Fans are cool. Literally. Fans are designed to move air. They either push cold air over hot components or pull hot air out of enclosed spaces. Either way, they create a cooling effect.

In relation to 3D printers, there are five areas where a fan is typically utilized:

- Control board: Fans are used to cool off the main circuits of the printer, such as the processor and motor drivers. Keeping these components cool is essential to a long life span.

- Hot end: Fans will be found in the vicinity of the cold end or heatsink of your printer’s hot end. These are used to keep everything except the heater block and nozzle from getting too hot during a print.

- 3D prints: Part cooling fans blow a stream of cold air just under the nozzle, cooling off freshly-extruded plastic.

- Power supply: Fans are what keep the high-power transformers, transistors, and resistors inside a power supply from overheating under load.

- Motor: Fans are much less common, but in some cases, the stepper motors of a 3D printer may have a heatsink or fan to keep them at an optimal running temperature.

So the question is, do you actually need a fan on your printer?

The short answer? Probably. All of the above parts, except motors, generally should have a fan. Note that power supplies are usually self-contained and do not require modification, so you don’t need to worry about the fan in there.

The long answer? Keep reading as we break down each area and explain where cooling may be needed.

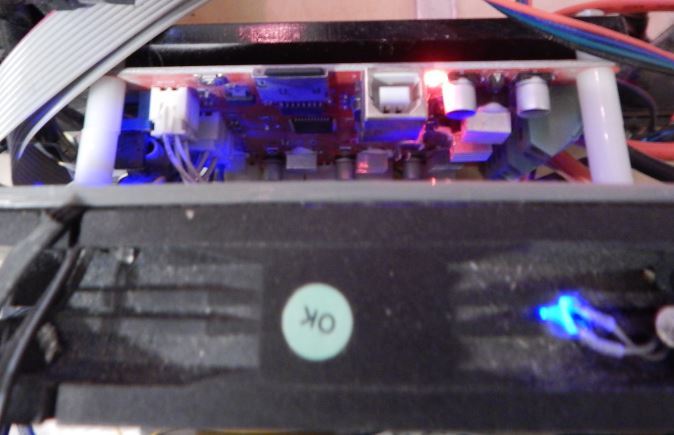

Control Board

The control board is integral to the operation of the printer. This means that it’s in your best interest to ensure that everything runs smoothly in this area.

Sources of heat:

- Motor drivers are what make things move in a printer. These chips (sometimes found in smaller, removable “daughter boards”) are responsible for power transfer to the coils in each stepper motor. This results in a tendency to overheat, which is why many of them come with small heatsinks.

- MOSFET transistors on the control board are responsible for controlling the heating elements in a printer and have a large amount of power being transferred through them. Some of this power gets converted to heat as it passes through, causing these components to get quite hot.

- The processor of a 3D printer can run up to several hundred thousand calculations per second to keep all of the different parts operating in sync, following commands for positioning, heating, and data interfacing, usually simultaneously. With all of the electrons flying back and forth, a lot of heat can be generated.

Fan(s) needed? Usually.

So, with all of these heat sources, you may be wondering why the control board hasn’t caught fire yet (unless you picked up an Anet A8, that is).

Generally, your motor drivers and MOSFETs will have heatsinks attached, which will dissipate the heat into the surrounding atmosphere. As for the processor, the heat generated is actually fairly minimal and is absorbed into the circuit board itself, so the processor is usually only marginally warmer to the touch than the surrounding circuits. The addition of a heatsink to the processor will practically ensure it never overheats during normal use.

So what would a fan do to help? While most of the hot components do have heatsinks, these are generally fairly small. This means that, over time, the heat will build up faster than it is dissipated, resulting in the chip eventually overheating. Depending on the quality and efficiency of your hardware, this may or may not occur within the time span of a typical print. A fan helps by pushing (or pulling) more air over the heatsinks, helping to dissipate the heat much faster than would otherwise be possible.

For shorter use periods, or on control boards with larger heatsinks (or more efficient components), a fan may not be necessary. However, it is still a good idea to have one, and in the case of smaller heatsinks and cheaper components, it’s certainly a necessity. Given that, we highly recommend having a fan for your control board.

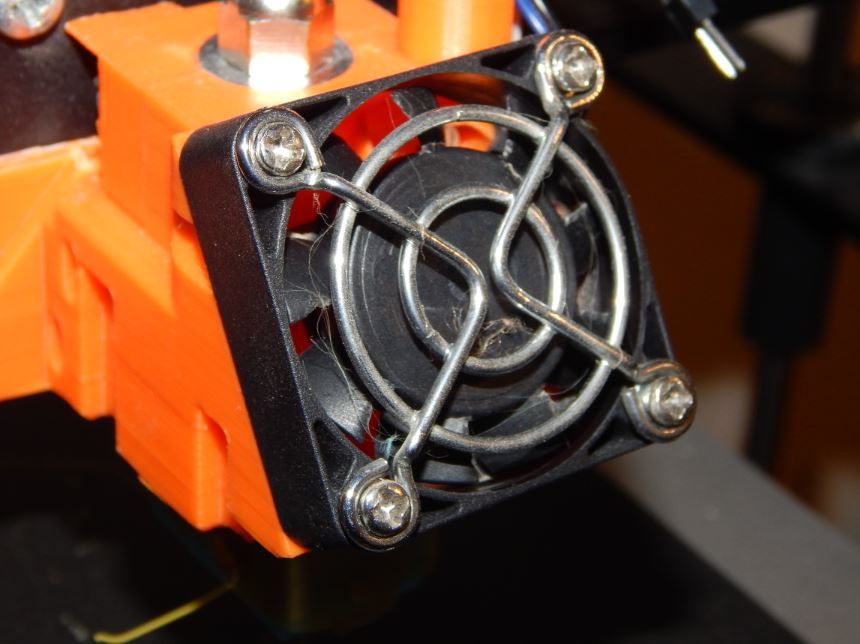

Hot End

The hot end is the part of an FDM 3D printer responsible for heating and depositing the plastic onto the print bed. Because of this, it must be able to generate enough heat to effectively melt the filament as well as stay cool enough near the top, where the drive gears push filament through. (Ever tried using gears to drive liquid? It’s called a jam.)

Source of heat:

- The heater cartridge, typically found in the heater block, can be capable of reaching and maintaining temperatures in excess of 350 °C. This presents a significant cooling problem, as the nozzle and heat block must maintain their high temperature while the rest of the hot end must be kept significantly cooler. In other words, everything that doesn’t need to be hot should be kept as cool as possible.

Fan(s) needed? Yes.

So how is this cooling performed? On most hot ends, there is a very thin metal tube connecting the heat block and the heatsink. The purpose of this tube, known as a heat break, is to minimize the amount of heat that is allowed to transfer into the heatsink.

The design of the heatsink itself can vary from printer to printer – this isn’t crucial to its operation. What is crucial is that the heat is dissipated as quickly as possible. This eliminates heat creep, the problem where filament that is waiting to be extruded is melted before it reaches the nozzle, resulting in unwanted clogs and inconsistent extrusion.

For this reason, it is a very, very good idea to have a fan cooling the heatsink. An alternative is to have a water-cooled hot end. But this would still utilize a fan to cool an externally-mounted water radiator.

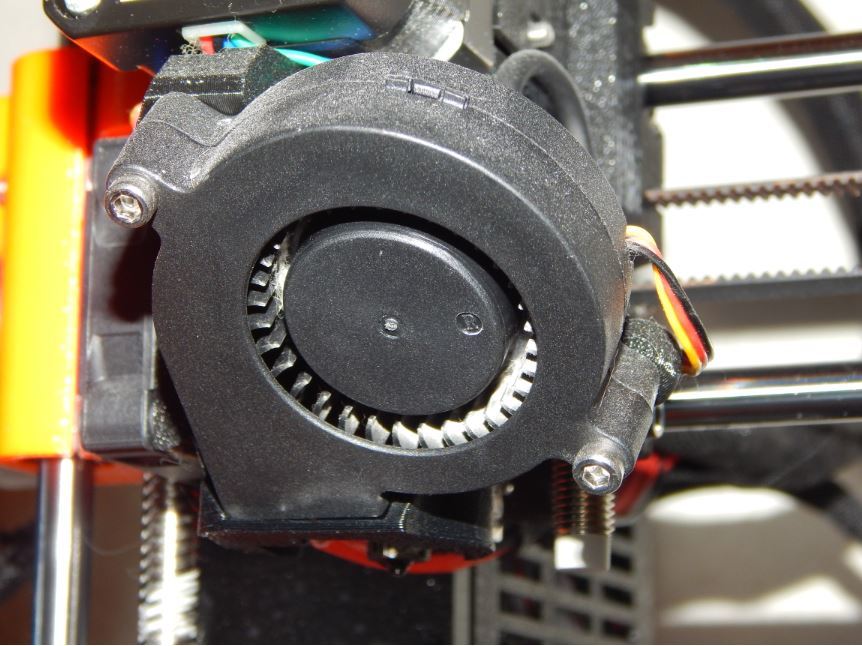

Part-Cooling Fan

There is a lot more variation in whether a part cooling fan is required or not. What this comes down to is the type of materials you typically use, and the settings you use to print them.

Source of heat:

- Molten plastic is deposited in layers on the print bed and on top of previously-laid plastic. Before each layer can be deposited, the previous layer must cool so the model maintains its shape.

Fan(s) needed? Usually.

A part-cooling fan is responsible for cooling freshly-extruded plastic as soon as it exits the nozzle. This eliminates warping and various other print problems. However, with specific materials – ABS, we’re looking at you – a part-cooling fan actually makes problems worse. So for these materials, fans are generally disabled or kept at low power.

With other materials, a part-cooling fan may only be required part of the time. In these cases, some settings can be changed to allow the print to complete without any fan at all. For instance, slowing down for very intricate detail could allow the print enough time to cool on its own before the next layer, without assistance from a fan.

However, in many cases, a 3D printer is used as a multi-purpose device, with users switching between materials as needed. In these scenarios, it is better to have a cooling fan and not need it, than not have a cooling fan and need it.

Additionally, on printers with high-volume extrusion systems, such as an E3D Volcano hot end, it may be required to have two part-cooling fans for optimal performance.

In most cases, a part-cooling fan is highly recommended unless your printer is dedicated to a single material that does not require part cooling during prints.

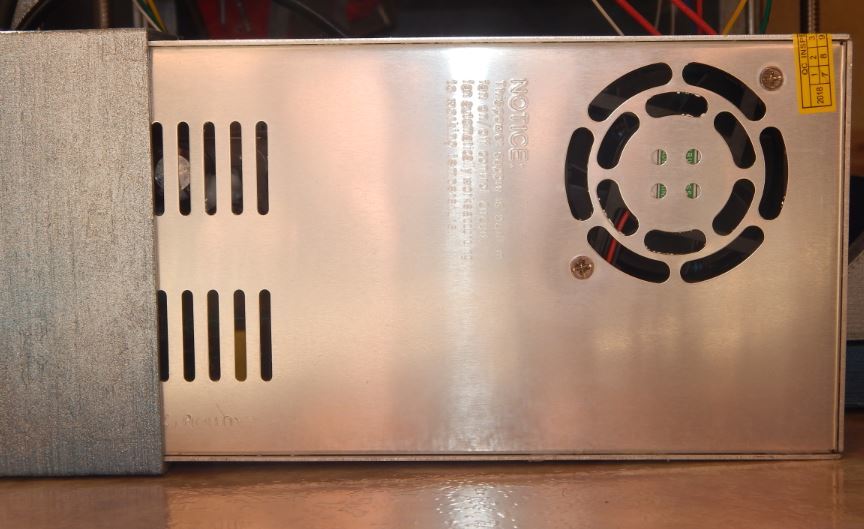

Power Supply

The power supply is responsible for converting AC mains power from the wall into more useful DC currents, at safer voltages.

Sources of heat:

- Transistors, transformers, and resistors inside a power supply all heat up significantly when under load. In other words, when a lot of power is flowing through them, they tend to get hot.

Fan(s) needed? No.

Power supplies are typically large metal boxes with a row of screw terminals at one end. According to the manufacturers, you’re not supposed to open them up in the first place. So, if the power supply comes with a fan already inside, it’s a very good idea to leave it there, as it was intended to be. Of the power supplies that come without fans, pretty much all of them are designed to run in such a way that they do not overheat. The only reason they would need an external fan is if they are consistently reaching unsafe temperatures during use.

So, for the majority of users, adding or removing fans from your power supplies is not recommended or necessary.

Motors

Stepper motors are responsible for moving things around within the printer, including the tool head and axes.

Sources of heat:

- Coils within each motor are subjected to high-current bursts of electricity, pulsed in patterns to make the motor spin in precise increments. This pulsing current generates heat, which is then transferred into the metal housing of the motor.

Fan(s) needed? No.

In most cases, the motors will never reach temperatures for which a fan is required. This is because most stepper motors are rated for safe operation at temperatures up to 100 °C. That said, there are certain cases in which motors do get hot enough to warrant the use of additional cooling, such as high-torque applications like extruders. However, in many cases, a simple heatsink will suffice, and additional fans are not needed.

Feature image source: best-cheap-3dprinters.com

License: The text of "3D Printer Fan – Do I Really Need One?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.