Putting 3D Printed Steak on the Menu

Readers of our previous article on 3D printed steak are probably wondering if Burger King’s decision to carry simulated meat is the tipping point to worldwide 3D printed meat. The answer is, well, sort of.

A slew of start-ups have entered this very crowded field, and each is trying to steak out (pun intended) a place in our diet. Animal-free meat is becoming a reality, although the industry still has a ways to go.

Challenges

The main problem with synthesized, extruded, and printed meat has been, and continues to be, one of mouthfeel. Real meat isn’t homogeneous; it has fat, gristle, connective tissue, and other bits of organic stuff in its structure. All of these factors subtly contribute to eating pleasure in ways that most don’t fully understand. Researchers are working on it, and we think multi-material 3D printing could be the solution.

The next big hurdle appears to be scalability. It’s one thing to create a few ounces of cultured cells in the laboratory. It’s quite another to create enough to make the menu of a fast-food chain. Several of the companies described below appear able, if not quite ready, to scale up commercial production, so it’s only a matter of time before we see some innovative solutions to this problem.

Other issues facing artificial meat production include accuracy of taste and whether or not the final product should incorporate animal tissues or genetic engineering.

On the bright side, printed meat is now in space and ready to go to Mars. Better yet, 3D printed fish and chicken are on the way to join their red meat buddies in your local market right here on Earth.

Below we’ve collected a number of the most promising and unique companies who are hard at work attempting to 3D print meat.

Printed Meat Reaches Orbit

Aleph Farms

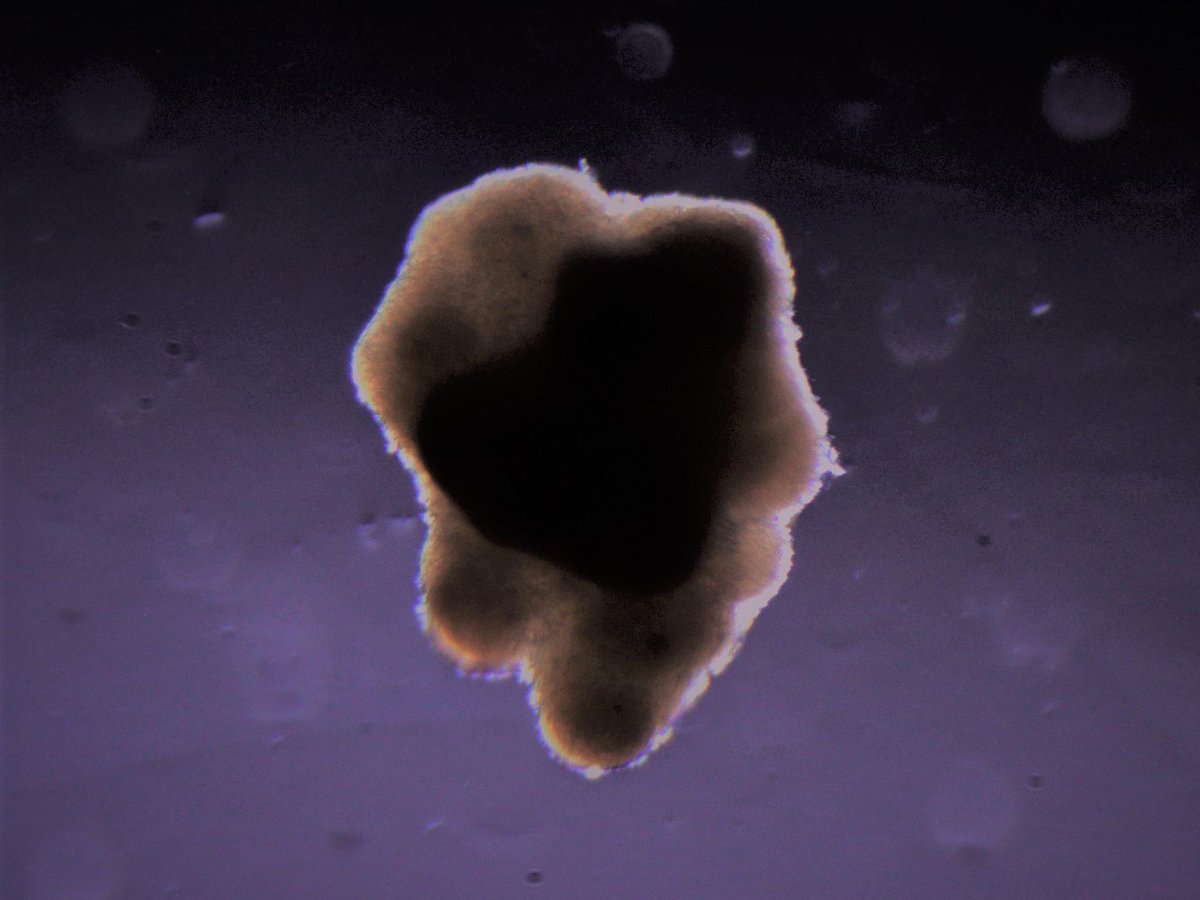

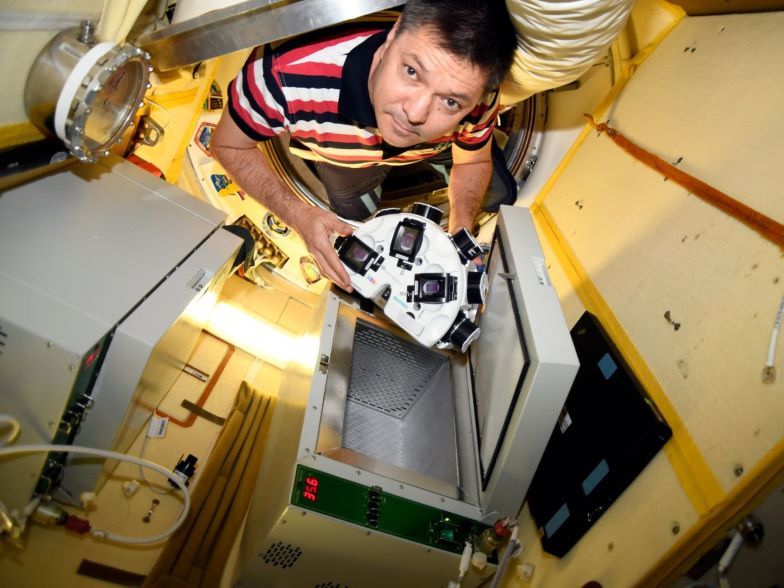

Israeli company Aleph Farms recently teamed up with American and Russian partners to stage a 3D printed meat experiment on the International Space Station (ISS). The collaborative experiment focused on the challenges and advantages of printing meat in a microgravity environment.

The process begins by extracting muscle, blood, fat, and support cells from cow tissue. A combination of hormones and nutrients encourages the cells to rapidly multiply, creating in four months what takes a couple of years in a feedlot.

Using a 3D bioprinter developed by the Russian company 3D Bioprinting Solutions, astronauts were able to culture and print Aleph Farms’ muscle tissue. It’s a small start, but such a process could be used to convert biowastes to meat on longer missions.

Solar Foods

Not to be left out, the European Space Agency teamed up with Finnish biotech Solar Foods to develop methods for culturing high-protein food for a future space mission.

The process uses hydrolysis to generate hydrogen and oxygen, which are then mixed with carbon dioxide, phosphorus, and ammonia and fed to a proprietary strain of bacteria. The resulting product is a high-protein powder with 25% carbohydrates and 10% fat. While not technically meat, it could be the first “food” grown on Mars.

Fish: BlueNalu

With companies lining up to create cattle-free beef, can fish and chicken be far behind? One California-based company, BlueNalu, is experimenting with what they call cellular aquaculture. The company has created a technology platform capable of culturing most varieties of fish without the need for genetic engineering.

Their latest proof of concept is cultured yellow amberjack, a fish in high demand yet limited in supply. If they can pull it off, the days of catch quotas and mislabeled products may be coming to an end. Right now, the limiting factor to commercial production is manufacturing sufficient “growth media”, the food supply and physical structure that encourage cultured cells to replicate.

Beef

MeaTech

MeaTech, an Israeli company, takes a different tack, starting with T-cells from an umbilical cord. The company isolates different “inks” – muscle, fat, and structure – which are then 3D printed and incubated while they grow. Like Aleph Farms, Meatech’s goal is to replicate specific cuts of meat in texture and composition.

Delft University

Delft University has taken extrusion to a new level. Their Couette-cell machine uses two nested cylinders, the outer one fixed and an inner one that spins while extruding. Spinning pulls and stretches the proteins, and the meat-like fibers that result do a decent job of simulating the texture and appearance of real meat.

Others

Mosa Meat, SavorEat, and Meatable are some of the other start-ups culturing bovine muscle cells in bioreactors. These companies extrude cellular material under pressure into something resembling ground beef for hamburgers. Unlike bioprinting, extrusion results in a less desirable mouthfeel, as the fibrous texture is lost.

Vegetarian Options

Many vegetarians may avoid meat for ethical reasons but are not especially pleased with plant-based options. This demand is encouraging the food industry to change its focus from simulated to synthesized meat.

Lab-grown meat reduces the need for water, nutrients, and farmland, making it better for our planet. Future concerns will lie with genetic engineering, feedstocks, and the risks of playing with nature. A primer on “clean meat production” explains the process and points out a few pitfalls.

Given the current challenges to culturing living meat cells in large quantities, plant-based substitutes are in the lead for now. But whether you want simulation or the real thing, the market for animal-free meat is on the move.

Novameat

Novameat, the Spanish firm we highlighted in our 3D printed steak article, wants to take things a different direction. They use a bioprinter to assemble a vegetarian filament made from peas, seaweed, and rice, with the goal of a meat-like taste and feel.

Redefine Meat

Israeli startup Redefine Meat also uses 3D printing to improve the texture and mouthfeel of vegetable-based meat substitutes. They recently bought JetEat, a similar company with plenty of bioprinting know-how.

Marfrig Global Foods

South America-based Marfrig Global Foods, a high-volume beef producer, is testing the vegetarian meat market. Their soy-based Revolution Burger will be featured by the Outback Steakhouse chain later this year, so it must be pretty good.

Scalability and the Future

One hurdle all these companies face is the scalability of their operations. Culturing meat cells is not hard, but producing billions of pounds to be consumed by a planet of carnivores is quite a challenge.

Future Meat Technologies

Future Meat Technologies may have figured out how to grow commercial quantities of cultured chicken. According to the company, the meat grown in their bioreactors creates 80% fewer greenhouse gas emissions, uses 99% less land, and only 4% of the water that conventional livestock farms need. Make enough bioreactors, and the scalability issue goes away.

Their process cultures chicken, beef, or lamb cells without a need for the structural carrier beads used by other firms. By removing the beads from the process, cell mass doubles every 24 hours. This is the real promise of printed meat: more food with less stress on the environment and nature.

(Lead image source: IEEE Spectrum)

License: The text of "3D Printed Meat: The Most Promising Projects" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.