Multi Jet Fusion (MJF) is one of the most popular ways to 3D print rugged and durable parts quickly. It’s also a top choice for volume batches of end-use-ready plastic parts in durable nylon carbon fiber and flexible materials.

MJF can create finely detailed components with consistent mechanical properties at incredibly high speeds. Many on-demand 3D printing service providers have one or 10 of these machines on-site as their go-to solution for customers’ spare parts, gigs & fixtures, unique components, and consumer products. It’s a popular solution in automotive, manufacturing, machine shops, and for anyone needing a robust functional prototype.

Getting your own MJF printer is a large investment (starting at $100,000) and out of reach for smaller operations. But luckily, you don’t need to buy your own printer or need to know much at all about MJF 3D printing. Services can print practically any part for you at a low cost — whether it’s a one-off prototype or a large batch of tools.

MJF printing services are also the first step in evaluating the technology for your application before you decide to buy a machine of your own.

If your not familiar with how MJF 3D printing works of if it’s the right choice for you, skip down to the end to our sections on the technology and the advantages. Now, read on to find out which are the top 10 MJF 3D printing services and what they have in store for you.

Craftcloud

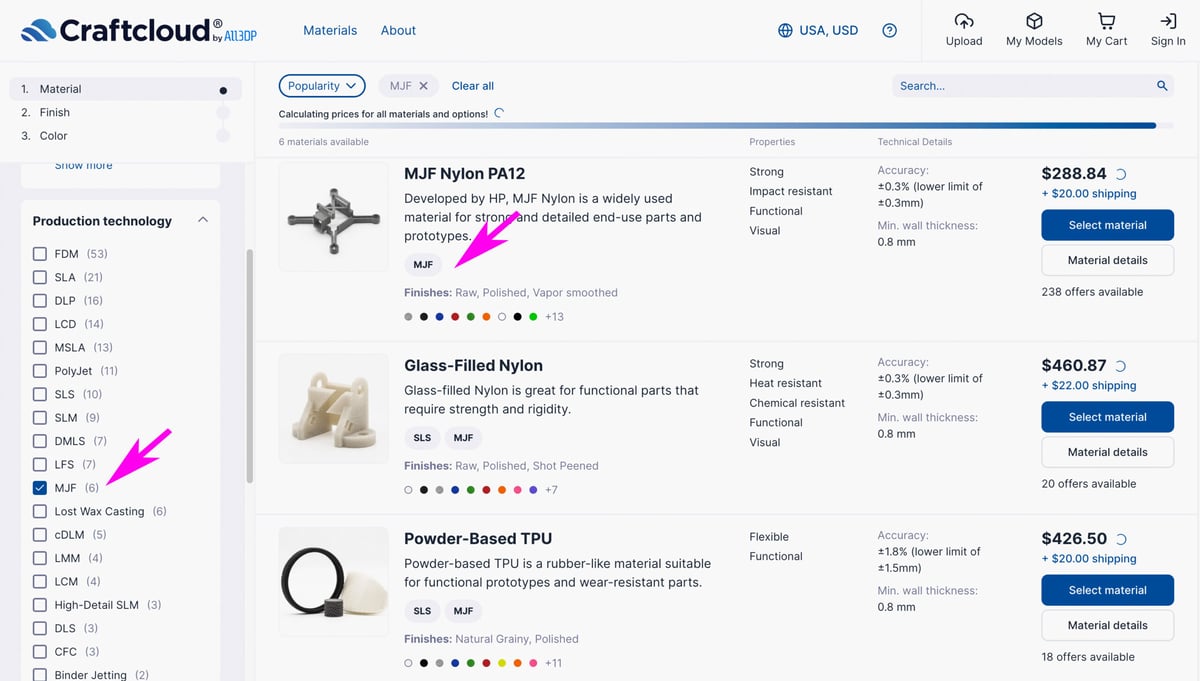

Craftcloud by All3DP isn’t exactly an MJF 3D printing service — but it will help you find one that’s right for you. Instead of a print service provider, Craftcloud is a marketplace for 3D printing services, including MJF, where you can compare prices, delivery times, and post-processing opinions from companies that do offer MJF.

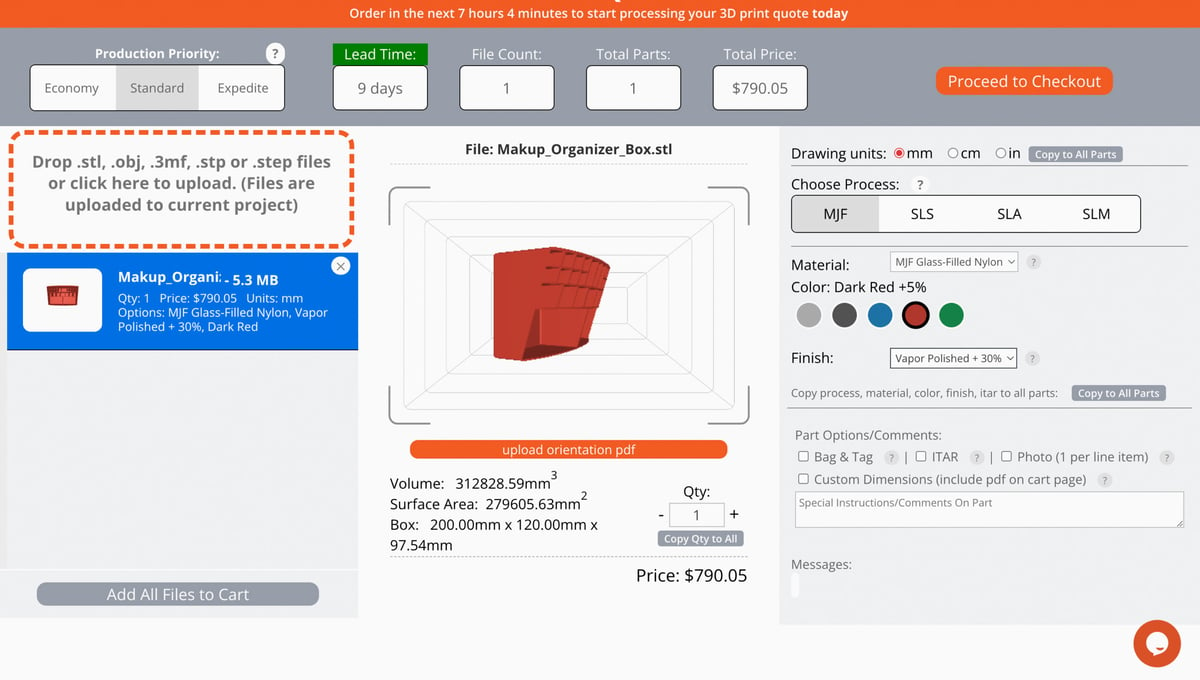

Currently, Craftcloud partners with more than 150 printing service providers all across the globe. Comparing them is easy — all you need to do is upload your CAD model, pick the material and finish you need, and browse through the list to find a quote that works. Craftcloud generates quotes instantaneously in real-time and doesn’t include any hidden fees, so you will always get an accurate quote.

Craftcloud has both nylon PA12 and PA11 materials available. The materials can be dyed up to 20 different colors, giving you great options for customizing your order. The service works for both one-off prints, like gifts or prototype samples, and small batches of fully functional industrial-grade parts.

Craftcloud also has an extensive library of material and support documentation to help you choose the right service provider.

- Materials: Nylon PA12, Nylon PA12 GF, Nylon PA11, TPU, PP

- Lead times: Varies by supplier

- Additional services: Color dyeing, polishing, vapor smoothing

Sculpteo

Sculpteo has been in business since 2009 and has quickly become one of the biggest names in 3D printing services. In 2019, the company was acquired by BASF and it has since added a slew of new materials and services to its catalog, with options for practically every industry.

Sculpteo offers four materials for MJF printing — nylon PA12, PA11, Ultrasint TPU01, and polypropylene (PP). PA12 has the most options available when it comes to post-processing on part surfaces. This material can be painted (14 colors) or dyed (3 colors), and the company also offers polishing and chemical smoothing.

PA11 can also be dyed with 3 different colors. TPU01 surfaces can be smoothed, while PP parts aren’t eligible for surface processing. Sculpteo says all materials are a good fit for end-use products, from automotive parts to consumer goods. Furthermore, PA12 can make functional prototypes.

Sculpteo’s MJF-printed parts have lead times ranging from 2-15 business days, depending on part complexity, material, and surface finishing. The ordering process gives instant quotes and includes handy CAD analysis and repair tools. Sculpteo also provides 3D part design and consultation, laser cutting services, and an extensive library of support and educational documents.

- Materials: Nylon PA12, nylon PA11, TPU01, PP

- Lead times: 2-15 business days

- Additional services: CAD analysis and repair tools, CAD design, consultation, documentation and resources, dyeing, painting, vapor smoothing, vibratory finishing

- Certifications: ISO 9001:25, ISO 14001: 2015, AS9100D, ITAR, RoHS

Uptive

Uptive may be a new name to 3D printing services but that’s only because it’s the combination of service providers GoProto, Re3DTech, Stanfordville, and Phoenix Proto.

This new collection of service providers has pooled its MJF offerings, which are quite substantial. The company not only offers the full range of MJF materials, but an impressive menu of post processing, and services. In fact, the company shines in post-processing options. The company can finish parts with vapor smoothing, cerakote ceramic surfacing, or metal plating. It can also apply hydrographics, clear coats, and dye or paint parts.

The company was among the first six businesses accepted into the HP Digital Manufacturing Network. As such, the quality of their parts is really not in question.

Uptive’s concept modeling service can help you turn our rough CAD files into print-ready 3D models for various technologies.

- Materials: Nylon PA12, nylon PA12 GB, nylon PA11, TPU, TPA

- Turnaround: From 2 business days

- Additional services: Concept modeling, CAD design, chemical treatment, coating, dyeing, painting

- Certifications: AS9100D, ISO 9001, ITAR

Weerg

Weerg is an on-demand manufacturing company based in Venice, Italy, and employs it more than 16 HP Multi Jet Fusion 3D printers to make parts for its European customers. The machines operate 24/7 enabling them to make runs of thousands of parts in just 2 days and at a lower cost than traditional technologies, such as injection molding, the company says.

Weerg has a good library of four materials, giving it the ability to print parts for a great range of applications from fast prototyping to end-use components.

Where Weerg really shines is MJF part post-processing, more precisely in applying colors (red, blue, black, green) in matte and gloss finishes. They can also add a soft-touch black finish to all MJF printed components.

Weerg offers instant quotes through its website, but it also does customized quotes for special orders, such as when you don’t have a CAD model for your part. Custom quote requests get a response within one working day. You can also ask Weerg to verify your parts’ printability during ordering. The company ships worldwide with relatively fast lead times and offers an extensive NDA contract.

- Materials: Nylon PA12, nylon PA12 GF, nylon PA12 white, nylon PA11, PP

- Turnaround: From 2 business days

- Additional services: Chemical treatment, coating, painting, graphite blasting, particle blasting, vibratory finishing

- Certifications: ISO 9001:25

Materialise

Materialise has been active in additive manufacturing for more than 30 years. Over this long history, they’ve built a reputation with their software solutions, but the company also offers a large range of on-demand 3D printing services.

These services include MJF printing technology. Materialise is a member of the HP Digital Manufacturing Network, which means its printing service has been certified by HP and guaranteed to meet the printer manufacturer’s quality and detail standards.

As for materials, Materialise is limited to only two options. The company offers MJF printing in nylon PA 12 and Ultrasint TPU 90A-01. Although limited in options, Materialise can still produce parts for demonstration and functional prototyping, in addition to small-batch end-use parts.

Interestingly, although the size of single parts is limited to the 370 x 274 x 380 mm volume of HP’s MJF machines, Materialise says it can create parts with practically unlimited dimensions by splitting prints into several sub-components. Post-processing options include sandblasting, dyeing, and painting. Delivery times start at 4 business days for TPU parts and 5 days for PA12.

In the catalog are also design and engineering services for additive manufacturing, in addition to consulting and training. Ordering online is easy with instant quotes.

- Materials: Nylon PA12, TPU 90A-01

- Lead times: From 4 business days

- Additional services: CAD design, chemical treatment, coating, dyeing, painting, particle blasting, vibratory finishing, machining, assembly, design, quality control report, reverse engineering

- Certifications: EN9100, ISO 13485, ISO 9001, ISO 14001

Protolabs

Protolabs was founded in 1999 with the goal of reducing lead times when it came to prototyping. Its 3D printing service launched in 2014 and has expanded since.

Protolabs’ MJF 3D printing service has a limited material range, including only nylon PA12, PA11, and Ultrasint TPU-01, but it can produce parts with what it has at great speeds. Protolabs offers lead times as short as one business day for MJF printed components.

For post-processing services, Protolabs’ offers smoothing and vapor smoothing and black dye. The company can apply taps and inserts into MJF components, plus part assembly.

Unlike many other companies on this list, Protolabs doesn’t offer separate design services, but they have a nice library of design tips and guide materials available to help businesses new to 3D printing.

- Materials: Nylon PA12, nylon PA11, TPU

- Turnaround: From 1 business day

- Additional services: Chemical treatment, coating, dyeing, painting, design consultation, quality control report

- Certifications: AS9100D, ISO 9001, ITAR

Zigg Zagg

Belgium-based Zigg Zagg is a manufacturing service provider that only offers MJF 3D printing. It has 10 HP machines offering a range of materials and post-processing to its European customers. MJF is all they do, so they’ve acquired quite a bit of expertise in the technology along with all of its various post-processes, design application, and use cases. The company can help you understand MJF and design your part for it. It also offers 3D scanning of your current part to turn it into a 3D printed part faster.

Zigg Zagg can guide you through how to apply MJF to you product needs and understand its benefits and limitations all the way from design through to mass production.

- Materials: Nylon PA12, nylon PA12 GB, TPU

- Turnaround: From 1 business day

- Additional services: Design, 3D scanning, reverse engineering, chemical treatment, painting, particle blasting, vibratory finishing

- Certifications: ISO9001, ISO13485, RoHS

GKN Additive / Forecast 3D

With more than 30 MJF printers in operation across the US, GKN Additive / Forecast 3D is one of the world’s largest experts in high-volume production.

In addition to a large material library, GKN offers fast delivery times. Our hands-on investigation into the company’s services found it offers a fast, one-day lead times for parts printed in PA12, with some size and finish limitations. Other MJF parts have lead times starting from 3 days. The service is also rather limited when it comes to post-processing, as it offers only black dyeing as an option.

In addition to 3D printing parts, GKN can design CAD files for printing. It also offers contract manufacturing services for both small- and large-volume production. The website has a decent library of guides and educational resources as well.

Forecast 3D focuses on domestic US deliveries so if you’re outside of of North America or you need your MJF part to be, check out some of the other options below.

- Materials: Nylon PA12, Nylon PA12 GF, Nylon PA11, Estane 3D M95A TPU, Ultrasint 88A-01 TPU, PP

- Turnaround: From 1 business day (PA12), 3-5 business days standard

- Additional services: CAD design, contract manufacturing, documentation, and resources

- Certifications: AS9100D, ISO 9001, ISO 14001, ITAR, RoHS

Endeavor 3D

US-based Endeavor 3D only offers HP MJF and HP’s metal 3D printing solution, Metal Jet. Like Zigg Zagg in Europe, it doesn’t offer any other technology so you could say they are HP specialists. In fact, they are one of only a handful of official HP Digital Manufacturing Partners in North America.

The company can handle rapid prototyping all the way to high-volume serial production. More than a print service, they want to be your manufacturing partner, which means that it combines engineering, manufacturing, and, they say, “creativity” for a long-term relationship.

- Materials: Nylon PA12, nylon PA12, TPU, nylon PA 12 White

- Turnaround: From 3 business days

- Additional services: CAD analysis and file repair, design, part dyeing, vapor smoothing, assembly, reverse engineering

- Certifications: ISO 9001:2015

JawsTec

We took a good look at the 3D printing services at US-based contract manufacturer JawsTec and were pleasantly surprised. Sure they also offer CNC machining and metal fabrication services but 3D printing has become the major focus. In fact, JawsTec is part of HP’s Digital Manufacturing Network offering parts on the HP Multi-Jet Fusion 4210 and 5210 machines.

If you’re not sure if 3D printing is for your or how to get started, you can avail yourself of JawsTec’s engineering and design services. They’ll assess your project feasibility, product design and validation, process optimization, production streamlining, and, basically, all you need to get your project off the ground.

Another bonus at JawsTec is the streamlined instant quote service. It took us about 5 seconds to get a quote on our MJF part including all of the color and finish options, plus we didn’t have to create an account.

- Materials: Nylon PA12, nylon PA12 GB, nylon PA11, PP

- Turnaround: From 2 business days

- Additional services: Vapor smoothing, polishing, dying

- Certifications: EN9100, ISO 13485, ISO 9001, ISO 14001

Fast Radius, a SyBridge brand

Fast Radius calls itself a cloud manufacturing and digital supply chain company because its focus is as much on offering an infrastructure for engineers to design and develop 3D printed products as it is on additively manufacturing them.

The company’s Cloud Manufacturing Platform provides software applications, manufacturing solutions, and a network of factories to produce commercial-grade parts. Its manufacturing capabilities include a range of additive manufacturing, CNC machining, injection molding, urethane casting, and sheet metal methods. The company ran into some financial trouble in 2022, but in 2023 it was snapped up by SyBridge Technologies, which offers a range of manufacturing solutions across multiple industries.

Fast Radius has its own manufacturing facility in Chicago, but also partners with a global network of micro-factories. Facilities house three HP technologies, the 4200, the 5200, and the HP Jet Fusion 580 for full color, but is discontinued from HP. Fast Radius is one of the few places that offers MJF using their TPA materials, which is a flexible and light weight.

- Materials: Nylon PA12, TPA

- Turnaround: From 5 business days

- Additional services: Chemical treatment, coating, dyeing, painting, vibratory finishing, design

- Certifications: AS9100D, ISO 9001, RoHS

Prototal

Prototal is one of Northern Europe’s largest suppliers of 3D printing, vacuum casting and injection molding serving primarily Norway, Sweden, and the United Kingdom.

The company says it not only has skillful model makers to guide you through part development and design, but it has the largest resin printer capacity in Northern Europe and can produce series involving several thousand parts at short notice.

Prototal also boasts an extensive menu of post-processing options from sanding, barrel polishing and dying, along with assembly, labeling and packaging.

- Materials: Nylon PA12, nylon PA12 GB, nylon PA12 white, TPU 95A, TPU M88a

- Turnaround: From 4 business days

- Additional services: Vapor smoothing, painting, coating, metal plating, assembly, threaded inserts, vibratory finishing

- Certifications: EN9100, ISO 13485, ISO 9001, ISO 14001

Extol

US-based Extol is a newcomer to our list. This manufacturing company has offered plastic manufacturing and assembly since 1985 but jumped into 3D printing when it realized that MJF could offer its customers more opportunities, flexibility, and faster production. The company operated HP MJF printers.

Unique on our list is this company’s ability to assemble and weld MJF parts together into your final product. Using the same plastic joining tools it has used for decades, Extol can combine your MJF parts into a final, larger component.

- Materials: Nylon PA12, TPU, PP

- Turnaround: From 5 business days

- Additional services: CAD analysis and file repair, design, vapor smoothing, assembly, plastic welding

- Certifications: ISO 9001:2015

MJF 3D Printing Explained

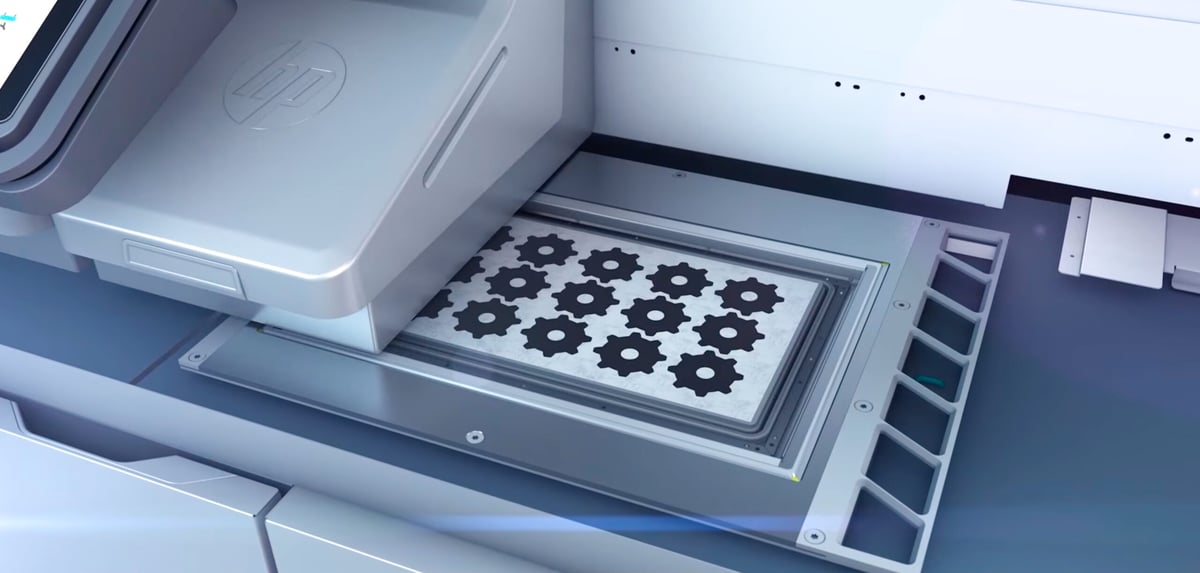

Only one company makes MJF 3D printers: HP. Even though the technology is a type of binder jetting, MJF is proprietary and comes with some unique features that make it popular.

The technology gets its name from the multiple inkjet heads used in the printing process. The processes of material recoating and agent distribution and heating are carried out by separate head arrays that move across the print bed in different directions, allowing the operator to optimize both processes independently.

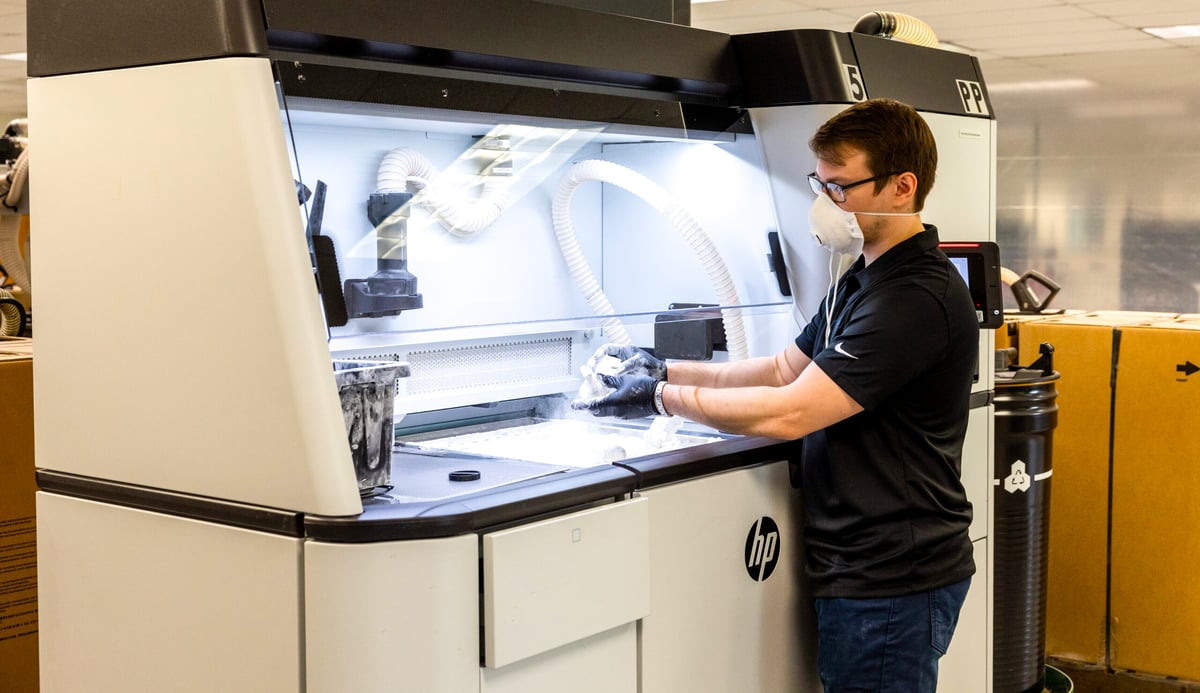

The MJF printer lays down a layer of material powder on the printing bed, then an inkjet head runs across the powder and deposits both a fusing and a detailing agent onto it. An infrared heating unit then moves across the print. Wherever a fusing agent is added, the underlying layer melts together, while the areas with the detailing agent remain a powder. The powdery parts shed off, producing the desired geometry.

The technology eliminates the need for supports that must be removed in a separate step because the powder bed supports the finished layer. Furthermore, each new material and agent layer is placed while the previous layer is still molten. This lets both layers fuse completely, delivering both durability and fine detail.

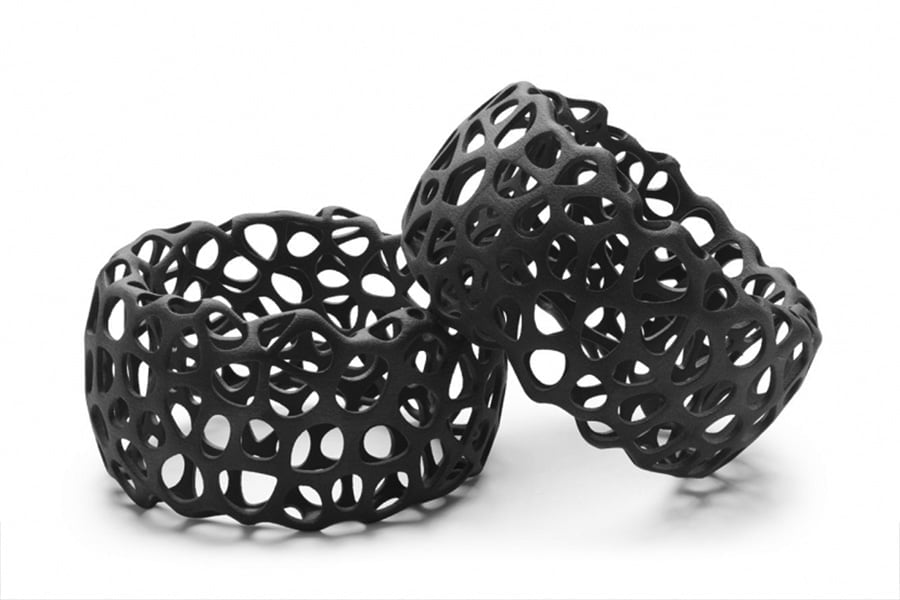

MJF can achieve very fast print speeds, making it an excellent choice for prototyping and fast production cycles. Due to the lack of supports, it offers great design freedom. The materials have high-quality surface details and mechanical properties, and they resist heat, abrasion, and chemicals. Consequently, MJF can produce end-use parts for demanding applications. The parts can also be dyed or painted during printing or post-processing, depending on the printer models.

Why Choose MJF?

In addition to part quality and materials, there’s another reason to select MJF over other technologies, such as polymer selective laser sintering (SLS) or binder jetting and that is consistency.

Because all MJF printers are manufactured by HP and all the materials are also made by HP, all 3D printing services listed below can, theoretically, offer the same part quality. No matter where you get your MJF part printed, you should end up with the exact same result.

This means that your company can have parts printed at services closest to where ever the part is needed and be assured of consistency.

However, just because all MJF printers are the same, doesn’t mean all MJF on-demand service providers are. When selecting your printing partner, focus on lead times, materials libraries, and additional services — such as coloring, polishing, chemical smoothing, design consulting, and NDA contracts — when choosing the best service for your purposes.

Lead image source: Multi Jet Fusion part by Hubs

License: The text of "MJF 3D Printing Service: The Best Providers in 2024" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.