ZMorph already has a solid reputation for its versatile 3D printers; we had a decent experience with the ZMorph SX not so long ago. The Polish company’s point of distinction is being able to offer multiple fabrication methods within the one desktop machine. And thanks to its modular design of detachable heads, a ZMorph machine can work with dozens of available fabrication materials — more than enough to satisfy even the most demanding professional designers, engineers, and educators.

The next generation model, the ZMorph VX, boasts of advanced solutions in print quality and machine reliability. The company promises that the machine is easier to set up and operate than ever before, and, while we’re inclined to agree, the process is not without its small wrinkles.

We recently got our hands on the keys to a full ZMorph VX setup, including single and dual extrusion, laser pro, CNC Pro, and thick paste extruder tool heads. Naturally, we’re a 3D printing first kind of publication, but read on for our full takeaway of the complete functionality of this hydra of a machine.

Verdict

Pros

- Stellar build quality and rigidity

- Voxelizer 2 software harmonizes different production techniques well

- Idiot proof tool changing

- Super (if tricky to get right) print quality

Cons

- Voxeliser 2 software frequently trips

- Dual Pro head can be prone to clogging

- Supporting user manuals/documentation need work

- Included CNC material holdings are terrible

ZMorph’s VX is a beast of a machine in more ways than one. Not only is it solid as a rock with a reinforced motion system and error-prevention measures, but it handles dual extrusion 3D printing, features fast and powerful laser cutting and engraving, and is capable of versatile CNC cutting, all unified within a slick (if occasionally buggy) software experience.

Design

One of few multitool 3D printing systems out there, the ZMorph VX builds on a legacy of modular multi-function machines that began back in 2012 as a fork of the Prusa Mendel RepRap 3D printer design.

Keeping the squat aluminum frame, trapezoid shape, and distinctive swappable tool heads of its predecessors, the ZMorph one-machine flagship exists today as the VX; a highly polished system that is available either as a dedicated 3D printer, a complete all-in-one solution, or something in-between.

For this review, ZMorph kindly furnished All3DP with the complete set, which includes both the single and dual extrusion print head, plus CNC Pro, Laser Pro, and Thick Paste Extruder tools.

The full set, as reviewed here will set you back approximately $4,400. Alternatively, a 3D printing only setup is available for some $2,800, which includes only a single extrusion tool head.

Despite the plethora of add-ons, the VX arrives all snugly packaged in a cardboard box, with all tool heads, standard tools (which are not needed for setup), safety accessories, tool head accessories and sundry other items that would be dull to list completely here. Suffice to say you get all that and the kitchen sink with the VX, which certainly, on first impressions alone, establishes the machine as a professional unit that means business.

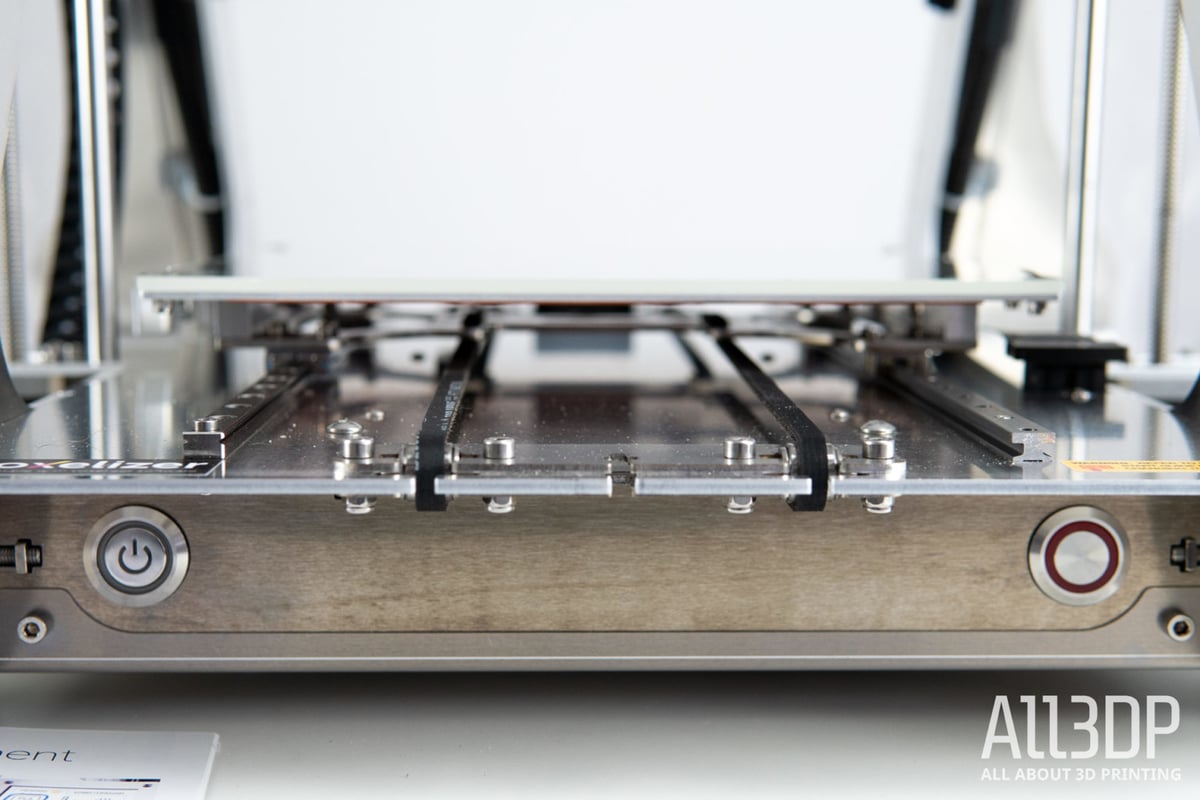

Sticking to its Prusa Mendel origin, the VX looks much like the ZMorph machines past. Here heavy duty aluminum plates provide insane rigidity, with a reinforced Cartesian XZ-head motion system that doubles up with dual glass-fiber reinforced belts.

Such rigidity is expected, given the machine’s design to be able to drag a CNC cutting tool through solid blocks of wood. Indeed, this stability is even more necessary for the 3D printing aspect of the machine, since there is no way to mechanically level the bed. The system auto-calibrates to give a level, and the bed stays put, no matter what.

Such care for rigidity continues in the very nuts and bolts of the machine, with copious amounts of Nyloc nuts securing bits to other bits in the face of the tremendous vibrations that occur throughout its various modes. Unflinching.

For various swappable and removable elements, the VX makes use of strategically placed magnets that make it idiot proof when setting up for the machine’s modes and configurations. The plastic enclosure is an excellent example of this simplicity, holding itself open via magnets and snapping shut when closed. So simple in design, but flawless in execution.

Nods to the VX’s origins in the RepRap project thread throughout the machine as 3D printed parts. The 3D printing tool heads feature many printed pieces, as do the two removable enclosures plus myriad other cable tidying clips, shrouds, and other non-essential knick-knacks within the machine.

Switching between 3D printing and CNC modes is a cinch, with a single ribbon cable the only critical connection needed to detach the heated bed. A single clamp is all that’s required to secure both the print bed or aluminum CNC plate in place, with, once again, strong magnets snapping them into position.

Fundamentally, the VX demonstrates a heritage of function driven design that manages to marry the mechanical requirements of 3D printing and other CNC functions well.

3D Printing

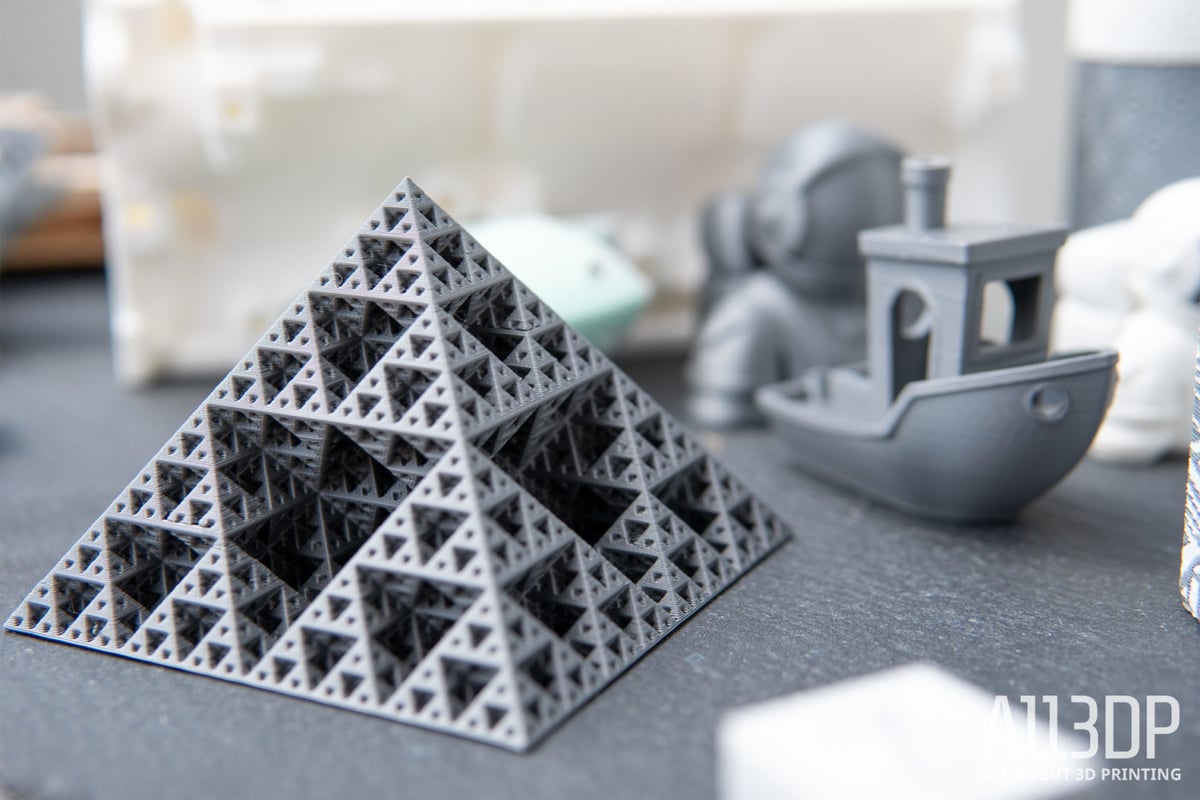

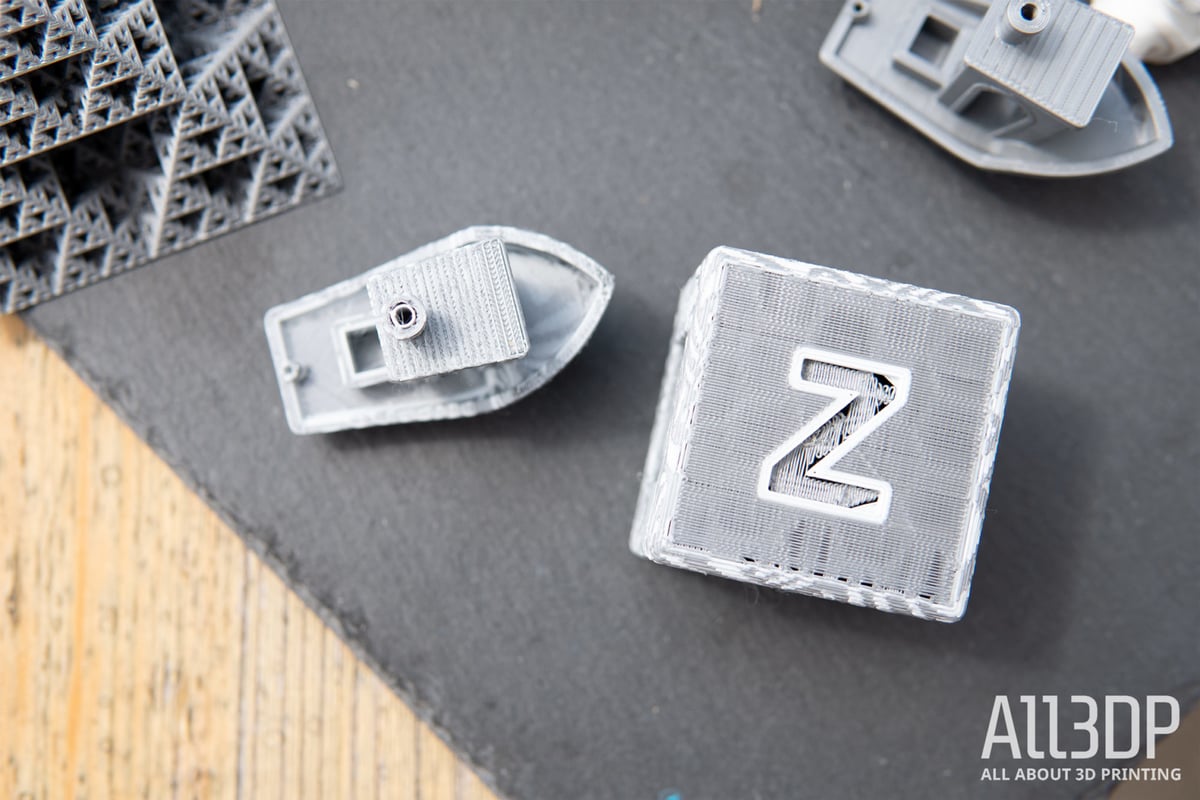

Our experience printing with the VX has been mostly positive. The sample prints provided with the machine are, as one would expect, flawless.

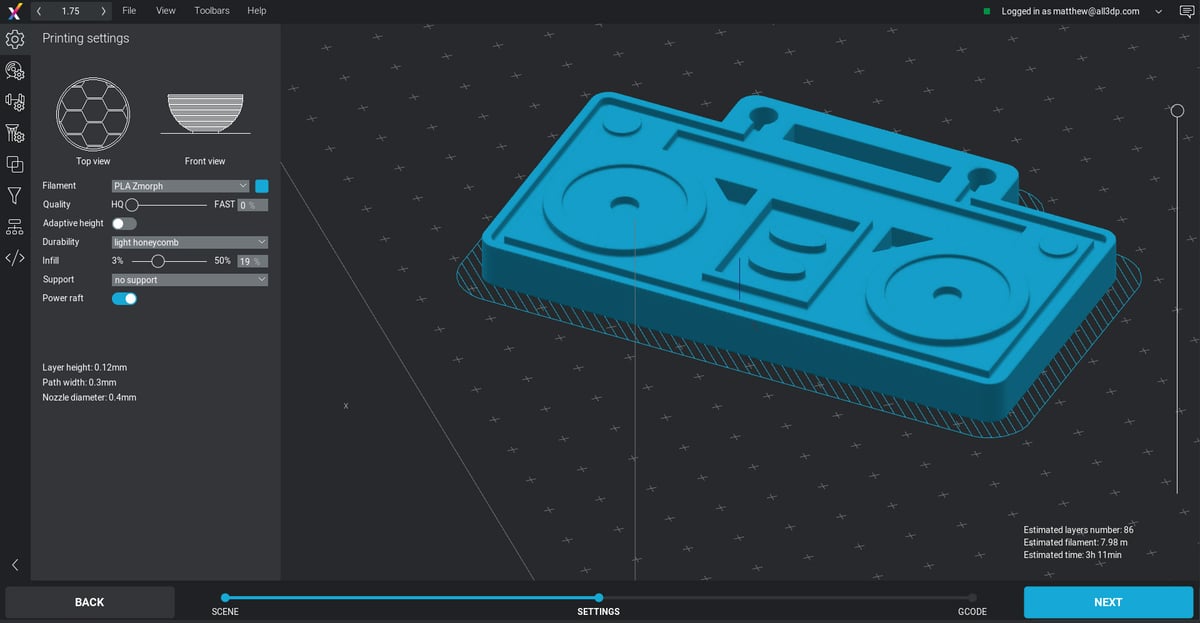

Jumping over to your own prints and using Voxeliser’s standard settings and pre-prepared material profiles, while excellent for the ease with which you can begin printing, leave a little room for improvement.

You get broadly fine prints using this middle-of-the-road configuration, albeit with unpleasant quirks such as poorly finished top layers and visible blobs from layer changes.

You could argue such things are within tolerance for a configuration for the bare ‘middle,’ but the knowledge that on other similarly priced machines (or even cheaper printers, scaling down the price to equate with single function 3D printers), you get overall better prints from similar default settings.

When printing well though, curves and transitions out of them are the smoothest we’ve seen. Curves to die for, for sure. Tuning and, using the slider, turning the print quality up to the proverbial “11” improves prints across the board, albeit with a cost in the time it takes to print.

ZMorph’s Voxeliser software features material profile management, allowing you to personalize the experience to the filaments you use. Physically speaking, switching between filaments is typical of any 3D printer. Use the printer’s UI to heat the nozzle, back the filament up and out of the hot end, and insert the new material. Simple.

Due to the heavy-duty build of the VX, the heated glass bed does not rest on spring tensioned screws or other similarly movable components. This means it’s physically impossible to level the bed manually. Instead, the VX comes with a few different firmware-led options, including an automatic three-point level whereby the nozzle probes the bed surface to determine each zone’s offset. This results in a level that’s suitable for most day to day printing with the likes of PLA, ABS, and co.

Alternatively, you can manually set the offset yourself for each of the three points using the VX’s responsive touchscreen and simple UI.

Dual Extrusion

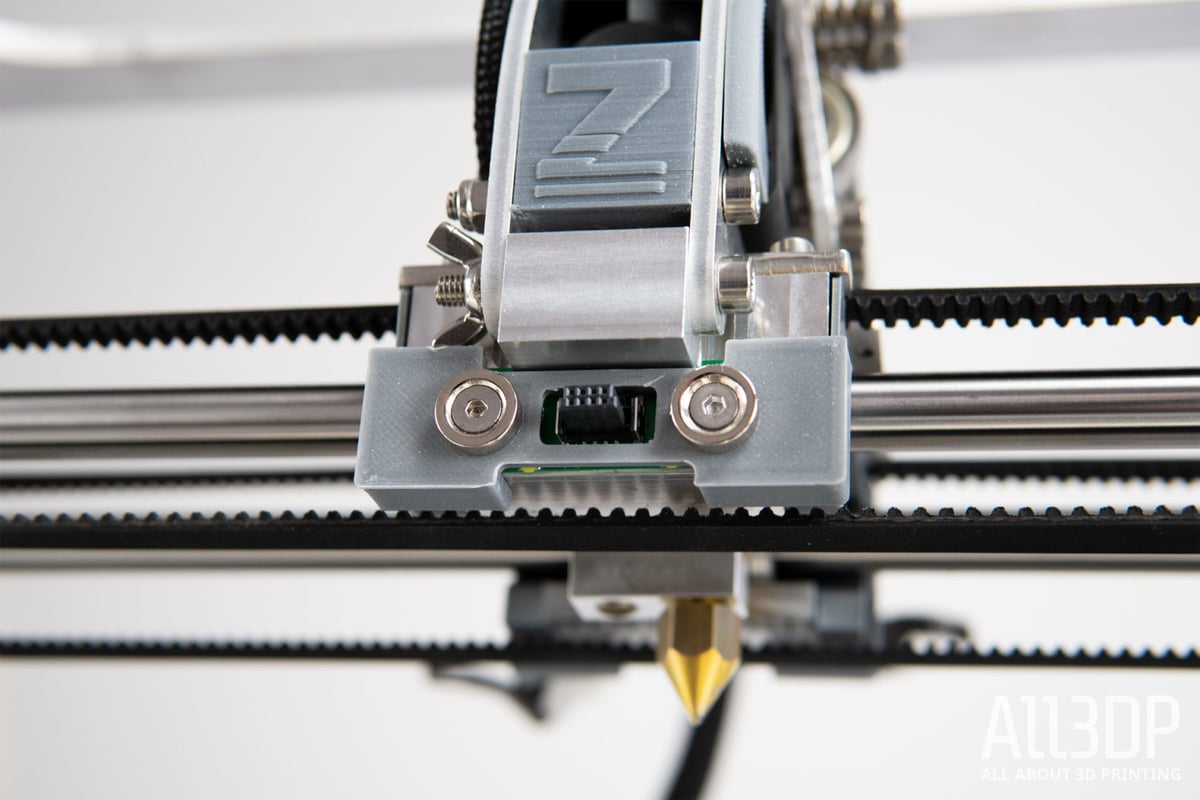

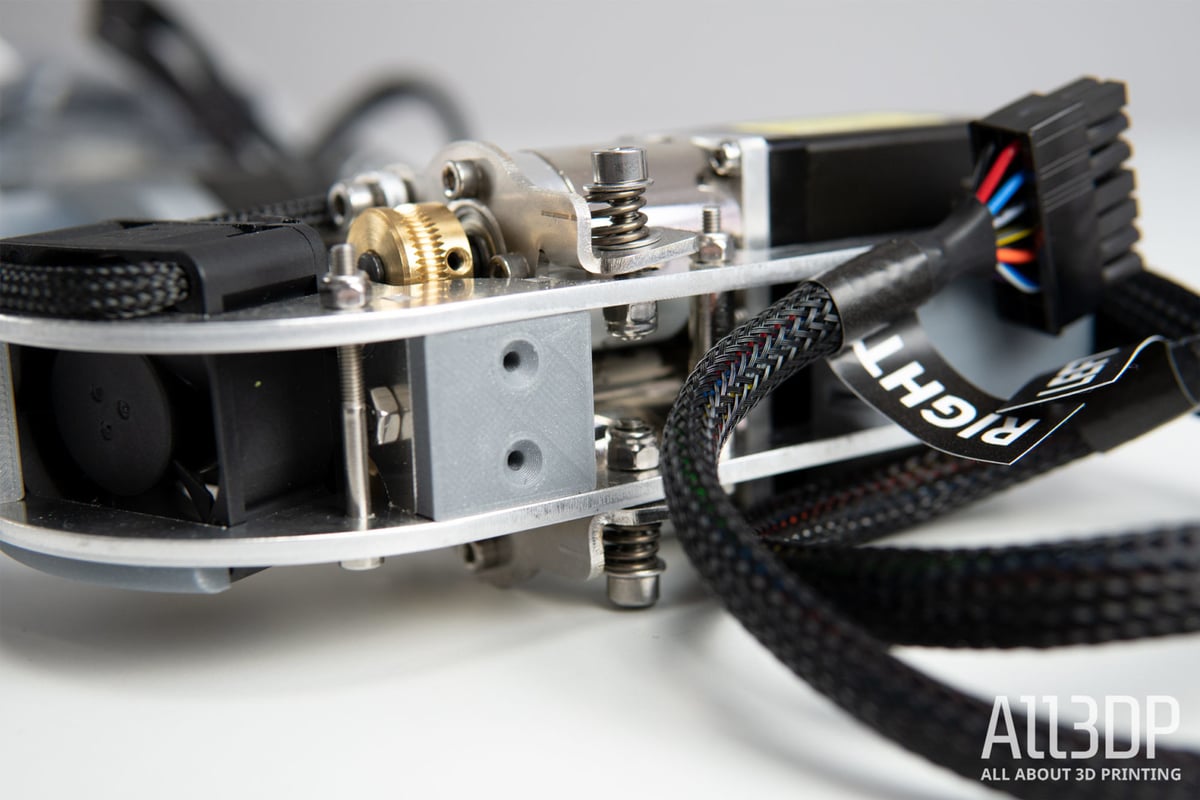

Switching from the Single to Dual Pro extruder is a smooth process; a simple case of unplugging a couple of easily accessible cables, loosening one bolt and then sliding the tool head out of its mounting.

Repeat this process in reverse to attach the new tool head, and you’re ready to print again. It’s a trivial matter of seconds, exemplifying the VX’s versatility as a multi-tool solution.

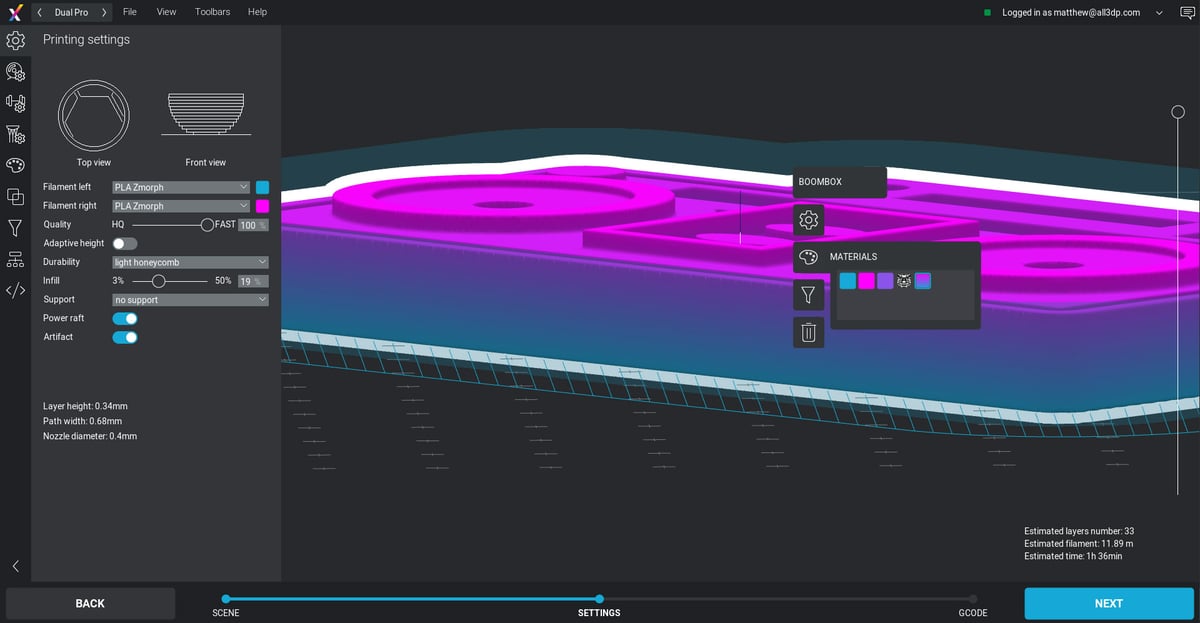

The Dual Pro tool head is ZMorph’s answer to multi-tone printing, allowing you to print two filaments binarily, or, crucially, with a mixture of the two. This allows for a plethora of different print effects powered by the filters provided in the Voxeliser software — including the ability to have a gradual gradient transition between the two colors or apply dual extrusion to ordinarily mono-material prints using texture mapping and an image of your choice.

In practice the Dual Pro functions well, resulting in tidy dual extrusion prints that hide the fact that both colors extrude through the same nozzle. You can expect clean separation between tones. Unfortunately, the wasteful purge tower that’s common in dual extrusion printing features here too, in the form of a separate shell that entombs your print.

We found it a semi-frequent occurrence that one of the extruders of the Dual Pro will clog and subsequently strip the filament, necessitating you open it up for a little TLC. The print results can be excellent, but we often found print anxiety setting in.

In the interest of full disclosure, we did encounter a significant issue early on in our printing with the Dual PRO, with severe layer shift and frequent clogging ruining the vast majority of prints. After consultation with ZMorph, the issue was pinpointed to our review unit shipping with the wrong Encoder for its Closed Loop system.

Which makes sense. The VX features a Closed Loop system on its steppers. In addition to eliminating the need for end stops, a Closed Loop system in essence checks that and detects when the tool head positioning goes out of whack from the steppers alone.

We were courteously shipped a replacement encoder with instructions for its replacement, and a fresh Dual PRO tool head for good measure. Be sure to reach out to ZMorph for a speedy resolution, should you experience similar issues.

Laser Engraving/Cutting

Swapping the 3D print build plate for CNC is even easier than changing tool heads, which is already the easiest of tasks. Strong, strategically placed magnets guide the plate into position and eliminate the possibility of misalignment — another example of ZMorph’s mature and well thought out design, emphasizing ease of use.

The Laser PRO tool head provided with the VX is a 2.8W class 4 laser product – the kind that can permanently damage your retinas, even indirectly. As such, we advise caution when using the function. The protective housing for the VX does not block UV light, so warn your neighbors, kick the cat out.. and so on.

A canny pair of orange Eagle protective glasses ship with the VX, and a metal shroud encloses the majority of the path of the laser when you have the Z-origin set properly. These go a long way to minimizing exposure to the laser, but even so we’d still not take any chances around it. Isolate the machine from wandering eyes when in use.

The documentation provided with the VX explains well the positioning of the laser in the Z-axis, allowing you to crack on with engraving and cutting in no time.

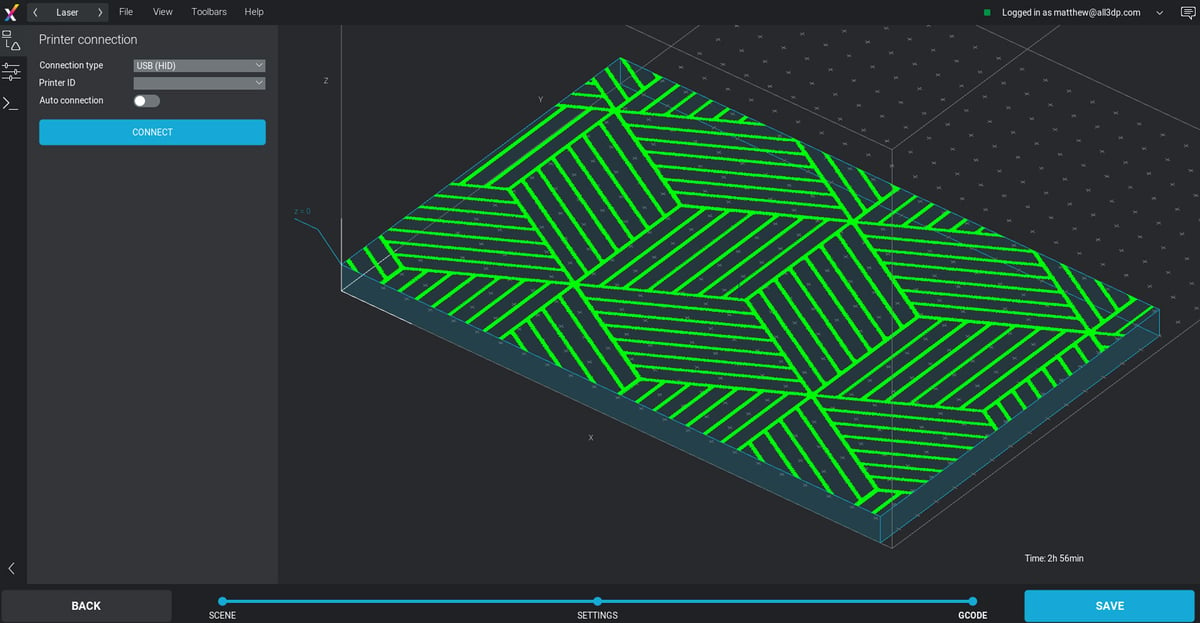

Of all of the VX’s functions, the Laser Pro requires the least amount of setup. Resulting engravings and cuts show crisp lines and no artifacts from the laser’s motion.

Besides positioning over your engraving or cutting medium, there’s little else to configure or set up on the machine. All of the heavy work here is conducted inside Voxeliser.

Voxeliser does a great job of letting you set up complex tasks utilizing different layers and processes, and is accepting of a variety of image file types. Experimentation with different materials proves simple enough thanks to the ability to configure repeat passes and – on the machine itself only – laser power and working speed.

One minor complaint — which puts into perspective how pleasantly effective and simple laser engraving with the VX — is that some of the default parameters are tailored to CNC cutting; tool head Z-hop being one example. Completely unnecessary for lasering, and a setting that, if left unchecked dramatically increases the time needed to complete large jobs. This is easily corrected, and you can even swing the balance the other way by amping the travel speed to whip the laser between paths with abandon (the tool head is rather light, and with the material well secured you shouldn’t experience any misalignment or movement-related artifacts.)

Naturally, the CNC and laser sections are, to some extent mirror images of one another with basic settings changed, but the shared sections like this could have been simplified to make the experience a cleaner one.

In addition, placing materials on the CNC plate and setting the correct origin for the laser (and CNC bit for that matter) is a bit of a crapshoot, with no preview mode or markings on the table to help you align things, this can make squaring jobs correctly or running to the edges of materials a little tricky to set up.

Voxelizer features a basic design creation tool for lasering. It could be great and serve as a powerful design tool for quick and dirty (and complex) laser cutting jobs. But as it is, it’s only capable of individual objects such as text and primitives. A merge function would make it properly useful.

CNC Engraving & Cutting

The CNC function of the ZMorph VX is, at its core, competent and useful. The provided ER-11 collet and adapters offer compatibility with a wide variety of drill and carving bits, and the Voxeliser software comes loaded with profiles for V-shape carving and several flat-head bits. With the basics provided in-box, you can quickly start cutting with little time investment.

Configuring new profiles is a simple process that blends seamlessly in the job preparation workflow Voxeliser offers. XXX mm bits are also compatible using the provided adapter.

The spindle speed is adjustable in 25% increments — an arguably inflexible arrangement that we struggle to see translating well when configuring jobs to the requirements of a given material. For our testing, we left things at 100% and encountered no noticeable issues carving through a variety of wood feedstock.

The aluminum material plate is fringed with threads for M4 screws and grooves for square nuts to fix material holdings in place. ZMorph provides a pair of plastic material fixings that we found to be too inflexible in their positioning and needlessly tricky to position tightly around the wood. It became a tedious process fighting these fixings in order to prevent our material from wiggling loose on the plate.

These basic clamps are the only ones mentioned in ZMorph’s documentation and online training courses, so the logic follows that they should suit the materials the company provides for you to get acquainted carving. Not so.

It was only after several messy and destructive attempts to carve large blocks of wood fixed (or rather, not fixed) in place with the plastic clamps that we realized ZMorph provides additional files on the VX’s internal memory for you to 3D print yourself. A little heads up would have been appreciated. That or, just include them in the box. The trouble was taken to print out the most basic and irritating to use clamps, so why not improve the user’s experience with a couple of better throwaways in the box.

We imagine experienced CNCers will quickly shed these peripherals in favor of their preferred fixings. Beginners taking on CNC for the first time should spend some time researching, and find alternatives.

CNC cutting and carving are versatile functions on the VX, with the Voxelizer software offering a number of options for how exactly the bit will attack your material. Such options can stack up, too, with multiple processes a possibility within the same cutting job. For example, you could carve an intricate pattern onto a board, and then cut shapes out of said prettified board, resulting in final products requiring only the slightest of finishing to be good enough for end use.

Though we have yet to try it (and are unlikely to do so), the VX is capable of PCB, and even light aluminum work.

Thick Paste/Ceramic

We can’t help but think of the ZMorph VX’s Thick Paste extrusion tool head as the ugly duckling of the family. It’s undoubtedly the least advertised feature of the machine, and in some cases, we’ve even seen it omitted from the company’s documentation for the VX.

In essence, this tool head is a large syringe with a stepper motor driving a plunger through its core. It’s not particularly sophisticated, but it does the trick.

In use, the Thick Paste extruder performs as one might expect. The key is to use homogenous paste; otherwise, the nozzle will clog to the point of stepper skipping steps, or explosively clearing itself and ruining the job. Even viscous liquids (we pushed things with marzipan) require a delicate touch with dramatically lowered print speeds to accommodate, otherwise the stepper struggles and stalls.

One unfortunate and perhaps missed trick of the Thick Paste extruder is its limited Z-height. The tallest of all of the VX’s tool heads, you are left with very little room to print up, something that limits you to flat ceramics, or, perhaps the more likely intended usage, small edibles.

Turning your hand to the edibles poses a greater challenge, with hygiene and temperature two new elements to manage. Melted chocolate is messy, needs tempering, cools quickly, and generally — in our opinion, betrays the investment of some $4,000 for a machine such as the VX.

Creating jobs for the Thick Paste extruder is much like using the Laser PRO, albeit simplified. Limited to 2D files (SVG, JPG, PN and a couple of others), you can either upload simple graphics or, as with the laser workflow, generate simple text and shapes inside the software itself. Some degree of finer control is given over the extrusion, but experimentation is necessary since every fluid you throw in will be different from the last, thanks to varying temperatures or changes in the liquid itself.

So. Yeah. It works, which is about as much as you can say for it. Cool as the Thick Paste extruder is, we would be surprised to see ZMorph support or expand this, other than bare compatibility, in the future.

Software

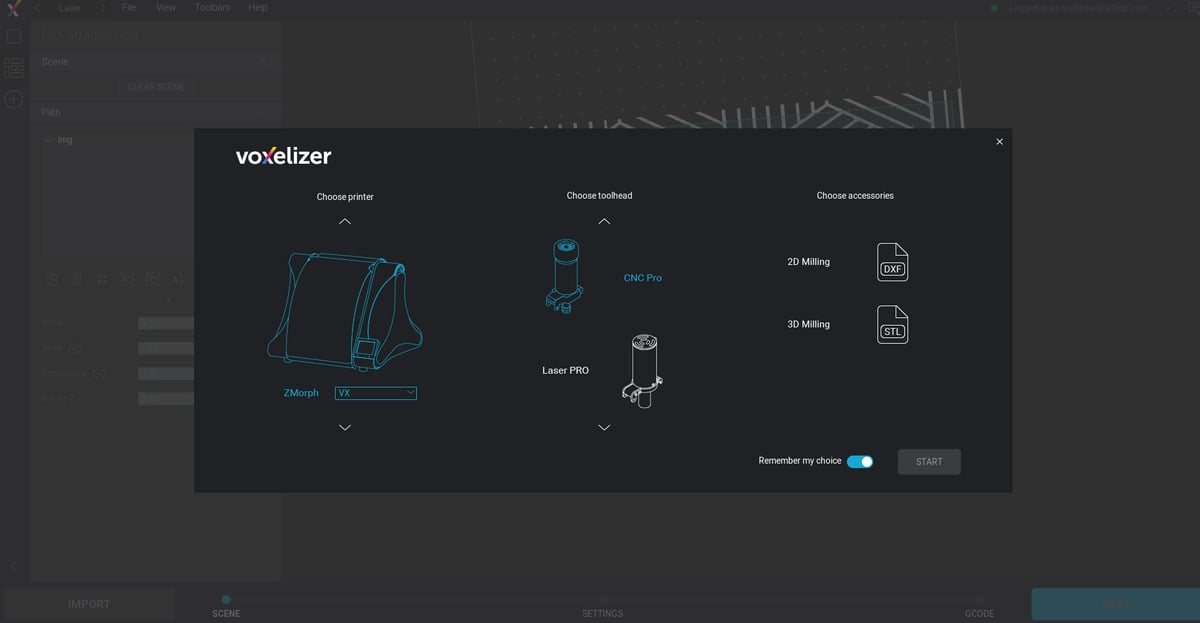

A deep dive on ZMorph VX would be nothing without an in-depth look at Voxeliser, ZMorph’s other product offering. Available independently for use with third-party 3D printers, a license for Voxeliser is included with every new VX machine.

Currently in its second iteration (so really, it’s Voxeliser 2.0), it is here that you can begin to understand one of the main things differentiating the ZMorph’s offering from other 3D printers. As the name suggests, it’s got something to do with voxels.

Where other slicing software takes a 3D model, and then in one step slices it into layer-specific tool paths and instructions, Voxeliser instead introduces an intermediate step; voxelization. Transmogrifying the 3D model into an equivalent representation comprised of voxels — think of them as three-dimensional pixels — this step allows Voxeliser to nondestructively apply filters and modifiers to your model.

Some are useful, such as thickening, slimming, smoothing and close holes filters. Others, such as surface embossing, are less so. You get the feeling that many of the options have been stuffed in to give the appearance of purpose and justification for the voxelization process, when, really, there are few cases where it provides the VX an advantage over dedicated design software.

Another neat trick up Voxelizer’s sleeve is tied to the Dual Pro too head, which lets you texture map images or gradients onto your model for 3D printing. Effectively allowing for dual extrusion on a single 3D model, you can ‘wrap’ an image around your object and configure the materials (and combinations thereof) to print it. Such a mode could be used to stamp out a company logo onto swag or, say, apply dazzle camouflage on a Benchy.

As such, the benefits of voxelization are clear. But they also come with some caveats.

For instance, the physical size of the voxels themselves has a default, which you can choose to change. The default value, at 0.16 mm sounds fine enough but can lead to Voxelizer ignoring small features in the model — especially negative space.

It took some head scratching for us to connect the dots when our attempts to print the Kickstarter Autodesk test ignored the removable pins and filled the entire area with infill. The conclusion from our experience there is to check you have an appropriate voxel size for the features you’re attempting to print.

Stepping back from the voxel aspect of the software — which is mostly related to 3D printing — Voxelizer does a rather good job at unifying the workflow of all of its functions. With one of the VX’s myriad tool heads chosen, you enter the corresponding workflow, with model import leading to voxelization leading to G-code generation. There is a consistency to it that gives a pleasing flow to the program, no matter your work.

A slick UI with helpful popup tooltips leave you in little doubt about what each setting does, and it’s nice to see a dark color scheme as default.

We’re not sure we’d start using Voxelizer as our daily driver for 3D printing on other machines, but as an all-in-one solution that lets you set up and achieve tasks across four different functions (we’re lumping single and dual extrusion together here), it’s up to the task.

Is It Worth It?

ZMorph’s machines have been a long-standing fixture in the all-in-one category, with the Polish company specializing early and honing their craft across several generations of devices.

In the VX, this shines through with many small touches that could only come from years of user feedback and the company’s own use of its machines.

In use, the machine handles all of its functions well enough. Except for the Laser Pro, which we found to be the easiest to use, each function suffers its own small quirks and issues; when 3D printing the Dual Pro tool head’s extruder at default tension strips filament, and the lack of usable CNC workholding come to mind.

Newcomers may find getting acquainted with the tool a little frustrating, with ZMorph’s online Academy covering some, but not all of the basics.

But such frustrations are minor when held against the sheer versatility on offer with the VX. Those with prior knowledge of the crafts for each of the machine’s functions will find a wickedly competent tool in the VX, taking up a small amount of desktop space but offering a decent enclosed work volume.

Specs

MAIN FEATURES

-

Technology: FDM/FFF, CNC Mill, Laser Engraving, Thick Paste Syringe

- Build volume: 250 x 235 x 165 mm (toolhead dependent)

-

Layer resolution: 25-400 microns

- Material diameter: 1.75 mm, 2.85mm (toolhead dependant)

- Nozzle diameter: 0.2 mm-0.4mm

- Platform leveling: Automatic

- Extruder: Single, Dual (toolhead dependant)

- Platform: Glass (3D printing), Machined Aluminum w/ clamp holes (CNC, Laser)

- Connectivity: USB, SD

- Materials: ABS and derivatives, PLA and derivatives, PVA, PET, ASA, Nylon, HIPS, Thermochrome, TPU, flex materials (3D printing); wood, polycarbonate, HDPE, acrylic glass, machining wax, modeling board, Dibond-like composites, copper laminates (for PCBs), POM, PVC foam (CNC cutting/ engraving); wood, leather, copper laminate (laser engraving); paper, cardboard, felt, thin gasket materials (laser cutting), chocolate, cookie dough, cream cheese, frosting, ceramics (thick paste printing)

TEMPERATURE

- Maximum extruder temperature: 250° C

- Maximum platform temperature: 100° C

SOFTWARE

- Software bundle: Voxelizer 2.0

- Supported operating systems: Mac OS X / Windows 7 and newer versions

Where to Buy

So how much is a ZMorph VX going to cost? They’re available worldwide now from ZMorph and authorized resellers.

License: The text of "ZMorph VX Review: Best 3-in-1 3D Printer 2020" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.