Fused deposition modeling (FDM) 3D printing is rapidly evolving. Among the plethora of 3D printers available, each with its own merits and drawbacks, the CoreXY design has been increasingly catching the eye of many enthusiasts and professionals alike. This unique design, which offers a blend of speed, precision, and compactness, has been gaining traction and seems to be a significant player in shaping the future of desktop FDM 3D printers.

Why the sudden surge in popularity? Much of it is driven by the impressive achievements of machines like Bambu Lab’s P1P and X1 series. These FDM machines have demonstrated that the CoreXY design can effectively achieve high-speed printing, which seems to be the next frontier in 3D printing.

In this article, we’ll delve into the fascinating world of CoreXY 3D printers. We’ll demystify the mechanics behind the CoreXY movement and see how it compares with other styles of printers, such as the Prusa i3 MK3. Furthermore, we’ll present an overview of some popular CoreXY 3D printers currently dominating the market.

But first things first, what’s a CoreXY 3D printer?

What Is It?

Understanding the mechanics behind the CoreXY’s movement can be a bit challenging at first, but its advantages make it worth delving into. At its heart, the CoreXY design utilizes a special belt arrangement that allows for high-speed, precise movements, making it an ideal choice for modern, high-throughput FDM machines.

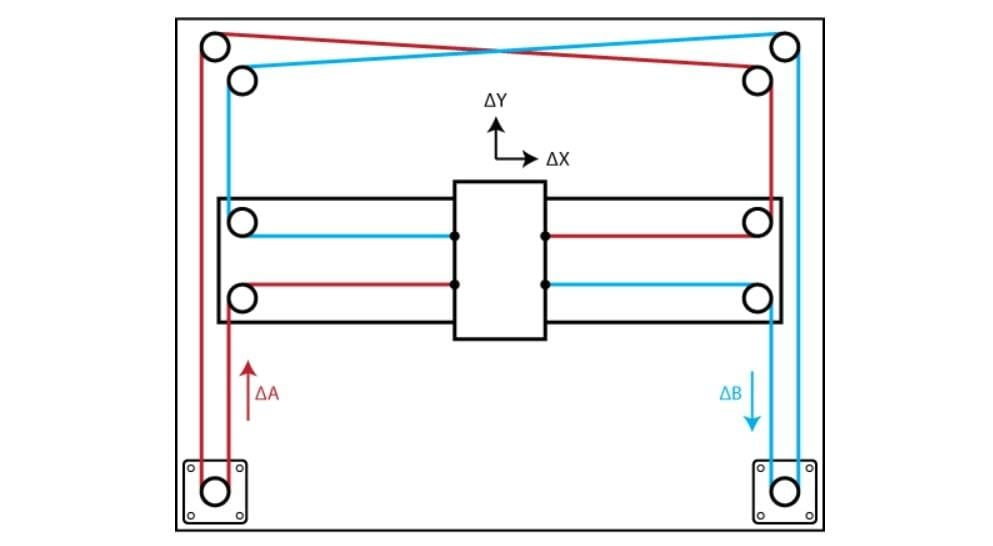

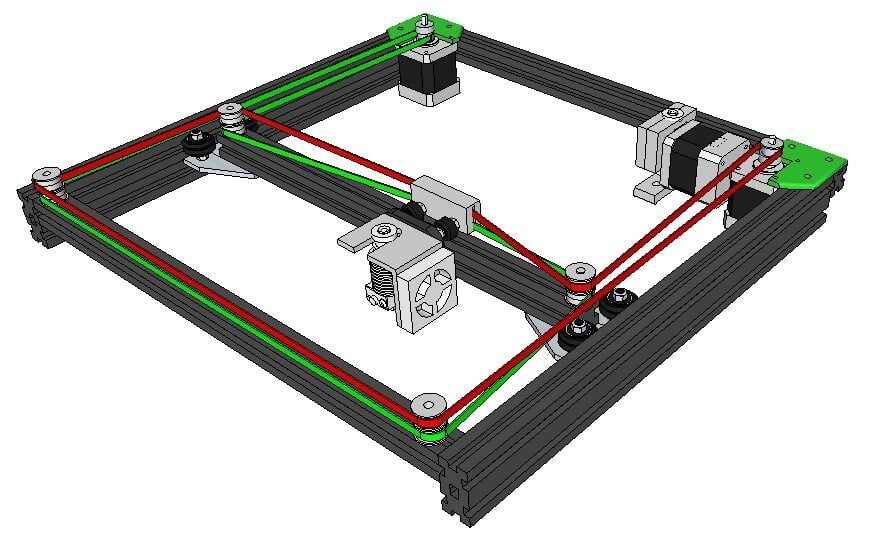

Distinct from traditional Cartesian 3D printers where one motor drives one axis of movement, the CoreXY configuration employs two motors working in unison to control the printhead’s movement in both the X- and Y-axes. These motors remain stationary on the frame’s corners, instead of moving with the printhead (like Cartesian printer designs), reducing the weight of the moving parts.

The true innovation in CoreXY lies in its belt arrangement that allows for such coordinated movement. If one motor rotates while the other remains stationary, the belt moves the printhead diagonally. Rotate both motors in the same direction, and the printhead traverses diagonally on the XY-plane. In essence, the printhead’s movement is precisely controlled by two motors working in unison. Vector 3D’s YouTube video offers a great visual representation of this.

Unlike its Cartesian counterpart, which traditionally moves the bed along the Y-axis, CoreXY printers often fix the printhead assembly to the XY-plane with the print bed moving up and down the Z-axis. This also means that the build plate of a CoreXY printer doesn’t move around and extend its footprint while printing, unlike their Cartesian counterparts.

These design choices eliminate excess vibrations from a moving build plate and heavy extrusion system, resulting in a more stable design and fewer print artifacts. The lightweight moving components of CoreXY printers allow for superior printing speeds without sacrificing print quality. And in the landscape of 3D printing, the combination of speed and precision is in high demand.

Advantages

The unique mechanical design of CoreXY 3D printers provides a multitude of advantages that sets them apart in the world of 3D printing.

- Speed: CoreXY printers stand out for their speed. The stationary motors result in lighter moving parts, enabling quicker printhead movement. This advantage facilitates larger print volumes in shorter timeframes, making CoreXY printers an attractive choice in the fast-paced realm of prosumer-level FDM printing.

- Accuracy: Alongside their impressive speed, CoreXY printers are renowned for their precision. The design minimizes the risk of vibration-induced errors, leading to highly accurate prints even at elevated speeds.

- Compact size: The printhead’s movement along the X- and Y-axes means that the print bed doesn’t need to extend in the Y-axis to reach the corners of the build plate. This means larger parts are possible in a smaller amount of space.

Limitations

While CoreXY 3D printers boast several advantages, they are not without their limitations. Understanding these can provide a balanced view of what these printers can offer.

- Assembly and maintenance: The intricate belt arrangement that is a hallmark of CoreXY printers is not only complex to assemble, but also to maintain. The delicate balance between efficiency and precision requires regular upkeep to prevent premature wear and stretching of the belts, avoid belt interference, and ensure optimal print quality.

- Cost: Generally, CoreXY printers come at a higher price point compared to more traditional printers. This is due to the complex nature of their design and the high-quality components used to ensure accurate and speedy operation.

- Z-axis constraints: Despite the advanced belt system for the X- and Y- axes, CoreXY printers use more traditional methods for movement along the Z-axis, such as a lead screw to move the build plate or gantry up and down. Although these methods are reliable, they can’t match the speed and agility of the CoreXY’s movement mechanisms for the XY-plane. This can sometimes create a disparity in the printer’s overall performance and speed.

Machines

The CoreXY design, with its distinct advantages, has been adopted by several noteworthy 3D printer models. Below are a few standouts that illustrate the capabilities of the CoreXY system.

- Bambu Labs: The X1 Carbon and P1P models are known for high-speed and brilliant engineering, and they exemplify the benefits of CoreXY design for prosumer-grade FDM printers. Their solid mechanical build and top-notch quality set a high bar in the CoreXY arena.

- Creality: Embracing the CoreXY design, Creality’s K1 offers the advantages of CoreXY kinematics along with a spacious build area, delivering excellent bang-for-buck value.

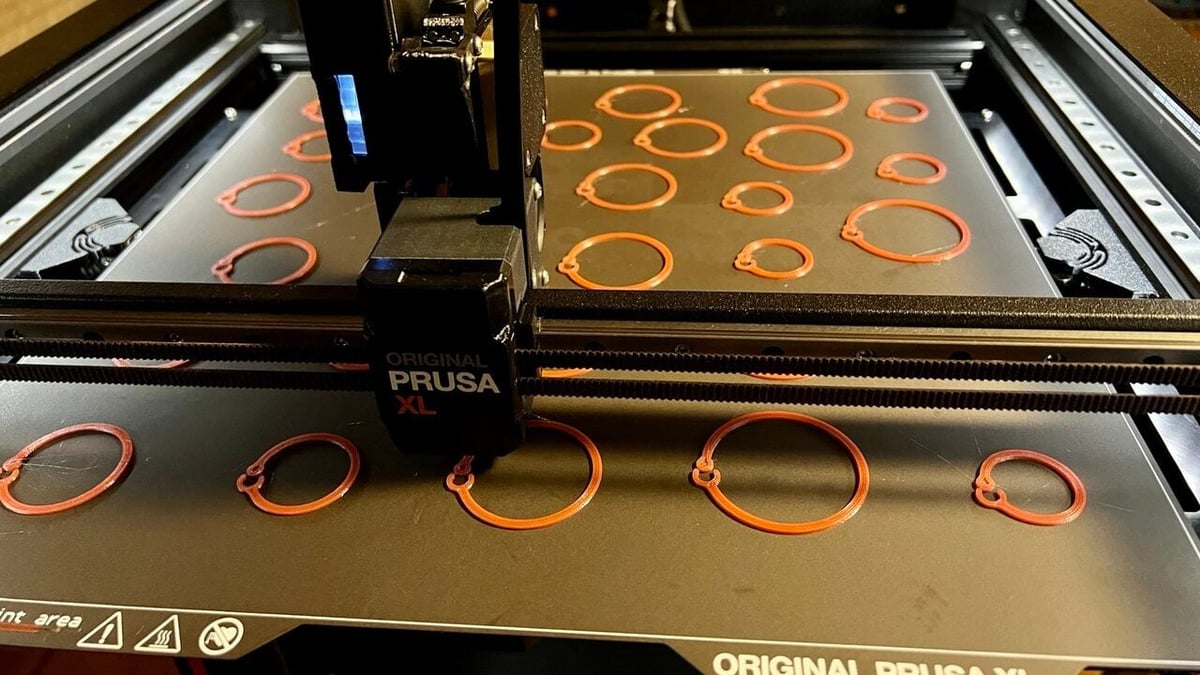

- Prusa: Marking Prusa’s entry into the CoreXY market, the Original Prusa XL marries the CoreXY’s benefits with Prusa’s well-known reliability and precision. Given Prusa’s rich history and reputation, this CoreXY iteration shows great promise.

- Voron: Voron’s range of open-source CoreXY printers, such as the Voron 2.4, stand out for their versatility, superior print quality, and strong community support. These attributes make them a favored choice among DIY enthusiasts.

License: The text of "CoreXY 3D Printer: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.