Many modern hobby machines are operated through computer numerical control (CNC). A CNC router (or mill) uses subtractive manufacturing; it’s similar to drilling but has the ability to cut horizontally as well as vertically. Since the machine can cut along various axes, it has the ability to make a huge array of shapes.

There are a variety of reasons why someone may use a CNC engraver, but mostly it’s in order to make a precision part from one solid material. This material is usually soft, like wood or maybe aluminum if the machine is strong enough. Unlike 3D printing, which can result in structural weaknesses, machining in this way ensures a strong, whole part. Furthermore, some materials that can’t be 3D printed are easily engraved.

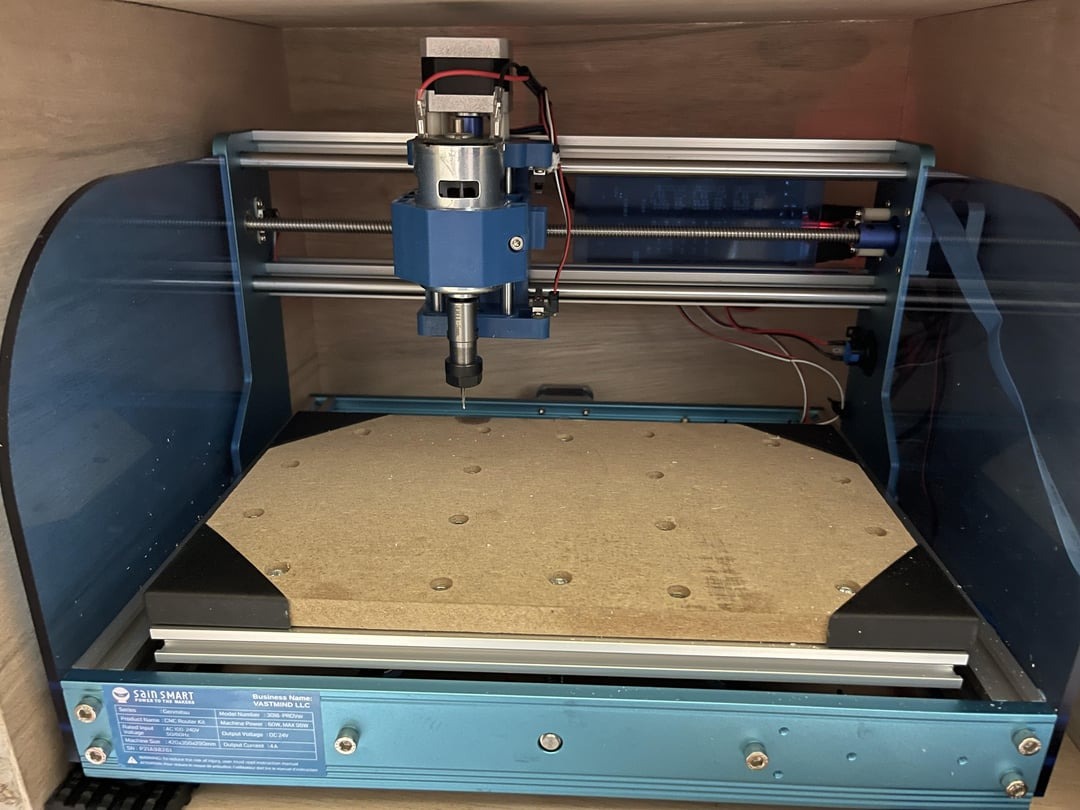

In this article, we’ll be covering the CNC 3018 including the Pro and Max variants of this desktop engraver. Let’s get started with the basics.

Overview

The CNC 3018 and CNC 3018 Pro are generic engraving machines. Similar to K40 laser cutters, there’s no single manufacturer or official design specifications for these machines.

Generally speaking, when a CNC engraver features numbers in its model number, it’s a reference to the size of its work area. In the case of the CNC 3018 Pro, the dimensions of its work area are 300 x 180 mm. This is a good size for a desktop engraver and is primarily why there are more CNC 3018s compared to other variants, like the CNC 2418 and the CNC 1610.

These machines can be used to cut anything from wax to wood, and working with them gives you an in-depth look at how CNC machines work on a mechanical level. If you’re looking to get started with CNC engraving or milling, these machines are a very good place to begin.

Note that, for the purpose of this article, we’ll be referring specifically to the SainSmart CNC 3018 Pro. See one in action here:

Features

Most, if not all CNC 3018s, require some assembly to get started, with Pro versions usually needing less. Even though machine setup is relatively straightforward, some work is required to get the machine running well. This includes the proper attachment of parts and taking time to learn the software, as well as a thorough inspection of the machine prior to use.

CNC engravers all come with the same main components:

- Spindle motor

- Bits (end mills and collets)

- Control board with power supply

- Stepper motors

- Clamps

Every component plays an important role in the machining process, and, as with most project-oriented tools, you can always upgrade various parts to achieve higher performance and quality.

When working with any autonomous machine, safety is important. First and foremost, this means supervising the machine while it’s working. However, installing an emergency shut-off switch or plugging the machine into an outlet controlled by a light switch is also highly recommended.

An In-Depth Look

Let’s dive a little deeper into what some of the above components are and do. Within the context of parts, it’s worthwhile mentioning that the main differences between stock and Pro models are the frame and the inclusion of some accessories.

Spindle Motor

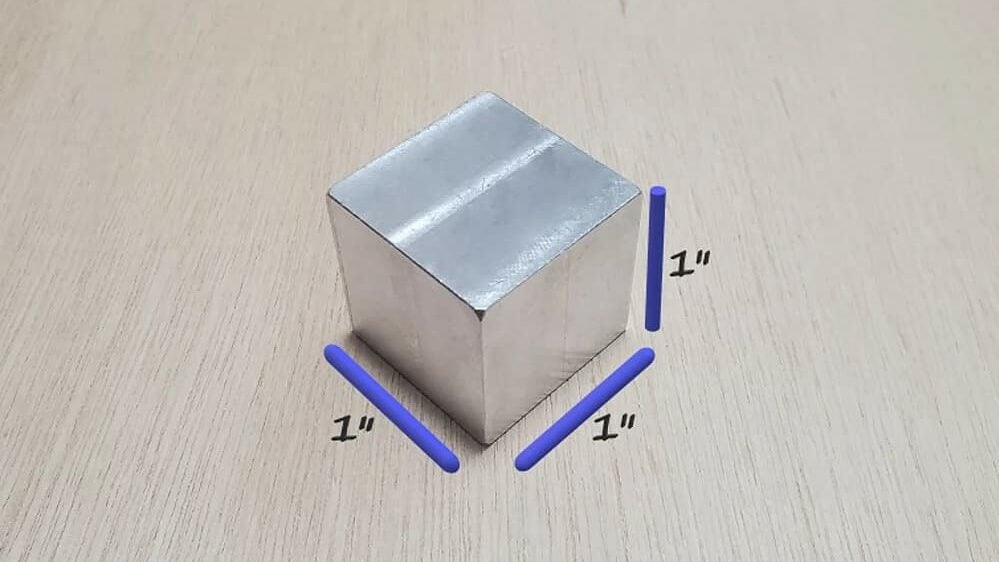

The spindle motor is what drives the machining process, and its speed and power determine what materials can be cut. The 3018 uses a 775 spindle motor with an ER11-style chuck. At this level of output, it’s recommended not to engrave anything harder than brass or aluminum 6061. Anything harder can result in the motor burning out or some parts breaking.

End Mills & Collets

End mills are used to cut material. The type of end mill used determines the type of cut that is made. Three commonly-used end mills are ball, bull nose, and square, but there are several other types available. Make sure to research what type you need and consider carefully what material it should be made from, how many flutes it should have, and which coating is best for your project.

Collets attach the bits to the spindle. The CNC 3018 (and Pro) specifically use ER collets for ease of access. There are differently-sized collets for different diameter end mills, so always make sure the collet’s outer diameter fits appropriately.

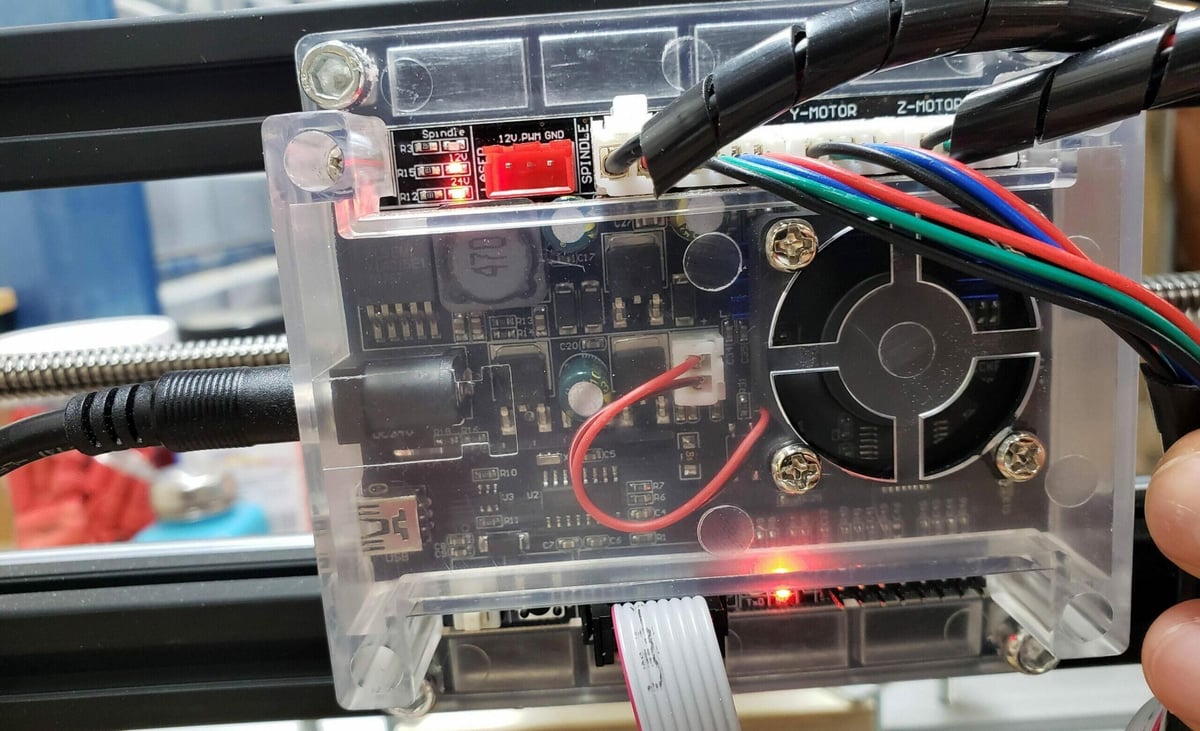

Control Board

The control board is the brain of the machine. Having a good board helps keep consistent results when cutting. The CNC 3018 has one that primarily uses GRBL, but other programs are also available.

Power Supply

The power supply is important. If the 775 spindle isn’t powerful enough for your needs, you’ll need to get a new motor. Depending on the new motor’s power, you may have to upgrade the power supply too.

Coolant

CNC engravers don’t usually come with coolant, but it can be helpful when cutting certain metals and is required with others. This is usually only needed if you’ve upgraded the spindle motor, however, and certainly isn’t something you need to implement onto a base CNC 3018.

Accessories

The CNC 3018 Pro also comes with a few extra drill bits, an SD card reader, and an ER11 collet with an extension rod.

Performance

Although they’re true budget machines, the CNC 3018 and 3018 Pro have the potential to do great work. To get the most out of each, it’s a good idea to learn about engraving and milling in general. This means researching spindles, end mills, speeds, and feed rates, which will prevent loss of time and money through accidental damage of bits, work material, and machine parts.

Once you learn the ins and outs of machining you should be able to cut material like brass and aluminum 6061. Upgrading the spindle could see you taking that further too.

Getting a CNC 3018 (Pro) is a great start to the machining craft. It gives you the opportunity to learn and experiment as you go, and in the process, you’ll learn how a CNC router works both inside and out. Projects will naturally form a large part of that, and when working on new projects, there are plenty of helpful resources out there for things such as tools, parts, and general information on CNC.

Tuning

CNC machines don’t require many components to operate, but they do require a lot of preliminary work, most of which consists of proper assembly. It’s also a good idea to learn introductory code so that you can make adjustments when doing probe commands. More in-depth research can be helpful for specific hiccups.

Upgrades

Upgrading allows you to accomplish more with the same machine. Just make sure you inform yourself well on how to properly replace parts and whether or not certain upgrades are dependent on others. Here’s what upgrading the following parts will do:

- Spindle: Upgrading the spindle should allow you to work with more materials. This will however also require switching out the power supply and mounting equipment.

- Endstops: Many versions of the CNC 3018 (Pro) don’t come with endstops. Adding some aftermarket upgrades helps when doing probes and homing the machine.

- Collets: Getting collets with different internal diameters allows for different sized bits to be used. This allows for faster, more diverse, and higher quality work.

- End mills: Different types of end mills are required for different jobs. Finding the right one is the key to success.

- Drill bits: Working on different materials requires different sizes of drills. Those drills also can be made from different materials to achieve peak functionality.

- Chamfer bits: Always helpful, chamfer bits are used for cutting the edges or the outside of a material.

- Coolant: Adding a coolant spray helps with machining hard material like metals. The CNC 3018 isn’t usually meant for this kind of work, though, unless you’re prepared to upgrade the spindle.

You may also find devices that already come with these upgrades, like the MySweety CNC 3018Pro MAX, which comes with an upgraded spindle and an all-aluminum frame.

Specifications

There are a few different brands of CNC 3018s out there, so specifications can vary. As mentioned above, the machine we’re referencing here is the SainSmart 3018 Pro.

Building

- Working area: 300 x 180 x 45 mm (11.8″ x 7.1″ x 1.8″)

- Materials: Woods, plastics, PVCs, soft aluminum (6061), nylon, acrylic, PCBs

Mechanical Specifications

- Spindle: 775 motor, 12 V, 3,000 RPM; 24V, 7,000 RPM; 36V, 9,000 RPM

- Upgradeable: Yes (switchable to laser module)

- Machine dimensions: 330 x 400 x 240 mm (13.0″ x 15.7″ x 9.4″)

- Frame: Extruded aluminum

- Linear system: Lead screw driven with rods and linear bearings

- Motion: Stepper motors 1.3 A, 12V, 0.25 Nm torque

- Z-Probe: No

- Limit switches: No

Software

- Programs: GRBL control (Candle)

- Interface compatibility: Windows, MacOS, Linux

Other

- Manufacturer: SainSmart

- Connectivity: USB

- Onboard controls: Yes

- Emergency shut-off: No (can be added aftermarket)

Examples

There are a few reliable places to get a CNC 3018 or its upgraded Pro version. We recommend purchasing from a reputable seller that offers warranties and easy replacements. Some retailers even offer technical support.

SaintSmart Genmitsu PROVer 3018 V2

This is the perfect device for those looking to dip their toes into the world of CNC. Genmitsu claims that set up takes less than 2o minutes and is designed to be beginner-friendly. The PROVer 3018 V2 can carve and cut a wide range of materials including plywood, MDF, PCB, acrylic, and even soft metals like aluminum. Additional ports allow for further extending the device capabilities, such as a laser module for engraving.

FoxAlien 3018-SE V2

As another budget device, the FoxAlien 3018-SE V2 stands out for its safety features. Unlike some other budget options, this CNC includes an emergency stop button and a full enclosure, which is perfect for busy workshops or home studios. Upgrades to a more powerful 300-W spindle (from the stock 60-W one) or a laser engraving module should be a breeze. Without any modifications, the FoxAlien 3018-SE V2 is perfectly capable of taking on woods, plastics, and soft metals.

License: The text of "CNC 3018 (Pro) – 2023 Buyer’s Guide" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.