Beyond Three Axes

Traditional FDM 3D printers can have many setups, the most popular being Cartesian and delta. These printers vary in their motion systems, but a common feature is that the toolhead moves linearly in the X, Y, and Z planes. All of these setups have limitations with respect to which geometries are possible to produce, and they usually require support structures simply because the deposition is made in one direction (top-down).

By adding extra movement axes, it’s possible to create complex and intricate geometries without compromising surface quality or adding extra supports. Traditional fabrication industries have long accomplished similar work with 5-axis systems for CNC milling machines.

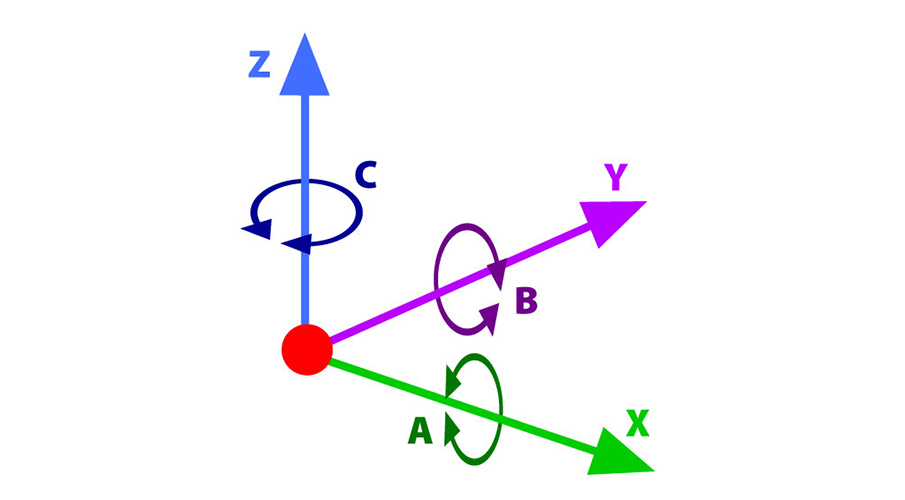

You may be wondering how these two extra axes are possible since the coordinate system has only X, Y, and Z planes. The answer is through rotation. The three rotational axes are labeled A, B, and C, and they respectively orbit the X-, Y-, and Z-axes. The diagram below shows all three linear axes plus the three rotational ones.

5-axis machines typically make use of axes A and B in addition to the linear axes. Although possible, 6-axis machines aren’t very common because there are actually very few advantages brought by the sixth axis (in relationship to machine complexity).

Five Axes in 3D Printing

For 3D printing specifically, having two extra axes allows for not only the complete elimination of support structures but also dynamic, non-planar surfaces. This enables new possibilities for higher quality surface finish, more design flexibility, and greater part strength. By printing from different directions, the part can come out much sturdier than by simply stacking layers in the Z direction.

While this solution seems to be the answer to many current 3D printing problems, 5-axis 3D printing is not without its own issues. First and foremost, machine dynamics are much more complicated than with 3-axis 3D printing. Also, the slicing process becomes problematic, as most slicers assume layers are built up in a single direction. This means some tool paths must be manually computed in more complex CAM software, especially in the case of 3D printing a non-planar surface, for example.

While there are still many constraints to 5-axis 3D printing, we’ll see in this article that it’s not only possible – it’s reality. Note that the majority of the machines on the market or still in development are hybrid systems. In other words, they’re generic CNC systems with changeable tool heads that allow for multiple functions.

That said, let’s dive into some of what we think are the most interesting machines and projects that use five (and even six) axes for additive manufacturing.

5AxisMaker (On the Market)

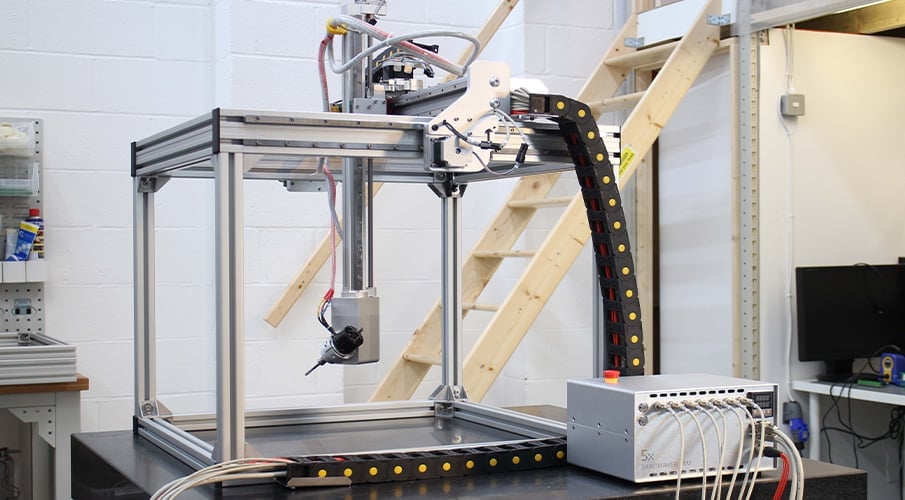

The 5AxisMaker is a desktop fabrication system that makes use of multiple tool heads, including one for 3D printing. The project was first launched on Kickstarter in 2014 and promised a wide variety of functions, including a CNC router, wire cutters, a waterjet, and even a touch probe.

As of writing, the British company offers four different models that vary mostly in build size. All models include a 15,000 RPM CNC milling spindle and a 3D printing extruder head with a 0.6-mm nozzle. Just be aware that the 5AxisMaker doesn’t have a heated bed, so you’ll be somewhat limited in which materials you can use.

With the cheapest model, the 5xm400 listed at around $6,530 (£5,000), this might be the most accessible 5-axis machine on the market. Although probably outside the reach of most makers and enthusiasts, it’s not a lot of money for a complex 5-axis system. Every model is available with worldwide shipping through the online store.

- Overall dimensions (5xm400): 790 x 580 x 800 mm

- Build volume (5xm400): 400 x 400 x 400 mm

- Mechanical resolution: 36 microns (X-, Y-, Z-axes)

- Standard nozzle size: 0.6 mm

Ethereal Halo (On the Market)

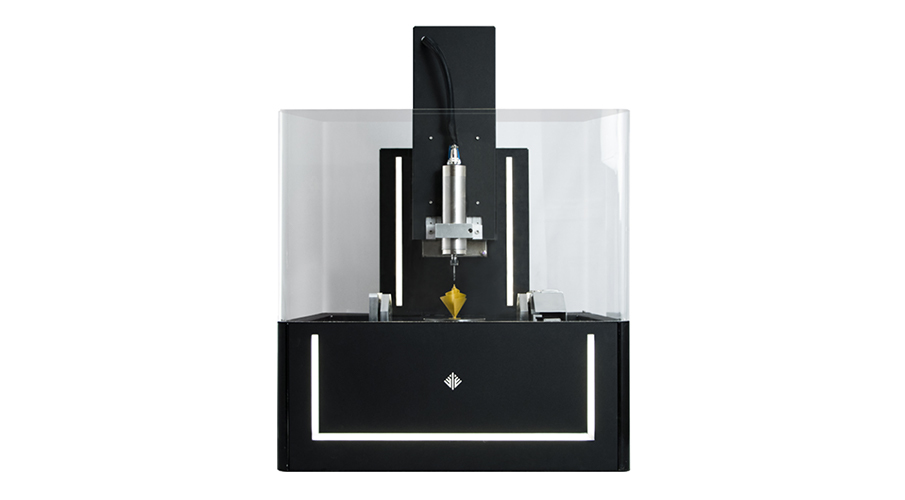

Ethereal Machines is a 3D printer manufacturer located in India. The company recently gained a lot of attention because of its flagship product, the 5-axis 3D printer CNC hybrid, the Ethereal Halo. In fact, they were awarded the CES “Best of Innovation” award in 2018.

The Halo is truly a hybrid machine, allowing both 3D printing and CNC milling to work together on the same part. The build plate and the tool head both move in the standard X-, Y-, and Z-axes, while extra rotation in the bed provides the two additional axes. It can produce parts from ABS, PLA, PVA, PC, NYLON, PETG, and more.

The company claims that the Halo is the “world’s first consumer-oriented 5-axis CNC machine and 3D printer,” and it’s currently priced at around $25,000.

- Overall dimensions: 1300 x 1300 x 1290 mm

- Build volume: Ø150 x 150 mm (5-axis)

- Mechanical resolution: 60 microns

- Standard nozzle sizes: 0.4, 0.8, 1.0 mm

Q5D Technology CU500 (In Development)

Yet another UK-based company, Q5D Technology revealed its 5-axis 3D printer in September 2019 at the TCT Show in Birmingham. Q5D is a joint venture between the electronics company M-Solv and desktop 3D printer manufacturer CEL-UK.

The CU500 3D printer is Q5D’s first product ever, said to be secretly developed in only 18 months. It’s a multi-tool machine with options for CNC milling heads and even a wire dispenser.

This printer’s unique feature is the ability to use the wire dispenser toolhead during a print job in order to embed a regular conductive wire into the final model. If that’s not enough, another tool head can extrude a copper paste that can be post-processed as a conductive circuit.

Every unit of the CU500 will be custom-made to address each client’s requirements. This means that each machine will include different tool heads and even custom build volumes. Because of this, the CU500 doesn’t have a firm list price but will end up costing around $245,000 (£200,000).

Verashape Vshaper 5AX (In Development)

Polish 3D printer manufacturer Verashape is also having a go with 5-axis systems. The prototype was first seen at Formnext 2017 and was developed in association with the Polish National Research and Development Center. Back then, the machine was known as the Vshaper 500 and was far from going into production. The rebranded machine, the Vshaper 5AX, is scheduled to be launched in May in Warsaw.

The Vshaper 5AX also combines different tool heads on its 5-axis motion system. Beyond the 3D print extruder and a CNC milling head for finishing parts, there’s also a touch probe for part quality testing.

With a cylindrical print volume of 300 mm in diameter and 300 mm in height, the Vshaper 5AX will likely be priced at around $560,000 (€500,000).

University of Oslo's Pentarod (Research)

In 2015, a master’s student at the University of Oslo decided to develop a 5-axis 3D printer for his thesis. Øyvind Kallevik Grutle came up with the first version after only 3 weeks of work, but it wasn’t quite there yet…

The second version, called Pentarod, is a modified RepRap Ormerod that uses a Fanuc system for motion control. The results are extraordinary.

The project is a proof of concept: Grutle wanted to verify that it’s possible to both produce smooth surfaces by printing on planes other than the typical XY plane and avoid the need for support structures. Both hypotheses were confirmed with the Pentarod, as seen in the video below.

Since the project was based on a RepRap design, Grutle had plans to open-source the 5-axis printer by releasing all files and build instructions. While this hasn’t happened yet, it’s possible to download his master’s thesis for further information on the development process.

Oliver Tolar and Denis Herrmann's 6-Axis Delta (Research)

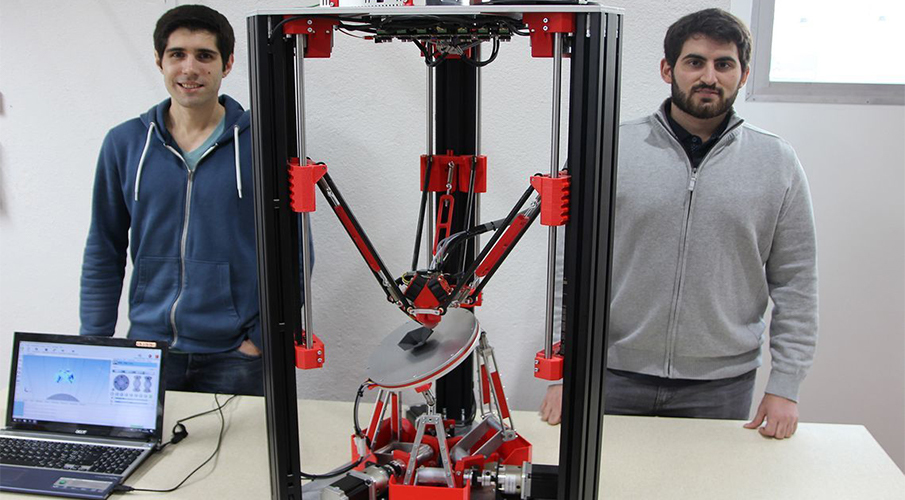

In 2017, two students from the Zurich University of Applied Sciences, Oliver Tolar and Denis Herrmann, developed an impressive prototype for a 6-axis 3D printer. The main idea behind their project was to eliminate the need for support structures entirely.

Unlike the other machines in this list, the students modified a delta 3D printer to have its build plate rotate around the extra three axes. The movement of the print bed is independent of the print head, which allows it to tilt exactly the right amount to eliminate any overhanging objects.

Oliver and Denis have also written software that coordinates various motions between the build plate and the print head. This is truly an amazing accomplishment, and the machine is still on display at the university as of writing.

(Lead image source: 5axismaker via YouTube)