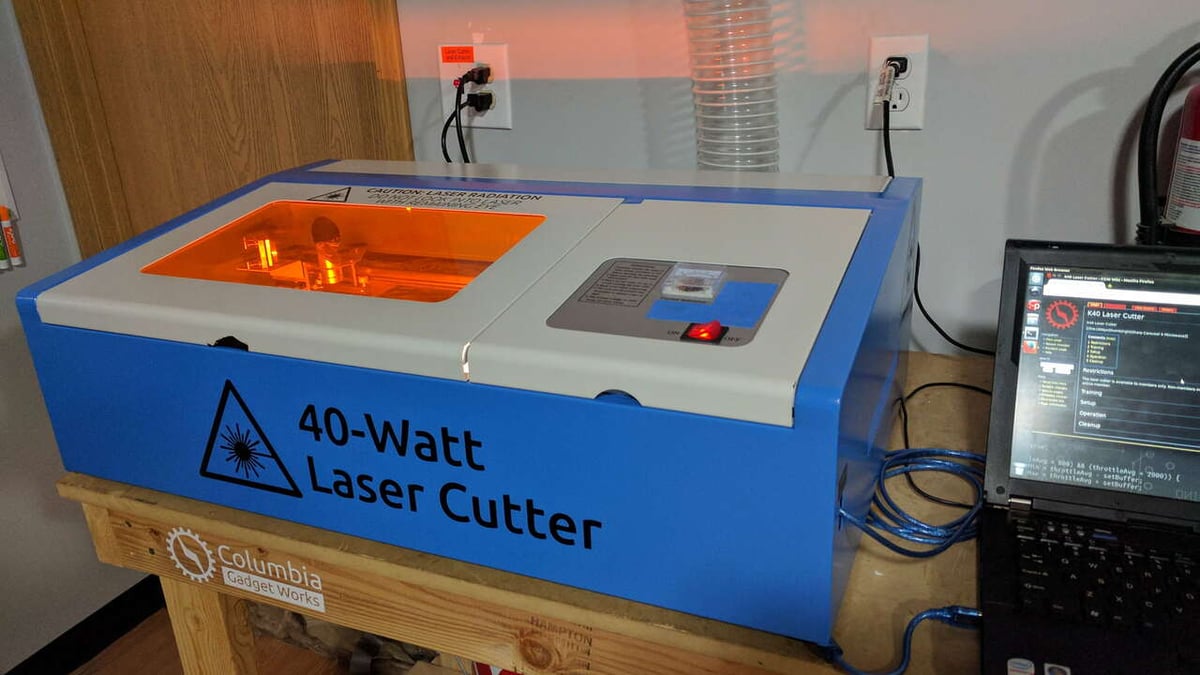

Laser cutters do just what the name suggests: They use concentrated light to cut material in 2D. They come in many sizes and are used for all types of applications in several industries. Moreover, they’re especially loved by the DIY community for their versatility.

Most laser cutters are fairly expensive, costing thousands of dollars. Over the years, however, prices have lowered somewhat. A hobbyist laser cutter can set you back as little as $200 or as much as $6,000 (and beyond). Along this price spectrum, “K40” is a moniker for an affordable laser cutter that goes for about $300 to $400.

This price range is a great entry point for beginners who want to get started with laser cutting. There’s no single manufacturer or official design specification for these machines, but they all work similarly. They’re usually in the 30-Watt range but are often upgraded to 40 Watts – hence the name “K40”. In this article, we’ll take a closer look at K40 laser cutters: their features, popular upgrades, as well as a few good models.

Let’s dive in!

Features

If you like to tinker, the K40 is meant for you. Although they come with the bare bones required to operate, they shouldn’t be considered plug-and-play machines, as you’ll need to do a fair bit of assembly with this cutter. As with any low-cost machine, you might also need to do some initial tune-ups. Replacement parts and upgrades are the norm for making your K40 a higher-quality machine.

If you do go ahead and work with these machines, know that they have high voltage and powerful lasers. Bear safety in mind, and always remember to take the proper precautions when using these machines.

Main Components

All K40 laser cutters should come with the same main components:

- A CO₂ laser tube made of glass

- Stepper motors

- A control board with a power supply

- An exhaust fan

- A coolant pump

Each part plays a major role, and most can be easily upgraded. Some models will also include an emergency shut-off button and air assist. Below, we’ll discuss each of these components in more detail.

Laser Tube

With laser tubes, you have to pay close attention to the equipment you’re working with. Usually, tubes are rated by their maximum output. This means that if a K40 has a 40-Watt CO₂ tube, it’s really a 30-Watt tube with a max output of 40 Watts.

When the max output is used, the machine is doing what’s known as over-driving the tube. In other words, it’s operating past the recommended power level. Pay close attention to the wattage rating and the level of power used.

Control Board

Control boards are of varying importance. Some are more powerful than others, more reliable, or have different capabilities. The right choice for you can take some consideration. Check out the in-depth comparison at AwesomeTech.

Power Supply

The power supply that comes with a machine is best suited to work with the laser tube it was paired with. Sometimes, the power supply can die, whether from improper or extended use.

If the laser tube is replaced or upgraded, you should check that the power supply is compatible with the new tube. When the machine is upgraded with a more powerful laser tube, the power supply will also need to be upgraded in order to account for the power difference.

There’s plenty of information out there on power supplies and how to choose the right one for you.

Exhaust

When cutting certain materials, such as PVC, toxic fumes can be emitted. These fumes can even be lethal. A fan installed in the rear of the machine redirects these fumes. This is usually just a simple exhaust fan (similar to the kinds found in bathrooms) that can easily be upgraded. Consider doing this if it’s not shifting enough air.

An exhaust hose is also included. Direct it outdoors so that your workspace is safe, clean, and free of unwelcome smoke.

Cooling

The K40 is water-cooled and often comes with some type of coolant pump, which keeps water flowing through the system. Distilled water is preferred, as it doesn’t have as many solids or ions.

In order to have a good working system, the water reservoir will need to be filled with ice to help further cool the laser tube. If a higher quality system is desired, you’ll need a water chiller. (We’ll discuss this more a bit later).

Emergency Shut-Off Button

Almost all machines come with an emergency shut-off button. If one doesn’t, and a button can’t be installed, it’s best to find a cutter that comes with one. Most laser cutters will also come with a laser test button, which isn’t as important but still helpful.

Air Assist

In layman’s terms, an air assist is an air compressor that blows air where the laser cuts. Its purpose is to expel debris and cool the laser simultaneously to prevent flare-ups. It also allows for more precise cuts and engravings.

Not all machines come with this feature. If there’s a nylon tube attached to the cutting nozzle, there may be the option of using it. Air assist is highly recommended and will extend the lifetime of several components. Look out for a 3D printable air assist.

Performance

Like many budget machines, K40 laser cutters have amazing potential. With a little tuning and a few upgrades, you’ll have a desktop machine that can easily cut through 6.35-mm (1/4-inch) wood, acrylic, leather, cardboard, and more!

Out of the box, K40s can cut a wide range of materials. It can usually cut up to 3.175 mm deep, which is pretty good out of the box! However, most people run into issues with space, cooling, and other types of hardware. These problems can be easily solved with upgrades.

To compare the K40 to other laser cutters is a hard thing to do, as the price tags are miles apart! However, some users have said that a K40 with the proper upgrades is pretty similar to the likes of a Glowforge.

Tuning

Regardless of how many upgrades you slap onto your K40, tuning is still essential! A tune-up starts with leveling the laser tube, which allows water to flow normally. The mirrors should be cleaned and properly aligned so the laser cuts accurately and without loss of power.

It’s best to make sure there is ice in the cooling water before doing laser tests. Leveling the bed comes next to make sure the focal point stays consistent during cuts. After this, you should be ready to get cutting!

Upgrades

As mentioned, a clear advantage of K40 laser cutters over other cutters is their ability to be upgraded. More expensive machines are usually more polished and harder to upgrade, which makes the inexpensive K40 a great machine to tinker with. The following are popular upgrades:

- Focus lens: One of the easiest upgrades is the focus lens. The stock focus lens is prone to deteriorate, which can affect the quality of your cuts. Also, a better focus lens can allow you to make deeper or more precise cuts.

- Gas assist: Another simple upgrade is adding a gas assist. A gas assist will help clear the cut or melted material around the laser, which can sometimes get in the way. All that’s needed is a small air compressor and a gas assist nozzle (if one isn’t already included with the machine).

- Water chiller: For an easy (but more expensive) upgrade, get a water chiller. Using a water chiller as a coolant system helps lengthen the lifespan of the laser tube. However, this isn’t always recommended because it can cost more than the machine itself. With a budget machine like this, it’s best to stick with ice water.

- Control board: A control board is a difficult but helpful upgrade to make the machine easier to use. It also has the potential to unlock new capabilities, which can really take your K40 to new heights! The only downside is that it can be a pricey purchase.

- Tube: The most dangerous, challenging, and expensive upgrade is changing the power supply and CO₂ laser tube from a 30-Watt tube (with a max rating of 40 Watts) to a true 40-Watt tube (with a maximum rating of 50 Watts). For the daring who can afford it, an upgraded tube ensures the machine can reach its full K40 potential.

Specifications

As mentioned above, “K40” is a blanket term for a budget 40-Watt laser cutter. Depending on where a machine is purchased, there may be small differences. The following specifications are based on the OMTech 40-Watt laser cutter:

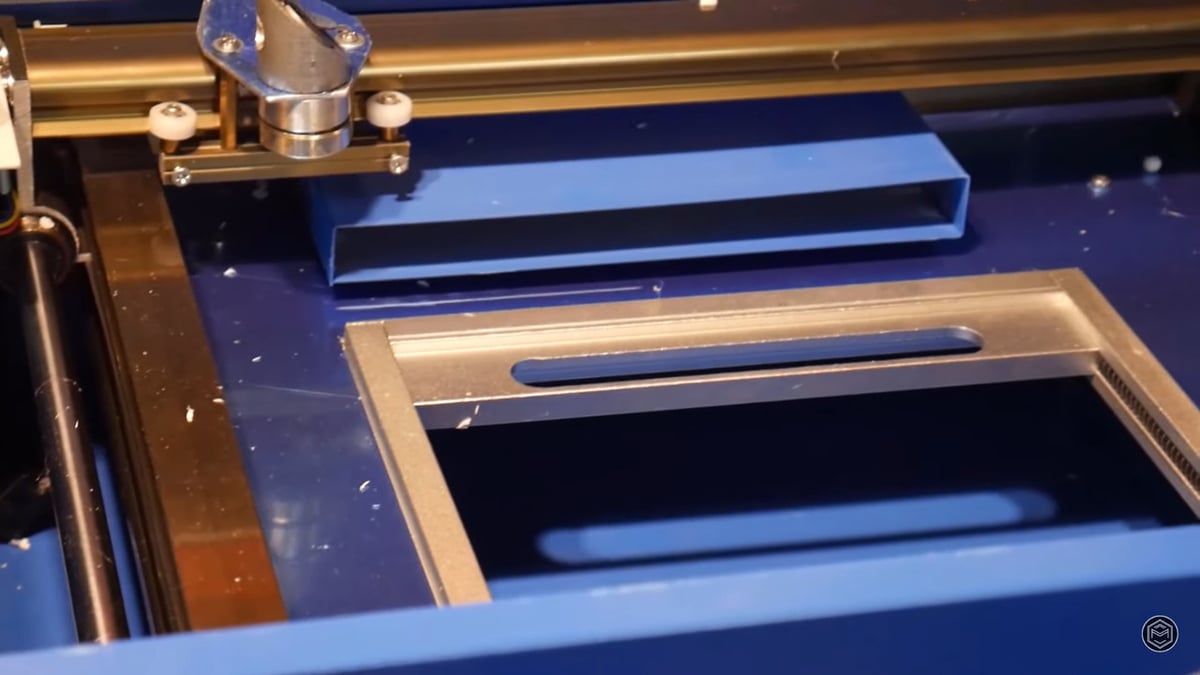

Dimensions

- Machine dimensions: 810 (L) x 498 (W) x 251 mm (H) (see image above for inches)

- Cutting area: 200 x 300 mm (8” x 12”)

Laser

- Laser type: CO₂ Laser 40-Watt

- Estimated lifespan: 1,000-1,300 hours

- Upgradeable: Yes

- Power Supply: 110 V 60 Hz

Mechanical

- Case: Folded sheet metal

- Linear system: Custom-extruded aluminum linear rails with a belt-driven v-wheel carrier

- Motion: Stepper motors

- Cooling: Water pump

- Air assist: No

- Recommended operating temperature: 5-25 °C, less than 70% humidity

- Connectivity: USB

- Onboard controls: Partial

- Emergency shut-off: Yes

Materials

- Maximum cutting depth: 3 mm (.12″) depending on material

- Cutting and engraving: Wood, fabric, leather, paper, cardboard, acrylic, rubber, cork

- Engraving only: Glass, marble, rubber stamps, stone, ceramic tiles, anodized aluminum, titanium

Software

- Interface compatibility: Windows, MacOS, Linux

- Programs: 40 Whisperer, LaserDraw, Inkscape, Shenzhouyike, LaserDRW, Winsealxp

- File compatibility: JPG, PNG, SVG, PDF, and more

Where to Buy

You can purchase a K40 laser cutter at plenty of different places. We find it’s best to purchase from somewhere reputable that accepts returns if anything goes wrong. The following are a few models worth checking out:

- OMTech 40-W Laser Engraver is one of the most popular K40 laser cutters on the market, and it’s the one we referenced for the specifications. Due to its popularity, you’ll be getting a pretty large user base, which will come in handy if any problems arise.

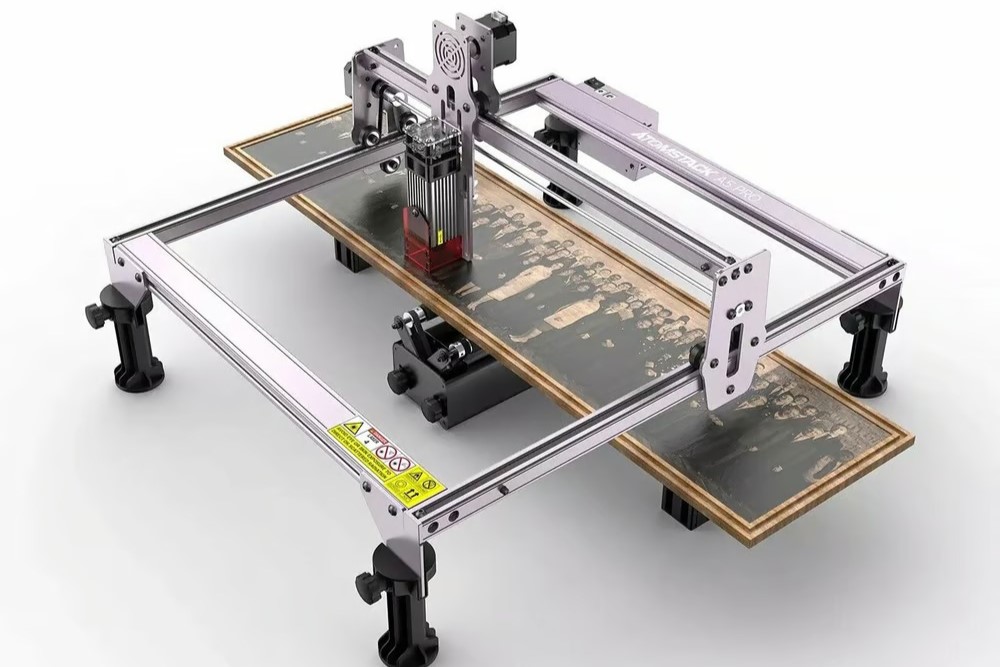

- Atomstack A5 Pro 40-W Laser Engraver doesn’t have a typical design, but it’s still a good option. It’s especially nice if you need more engraving space, which is somewhat limited in other K40s.

- Mophorn Laser Engraving Machine is very similar to the OMTech K40 but has a cheaper price point. It comes with software and all the goodies that you would expect, like a water pump, smoke fan, and USBs for connectivity.

License: The text of "K40 Laser Cutters: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.