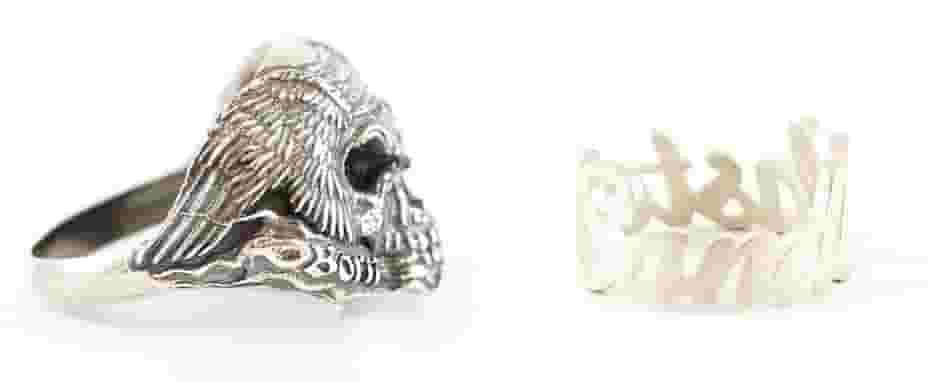

Heart-warming stories of newlyweds 3D printing their own silver wedding bands are not hard to find online these days. You’ll also find folks who have minted their own silver coins from 3D printed molds. In fact, you can 3D print almost anything in silver. Let’s look at how.

Depending on what you want to 3D print in silver, there are a few methods to choose from. When we talk about “3D printing” silver jewelry, 95% of the time, we’re talking about 3D printing the mold or model used to cast the jewelry. This is also true with services that 3D print in silver.

If you upload your digital jewelry design to a 3D printing service, such as Craftcloud, for example, and select sterling silver as the material, you’ll notice that the method mentioned is “lost wax casting”, which means that your design will be 3D printed in wax, then that wax model will be used to make a mold, and the rest of the jewelry-making process is the same as the thousand-year-old traditional method.

But it is also possible to directly 3D print using silver, which typically involves silver powder used in a laser powder bed fusion or binder jet 3D printer. This is becoming an attractive alternative for large jewelry companies who want to offer customized items or respond to shifting trends faster.

How is 3D Printed Silver Jewelry Made?

3D printing hasn’t disrupted the age-old process of jewelry making that much. The real change is in the making of the wax model. Today, with relatively simple computer-aided design (CAD) software, anyone can create a jewelry piece, like a ring or a statuette. 3D printing the wax model from a computer file has dramatically increased the average person’s access to creating custom jewelry, since there’s no craftsperson skill in carving wax required.

This method can be used to create all sorts of other objects, too, such as coins, keepsakes, and art.

Once the digital file has been printed in wax, it’s then encased in liquid plaster or ceramic or even sand. Once dried, it’s heated to cleanly melt out the wax model leaving a perfectly shaped mold into which molten silver is poured. Once cooled, the mold is removed and the silver item is polished.

Order 3D Printed Silver

Today there’s an abundance of online printing services you can reach out to for 3D printed silver. As we mentioned, most of these services will 3D print the mold for your silver part, then have it cast in silver for you. How is this different from ordering any type of custom silver jewelry?

3D printing services enable you to upload your own design as a digital file. There’s no back-and-forth with a jewelry designer, and it’s usually more economical. The downside is that these companies will print exactly according to the file you upload, so a best practice is to first order your part in a low-cost plastic as a model so you can be sure of the size and shape, then reorder it in silver.

Print services will give you the price of your silver part in advance, which is based on the amount of silver it will contain. Unlike jewelry ordered from a jeweler, your silver parts will not likely have a silver authentication stamp, called a hallmark. Only a few companies, including iMaterialze, offer hallmarking.

*To give you a sense of cost for 3D printed gold jewelry, we uploaded the same sample pendent (designed by mishkin2 via printables) design to each provider and ordered it in sterling silver 925.

Can Your Directly Print Silver With a 3D Printer?

Yes, metal 3D printers use silver in powder form to directly 3D print silver parts, including jewelry, fashion accessories used on luxury products like handbags, and even parts used in dentistry.

In a process called laser powder bed fusion (LPBF), which is also called selective laser melting (SLM), silver powder is loaded into the vat of the 3D printer and a laser fuses the metal powder together layer by layer to make a fully metal part. The process follows these steps:

- A 3D printable part is designed in 3D modeling software.

- In the printing process, a layer of powder is first flattened over the printable area.

- A laser beam selectively sinters the object’s first layer in the bed of powder.

- The process repeats with a new layer of powder being spread atop the previous layer, which is again selectively sintered.

- The final part is removed from the powder and a cleaning process (usually sandblasting or compressed air removal of excess metal powder) is performed before the part is put into use.

Despite the advantage of being able to directly 3D print a metal end-use part, LPBF machines are expensive, starting at around $100,000 for a base model. Plus, you’ll need several liters of silver powder to fill the powder bed for each print run.

More custom jewelry companies, however, are adopting LPBF because it accelerates custom jewelry production. In one print run, you can print a dozen rings or more where each one is different. There’s no modeling step since it’s a direct digital model-to-printer process. Another benefit is the complexity of parts that you can print with the fine detail possible with LPBF 3D printers. There’s also the ability to print only on-demand, which eliminates stock and enables jewelry companies to react quickly to the latest jewelry trends.

One example is a start-up called Cloud Factory that offers custom jewelry designs and products to influencers and celebrities who want small quantities of unique silver parts. The company’s in-house printing processes and post-production operations enable them to use silver 3D printing for volume manufacturing jewelry that’s both cost-efficient and sustainable. The flexible 3D printing LPBF process allows clients to launch products quickly and adjust merchandising selections according to new content or fast-changing trends, the company told All3DP.

Cloud Factory uses an SLM125 3D printer from printer manufacturer Nikon SLM Solutions and the 925 sterling silver powder they use is 100% recycled from precious metals sources.

When it comes to look and quality, Cloud Factory says there’s no “visible difference between traditionally manufactured and 3D printed jewelry. The only difference can be in the design as direct 3D printing enables us to create textures and structures that are otherwise impossible to make.”

Not all LPBF printers are suitable for silver. There are many print parameters controlling the temperature and strength of the laser, and other printing factors that have to be established for you to achieve predictable and consistent results. These printers below have “certified” silver on their machines and have tested and established a set of perimeters you can follow to ensure successful 3D printing.

Silver Certified Laser Powder Bed Fusion 3D Printers

- SLM 125

- EOS M100

- GE Additive Concept Laser Mlab R

Production Volume 3D Printing with Silver

There’s another 3D printing technology used in 3D printing silver for professional and industrial-level applications called binder jetting, that’s used for large volumes of pieces.

3D printer maker Desktop Metal qualified 925 sterling silver as a new material for its 3D printer called the Production System in 2022.

“The qualification of precious metals for direct 3D printing on high-speed binder jetting systems is a major milestone for the jewelry and luxury goods industry,” said Ric Fulop, founder and CEO of Desktop Metal. “All the design freedom and customization of 3D printing can now be delivered directly at high volumes without all of the labor associated with traditional manufacturing processes.”

The binder jetting 3D printer from Markforged called PX100 is another silver option. Although, not listed as one of its qualified metals, when we spoke to the original makers of the machine, Digital Metal, before they were acquired by Markforged, we learned about a unique jewelry application where they worked with the jewelry maker to create parameters for a unique metal.

HP makes a 3D printer that uses a technology called MetalJet, which is a method of 3D printing that uses a liquid binding agent deposited in tiny drops on powdered materials in layers to create solid, complex shapes. As the build progresses, the print layers are bonded together, resulting in a powder box with the desired part geometry inside.

The Legor Group, a precious metal and jewelry company, worked with HP to establish its new 3D Metal Jet Printing Service earlier this year. Legor developed its own silver material called Powmet, which has a very fine and homogeneous particle size ideal for the HP 3D printers.

“The Legor 3D Metal Jet Printing Service was created with the aim of promoting a new way of making jewelry and fashion accessories using all the potential of the revolutionary BinderJet technology … to push more and more players in the manufacturing sector to rethink the entire production process, revolutionizing it at every single stage, as much in the concrete realization of the objects as in the concept, planning and design,” Legor said in a statement at the launch of its new service.

Silver Plating 3D Prints

Plating, or electroplating, is the process of depositing a thin layer of metal onto the surface of an object, which could be a metal, like steel or a plastic. If you don’t want your part printed as solid silver, many 3D printing services, like Craftcloud, offer plating. Alternatively you could have your jewelry 3D printed in less-expensive steel, brass, or nylon, then take them to a precious metal plating company or jewelry repair shop.

Keep in mind that plating is a decorative coating and because of this, it is possible that it will get damaged or fade over time, especially if the part is used frequently, so it’s not often recommended for jewelry, unless you plan to have it replated every so often, but is ideal for figurines.

Where to Sell Your Custom Jewelry Collection

With the exit of Shapeways from the entrepreneurial custom jewelry industry, where are your alternatives to sell your creations?

Although there’s nothing at the moment that combines a marketplace with a 3D printing service quite like Shapeways did, small jewelry businesses can launch their own websites to house their collections, take orders, and have pieces produced at 3D service providers like Craftcloud.

Craft and jewelry marketplaces, such as Etsy, are another way to get your designs in front of shoppers. In fact there’s an entire section on Esty for custom and personalized jewelry.

Another potential outlet is social media platforms, such as TikTok, Instagram, and Facebook. One custom 3D printed jewelry maker we mentioned above, Cloud Factory creates unique jewelry pieces for social media influencers to sell to their followers, which also brings the company traffic to their own shop.

License: The text of "How to 3D Print Silver Jewelry & Sell It (Without Shapeways)" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.