Intro

Currently, the textile industry is the third-largest consumer of water in the world, due to the unsustainable need to continuously water cotton crops. It’s a large threat to the environment, and a solution is needed. Some believe 3D printing is the way to fix this.

Although in its infancy, the field of 3D printed fabrics has already shown a lot of potential. Even NASA has taken an interest, and researchers are getting close to bringing some 3D printed fabrics to consumers.

3D printing not only provides a solution to the environmental crises caused by the textile industry, but it has also opened many new doors for textile scientists.

Read on as we have a look at some of the most promising applications of this technology.

MIT: Soft Fabric

One of the most recent developments in the field of 3D printed fabrics comes from a group of researchers at MIT. Traditionally, one of the biggest difficulties with printing fabric has been the comfort and flexibility of the products, so they set out to fix this.

To achieve the desired texture, the researchers decided to focus primarily on structure. They modeled their fabric after the protein collagen, which has an intertwined structure that gives it both strength and flexibility.

To bring their designs to life, they experimented with many materials but ultimately found that basic TPU provided the best results.

Their designs were very effective, and they created a flexible yet strong fabric that is as “soft as skin.”

They believe their fabric could have many uses in the medical field as well as in textiles, since 3D printing enables the creation of limitless shapes and sizes. It can function as a brace, a surgical mesh, or even a cardiovascular stent (used in heart surgery).

Danit Peleg: Homemade Clothes

As her final project, student designer Danit Peleg at Shenkar College of Engineering and Design managed to design and print full outfits from FilaFlex TPE on a desktop printer.

The outfits, printed in sheets not larger than an A4 paper on hobby-grade Witbox FDM 3D printers, are completely safe to put in the dishwasher.

The designs are mostly meant only as a concept. Indeed, the see-through nature of the outfits does require one to wear fabric to cover up underneath. However, Peleg states that, in the future, she hopes to see similar designs being printed with more advanced materials to solve some of the current issues.

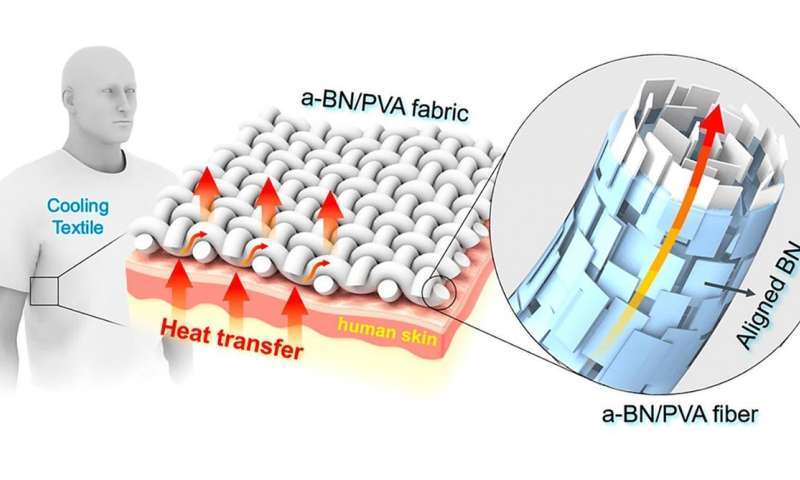

University of Maryland: Heat-Wicking Material

While many people can easily envision the fashion applications of 3D printing fabrics, they often overlook the practicality of the technology. The University of Maryland has been doing the opposite, and they now believe that they can make heat-wicking fabrics.

In particular, they have developed a fabric structure that pulls heat in one way and out the other, essentially operating as a personal, powerless air conditioner. 3D printing has allowed them to use a unique material, which is a blend of polyvinyl alcohol (PVA) and boron nitride, to maximize the thermal conductivity of the fabric.

This fabric is predicted to have a major impact on athletic wear, and it is a very real possibility that you may even own cooling clothing made out of this fabric in the near future.

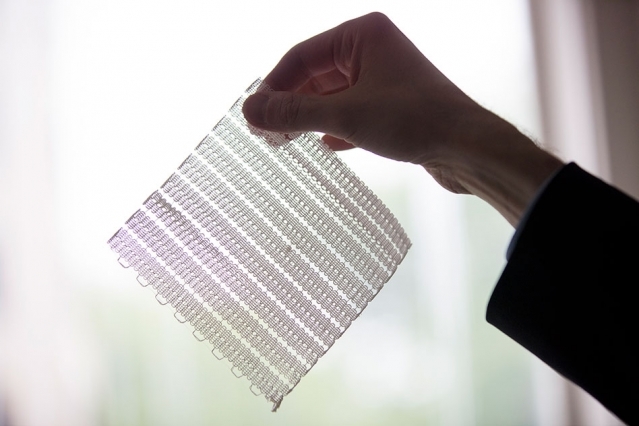

NASA: "Scale Maille"

Once again, NASA is at the forefront of an upcoming 3D printing application. This time, they’re researching 3D printed fabrics for their astronauts, as they believe that the technology will allow them to make highly insulated and protective materials.

They’re also interested in the versatility of the fabrics, as they are foldable yet strong: “We call it ‘4D printing’ because we can print both the geometry and the function of these materials.”

Their fabric is produced from a special flexible metal material, and the final product, which is printed in one piece, resembles tiled chain mail. The strength, foldability, and thermal control offered by this fabric are very unique, and NASA will surely find countless applications for it.

(Lead image source: Sculpteo)