Every maker at some point has bumped into the terms computer-aided design (CAD) and computer-aided manufacturing (CAM). After all, we’re talking about essential software for designing and manufacturing, which is what makers do by definition.

By now you’ve probably heard the typical explanations of the purposes of CAD and CAM, but to genuinely understand both software and their roles, we need to dive right into the heart of the question: what exactly do they accomplish, and how do they relate to one another?

What Is CAD?

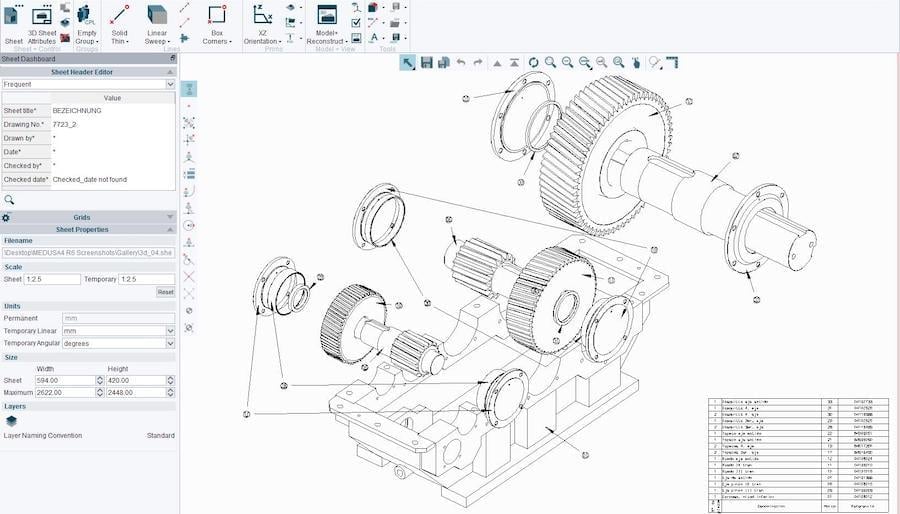

In simple terms, computer-aided design, or CAD, refers to the use of computer software for supporting a design process. In the early days, it merely substituted the manual 2D drafting of technical documentation, which alone already made a huge impact on the industry.

3D modeling tools arrived to completely change the way designers and engineers create things. Think about it: Every single industrialized product that we know has gone through CAD software at some point, be it during development or for documentation.

The use of CAD increases productivity for many reasons, but mainly due to the faster design iteration allowed, which ends up improving the final quality of the designs as well. With high-speed internet and cloud services, the collaboration on product development has never been easier, allowing teams contribute from everywhere.

CAD has also provided the infrastructural platform for other computer-aided tools, namely CAE and CAM, as we’ll see next.

What Is CAM?

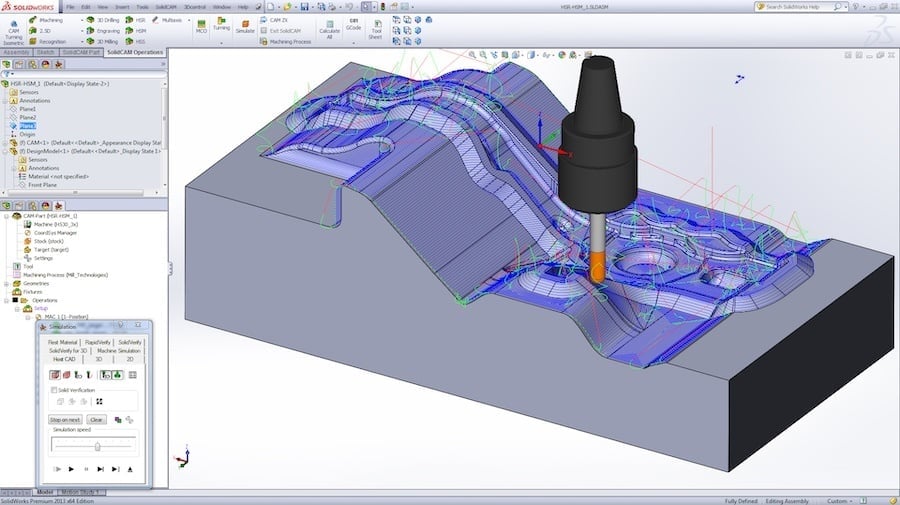

CAM stands for computer-aided manufacturing, which is the use of software to automate manufacturing processes of parts and products. Before CAM, CNC machines required direct inputs from operators known as machinists, who programmed these machines directly to perform operations like cutting, drilling, and so on.

Needless to say, it required a lot of skill and experience from machinists, including thorough testing of programs to avoid mistakes and even machine damage. It often led to a bottleneck in manufacturing, and once validated, CNC programs would remain unchanged for long periods.

With CAM, all the programming is done digitally instead of manually inputting operations directly onto the manufacturing machine. CAM software outputs files that are then loaded into the machine which have already been simulated and checked for errors.

This automation has improved manufacturing in many ways, not restricted to time savings. By simulating the process digitally, engineers can instantly test out different process settings and strategies, leading to better and more efficient manufacturing operations altogether.

The Differences

While CAD and CAM software share many aspects, they are clearly different tools used for different purposes.

CAD relates to the early stages of development: exploration, conceptualization, creation, modification, analysis, detailing. It’s the digital drawing board used throughout the entire design process.

CAM, on the other hand, cannot create or modify designs. Instead, it assists the fabrication of those CAD designs the best way it can, usually faster and mostly fail-proof.

So, the fact is that these tools complement each other. With CAD, ideas are converted to computer designs, while CAM helps to make these designs a reality.

Lead image source: Revista Ferramental

License: The text of "CAM vs CAD: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.