While there are several 3D printing technologies, the most common is fused deposition modeling – better known by the acronym FDM (or sometimes FFF). FDM 3D printing involves a machine that feeds stringed material, known as filament, through a hot end, where the material is melted. The printer also moves a printhead around the build area to extrude this melted filament and construct a part layer-by-layer.

Within FDM 3D printing, there are sub-categories, or styles of printers, that define a machine’s structure and motion system. The majority of them are “rectilinear”, meaning that they make use of linear rails or belts to position the printhead relative to the print bed.

Because their firmware uses Cartesian coordinates to move parts around, in the absence of a more specific name, rectilinear printers are often simply referred to as “Cartesian” printers (which, yes, can get confusing). One of those more specific subtypes of rectilinear printers is CoreXY printers, which have particularly complex motion systems that offer a few benefits. So, let’s look at the differences between CoreXY and other rectilinear printers.

Rectilinear

Even though the term “Cartesian” is frequently used to label or categorize printers, it can be very misleading. That’s because classifying a 3D printer can be broken down into two schools of thought: the coordinate system used by the firmware or the structure and motion system of the machine.

The vast majority of all FDM printers – including delta and SCARA printers – use Cartesian coordinates (i.e. X-, Y-, and Z-axes) to position the printhead relative to the print bed. As such, the term “Cartesian” isn’t a very useful way to distinguish between devices.

“Rectilinear” is a much more useful term. It focuses on the square or “boxy” printers that employ linear movement, relegating delta and SCARA printers to their own sub-categories.

Rectilinear printers have several subtype (as well as untyped) variants, with the CoreXY printer being one of them. That said, many rectilinear printers are i3-style Cartesian-XZ-head printers – also known as bed slingers. So, we’ll focus primarily on them in this section.

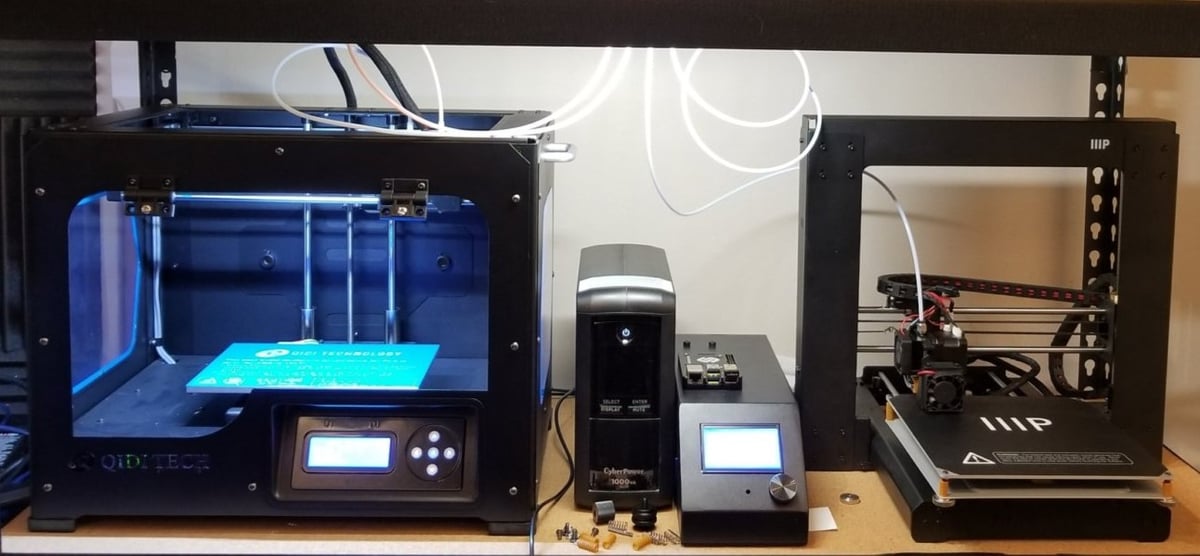

Examples

- Prusa MK4

- Creality Ender series

- Bambu Lab A1 and A1 Mini

- Sovol SV06

Look & Function

The first and perhaps most noticeable aspect of any style of FDM 3D printer is its structure. Standard i3-style printers look similar to the letter ‘H’ from the front and contain a solid base, with extending gantries that make up the rest of the frame.

The motion system on this type of machine involves moving the printhead along the X-axis gantry, and this gantry then moves up and down along the Z-axis. In the meantime, the print bed moves forward and backward along the Y-axis gantry, located at the printer’s base.

The structure and motion of an i3-style printer are overall straightforward because each axis or gantry moves separately from one another. For example, the Prusa MK4 uses individual belt loops for the X- and Y-axes and a separate lead screw for the Z-axis. This allows i3-style printers to move parts in a straight path very easily because the motion of one axis isn’t affected by that of another.

Besides making an i3-style printer easier to understand and providing easier linear motion, the simplicity of this type of machine also makes them easier to build. This, in part, accounts for the current widespread popularity of these types of machines.

Moreover, there are also many upgrades and attachments available for i3-style printers because this printing style has a larger user base, and it’s easier to design parts for a simpler machine. Another benefit of the i3-style printer is its low cost, as the parts to build them are pretty cheap and widely available. A downside of this style is that it requires a moderately large footprint, meaning that you don’t get a lot of build volume for the space the frame takes up.

Pros & Cons

Like any machine, there are pros and cons to the i3-style printers.

Benefits

- Price and availability: The i3-style of printer is the most popular, so there are many options available for parts, upgrades, and pre-made printers. Partly due to this, these printers are one of the least expensive styles, as there’s more competition for lower prices.

- Simplicity: i3-style printers are pretty simple to understand concerning their structure and motion.

- Motion options: Because each axis on an i3-style machine is independent of the others, you have more options (e.g. belts, lead screws) in how you can move parts.

- Great straight motion: On each axis, parts move in a directly linear path, so it’s easier for components (e.g. printhead, print bed) to move in almost perfectly straight lines.

- Community support: As i3-style printers are so popular, a lot of community support is available.

- Easy to upgrade: Another benefit of this style’s popularity is that more people make optional upgrades and attachments for i3-style printers that can enhance their usability and performance.

Drawbacks

- Large footprint: i3-style printers take up a lot of space and have a larger footprint for the size of their build volume.

- Heavy frame: Due to how large their frames are, i3-style printers can get pretty heavy, especially if they’re sturdy.

- Slow: Because each axis moves individually, i3-style printers aren’t very fast at printing parts. More importantly, the movement of the print bed along the Y-axis impacts the maximum acceleration, which also imposes limits on speed.

- Vibration: i3-style printers are at a disadvantage when it comes to input shaping (vibration compensation) features. As the mass of the print bed increases throughout a print, the set frequency for the Y-axis becomes less valid.

CoreXY

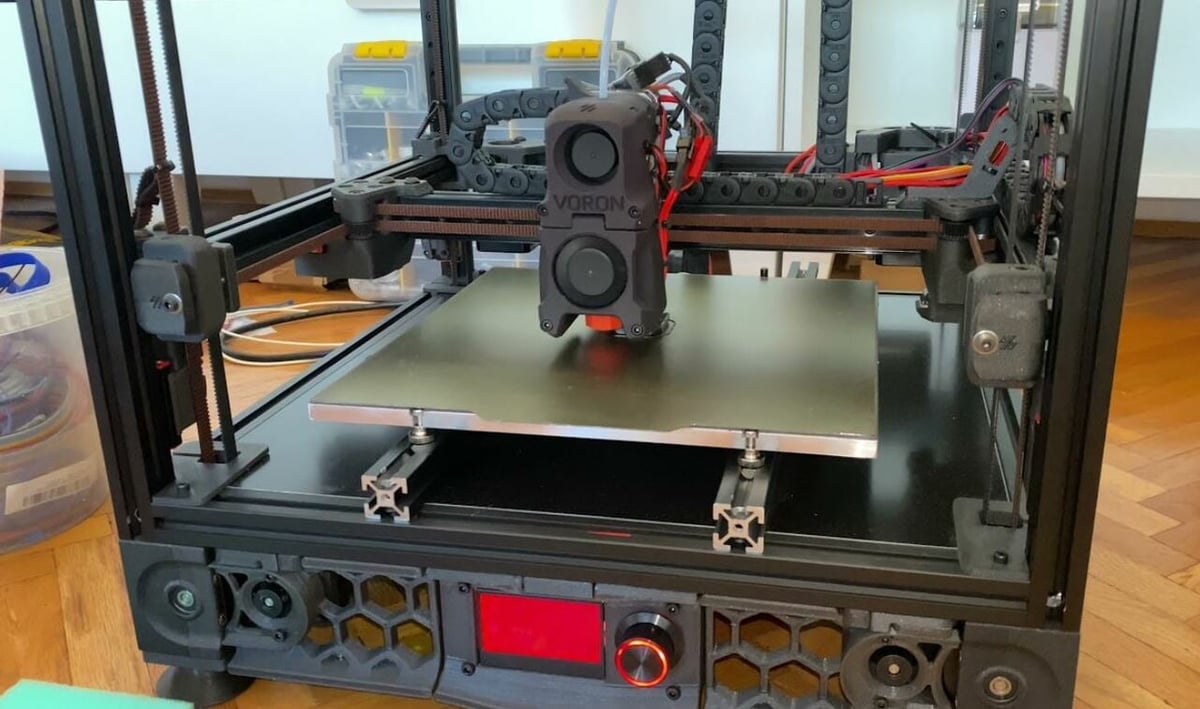

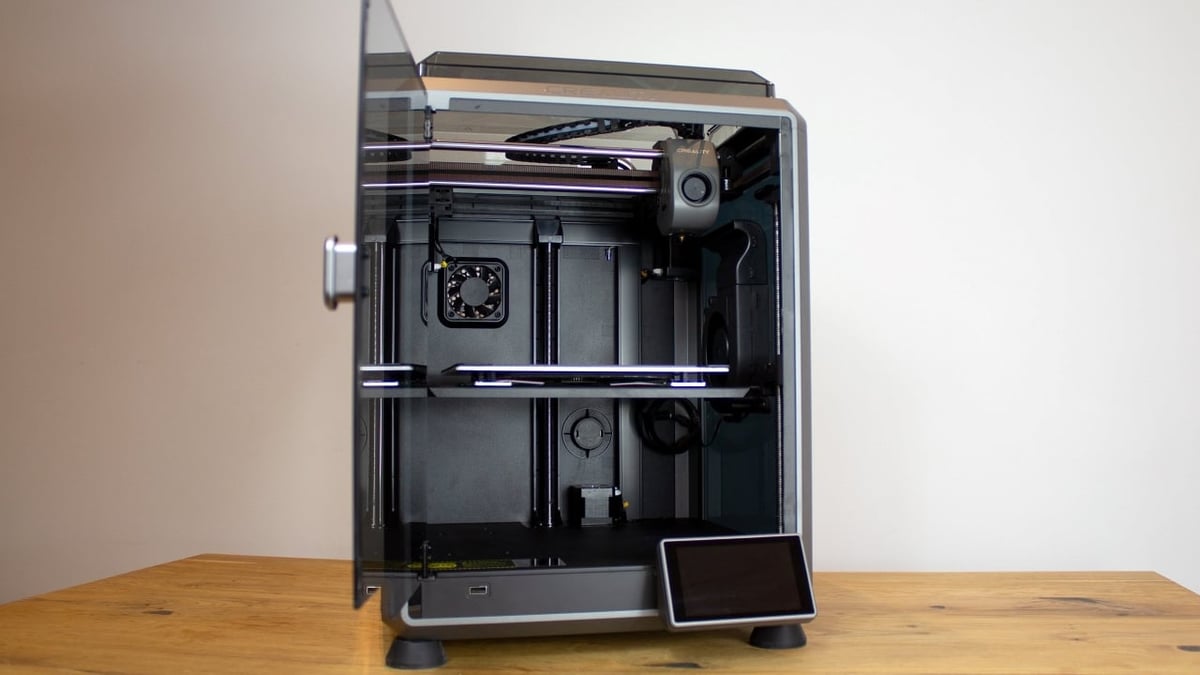

CoreXY has become an increasingly popular type of FDM printer over the past few years, with well-known machines like the Bambu Lab X1 Carbon and Voron 2.4 following this style. CoreXY defines a complex motion system and structure of a 3D printer that provides some unique benefits over other printing styles. CoreXY printers have a boxy frame and resemble the letter ‘H’ (or a boxy ‘A’) when viewed from above.

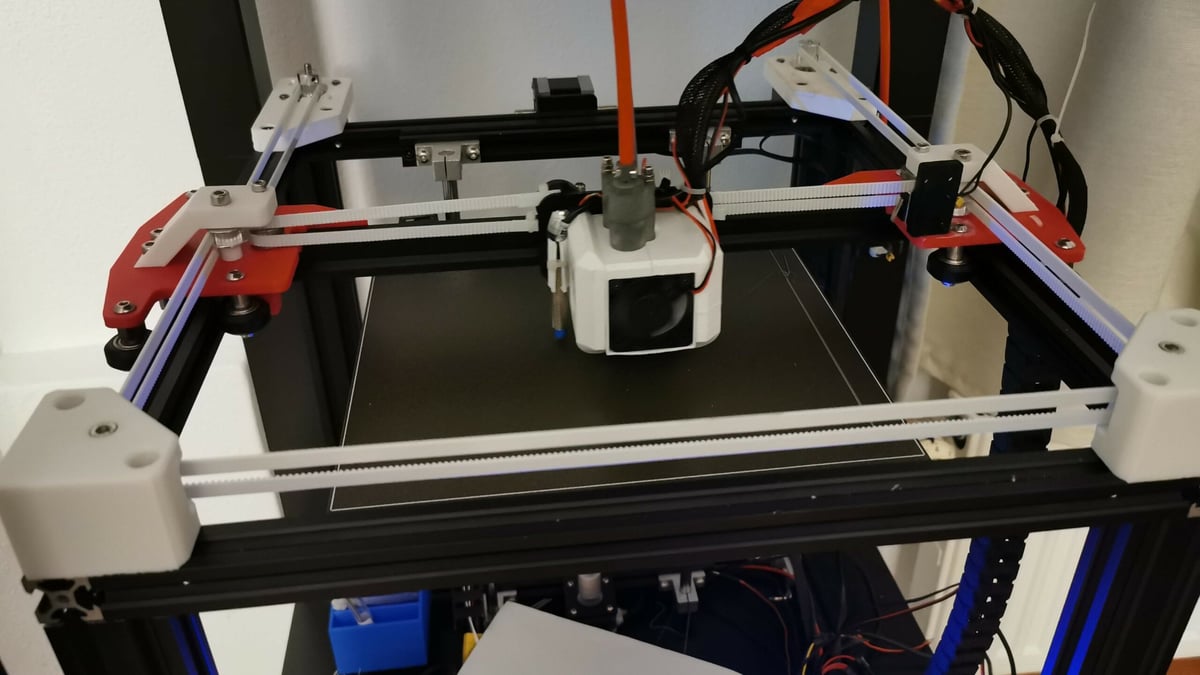

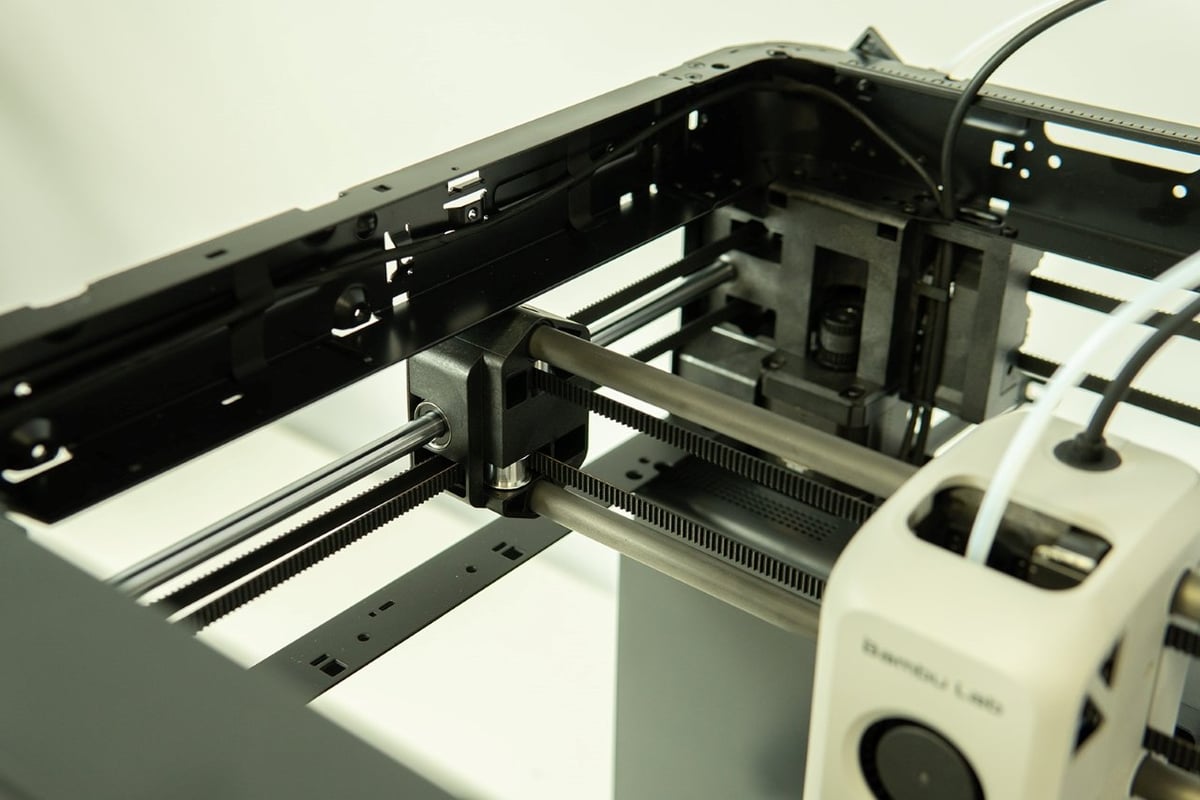

The CoreXY motion system involves a build plate connected to the Z-axis gantry to move up and down to reach the nozzle on the printhead. While this motion is pretty direct and simple, the CoreXY style’s XY motion is where things get a little complicated.

On a CoreXY printer, the printhead moves across the X- and Y-axes through a configuration of two long belts that run along the printer’s top gantries and frame. To understand how the printhead moves with these belts, we first must cover where the gantries are placed.

Looking at a CoreXY printer from above, you’ll notice a box or rectangular assembly of gantries, with one crossing gantry. The printhead lies on a carriage that moves across this crossing gantry, which we’ll refer to as the X-axis gantry. The X-axis gantry moves along the Y-axis by sliding down the two side gantries of the rectangular gantry frame.

Examples

Look & Function

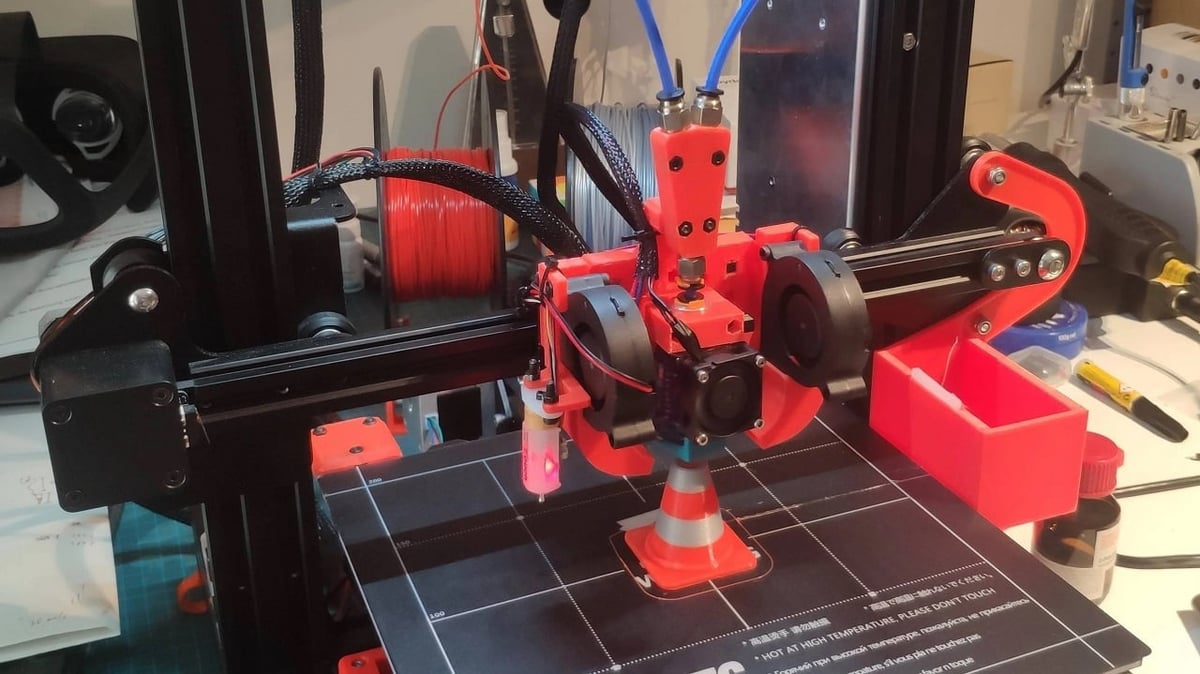

The two motors associated with the printer’s X- and Y-axis movement are placed next to each other, and their axles are connected to pullies that move the two belts on the printer. The belts can be configured in different ways (crossing or not crossing) but usually follow a similar format, where they move in a complicated path around the gantries. The ends of each belt connect to one corner of the printhead’s X-axis gantry carriage.

The result is that when one of the stepper motors rotates, the printhead moves diagonally in one direction, and when both motors turn, the printhead moves in a linear path. This allows the printer to make better diagonal movements but is worse off for straight moves because coordination of both motors is needed for these actions.

The benefit of CoreXY printers is that they can achieve extremely fast print speeds because the belt configuration allows the printhead, which is usually lighter on a CoreXY machine, to move faster. CoreXY machines, when built properly, are very accurate in their movement compared to other printing styles.

While the CoreXY style’s complexity is the underlying cause of this printer’s beneficial characteristics, it’s also the source of a few problems. As you might have figured out by now, CoreXY printers are more difficult to comprehend (in concept) and build. Moreover, they’re more expensive to build and require precise alignment of the axis (gantries and belts) to perform well.

Pros & Cons

Below, we’ve listed the pros and cons of the CoreXY FDM style.

Benefits

- Speed: The belt configuration for the printhead’s XY motion on a CoreXY machine allows it to move faster, reducing print time.

- Easy diagonal motion: On a CoreXY machine, if you rotate only one stepper motor on the XY assembly, the printhead will move diagonally. This allows CoreXY machines to make better diagonal moves than if the X- and Y-axes moved individually.

- Accurate movements: CoreXY printers are considered very precise and accurate in their movements, allowing for improved dimensional accuracy on produced prints.

- Stable, lightweight printhead: As the printhead on a CoreXY machine has to be able to move pretty fast, it needs to be lightweight and properly secured to the crossing gantry. This can reduce the chance of certain print quality issues occurring, such as ringing.

- Minimal footprint: As the XY assembly on a CoreXY machine usually takes up the entire top area of the machine, these types of printers have a fairly small footprint compared to their build volume.

Drawbacks

- Confined to belt-driven XY motion: The CoreXY style requires belt motion for the printhead’s XY movement. So, unfortunately, you can’t use other forms of motion, such as lead screws.

- Expensive: CoreXY printers tend to be a fair amount more expensive than simpler styles of printers, such as i3-style machines.

- Complicated assembly: Assembling or building a CoreXY machine can be somewhat complex and difficult, as you need to pay close attention to the alignment of the axes for the print to perform well. You also need to place the pulleys and loop the belts in a specific manner.

Final Thoughts

Now that you know more about how CoreXY machines compare to other FDM 3D printers, hopefully you can start to determine what style is right for you. There’s no one style that’s better in all scenarios, so the best option for you depends on a few factors.

An i3-style printer is probably best for those who have never worked with a 3D printer before. That’s because this printing style is much simpler both to understand and to build or modify. They cost less than CoreXY machines and come in more variations (with more DIY and purchasable options available). There’s also an abundance of resources and communities available that you can turn to if you ever need help.

On the other hand, you may want to build a CoreXY machine if you’re okay with working with a more complex motion system and have some experience with 3D printers. That being said, Bambu Lab’s release of the X1 Carbon, P1P, and P1S – all of which are CoreXY machines – has done a lot to simplify the 3D printing experience for users. These machines require little to no tinkering, allowing beginners with no prior 3D printing knowledge to achieve great results.

The CoreXY style is also better for those who want the most build volume per frame volume, as this printing style doesn’t have that large of a footprint. CoreXY printers are also probably the better option for printing fast and with a high degree of dimensional accuracy (e.g. for mechanical components).

Of course, there are many other situations where your choice may differ, so select the style that you think fits your needs best!

License: The text of "CoreXY vs Cartesian 3D Printers: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.