Additive manufacturing has pushed our production capabilities far forward, enabling us to create complex 3D structures that are not possible with existing subtractive manufacturing methods. However, the two most common forms of additive manufacturing, FDM and resin printing, are not compatible with materials needed for the production of precise electronics, and so are limited to largely structural or mechanical parts.

Specialty techniques and equipment are needed for 3D printing electronics (3DPE), a field that has been rapidly growing in the past decade. Additively manufactured electronics (AMEs) enhance flexibility, improve efficiency, and promote more complex designs of electric parts. For example, components and circuits can be built into or onto the structure of a component, removing a number of steps in the process of prototyping and mass manufacture.

The technologies behind 3DPE tend to involve a process similar to SLA 3D printing, with UV-curing conductive and insulating inks in place of resin. Inks get deposited on top of existing objects to create circuits on their surface, or used on their own to make standalone circuits.

In this article, we’ll discuss what makes the most advanced companies for 3D printing electronics special and the types of systems they offer.

Nano Dimension

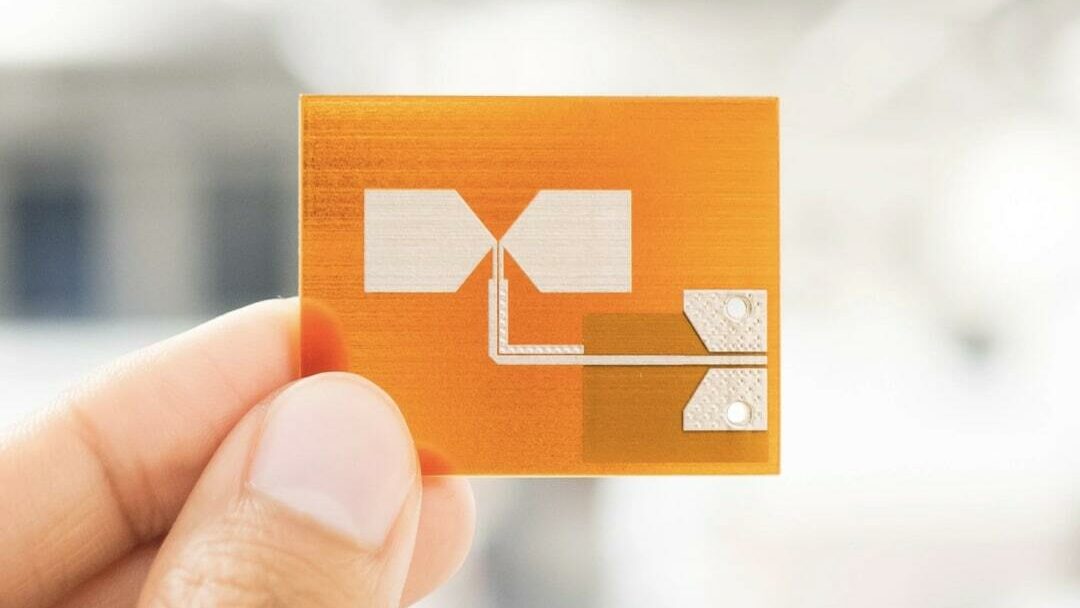

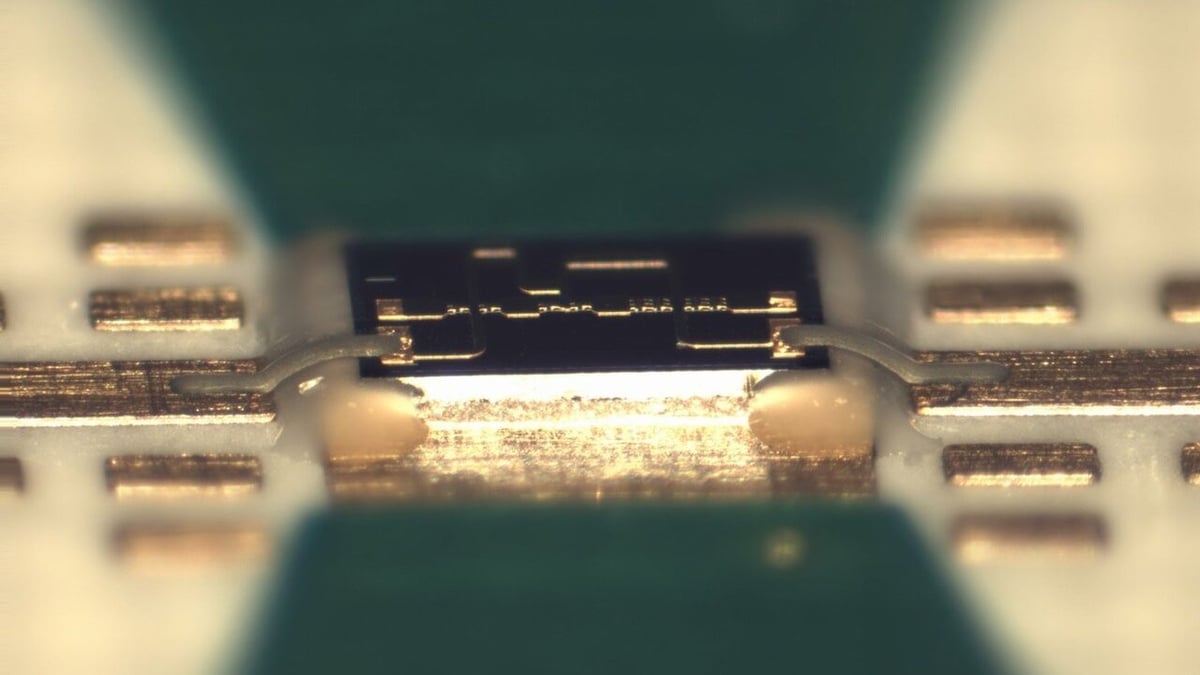

Nano Dimension is an Israel-based company specializing in high-accuracy additive manufacturing for electronics, especially in intelligent systems. Nano Dimension’s products are renowned for the significant number of layers that can be printed on their machines. Their current star product is the DragonFly IV, a printing device for electronics that can print up to 50 layers.

Nano Dimension mostly works with medium to large companies looking to design, test, and iterate quickly through prototypes when developing their products in-house, which saves lots of money and time over traditional PCB manufacturing methods like acid-etching.

Their DragonFly IV printer prints using a conductive ink that contains silver nanoparticles of 10-100 nanometres in diameter. This formulation results in less oxidation and toxicity than the copper used in acid etching. They also use a proprietary dielectric polymer that enables 18-µm resolution! Each layer is cured using strong UV lights.

Nano Dimension’s advanced technology has found its way into several impressive systems, including RF circuits to be used on the International Space Station, touch sensors in automobiles, and even a Fresnel dual frequency lens – something that Nano Dimension claims was “previously impossible” to make!

Neotech AMT

Based in Nürnberg, Germany, Neotech AMT is a tech company specializing in 3D printed electronics manufacturing systems and has been pushing the frontiers of the field since its development began in 2006.

Neotech offers three different models of printers, as well as other editions built on request. These models range from low-throughput benchtop systems ideal for rapid prototyping and research and development to high-volume, low-maintenance industrial systems designed for mass production.

While their device offers a wide range of applications, Neotech largely focuses on companies looking to incorporate 3D printed electronics into mass production. Their systems use a modular configuration to suit changing design needs. They can accommodate a variety of print heads, each of which uses a different technology to “extrude” the inks.

The use of a 5-axis motion system in all of their printers means that ink can be deposited all over contoured and 3D objects, enabling significantly more complex designs. In addition to this, Nanotech claims that they can print parts with electronics built into or covering them, opening significant room for design possibilities.

Some of Neotech’s main applications include 3D printed antennae for smartphones, heater patterns for automotive, and specialty biomedical rehabilitative technology.

IDS

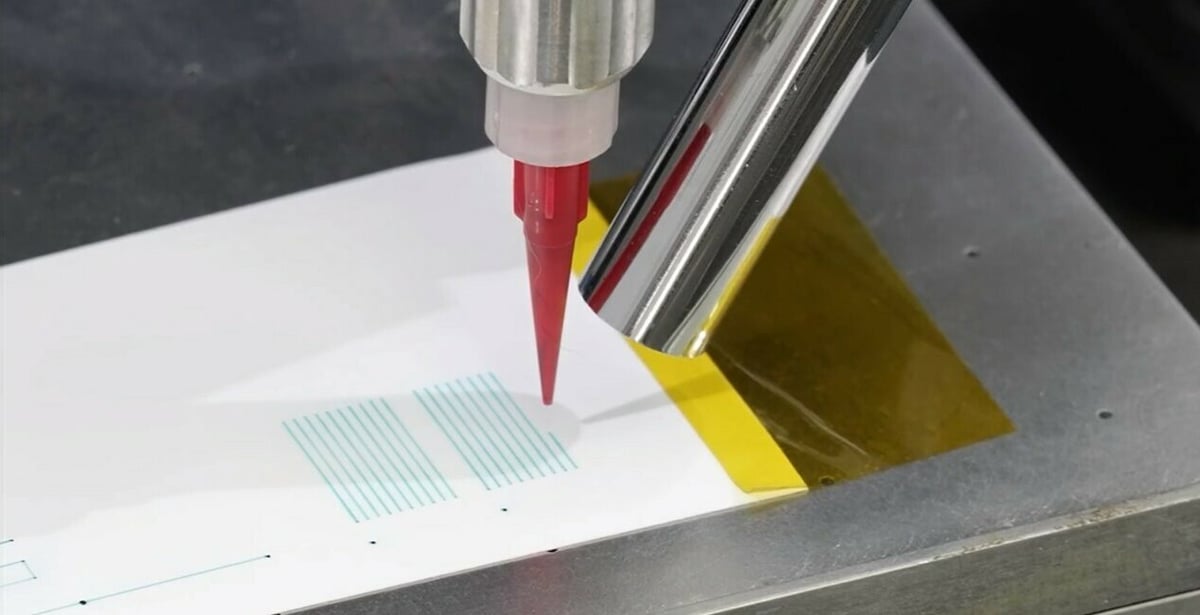

A New Mexico-based company, IDS, Inc. (Integrated Deposition Solutions) largely works in aerosol printing technology. They produce extremely high-precision machines as well as kits to add AME capabilities to existing motion systems, introducing a previously unseen level of modularity to the 3DPE landscape.

IDS claims that they use a patented “direct-write aerosol jet” printing technology, operating at print speeds of up to 50 mm/s – comparable to a lot of common 3D printers! Their technology uses an “aerodynamic lens” to focus ink droplets into a fine line with “little to no” over-spraying capable of line trace widths of 20-200 μm.

Three models of aerosol jet printers are available; the NanoJet FS and NanoJet Desktop are standalone devices in full and desktop formats, respectively. The NanoJet Subsystem can be fitted to existing motion systems to give them the same print capabilities as a standalone device.

These printers are all able to print over contoured surfaces to a limited extent ( >5mm of range from the surface), which allows for conforming electrical circuits to be printed around objects. Compatible substrates include polyimides, FR-4, glass, and silicon. The modular print head of all of their devices enables one printer to print up to two inks in parallel. Conveniently, the print head can also be mounted onto actuators including robotic arms to enable non-planar and more complex prints!

IDS’ technology has been used to produce high-density interconnects in a variety of circuits, biomedical electronics printed onto flexible substrates, and inductors used largely in wireless power transfer.

BotFactory

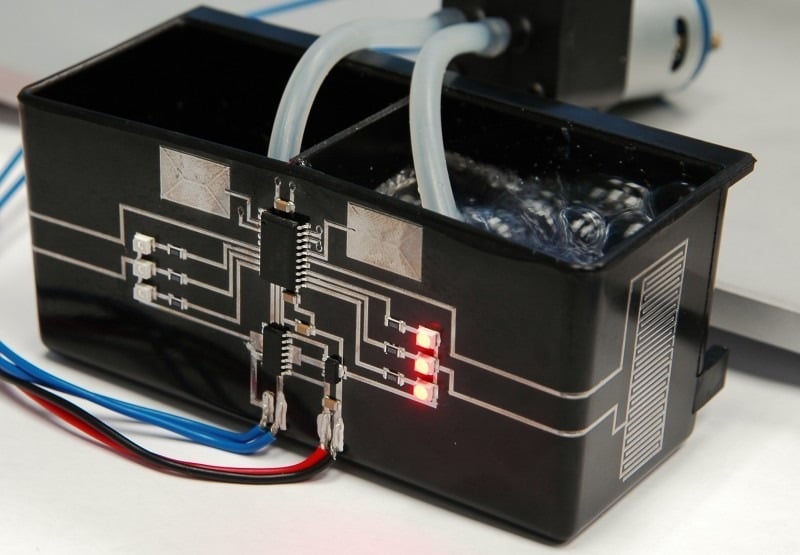

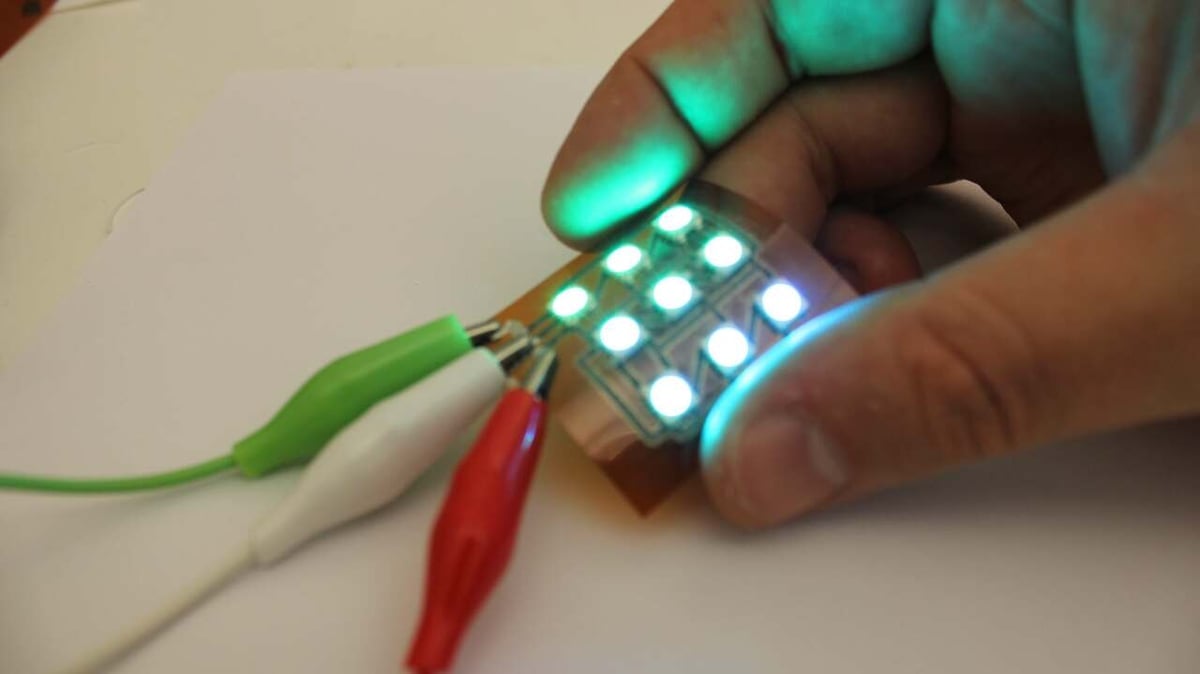

Founded in 2013, BotFactory Inc. is an NYC-based technology company that focuses on rapid prototyping tools used in electronics manufacturing. One of the standout features of their product line is how they incorporate both PCB production and pick-and-place processes into their machines, enabling faster and more efficient prototyping, a novel feature in a desktop form factor.

BotFactory’s main printing device is the BotFactory SV2, which is available in one of three different versions, including Starter, Enhanced, and Professional. The Starter and Enhanced devices are capable of printing two- and four-layer PCBs, respectively, while the Professional offers high-precision 200-micron traces and clearances that are ideal for advanced systems.

BotFactory uses conductive and insulating silver nanoparticle inks that cure with heat rather than UV light which is often used by competitors. The conductive ink can be used on either FR-4 or Kapton, whereas the insulating inks can be printed on any flat, non-porous surface.

The BotFactory SV2 printer has been used to create noncontact IR thermometers for medical use and a UV sanitizer for household items, but more can be found on their website blog.

Despite the price range of $16,000-$25,000, the SV2 can be extremely well-suited for small-scale manufacture or rapid prototyping and iteration within research due to its desktop form factor and accessibility.

Optomec

Another New Mexico-based company, Optomec primarily serves as a supplier of digital systems, spanning metal and electronics additive manufacturing technologies.

They largely provide industrial solutions for AMEs with one of their three models of electronics 3D printers. All their devices use aerosol jet technology, designed in collaboration with DARPA. This technology can be used to print either 2D or 3D designs by atomizing the inks and focusing the droplets onto a substrate using a “sheathing gas”, which can be nitrogen or compressed air.

Optomec claims that their aerosol jet technology is very versatile, being able to print bio-materials onto plastics, ceramics, and metal structures with traces of 100 nm down to 10s of microns in width! Optomec printers are also able to print basic components, including resistors, capacitors, antennas, sensors, and thin film transistors.

Some fascinating applications of their AME technologies include solar and fuel cells, high-frequency RF interconnects, and minimal touchscreen displays!

License: The text of "3D Printed Electronics: The Most Advanced Companies" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.