Two Sides of the Same Coin

Additive manufacturing adds material. Subtractive manufacturing takes it away. Both are used for prototyping but may also be used for production.

Hybrid approaches involve both additive and subtractive processes, taking the best of both worlds. An example of such would be polishing a 3D printed part.

In the context of large-scale production, both additive and subtractive processes are generally slower and more expensive than traditional approaches, such as injection molding or casting.

Additive Manufacturing

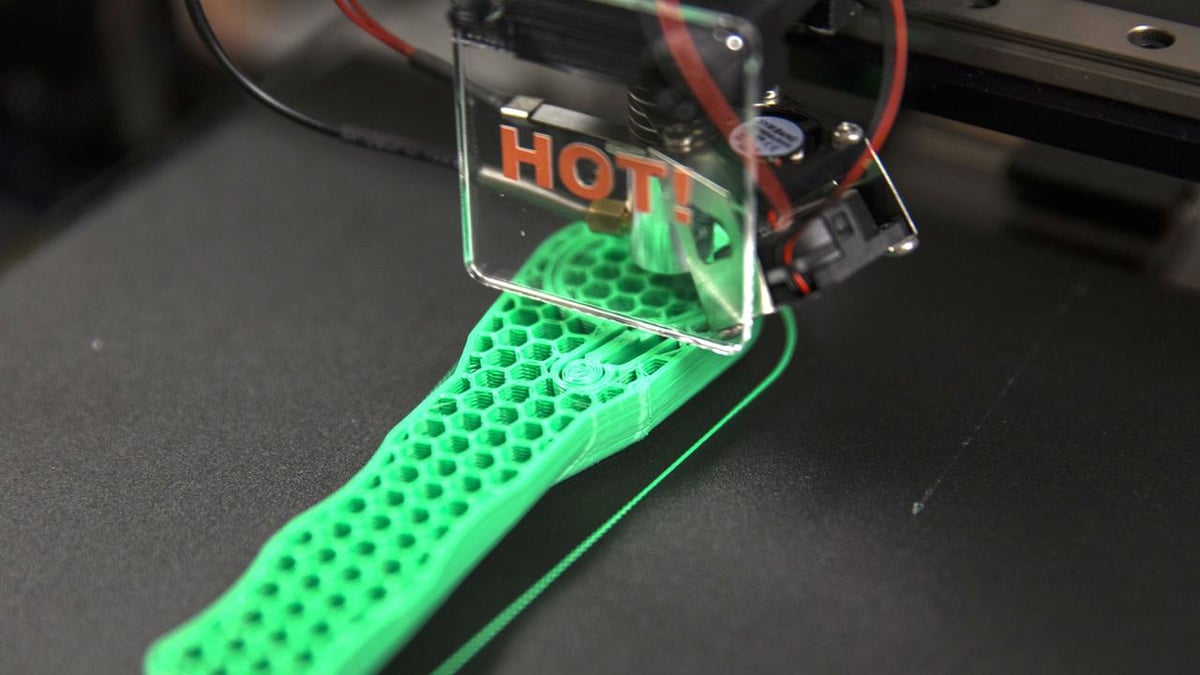

Additive manufacturing is any process in which parts are produced by depositing material to create the desired shapes. 3D printing is the most common additive manufacturing process, but other examples might include welding or sculpture modeling (by adding clay or similar materials).

Usually, the term additive manufacturing applies only when the process is automated or computer controlled, ensuring that parts are precisely made (within certain tolerances). Thus, in the strictest sense, welding by a human wouldn’t normally be considered additive manufacturing.

Strengths

3D printing can produce structures, such as complex or hollow interior sections, that are impossible to produce using non-additive processes. Indeed, the majority of 3D prints are purposely made with hollow sections to reduce cost, material, and printing time.

With the right printer, anything that can be designed in a CAD system can be 3D printed. In many cases, moving parts like bearings and hinges can be created directly using 3D printing. It’s even possible to produce parts using multiple different materials.

Additive manufacturing also generates less waste than subtractive processes, since material doesn’t need to be cut away and discarded.

Weaknesses

A key disadvantage of additive manufacturing is that parts often don’t have the strength, heat resistance, or surface finish required for final parts. Additive processes generally result in tiny pores in surfaces. These weaken the part and can lead to contamination or infection when used in food or medical applications.

3D printing is most economical for small quantities of parts, since setup time is minimal. Very large parts are difficult to produce using 3D printing.

Subtractive Manufacturing

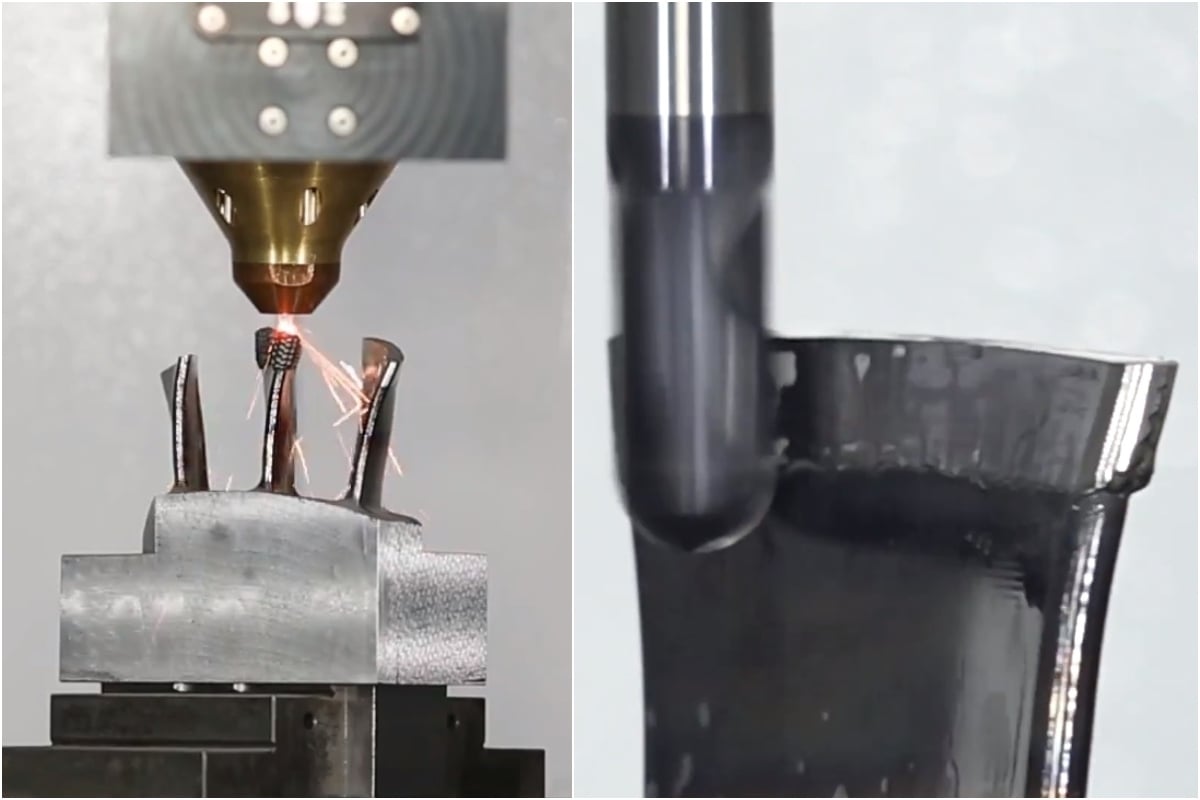

Subtractive manufacturing is any process in which parts are produced by removing material from a solid block to produce the desired shape. This is primarily done using computer numerical control (CNC) machines, which utilize various tools that are able to move and cut in three dimensions.

Laser cutters are also commonly used for subtractive manufacturing. Electrical discharge machining (EDM) is another subtractive manufacturing process.

Similar to the term additive manufacturing, a process is typically only labeled subtractive manufacturing when it is automated or computer controlled. As such, handmade carving or the operation of a lathe, drill press, or saw would usually not be referred to as subtractive manufacturing.

Strengths

CNC machining can produce stronger parts with much better tolerances and smoother finishes than additive manufacturing techniques. This is especially true of features such as threaded holes. Additionally, extremely durable metal parts can be produced using CNC machining.

Weakness

CNC machining can require substantial setup time. For this reason, subtractive manufacturing may be expensive for anything but high quantities of parts.

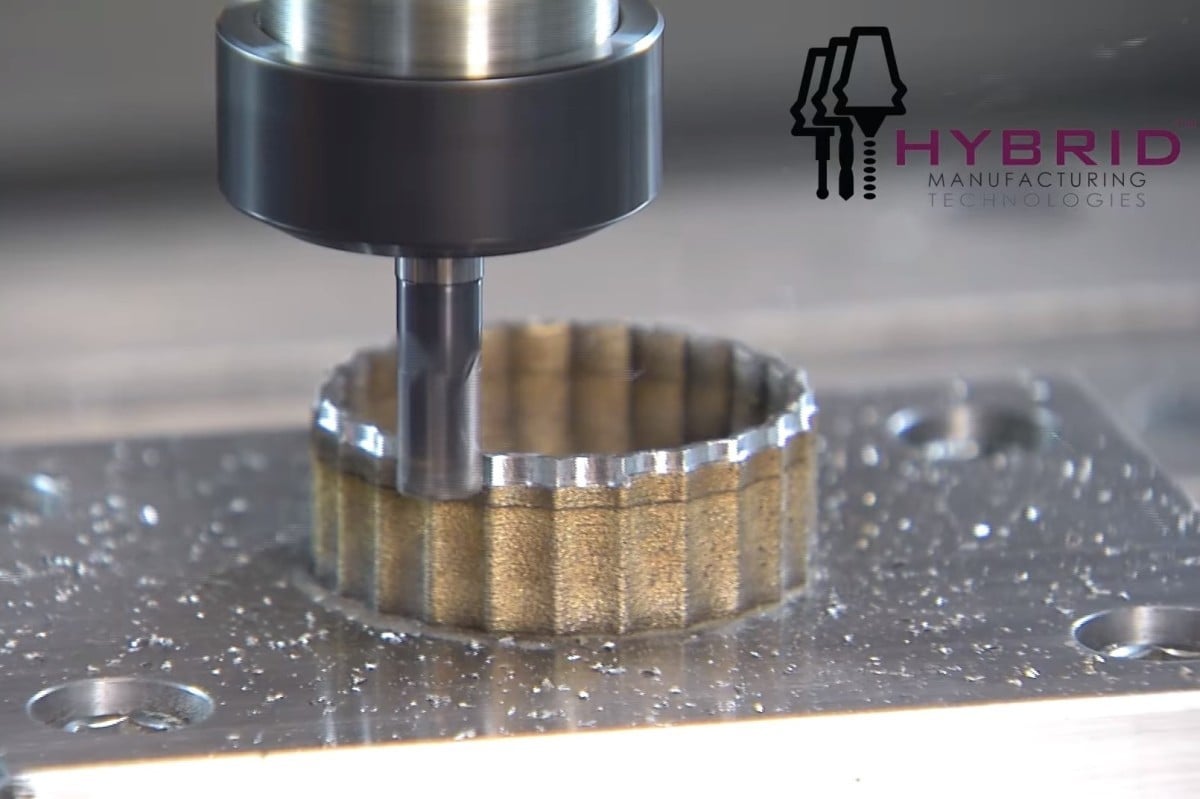

Hybrid Processes

Sometimes, the best way to produce a part involves a combination of additive and subtractive processes. For example, it’s difficult to 3D print small threaded holes. A more effective technique is to 3D print a part with holes (an additive process) and tap threads in the hole (a subtractive process) after the 3D print is completed.

If a smooth finish is required on 3D printed parts, it’s often useful to polish them (a subtractive process) after the 3D print is completed.

Injection Molding and Casting

Both additive and subtractive manufacturing are generally slower than other manufacturing techniques. They’re most appropriate for prototyping, low volume production, or expensive components that cannot easily be mass produced.

For higher volume production, injection molding or casting are generally faster, and therefore more appropriate. Injection molding refers to the process in which the material to be molded is injected under pressure into a mold. In casting, the material to be molded is poured into the mold.