AI-Powered Design?

Generative design is a computer and AI-driven process where design solutions are automatically created according to user-pre-defined needs and constraints. Or, to boil it down: software comes up with a design of a part or product according to what you say the part or product should do and the properties it should have.

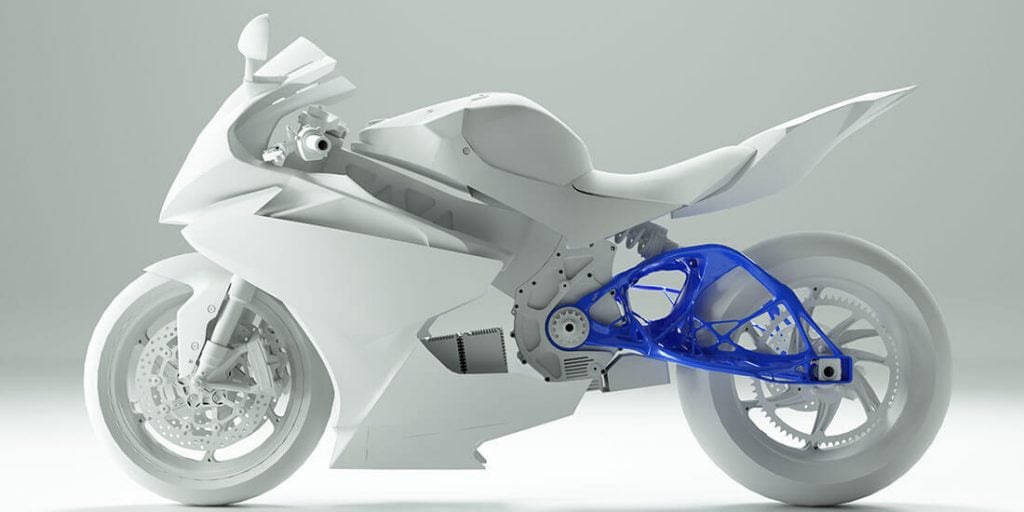

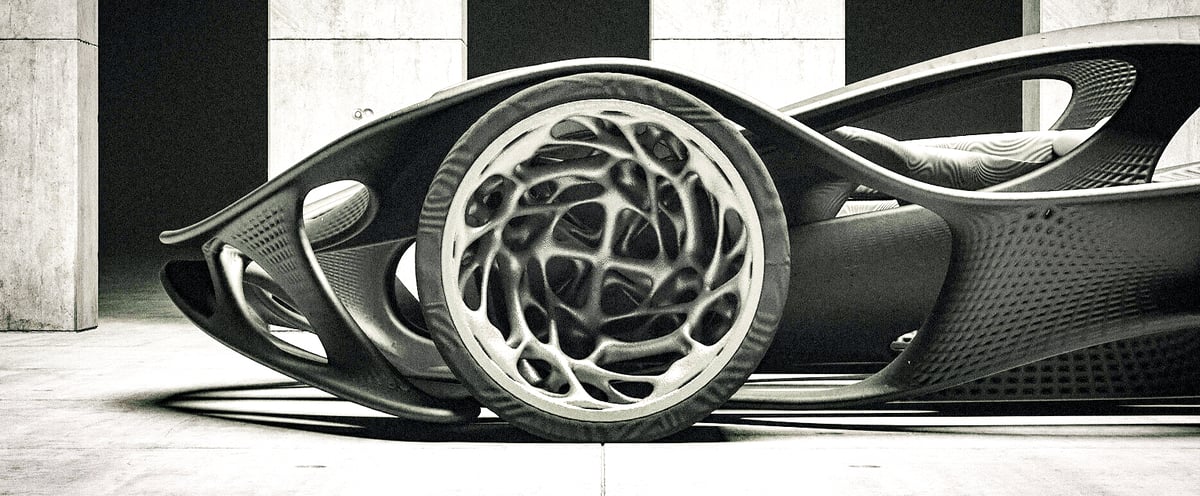

The more variables you enter into generative design software, such as the intended use, manufacturing method, available material, and instructions to find the lightest weight or strongest shape, the better your computer-generated outcomes will be. These results could be thousands of possible designs to consider. And interestingly, they very often look organic in nature, with curves and branches resembling the shape of a tree or the microstructure of bone. Generative design has been likened to the evolutionary trial-and-error processes that nature goes through to achieve optimal structures, only much, much faster.

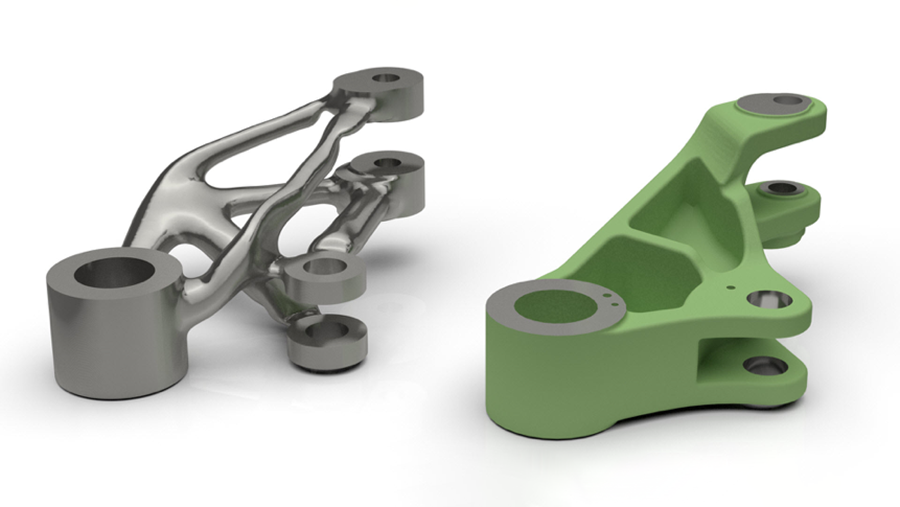

Let’s look at the bracket example pictured below.

The bracket on the right was the original design. The bracket on the left is the part optimized to reduce the amount of material used while maintaining the same strength and conforming to the same size. The final bracket may be injection molded, machined, or 3D printed. Often AI-generated designs are so complex they are only manufacturable by 3D printing methods.

Generative design does not replace the designer or engineer. It is a tool they use to accelerate design investigation and part optimization. The AI can generate results so numerous and varied that they would be difficult, if not impossible, for a human designer to create in any reasonable amount of time.

Hopefully, this design method is becoming clearer, but know that there is still debate in the manufacturing industry about what generative design really is. Many software products boast generative design features that use algorithms to transform part requirements into product geometry and design. However, they don’t generate dozens or hundreds of options, rather, they refine a single part (which sounds a lot like parametric design). The two concepts are similar, but generative design is commonly associated with multiple options for a design rather than multiple iterations.

Shape optimization algorithms or topology optimization have long dealt with one of the most basic engineering problems: how to create sufficiently strong parts with the least amount of material possible, but critics say today’s generative design with AI goes a step further, providing mass volumes of options, some of which are fantastical and impractical, yet inspiring. An important point is that engineers are no longer limited by their skill level, experience, or creativity.

At the end of a generative design analysis, engineers are presented with concepts to further explore and refine, or with ready-to-manufacture design solutions that fully comply with all project requirements for weight, load, materials, and more.

How Does Generative Design Work?

Generative design is a creation tool, and like many other computer-aided processes, it requires a human to drive it. As such, success is tied to user-inputted data quality. Here we can borrow the computer science concept of GIGO (“garbage in, garbage out”), in which erroneous input data will produce erroneous results.

Although generative design tools put sophisticated design in the hand of practically anyone, don’t underestimate the skills required to properly define the initial conditions of the required part. In general, the information required by generative design software to work the problem includes:

- The physical constraints of the design space, which include every interface of the new part in a larger assembly (like mounting holes) and the spaces where the new part can’t occupy. Generative design is often used to redesign parts to occupy smaller spaces.

- All forces and loads involved, including what regions need to be reinforced or simplified in order to sustain the stresses of movement or operation.

- The criteria or the final objectives that the algorithms will strive for, such as minimizing the part’s mass or cost, and defining the safety factors required by the project.

- The manufacturing process used for fabrication. This is where the design freedoms of 3D printing really shine.

- The material(s) considered for fabrication. If there is more than one considered material, different design solutions will be provided for each to fulfill the project’s requirements.

With all these initial inputs (there are many more options), the generative design tool can do its magic. It usually starts with an unoptimized generic design and analyzes the stress distribution in it. The software then initiates its iterative process of creation: adding material in high-stress areas, reducing material in low-stress areas, and rechecking the overall stress distribution. It keeps repeating these steps until the pre-defined criteria are met.

A successful generative design study will result in multiple design solutions. Now it’s time for human professionals to step in again and choose one or a few solutions based on their own criteria and experience. Generative design software also aids the user in making this selection through different data visualization features for comparing the solutions.

It’s not guaranteed that a generative design study will always result in converged solutions. Sometimes the project’s requirements are too demanding for the algorithm to come up with a possible solution. If this is the case, you might adjust the criteria, constraints, or materials and run the study again.

What Are the Benefits of Generative Design?

Now that we understand what generative design actually is and how it functions let’s pinpoint the actual benefits of applying these tools in part-making.

- Outside-the-box creativity. Generative design removes all creativity limitations associated with traditional design processes, creating optimal non-conventional shapes and forms otherwise inconceivable by human beings.

- Balanced priorities. It enables the exploration of solutions based on performance aspects and manufacturing capabilities already available on a given site.

- Reduced analysis. The built-in testing and computational simulation reduce any further costly virtual computer-aided engineering (CAE) analysis.

- Reduced workload. It liberates professionals from tedious trial-and-error repetitive tasks and increases productivity by offering hundreds of viable design solutions.

- Reduced human error. By automating much of the design process, the risks of introducing human error into the design are reduced.

- Reduced costs. By providing high-performance designs with less material usage and by reducing development time and product time-to-market, money is saved.

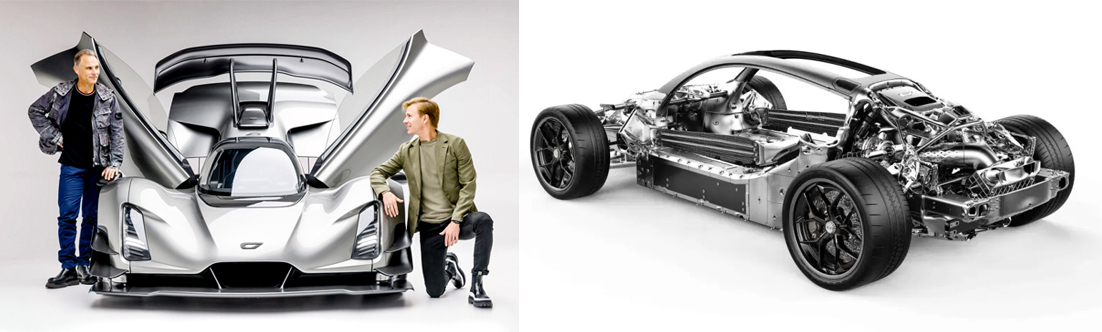

- Part consolidation. Especially when employing additive manufacturing processes, engineers can explore opportunities to consolidate parts and replace entire assemblies with a single part. This results in positive economic impacts on both supply chains and maintenance programs.

Algorithms & Aesthetics: The Future of Generative Design

As the IoT and AI become more prevalent in our everyday lives, generative design might become the norm for product design. Once inconceivable, designs provided by this technology will positively impact not only the industry but also the environment, as fewer resources will be required to produce everyday products. Fewer resources also mean less waste.

With the range of fields that can benefit from generative design, you might be curious how you too, can try it out. Check out our guide to the best generative software tools below, which include Fusion 360, Creo Generative Design Extension, Ansys Discovery, nTopology, Dassault Systèmes CATIA Generative Design Engineering, and more.

It’s important to reinforce that generative design is only a tool and still requires humans to work it. Although a probable game-changing technology, it simply can’t replace skilled designers, architects, and engineers. What makes this technology so powerful is the collaboration between humans and machines.

_______________________________________

Top image: left, a generatively designed brake caliper using a proprietary generative process called Anadiaplas from Spyros Panopoulos; middle, a generatively designed wheel carrier using MSC Apex Generative Design software; right the Karen Ultralight Electric Violin designed by Anima Design for Katahashi Instruments.

License: The text of "What is Generative Design – Simply Explained" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.