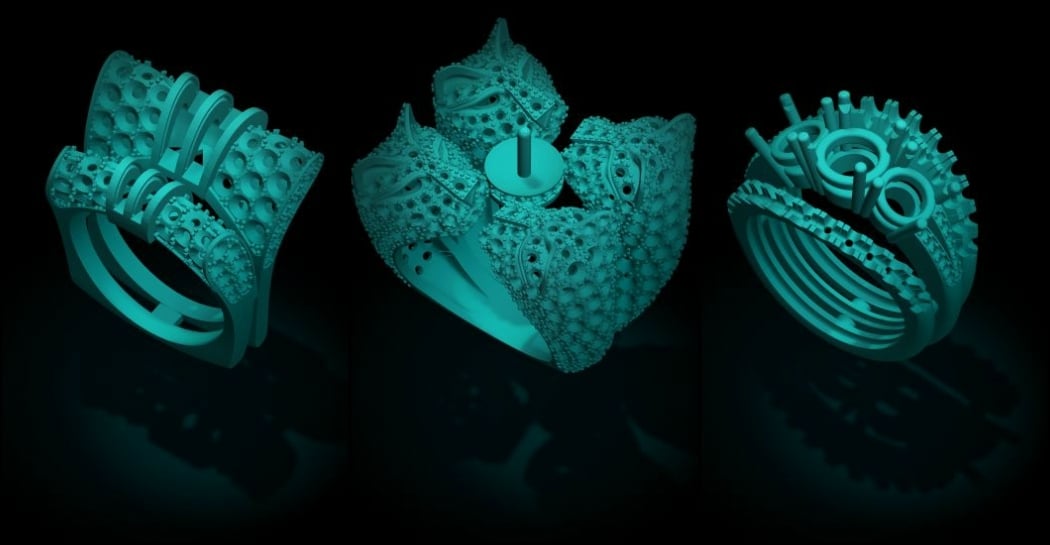

3D Printed Bling?

3D printing is becoming popular in the world of jewelry. The technology has brought flexibility and creativity into the design, adding a plethora of possibilities and accessibility to unique jewelry pieces. The speed of 3D printing and the ability to make multiple design iterations in one day is key to using this technology. Reduced lead times make 3D printing a favorable technology to make jewelry, as this gives a competitive market edge.

By opting for this production method, you can create complex one-of-a-kind designs for each customer and fabricate intricate, complex designs. Or, you can use 3D printing for prototyping to make sure the finished product is exactly what you want, even if you decide to produce multiple of the same design.

The production process is somewhat complex, as 3D printing metal is one of the most complicated additive manufacturing processes. Because it’s essentially a wearable art piece, care must go into polishing after it comes off the print bed. Adding stones or jewels further complicates the process. However, this still can be the faster way of getting the perfect adornment.

In this article, we’ll look at how to 3D print jewelry and polish the pieces, the best software for designing jewelry for 3D printing, and available services that can help you get your design 3D printed.

Two Methods for 3D Printing

When it comes to 3D printing jewelry, two main methods are used: Investment casting, which doesn’t differ too much from the traditional manufacturing method, and direct 3D printing, which throws caution to the wind and paves its own way.

Investment Casting

Investment is the most popular method to 3D print jewelry. It combines 3D printing with traditional mold manufacturing techniques. The first step is to 3D print the castable model in resin. This is accomplished through either stereolithography (SLA) or digital light processing (DLP).

Next, the 3D printed model is covered in gypsum to create the mold. Once the gypsum is set, the resin is drained and liquid metal is poured in. From there, it’s a traditional metal casting process. Once the metal is set and the mold is removed, the item is carefully taken out, mechanically handled, and polished.

This method is great because you don’t need a special form of the metal and most any metal can be used.

Direct 3D Printing

Direct 3D printing is exactly what it sounds like, 3D printing the final piece of jewelry directly out of metal. It’s a much less popular method as it is much more expensive than investment casting. However, it does give you a wider range of possibilities that casting isn’t capable of.

Direct 3D printing involves sintering metal powder particles together with a laser using powder bed fusion techniques, otherwise known as direct metal laser sintering (DMLS) or selective laser melting (SLM). The type of metal available depends on the 3D printer used, but there is still a wide range of metals available.

The Design Process

It goes without saying you will need to design before you can 3D print jewelry. This is where CAD software comes into play. Perhaps unsurprisingly, there are CAD programs specifically designed for modeling jewelry:

- Matrix: A popular and efficient tool. The interface is entirely made for professional jewelers and also contains a step-by-step builder for creative exploration.

- Firestorm CAD software: Has a short learning curve and easy-to-use editing tools, so there’s no need to be a software expert to use it.

- Rhinogold: Allows you to create very detailed pieces of jewelry from a large choice of components to combine. The platform also comes with a modeling and engraving module.

- 3D Design: Has a realistic rendering interface and allows you to see photo-realistic images of designed 3D models. With a bit of training, it’s easy to use, thanks to its intuitive interface. 3D Design creates highly detailed 3D objects and is very ideal for professional work.

Get Your Design 3D Printed

If you’re a start-up or a budding entrepreneur, you might not have the budget for your own metal 3D printer or casting equipment. But that doesn’t mean you can’t 3D print jewelry and your dazzling designs!

A great option is to use a 3D printing service, such as Craftcloud, All3DP’s 3D printing and price comparison service.

Feature image source: DWS Systems

License: The text of "How to 3D Print Jewelry – Tips for Designers" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.