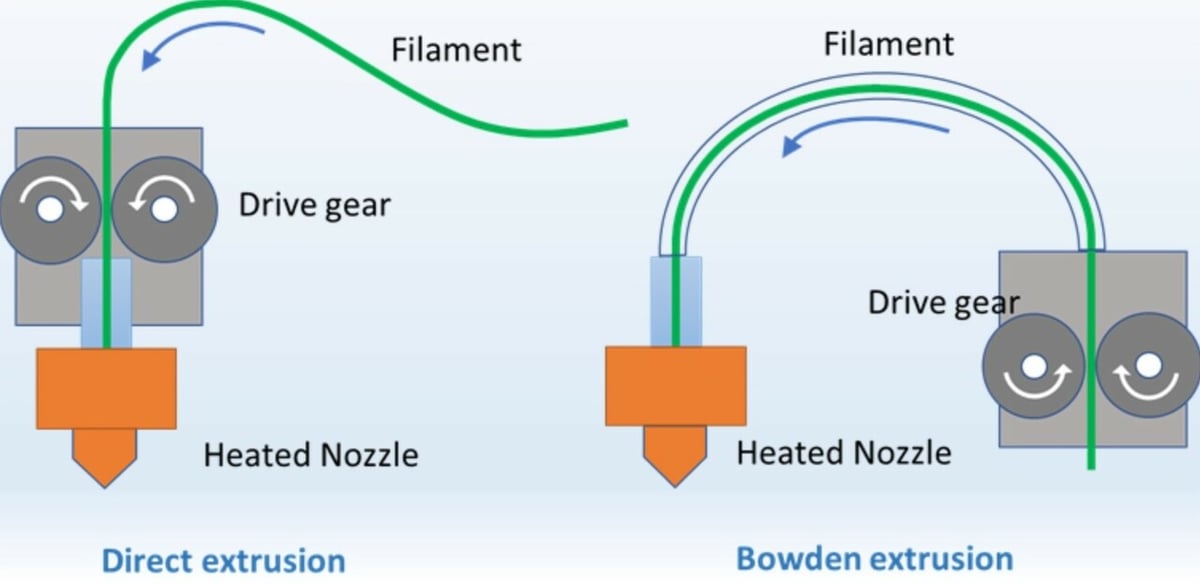

The two most common types of feeding systems for fused deposition modeling (FDM) 3D printers are Bowden and direct extrusion. 3D printers use one of these systems as a way to feed the filament into the hot end to be melted. In a nutshell, extruders consist of a stepper motor and a hot end. The stepper motor grips the filament and feeds it to the hot end, which melts the plastic onto the print bed.

With Bowden systems, the stepper motor that feeds filament into the hot end is located on the frame, with a tube connecting the filament spool and the hot end. This important tube guides the filament evenly as it makes its way, preventing it from snapping or stretching from constant movement.

Direct extrusion systems are pretty similar, except the feeder stepper motor is mounted directly on top of the hot end. This system has a much shorter path for the filament but usually still uses a small amount of tubing, which stays in place above the hot end.

Naturally, Bowden tubes have distinct advantages and disadvantages from direct extrusion systems. Read on to learn more!

Advantages

There are quite a few advantages to having a Bowden extrusion setup in your 3D printer.

The lighter printhead allows much higher acceleration, jerk, and print speed, especially with CoreXY printers, where the printhead moves with both the X- and Y-axes. Even if using the same print speeds, there will be less strain put on the stepper motors, so less torque will be needed, and less ringing will be present on your parts.

Additionally, it should be easier to work on the extruder as the motor won’t have to be detached if the hot end needs to be removed for maintenance.

PLA may have less stringing and oozing when printed with a Bowden setup on some printers, which might be because the longer retraction distances and slower speeds will pull the filament more evenly out of the nozzle.

But it’s not all sunshine and rainbows.

Disadvantages

While a Bowden extrusion setup may be beneficial in some cases, there are also disadvantages worth considering.

A greater retraction distance will be required to keep stringing and blobbing under control. Also, you will need a more powerful stepper motor and filament clamp to force the filament around the bend of the tube.

The maximum flow rate may be reduced, even with a powerful feeding stepper motor, because the filament will accumulate friction as it moves through the tube.

Flexible filaments like TPU may be more difficult to use due to the amount that they will compress and expand inside the tube with retractions. It’s still possible, but it may be more challenging to tune in settings.

Different Options

There are a few different types of tubing that claim to provide a better experience than the standard PTFE option that may come with your 3D printer.

Capricorn tubing is arguably the most popular and it’s advertised as having a smaller inner diameter to aid in retraction, especially with longer Bowden tubing runs and flexible filaments. Capricorn and TH3D, another known brand, claim to have additives that will raise the temperature resistance of the PTFE tubing and reduce carbonization, allowing the user to print with higher-temperature technical materials without upgrading to an all-metal hot end.

If you have issues with clogging due to the Bowden tube charring near the nozzle, upgrading to Capricorn or TH3D may be worthwhile.

Upgrading is fairly simple on most printers. You just need to depress the plastic rings on each of the two tubing clamps to remove the old tube and slide the new one in. Make sure that the tube slides all the way down to the nozzle to prevent an air gap, which will cause problems like clogging and excess stringing as molten filament fills the gap.

Final Thoughts

Ultimately, there’s no clear-cut winner when it comes to extrusion setups and 3D printers.

For most, in fact, the differences between them may not matter at all. The quality of a 3D printer depends on many more factors than just its extruder design, and the best printers will account for any of the weaknesses mentioned above.

That being said, if you value higher speed and accuracy and aren’t planning to print with high flow rates or flexible filaments, a Bowden extruder could be the way to go. But if you don’t mind trading speed for peace of mind when printing with a wide range of materials, a direct extrusion setup may suit you best. If you’ve already got a printer with a Bowden setup, like the Ender 5, and you want to switch it up, you can!

License: The text of "Bowden Tube: Pros & Cons, Best Options, and More" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.