3D printing as a manufacturing method has been around for nearly 40 years. Most will be familiar with how it’s been applied to consumer items like figurines, vases, and gadgets as well as professional items like prosthetics, medical devices, and car parts.

Yet, for almost a decade now, 3D printing has also been applied to large, permanent structures, such as bridges, shelters, houses, and offices. The ability to print a building has huge potential to revolutionize the construction industry and bring rapidly built and affordable housing to the millions in need.

But how do you print a house? In this article, we’ll look at the various techniques, machinery, and materials that can be used.

Background: Materials

Tightly bound to house-printing techniques are the materials they use. Naturally, there are many different options, and each has its pros and cons. Some of the main types include the following:

- Concrete

- Mortar

- Plastic

- Locally sourced materials

- Sand

- Metal

It’s important to note that not all methods and materials are well suited to every environment. This has to do with climate but also cost and accessibility, where both of the latter are especially important considerations in the more economically diverse parts of the world (where safe and reliable housing is often most needed).

Concrete Deposition

Concrete deposition is the most popular technique currently used to 3D print buildings, as the structural integrity of the material has been well established.

The method is fairly similar to how desktop FDM printers and CNC machines work. That is, in the most common case, a frame and rails are arranged to support a printhead and allow it to move. Within the limits of the rails, the arm builds the structure layer by layer by extruding concrete material from the nozzle. There’s also the option to do the same with a robotic arm, such as that employed by Apis Cor.

Around the world, there are now many buildings and other structures that were made using this method. One notable example is the Netherlands house in Eindhoven, Project Milestone. There, a full-size printer was used to produce a one-piece building on site. Meanwhile, in Chennai, a company called Tvasta was able to produce India’s first-ever 3D printed house at the IIT Madras campus.

Sand Forming

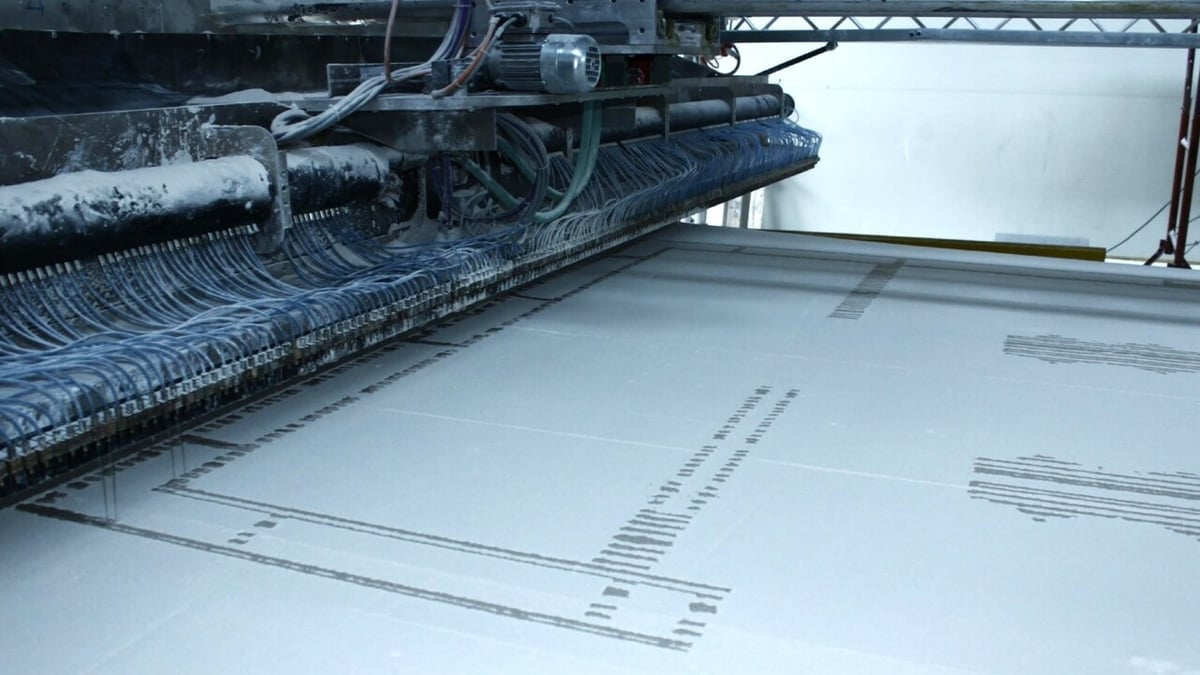

This process was originally developed in Italy and entails depositing sand in very fine layers, each of which is jetted with a binding agent to make solid. This same technique has been widely used to make smaller parts but is now a recognized technique for building larger structures. The process is more labor intensive and time consuming than concrete deposition, but it can be of benefit in hotter, drier countries.

D Shape’s UnaCasaTuttaDiUnPezzo is in fact claimed to be the world’s first “one-shot” printed house. Unlike many 3D printed concrete buildings, this structure was printed and then transported to its final location atop a hill on the property of the architect, Marco Ferreri.

The theory has since been born out with the beautifully made dwellings at Kisawa Sanctuary, Mozambique. The main bodies of these buildings were made using sand forming, and as a result, the structures are both cool during the day and warm at night.

Plastic Deposition

Plastics or plastic derivatives are very familiar to the average 3D printing enthusiast. Most will have used one of PLA, ABS, TPU, or PETG to produce models of their own. What if you could print an entire full-scale house or outbuilding using only plastics? Well, that’s actually possible now using large-scale 3D printers that operate on the same principles as standard home 3D printers. Of course, not all types of plastic filament are suitable to print a building that’s placed outside and exposed to the elements.

One of the main advantages of printing structures using plastic is that it’s easier to print parts off-site before transporting them to and assembling them at their final destination. There are emerging companies that can, in the space of 24 hours, print an entire building in a factory before delivering and installing it at the desired property within the same time frame.

One such company is Azure Printed Homes, which uses recycled plastics and waste materials to print both small houses and outdoor home offices. In a similar vein, the Urban Cabin project from House of Dus used bio-based materials to produce small, self-contained shelters. The idea was to place them in former industrial areas where redevelopment of green spaces is key. They provide quiet spaces for anyone visiting the area to enjoy the tranquil surroundings.

Recycled Waste Deposition

From the 3D printing of plastic structures, we can see that the use of alternative materials is at the forefront of the 3D printing construction scene. And as it turns out, the idea extends beyond plastics.

Waste materials aren’t limited to recyclable plastics: Metals, paper products, and biowaste are additional candidates. These options may not spring to mind when one thinks of building a house, but innovators are challenging norms in order to address multiple crises and solve the question of accessible material.

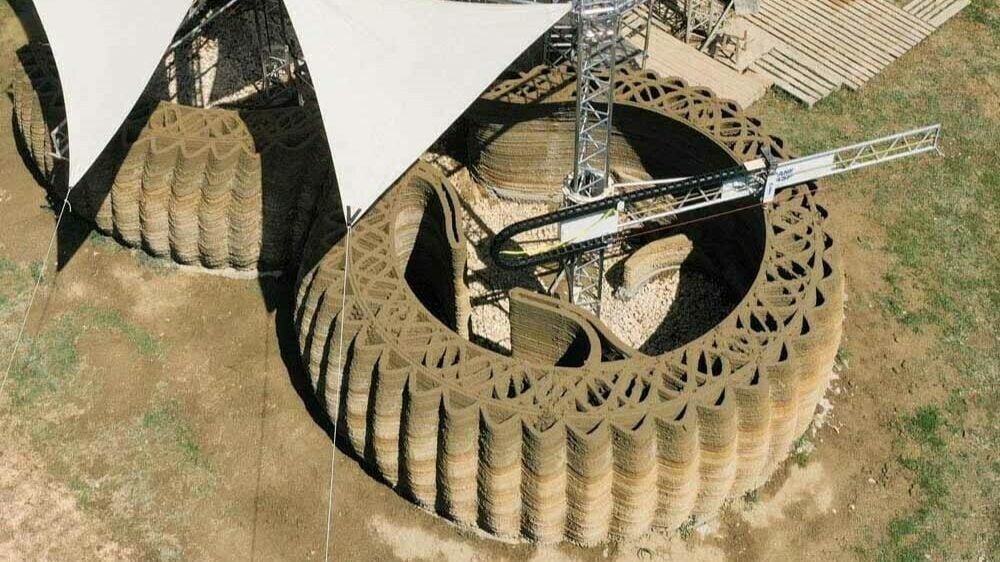

For example, WASP’s Gaia House made heavy use of rice waste. In particular, the organization used a combination of 25% raw earth, 40% straw chopped rice, 25% rice husks, and 10% hydraulic lime. As you likely guessed, the materials were locally sourced and some were even found on the building site itself. WASP prints its houses using its own Crane printer, which is a large deposition printing machine designed to be used on-site and complete construction within days.

Earth/Clay Deposition

We’ve already mentioned the use of earth in the construction of WASP’s rice waste buildings, but there are other examples of projects that capitalize on using earth or similar materials.

The main advantage of 3D printing houses using earth, mud, or clay is that the resources are plentiful. Building costs and timescales heavily depend on buying and shipping materials, so it makes sense to use the what’s right under your feet!

A good example of this is WASP’s TECLA project habitats, which again uses its Crane WASP to print layer upon layer using locally sourced soil. The Crane has a maximum building area of 50 square meters, making it possible to construct a large building in a matter of days.

Other Methods

Innovation is key in the design and construction of 3D printed houses, and as we’ve now seen, there are many different ways to approach the task. So far, we’ve covered the main ones, but there are a few notable projects that don’t quite fit the above categories.

One example is the Yhnova House in Nantes, France. Essentially, each wall consists of a polyurethane shell with concrete poured in between. The shell was printed using a robotic arm, which was guided around the building’s foundation by a laser sensor that makes use of a digital mockup of the house. The Yhnova House holds claim to being Europe’s first inhabited 3D printed house, which is a title not to be sniffed at!

Other innovative examples include Mighty Building’s range of buildings, including the House Quatro, the Super Quatro, and the Two Story. All were made using factory-printed composite stone panels, which are machine finished and treated before being assembled on-site. Their self-developed Light Stone Material cures into a stone-like composite when exposed to UV light, and each layer is reinforced with glass fiber, ensuring every wall, floor, and ceiling contributes to a robust structure.

Honorable Mention: Metal Forming

Although it hasn’t been used in the construction of houses, another 3D printing method that has potential in the construction industry is metal forming. To date, it’s most impressive achievement has been a bridge spanning a canal in Amsterdam. Have a look at the work being done by MX3D, which shows some of the innovative structures made using this method.

This method combines a robotic arm and a welder to form a framework. In the scope of building a 3D house, this method isn’t an all-in-one solution, as it would only form a skeleton, but it’s absolutely a time- and labor-saving method.

License: The text of "The 5 Best Ways to 3D Print a House" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.