Business owners ask phenomenally more complicated questions than hobbyists when evaluating a 3D printer. You’re concerned about more than print specifications. You need to know about reliability, repeatability, service-ability, ROI, training, and you have a specific application in mind.

Whatever you print, your 3D printer has to be a flexible workhorse that’s easy to use and contributes to your bottomline.

That’s why this in-depth professional review of the Ultimaker S5 goes beyond all others to give you the use case, print tests of end-use and prototype professional-level parts, software and connectivity evaluation, and a rundown of the full ecosystem of offerings available to you as a professional. Why should you trust us? Because we’ve been using and reviewing desktop printers of all shapes, sizes, and price points since 2015, taking time getting to know the systems and what’s expected of them, and in turn making unbiased recommendations and giving our readers valuable purchasing advice ever since.

Verdict

We put the Ultimaker S5 Pro Bundle through an exhaustive printing regimen in our lab, challenging it with a mix of fast prototyping and demanding engineering materials in a production environment, and we’re satisfied that it lives up to its promise – the act of printing is simplified, and your intent is what shines through. The cloud control and management tools are powerful, and the printer’s versatility, paired with high uptime should make it a valuable tool in any business’ arsenal.

Any review of a product pitched at professionals with long-term usage and demanding applications in mind should be in-depth and exploratory. This is something we’re committed to but we also see the value in being succinct, which is why we begin our pro reviews with the end: the verdict, telling you, bottom line, if this printer is worth your time?

We approached the Ultimaker S5 Pro Bundle with its promise of “always-on productivity” firmly in mind. This is a machine for businesses to achieve a lot with regularity. Except for few early errors forcing power cycles of the machine, we can confidently declare that the printer has remained a permanent fixture in our lab, always-on, receiving print jobs remotely from within and without the building with unfailing reliability.

The prints are broadly good, but not flawless in every case.

This is, we feel, in line with a machine that lets you use third-party materials. The system exerts less control over feedstock and environment than industrial printers that cost multiple times the S5 Pro Bundle, but it does offer flexibility and choice. And, to Ultimaker’s credit, it goes to great lengths to make the use of diverse materials, mostly, painless.

Although you need to select your materials carefully, Ultimaker’s partnerships with material providers takes the trial and error out of printing with reliable print profiles (hundreds of them) and, effectively, a quality selection slider in its user-intent profiles enabling you to eke out microns tighter tolerances and save on print time.

Fully networked, and with Ultimaker’s software offering leveraged properly, we can see the S5 Pro Bundle slipping almost seamlessly into product design and in-house production workflows. The interplay of hardware, software, and cloud work well (albeit with minor wrinkles we hope Ultimaker addresses soon). If you’re familiar with 3D printer set-up, you could be ready to run with multi-material prints within 30 minutes, otherwise comfortably budget an hour.

The humidity-controlled filament box with six material bays, called the Material Station, combines with the printer for diverse and long-term print jobs without the need for intervention. Material switching and long-term use are two great strengths of the system. The minutiae of print setup are mostly automated, resulting in a relatively hands-off experience.

Tying our impressions of the Ultimaker S5 Pro Bundle full circle, it’s our opinion that even the occasional frustrations, many of which come with the territory of sub-industrial 3D printing, can be overlooked by the machine at its best, in lockstep with the Digital Factory – its 3D printer management – and the ease and usefulness of the workflow it presents as a complete printing solution for your business.

Ultimaker tells us it’s in the process of patching things for the S5.

Of the issues experienced using the machine, particularly material profile synchronization not being a standard part of the cloud operations of the printer and platform, some have already been patched by Ultimaker (more detail on this below in the Platform, Digital Factory & Software section). It seems like there are still some dots left for Ultimaker to connect, which some might question for the machines close to $10,000 price tag (and hundreds, if not thousands in additional subscription costs for larger enterprises.) Still progress is progress, and we have no doubt such small wrinkles will continue to be ironed out.

Pros

- Robust integrated ecosystem (machine, software, subscription services)

- Automated print and material profiles simplify print prep

- Fast and efficient setup

- High-uptime

- Wide material compatibility (incl. carbon fiber and metal via optional CC print core)

- Tools for business intelligence (traceability of printing via reporting)

Cons

- Kinks in the cloud functionality yet to be ironed out

- Only a single build plate (that’s known to break)

- Tricky to track multiples of materially similar third-party filament

What is the Ultimaker S5 Pro Bundle?

The Ultimaker S5 is Ultimaker’s debut and primary S-series 3D printer. Launched in 2018 to mark a new professional focus for the company, the machine has undergone continual evolution to further underline this focus, with an enterprise-level suite of software tools and account management options giving project owners complete oversight of their jobs, printers, and operators.

Altogether this evolution has helped to mark the Ultimaker S5 out as a mature desktop solution for professional 3D printing applications, seeing the company’s machines successfully installed in enterprises of all sizes, including optics experts Carl Zeiss and market-leading robotic packaging machines at Gerhard Schubert GmbH.

As a standalone unit, the S5 offers the robust dual-extrusion 3D printing with a growing library of engineering-grade materials, with cloud-based operability coming from Ultimaker’s Cura slicing software and the recently launched Digital Factory printer fleet and organization management platform.

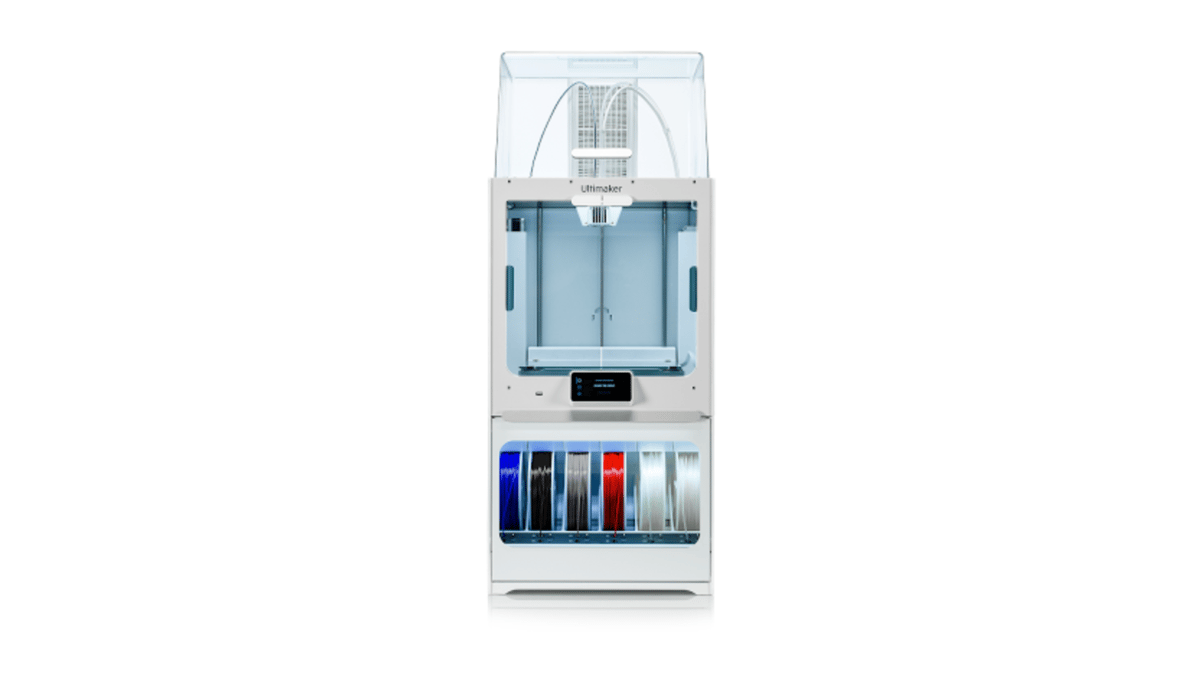

Beyond the Ultimaker S5’s functions as a single printer unit, its operations can be augmented and improved further with Ultimaker’s Material Station and Air Manager units, which altogether are known (and sold) as the Ultimaker S5 Pro Bundle. The units, respectively, allow you to load up to six spools of material for seamless material switching or reloading between and during prints and stabilizes the print chamber temperature and filter airborne particles from the printer chamber and surroundings by way of HEPA filter.

These units complete Ultimaker’s vision of the S5 as a productivity powerhouse suitable for the shop or production floor. At ~$9,550, it is Ultimaker’s costliest offering, but it’s also the company’s most advanced.

To find out whether the S5 Pro Bundle lives up to this, we put the system to task in our lab to see how it all works and whether it hits the mark or lacks substance. Ultimaker kindly provided an unused review sample of the complete S5 Pro Bundle for our testing. After several weeks of using the Ultimaker S5 Pro Bundle, we’re inclined to give the printer the nod, even if the experience hasn’t been as without hiccups. Below, we outline the hardware and software in more detail and our experience using them.

Pro Review Use Case Selection

At All3DP, we know evaluating professional printers are like comparing apples and oranges because so much depends on the application. What you’ll use the printer primarily for and under what conditions makes a substantial difference in your selection. That’s why no review is accurate or complete without taking a use case into consideration.

For this review of the Ultimaker S5 Pro Bundle, we took the point of view of a 3D printing service bureau as our use case scenario. These types of companies print whatever their clients request, so their printers have to be flexible, versatile, and dependable. Material changes need to be quick and easy. Hardware has to be reliable. Prints must be fast, and the machines must be easy to operate especially remotely.

To find out what type of parts are typical prints for a service bureau, we turned to our own Craftcloud, the 3D printing marketplace that offers customers 3D printing project quotes from the top service bureaus around the globe. Thousands of print orders go through Craftcloud every week, and from those orders we discerned a range of prints that would be tackled using fused deposition modeling printing tech, ranging from fast prototyping plastics to tougher engineering-grade materials. Armed with a database of anonymized prints to take as inspiration, we compiled a selection that is representative of real orders going to a real 3D printing service, and put similar models to the Ultimaker S5 Pro Bundle as our “live” use case.

Technology, Automation & Materials

The 3D printer at the core of the S5 Pro Bundle is virtually unchanged from the S5 launched in 2018; it’s still a tremendous dual extrusion machine with a novel and useful versatility in its print core system.

However, almost everything else has changed recently and the ecosystem is a whole new dimension that makes it a recommendable enterprise-friendly installation, albeit one with a few minor wrinkles to iron out.

Dual Extrusion Using Print Cores

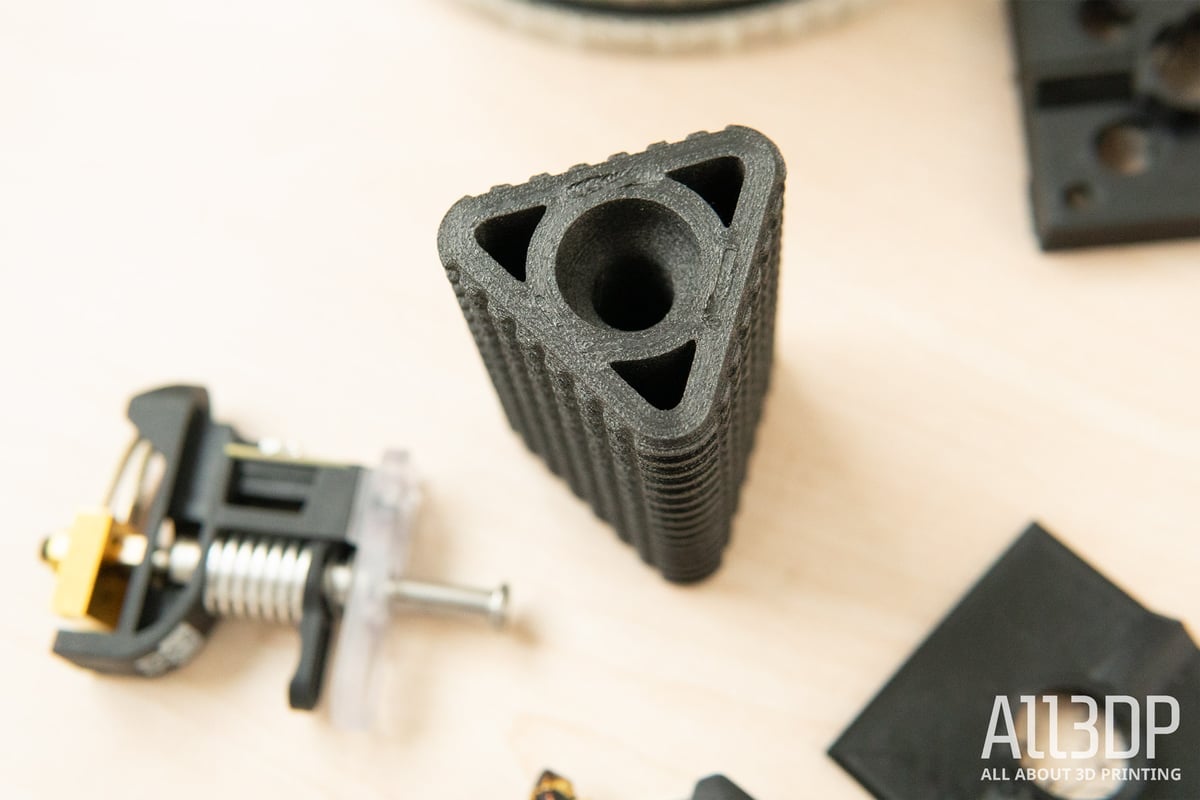

Ultimaker uses its self-developed and partially patented print core technology at the business end of printing. Almost cartridge-like in nature, these interchangeable hot ends can be swapped in and out of position on the S5’s print head with a satisfying click. Don’t underestimate the convenience of this feature if you need to frequently jump back and forth between prints using soluble supports, dual combinations of materials, and tougher engineering materials. Printers that require tools to change print heads provide an opportunity to introduce errors and, it takes more time. Ultimaker’s system is effortless and just works.

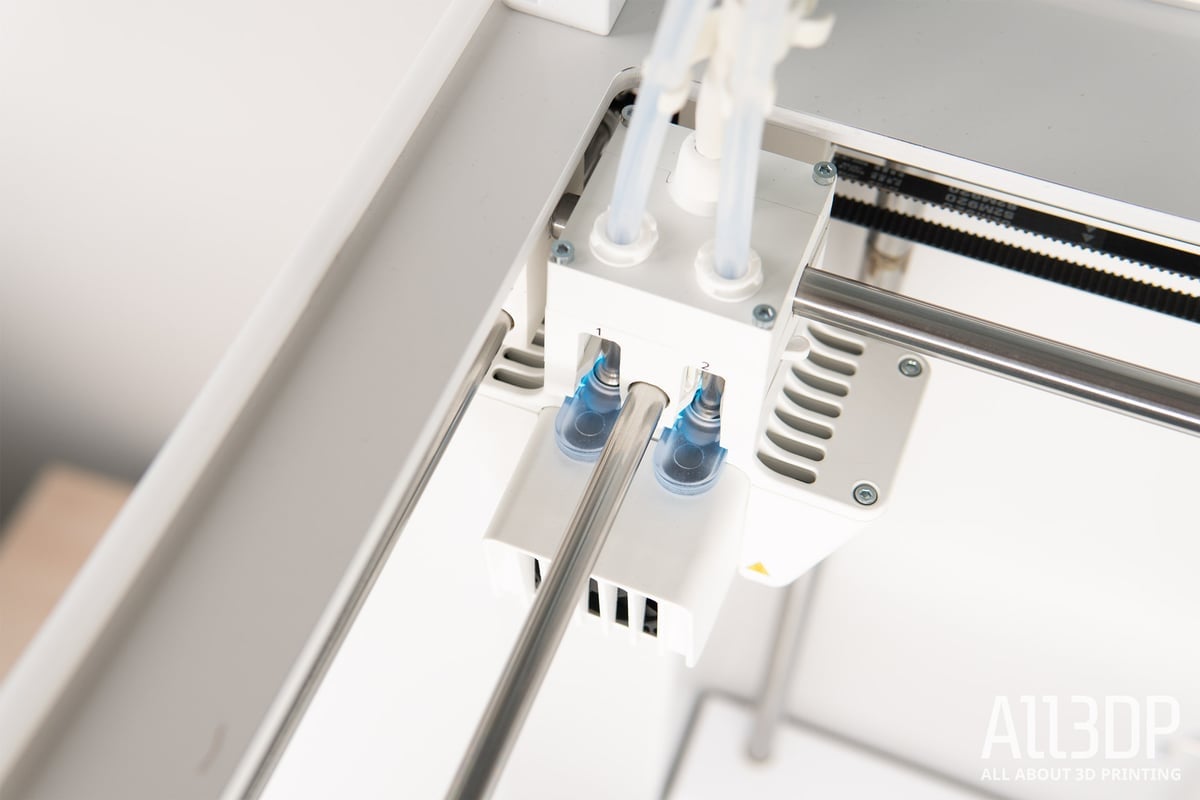

There are two print core bays, each accepting one of the three application-specific cores Ultimaker offers (AA, BB, or CC).

Each letter corresponds to a print core’s abilities, with the AA cores specifically “standard” thermoplastics, such as tough PLA, copolyesters (CPA), polyurethane (TPU). The BB core is exclusively for use with polyvinylalcohol (PVA) water-soluble support material. Lastly, the CC Red core, which features an abrasion-resistant ruby nozzle tip, is specifically for composite materials that would quickly ruin the other cores’ brass nozzles. (CC 0.6 and CC 0.4 cores will release in 2021, offering abrasive-resistant steel nozzles and titanium heatbreaks in contrast to the CC Red 0.6’s ruby-tipped nozzle and steel heatbreak.)

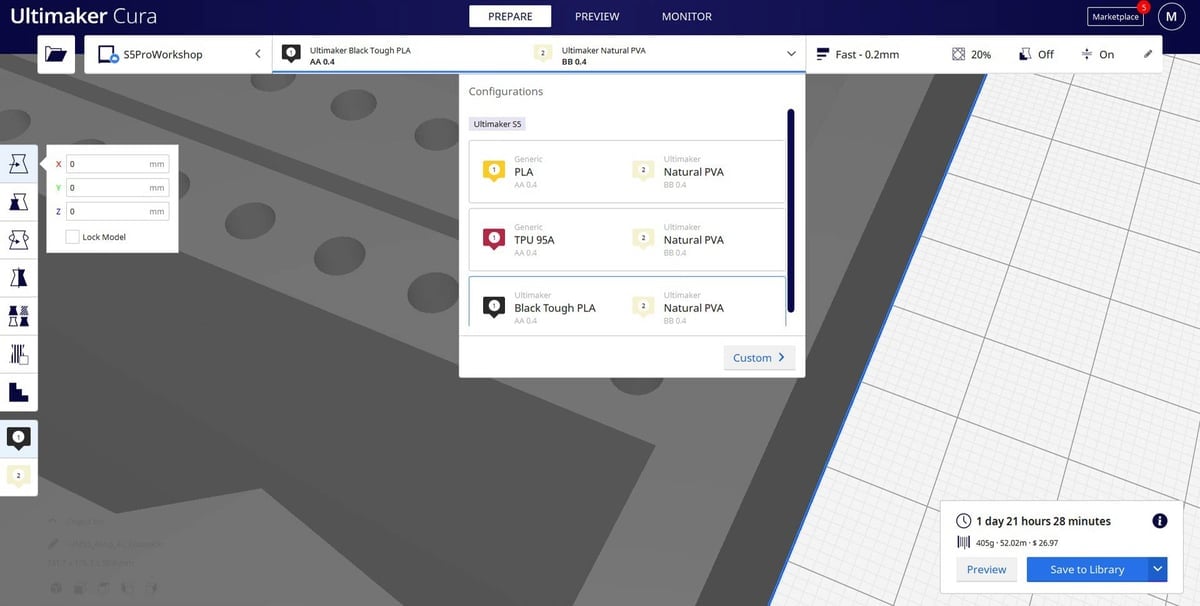

Each print core contains a chip that communicates the core’s presence and type to the printer, helping to maintain harmony between the S5’s various components and systems. In practice, this system means the printer knows what its current setup can print at any given moment and can alert the user to material incompatibilities, preventing failed prints and the waste of time and materials. This knowledge carries over to the Cura slicing software, where (if using the Material Station loaded with multiple materials) you are presented with the various possible “configurations” of material available for you to print with.

The Ultimaker S5 comes with both AA 0.4 and BB 0.4 print cores as standard (0.4 corresponds to the nozzle opening of 0.4 mm – an industry standard that gives a good balance of print detail and speed.) These two Cores give a pretty broad range of material compatibility out of the box, with the ability to print PVA support material most critical for models with complex geometries. A spare AA 0.4 print core ships with the S5 Pro Bundle, too, letting you tackle prints that combine functional thermoplastics.

To print carbon composites, metals, and similarly abrasive materials, you will need the CC Red 0.6 print core, sold separately. We had a barely-used sample of this specialist add-on in our office from a past feature, so we tested it out in our S5 Pro Bundle setup. (As with all Ultimaker print cores used for this review, it worked flawlessly.) This “tough” print core functions exactly as the other print cores do, snapping into the print head and giving the printer seamless compatibility with demanding materials. A note on this and the S5’s ability to handle composites – just as the CC Red 0.6 nozzle can withstand abrasive materials, so too can the printer’s filament feed gearing both on the base Ultimaker S5 unit and the additional material handling feed points on the Material Station add-on. No modification of the printer is required.

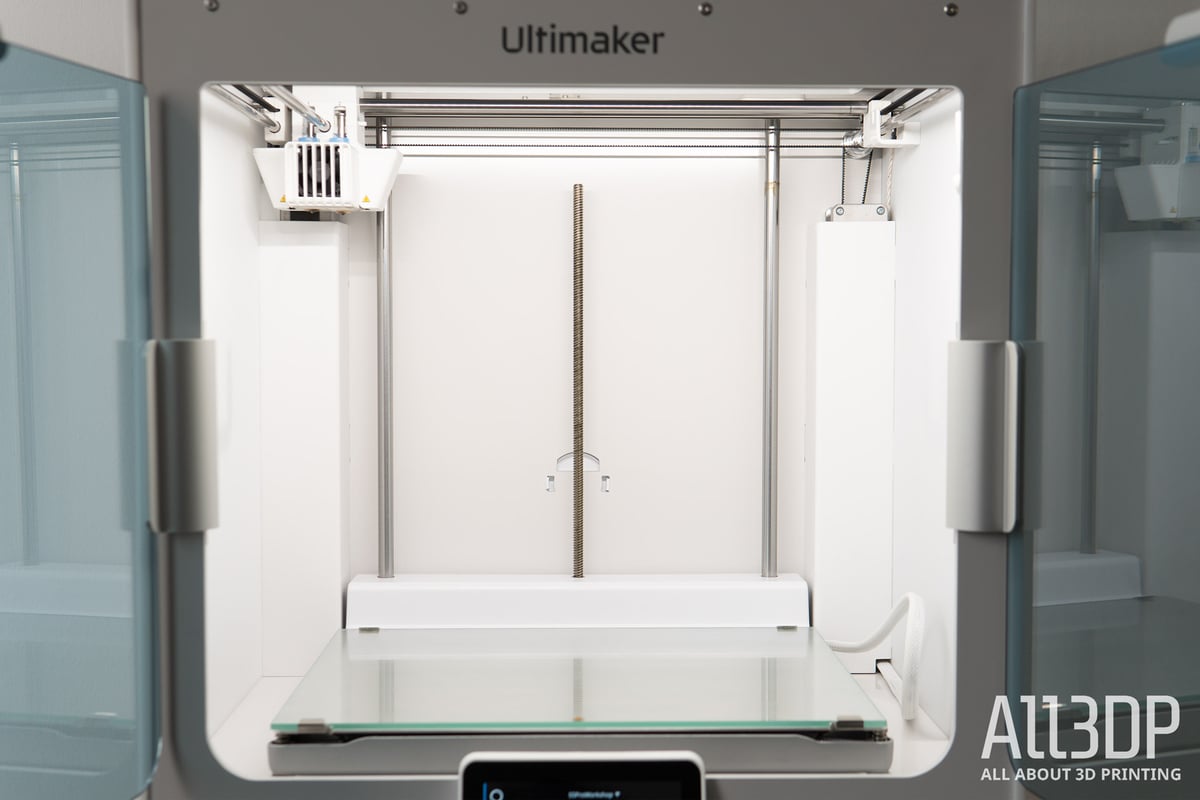

Print Chamber

Inside the LED-lit interior of the Ultimaker S5, you have a 330 x 240 x 300 mm build volume that’s fully accessible to both Print Cores (similar dual extrusion systems do not.) The uncluttered space is home to a removable glass print bed that can be heated to 140 ℃.

Some three years after release, we have to question Ultimaker’s decision not to have diversified its print bed offerings. Glass, while versatile, is fragile and can be unforgiving material to print on with some thermoplastics – it’s not uncommon to hear of the S5’s glass plate bonding too well to prints, taking flakes of glass away with the printed part once forced from the plate. A question of operator error – the insufficient application of adhesive to the plate to act as an interface layer – but an easy mistake to make nevertheless, and one that can ruin the sole print bed provided with the printer.

We find this a disconnect in a machine package favoring high uptime and productivity, which uses a glass that can fuse to prints, only to provide a single glass bed sheet in the package. It’s an unforgiving decision that nickels and dimes users over something many will inevitably have to invest in. Print beds better suited to different materials (that won’t disintegrate because of an insufficient layer of glue), or spares, would amply address this.

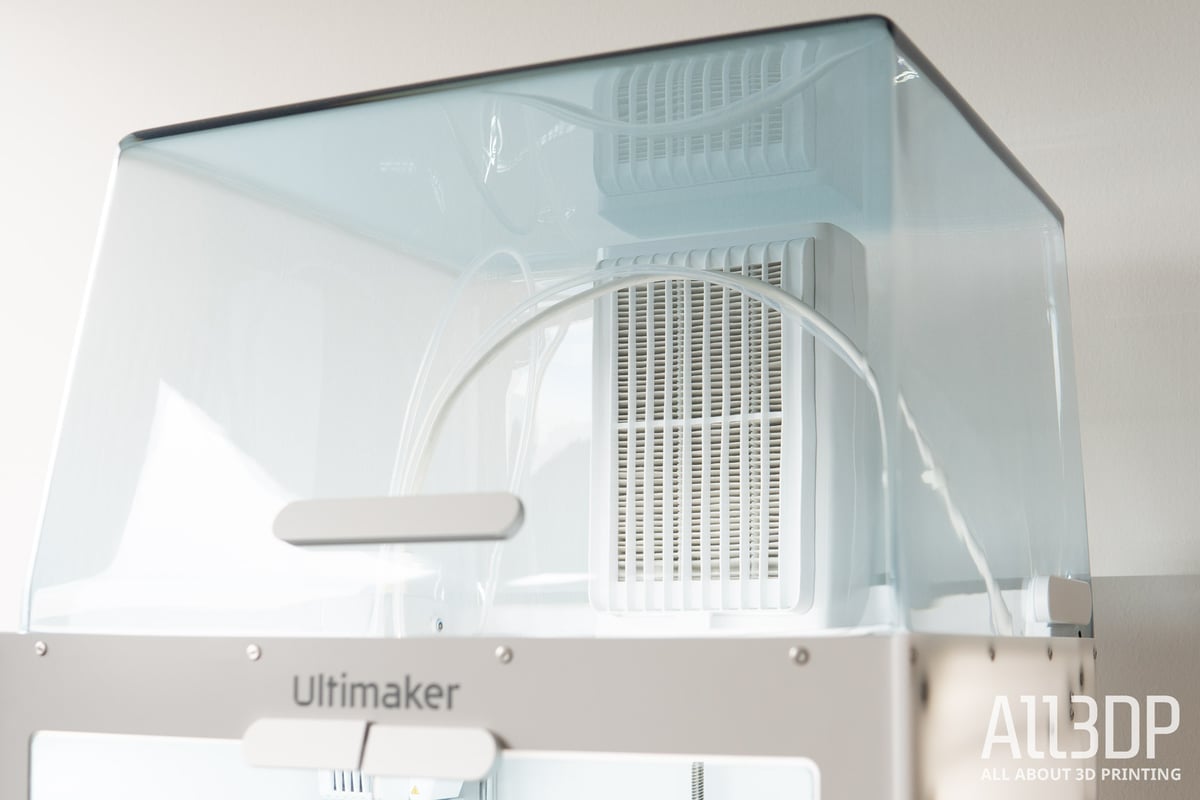

The print chamber of the standalone S5 printer is partially enclosed with two out-swinging glass doors and becomes completely enclosed with the addition of the Air Manager unit, which fixes in place atop.

There is no active heating of the print chamber, which precludes the Ultimaker from printing more extreme engineering materials, such as PEEK.

Preflight & Automation

Traveling up and down on a lead screw guided by two support rods, the bed’s gantry provides a stable platform for the Ultimaker S5 to print on. There’s no manual leveling or intervention required of the operator, with an (in our experience faultless) automatic-bed leveling routine baked into the beginning of every print job the machine performs.

This is a boon for productivity; all the operator needs to do between prints is clear the plate and confirm the plate is clear. The printer will automatically pull the next print assigned to it from the queue and continue printing. (This sounds quick, but note there are cool-downs and preheating times that space prints out by some minutes.)

No further calibration was necessary out of the box, but you can access calibration routines to correct any deviance that creeps in between the two print cores and their alignments in the X- and Y- axes. This can be triggered at any time by the operator, and the printer will also detect the need for recalibration. Smart.

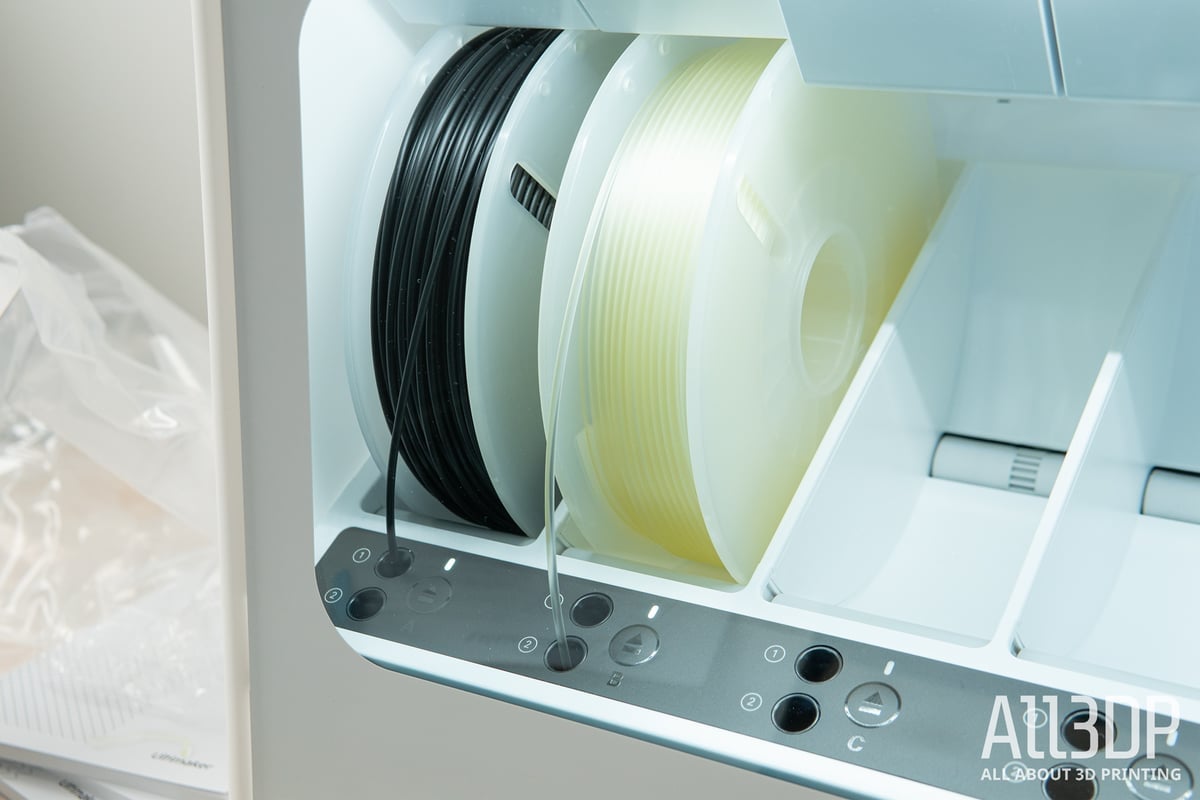

Material Station

An integral part of the Ultimaker S5 Pro Bundle is the Material Station. Sitting beneath the S5 printer as a base unit of sorts, this illuminated, humidity-controlling box feeds filament to the S5 printer. It also addresses one of our chief criticisms of the standalone S5 printer – the filament spools’ positions. The Material Station offers six front-loading filament bays, which is utterly convenient. Note that you can only use spools 50–70 mm wide and 197–203 mm in diameter.

At the point of loading, you choose which of the two filament paths to the print core each filament can take. Some planning with respect to the print cores and filaments you use is necessary.

Many materials in 3D printing will absorb moisture from the environment if left out and unprotected. The Material Station, Ultimaker claims, controls the humidity level inside the cabinet, recharging its silicate absorption medium enough never to require changing. The Material Station won’t dry your filament, but it will maintain an acceptable level of usability with severely hygroscopic materials such as PVA, one of the printer’s specialties. Certainly, in our time printing with the Ultimaker S5 Pro Bundle (across several weeks of humid summertime), with PVA and nylons loaded from day one, we did not experience noticeable degradation in material quality.

The Material Station can also read the NFC chips embedded in Ultimaker brand spools of filament, detecting the materials automatically and relaying this information to the printer, connected Cura software, and the Ultimaker Digital Factory.

Material loading and unloading happen automatically – rollers nestled at the rear of each material bay spool filament as it backs up through the Material Station’s long feed path down the rear of the machine.

As a complete package, the S5 printer and Air Manager units connect to the Material Station for power and communication. The Material Station is “always-on,” protecting filament from moisture even if the S5 printer powers down.

Material Configuration

You are free to use any 2.85 mm filament in the Ultimaker S5 Pro Bundle, provided it fits the machine’s operational parameters (280℃ maximum hot end temperature, 140 ℃ maximum heat bed temperature). With that said, there are three different classifications of materials of sorts, each offering a different degree of ease of use in the S5 ecosystem: those produced by Ultimaker, which come on NFC-chipped spools that the printer can “read”; Ultimaker Material Alliance materials, which are those produced by manufacturers that have verified optimal print settings and provided material profiles for use when slicing; and lastly those that are neither, they can work in the printer but require the manual set up.

Using non-Ultimaker branded but approved third-party materials in the S5 Pro Bundle was more frustrating than it should have been. In contrast, Ultimaker’s own materials are recognized instantly and show Ultimaker’s ecosystem at its best, unquestionably. The printer asks nothing of you and works.

Upon loading third-party materials, you are asked to designate a generic profile that best matches what the material is. This is also simple and offers the best default behavior for a given material.

However, to use verified and tested materials from Ultimaker’s Material Alliance – a program of third-party manufacturers that provide optimized print settings for use with the S5 – you must download the material profiles from the Ultimaker Marketplace – accessible in the Cura software or via web browser on your Digital Factory account. The downloaded material profiles synchronize to your software, but they do not automatically synchronize to the S5 Pro Bundle hardware.

Synchronizing material profiles to the hardware requires you to have a local connection, which is not the default once your machine is connected to the Digital Factory. This poses a problem if you rely on the cloud-based Digital Factory to operate the S5 Pro Bundle – as we did during testing – because Material Alliance profiles will not automatically synchronize with the printer. This means the materials are not known to the printer at loading, and consequently, the Cura slicing software prevents you from using them. You cannot designate a generic profile on the printer at loading and then use the material-specific profile in the software for slicing – the printer recognizes this incompatibility and asks you to load the “correct” material.

Only by recreating a local connection to the printer by repeating the Wi-Fi setup wizard could we connect and add our manufacturer verified profiles for use. Ultimaker is aware of the issue, and while there is a support blog post that gives some steps to help troubleshoot the issue (it didn’t help us in our particular situation), shortly after putting our experience to the company a workaround was introduced in a firmware update (6.5). Up-to-date machines can load material profiles from USB for a one-time manual synchronization with the S5 printer.

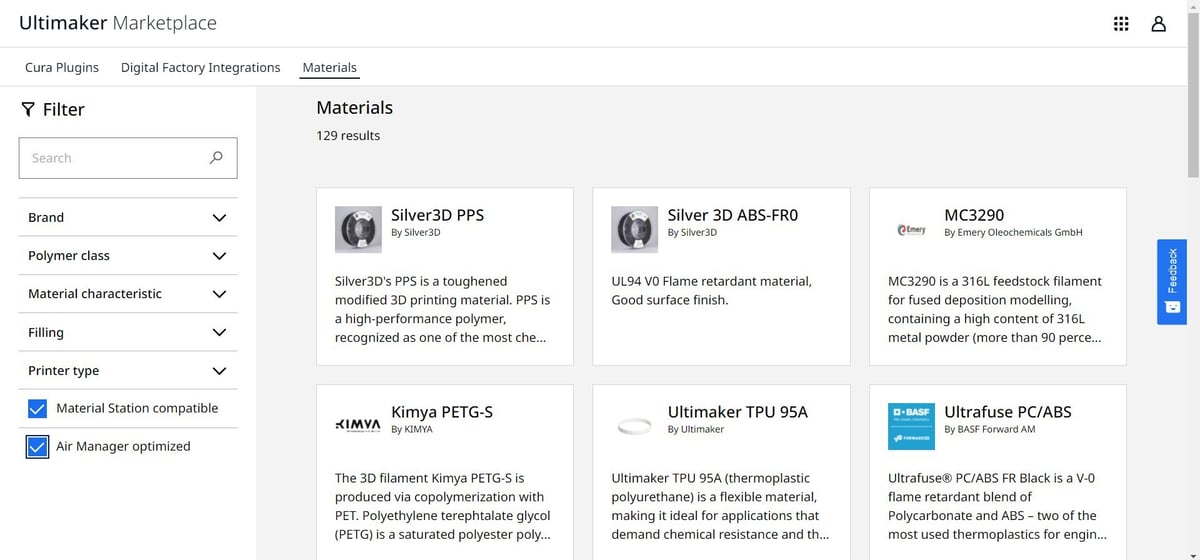

We also found that the introduction of the S5 Pro Bundle appears to have resulted in a slight fracture of Ultimaker’s Material Alliance partner profiles, with only some marked as optimized for the S5 Pro Bundle, taking advantage (or rather factoring in) the now fully enclosed nature of the machine and difference in materials handling from the Material Station.

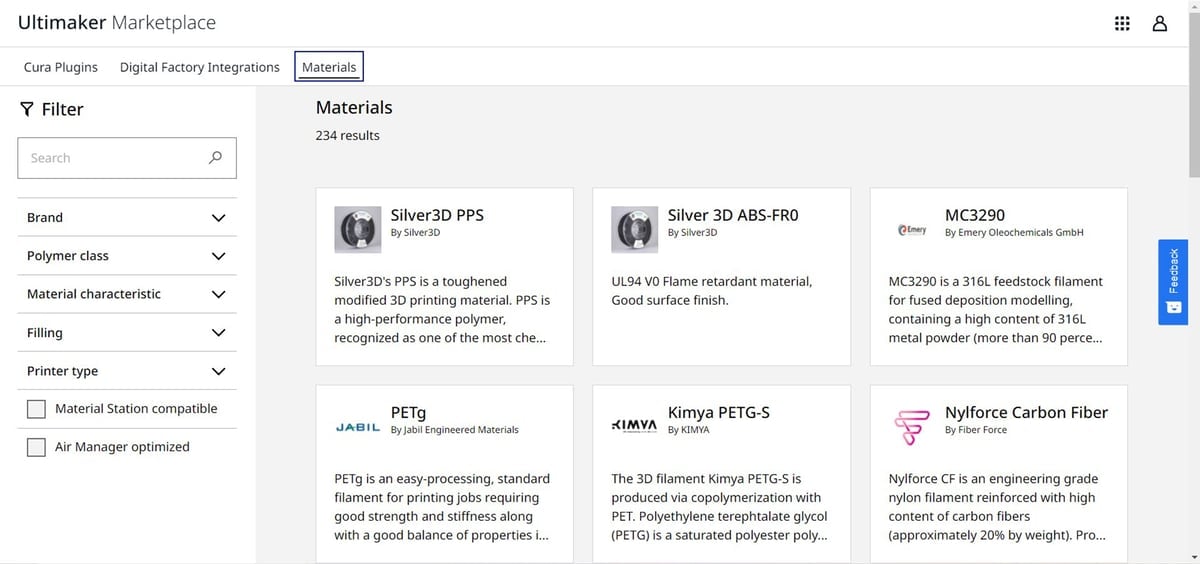

At the time of writing, of the 271 available material profiles in the Ultimaker Marketplace, only 128 are designated Material Station compatible.

About 127 are optimized for the Air Manager. Just short of a tenth of those are Ultimaker’s own material offerings. This is not to say you cannot use the other 144 materials in the S5 Pro Bundle – just that they may not take full advantage of the hardware.

You can opt to use non-Alliance materials with the S5 Pro Bundle, but it requires you to flag them as “generic” to the printer. The process of printing with them is virtually the same. You don’t have the option to name them though, so if using a handful of materially similar filaments (all designated as “Generic PLA,” for example), then you are presented with a list of multiple “Generic PLA” material configurations in the slicing software – not so helpful and, especially so across a larger organization with multiple machines and operators, probably quite difficult to track.

Air Manager

Topping off the Ultimaker S5 Pro Bundle is the Air Manager, a hinged transparent plastic hood that clips into place on top of the printer. This device is simple in concept, closing off the print chamber for better temperature stability and adding a HEPA filter to scrub, Ultimaker claims, up to 95% of ultrafine particles. Because of this, we opted to install our Ultimaker S5 Pro Bundle in our office space rather than our lab, and found there was a distinct lack of smell or fumes. While we’re talking about our office environment, also know that the S5 is not a whisper-quiet machine. Expect volumes in line with that of a standard office copier for the duration of a print.

As with the Material Station, the Air Manager’s presence is known to the S5 printer, with its behavior adjusted and factored into the print settings of some materials. The filter is accessible from the front of the machine, making replacements a relatively simple process.

Platform, Digital Factory & Software

Another critical element that separates a professional 3D printer from expensive consumer machines is the sophistication of its software and, ideally, further platform tools for management and diagnostics. Ultimaker approaches this with its Cura slicing software, a program familiar to scores of 3D printing users and a mainstay of the open source origins of desktop 3D printing, and its Digital Factory offering, a cloud-based project, print queueing and management platform.

As a trio of units, the Ultimaker S5 Pro Bundle’s individual elements interface with one another seamlessly. Over-the-air firmware updates are prompted automatically and applied with your consent.

The printer can be used in isolation from Ultimakers’ cloud-based offering – local wireless or Ethernet connection is all you need to send prints directly from Ultimaker’s slicing software to the printer. You can also save print files to a removable USB stick and physically transfer the file to the printer. If using the machine in this way without leaning into Ultimaker’s cloud-based offerings, you can still benefit from software plugins and verified material profiles. However, it must be said that the full Ultimaker Essentials (or Professional and Excellence) subscriptions push hard to make a case for your business to adopt it as a platform for your 3D printing.

Ecosystem

Ultimaker’s ecosystem can get a little confusing and ill-delineated – especially online where an ocean of new tabs can overwhelm: but it can be summed up as seven core elements.

- Hardware

- Ultimaker Account (& subscription)

- Software (Ultimaker Cura Enterprise)

- Marketplace

- Digital Factory

- Academy

- Support

You have your hardware, the Ultimaker S5 Pro Bundle. By this point of the review, you’re likely familiar with what the Ultimaker S5 Pro Bundle is.

Then, administratively and operationally, you have your Ultimaker account. From your Ultimaker account, you can access the Marketplace, Digital Factory, Academy, and support services, in addition to managing your subscription.

Digital Factory

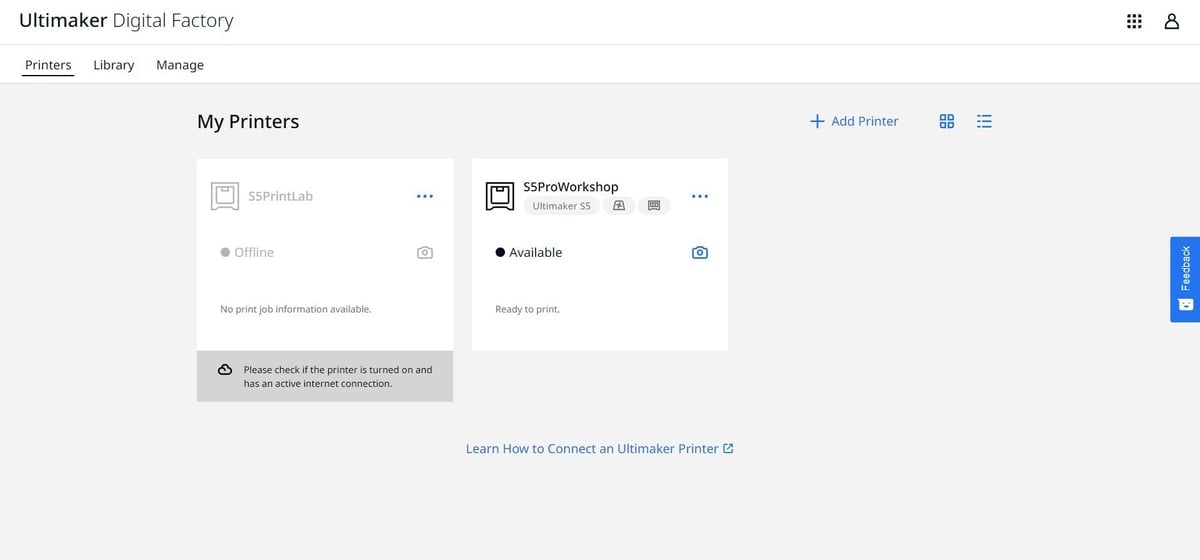

The Digital Factory is the primary space you will operate in online. This dashboard gives a complete overview of the machines, projects, project files, printable files, teams, and team members associated with your account. As the account admin, you have control over the structure and makeup of the teams in your organization and their access to particular projects and machines associated with your network – two-factor authentication can be enabled at the account level, and machines can be locked behind passcodes you assign. This will matter in a shared environment, providing extra security against accidental configuration changes on the printers.

In addition to a live view on the status of networked Ultimaker machines accessible to your account, you can also pull machine and project print logs, including print success, failures, and abandoned jobs. (Access to such business intelligence analytics is only available with the Professional and Excellence subscriptions.)

Overall, as a management platform for organization-wide control of projects and machines, Ultimaker’s Digital Factory makes a lot of sense. It an essential for both larger organizations with multiple teams and needs of their printers, and for those with multiple projects making use of few printers and a simple overview of progression or lineage of printed parts is required.

You can quickly build a picture of what is happening with the machines at your disposal, the jobs they’re doing, and live statuses all in real-time.

Furthermore, you can pull detailed reporting for individual printers within your specified time range and, separate from the machines, reports charting activity in the projects in your Library. This kind of data and oversight does not come naturally with many printers, and to see it implemented in such an intuitive form is a major pro in Ultimaker’s favor. This can expand to fleet reporting, again, only within the bounds of Ultimaker’s Professional and Excellence subscriptions.

The primary view in the Digital Factory is an overview of your printers, with direct control, configurable access rights, and downloadable reports available for each.

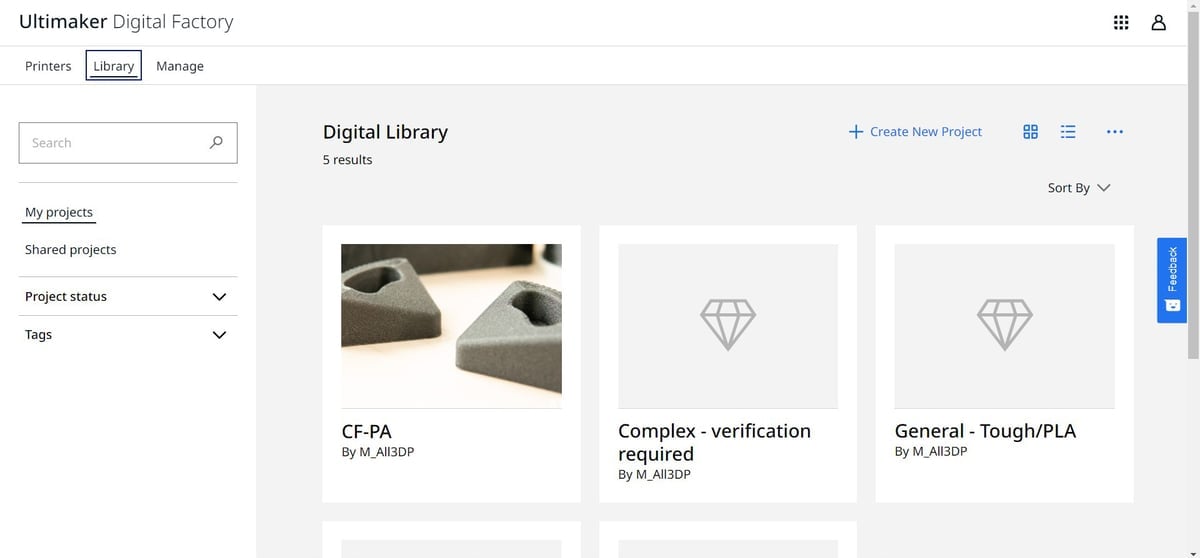

You also have a “Library” view to create, manage, and share project spaces, assigning teams or individuals to said projects. Any files can be uploaded to project spaces, not just printable files generated in Ultimaker’s Cura software, which gives versatility to the platform as a tool for collaboration and tracking development over time.

Applying this system to our hypothetical print bureau, we set up separate project areas for prints of varying complexity and materials. Collaboration within the workspace allows for supporting documentation for the model, including the 3D model itself, and versions of prints uploaded directly from the slicing software to test different slicing parameters.

Within these project spaces, you can set requirements that serve as a reminder to those working within. The S5 printer will prevent you from printing with a material that doesn’t match what it thinks is loaded, so it follows that a print originating from a project with set requirements could, at some point in the future, also be blocked if model-specific requirements, either by design or material, are not met. Such intelligence in the print process seems a suitable endpoint, but Ultimaker isn’t there yet.

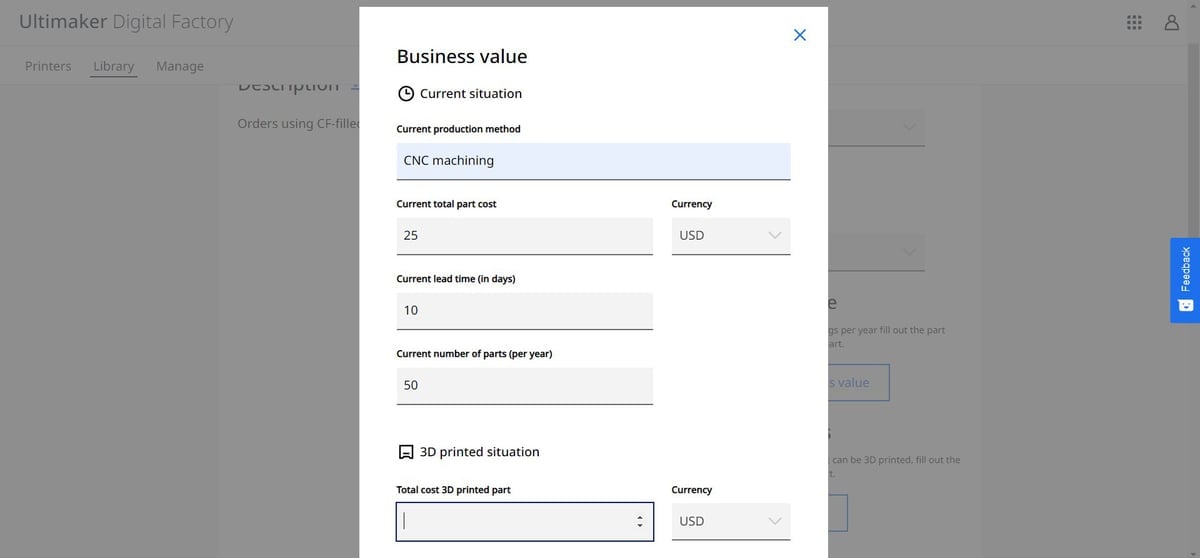

The Digital Factory also incorporates a print price calculator into project views, which will give you the projected savings on a printed part versus its cost when manufactured using other means. It seems to be of less immediate value to generalist printing and is clearly more a tool to help convince decision-makers of the system’s value – which makes sense, given the S5 Pro Bundle’s close to $10,000 price tag. In a pinch, it provides cost and time savings for the project but you have to know the price per print from the outset. You can calculate the cost of a print using the Cura slicing software, but only after manually inputting the price of your materials – this point of data is not linked into the Marketplace material profiles, nor is it carried through to your projects in the Digital Factory. A missed opportunity, but something we could imagine developing in future versions of the Digital Factory.

The amount of filament used per print in mm3 is included in printer reporting (which does not match up to Cura’s weight-based estimations for cost calculation,) so seemingly, there are dots still to be joined in the background of the Digital Factory.

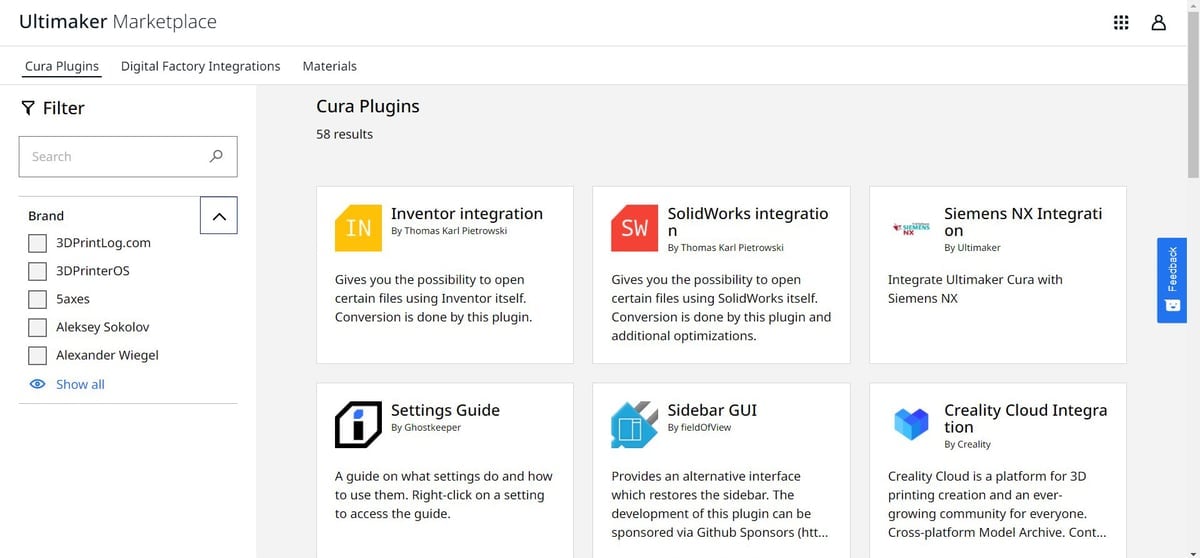

Marketplace

From the Ultimaker account dashboard, you can also access the Ultimaker Marketplace, Ultimaker’s space for third parties to share functionality-enhancing add-ons for the Cura software. It’s also where material manufacturers share verified material profiles. Generally free to enable, some lead to subscriptions separate from your Ultimaker account. Some integration with popular CAD software, such as Siemens NX, allows compatibility with said programs’ native file types.

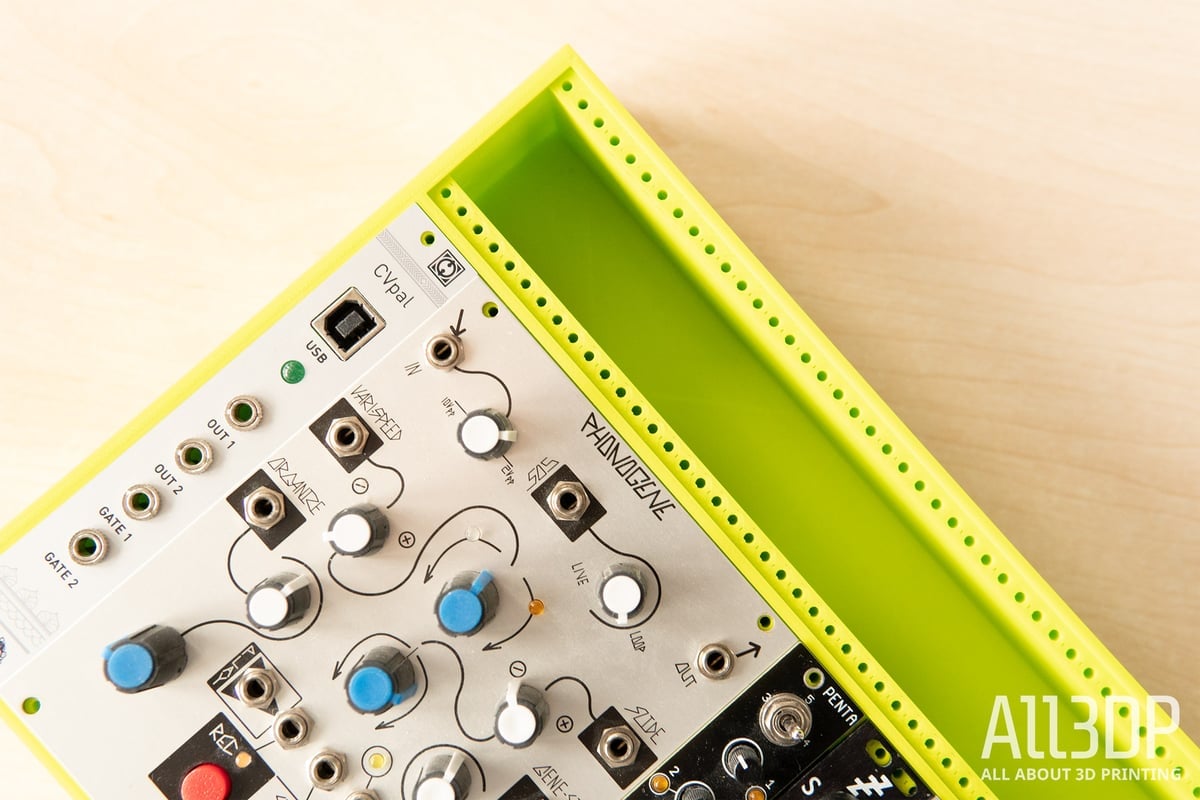

Close to our wrapping up this review, Ultimaker launched Cura 4.10, which introduces native CAD file compatibility for Ultimaker Professional and Excellence subscribers. This new ability means you can open CAD files such as STEP, IGES, and DWG, directly in Cura, including assemblies. This should mean a simplification of the process of printing files from CAD suites – no more exporting to STL or OBJ file types. To access this feature, you must enable it from the Ultimaker Marketplace.

The Materials section gives you access to the library of S5-optimized print profiles from Ultimaker partners. As mentioned above, these material profiles do not currently synchronize to your machine via the Digital Factory connection, which can prove a frustrating break to the flow of operating the S5 Pro Bundle.

API access and dedicated (timeboxed) software engineer support as part of the pricier Ultimaker subscription services means integrations with the software and hardware can be custom to the enterprise.

Ultimaker Cura Enterprise

A core component of any professional 3D printer is its slicing software. The means by which you convert your 3D model into machine-readable instructions for printing, the slicer is where material parameters are set and physical characteristics of the final print are determined.

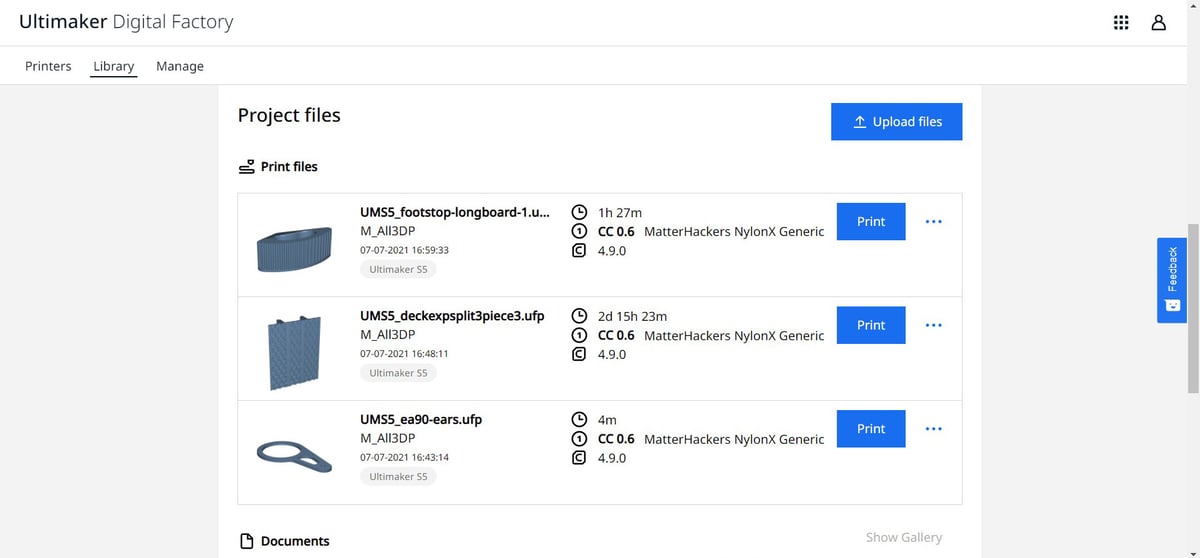

Separate from the browser-based experience of the Digital Factory, but still linked to your Ultimaker account, is the Ultimaker’s Cura slicing software. This is the program necessary for the initial preparation of 3D models for 3D printing (this need only be done once – print files can be directly uploaded to projects in the Digital Factory for distribution and recall and can be printed without the need for reslicing or even access to the original model.)

Available both as a standard user and Enterprise versions, any version of Cura can be used with the S5 Pro Bundle in isolation from the company’s Digital Factory. But there are clear benefits from the connection. The enterprise-specific version of the software differs with easy distribution for system admins, verified network security, and long-term support.

At its core, Cura Enterprise is as the basic Cura slicing software always has been – users familiar with past versions of the slicer will be at home in Cura Enterprise. It is a straightforward program that allows you to skip through the basics of print preparation without needing to go into nitty-gritty detail – especially so when using Ultimaker materials and taking advantage of the company’s plethora of intent print profiles.

All Ultimaker materials have the complete array of intent profiles available to them, meaning you can opt between speed, with thicker layer lines and faster movements with a small sacrifice in print quality; quality, fine layers and detail; engineering, which favors precision and landing the print within a finer margin of the model’s desired dimensions; or default, which is broadly middle-of-the-road with speed and quality.

Most of these styles of printing offer room for adjustment in the layer thicknesses, but not much else from the simplified print settings dialogue. You do still have complete control, though, and can dive into much deeper granular control. Engineers retain the freedom to customize the slice of the model. Ultimately, the material and intent profiles provide the shortest path to decent print quality, but Ultimaker still grants control over the minutiae of printing.

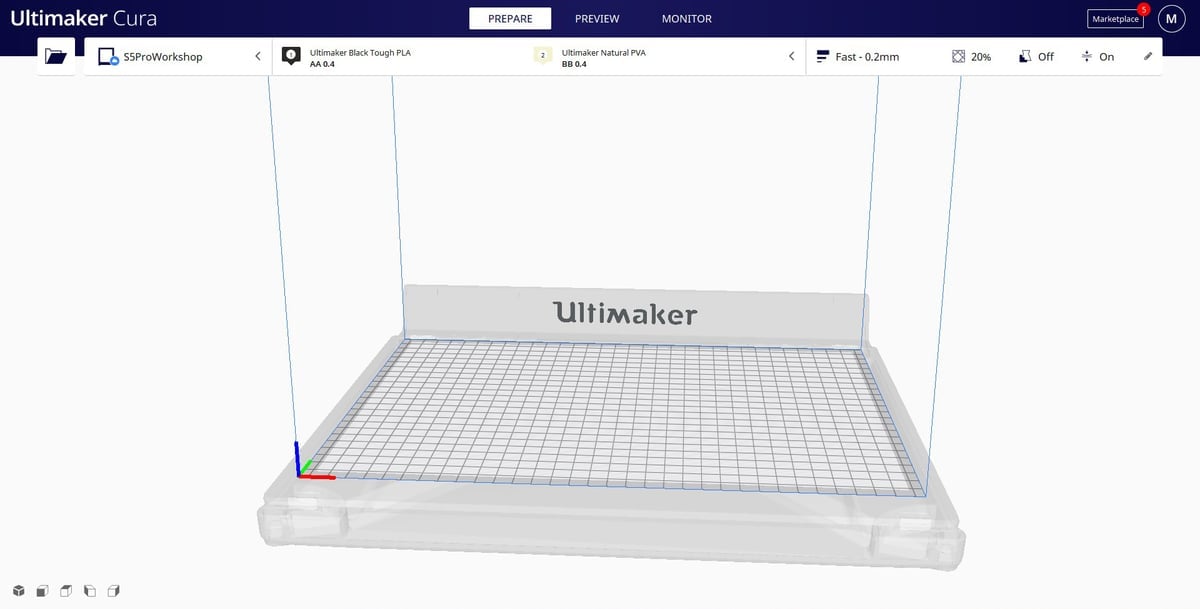

Landing in Cura, you can drag and drop a model into the workspace, as well as via your systems file browser or, using the Digital Factory connection, call up your projects and files and select a model from the cloud.

You can also select the materials you wish to use from the pre-populated list of possible configurations, generated by the Material Station and what was told to the printer when loading materials.

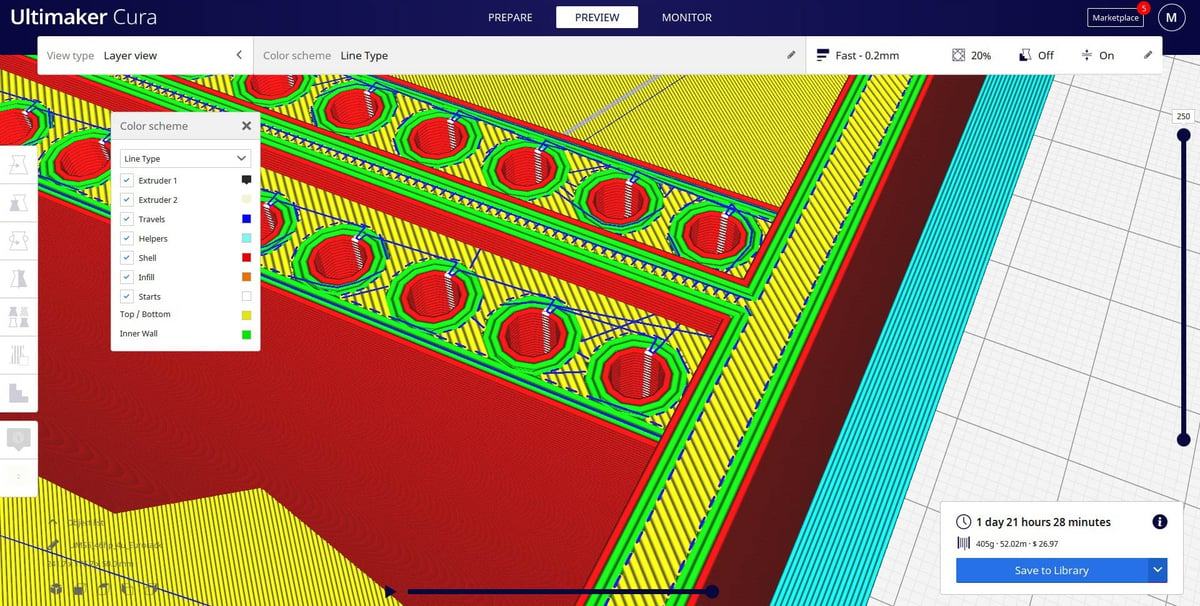

Once your print is oriented, and your settings configured, hitting “Slice” will generate the tool pathing for the printer to follow to build your model. This file, exportable as the Ultimaker native UFP file type (which includes metadata and preview imagery, in addition to the machine language G-code file), can be saved to external media for physical transfer to the S5 Pro Bundle, sent directly to the machine via the Digital Factory cloud connection, or uploaded to a project file in your Digital Factory library.

A detailed preview of the specific tool pathing, with color-coded lines to indicate different elements of the physical print or characteristics of the printing action, such as print speeds or line widths.

Printing & Usability

So, lots of talk about what the printer is and its terrific cloud capabilities, but now we’ll turn our attention to what the machine is actually like to use – an experience we’d sum up as productive. The potential of the S5 Pro Bundle as a workhorse for any print bureau is clear.

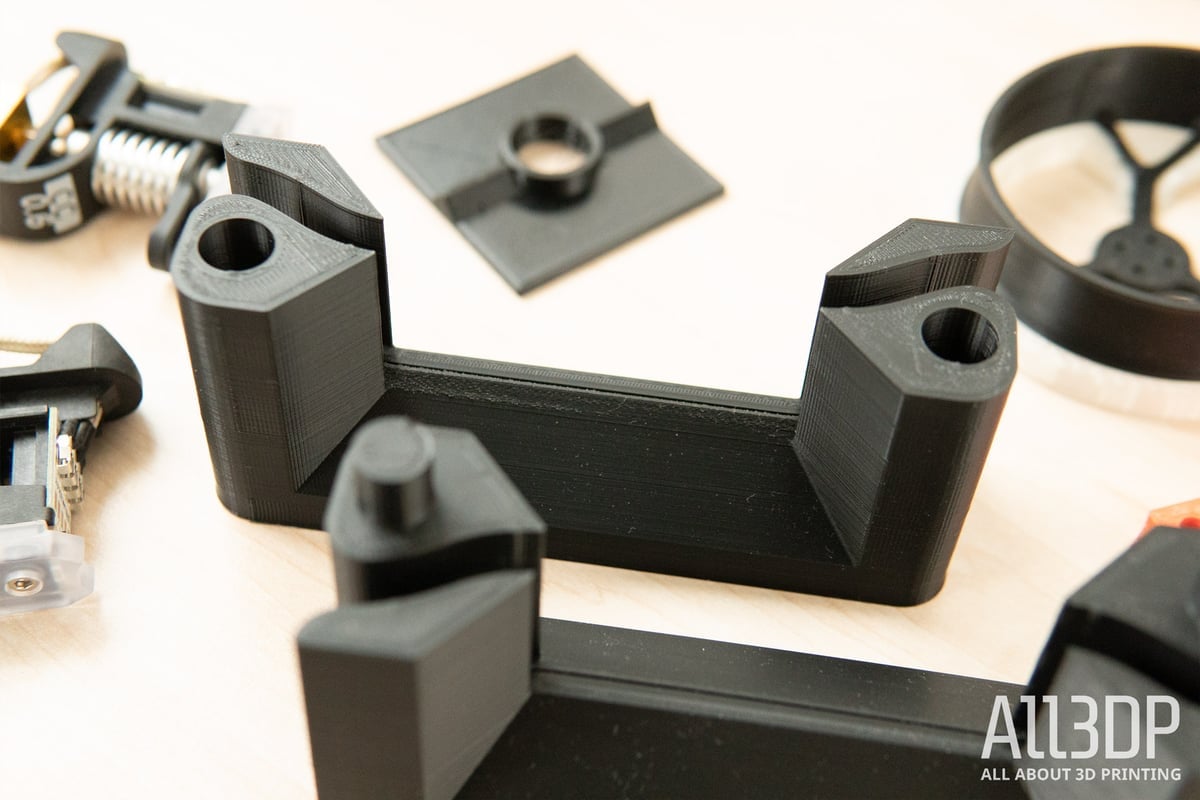

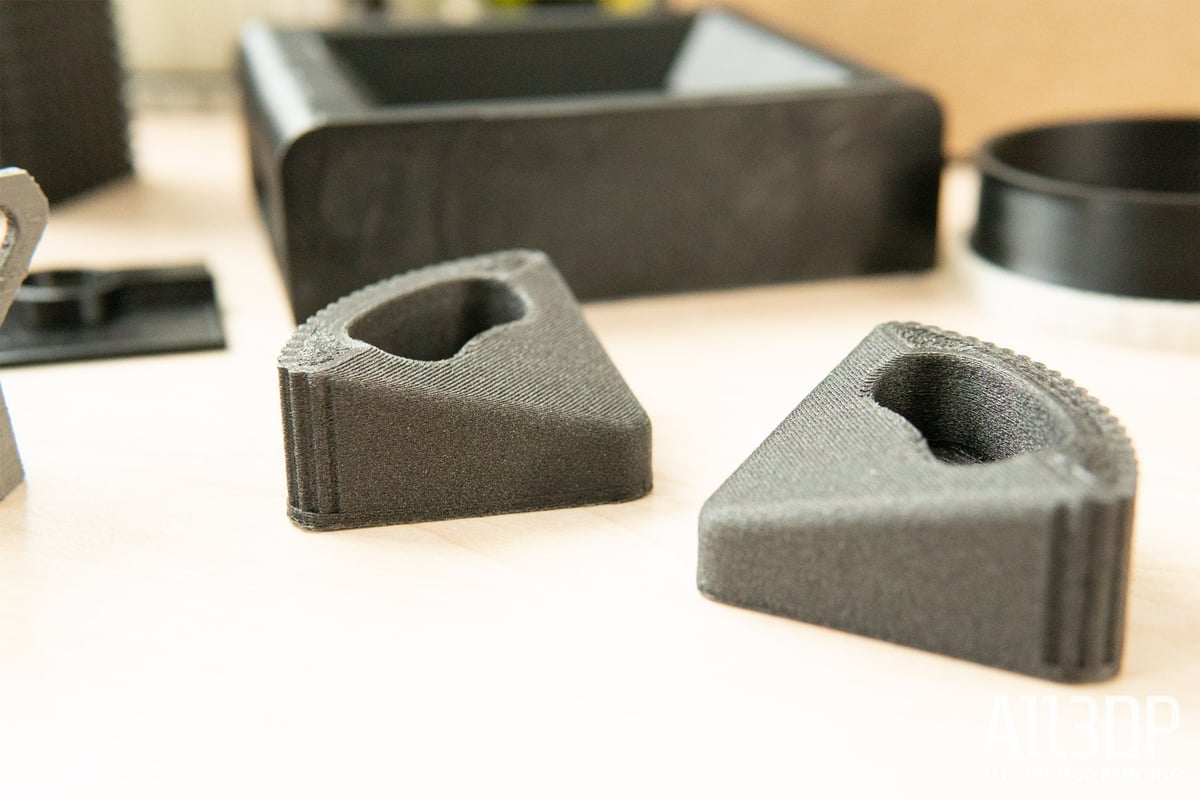

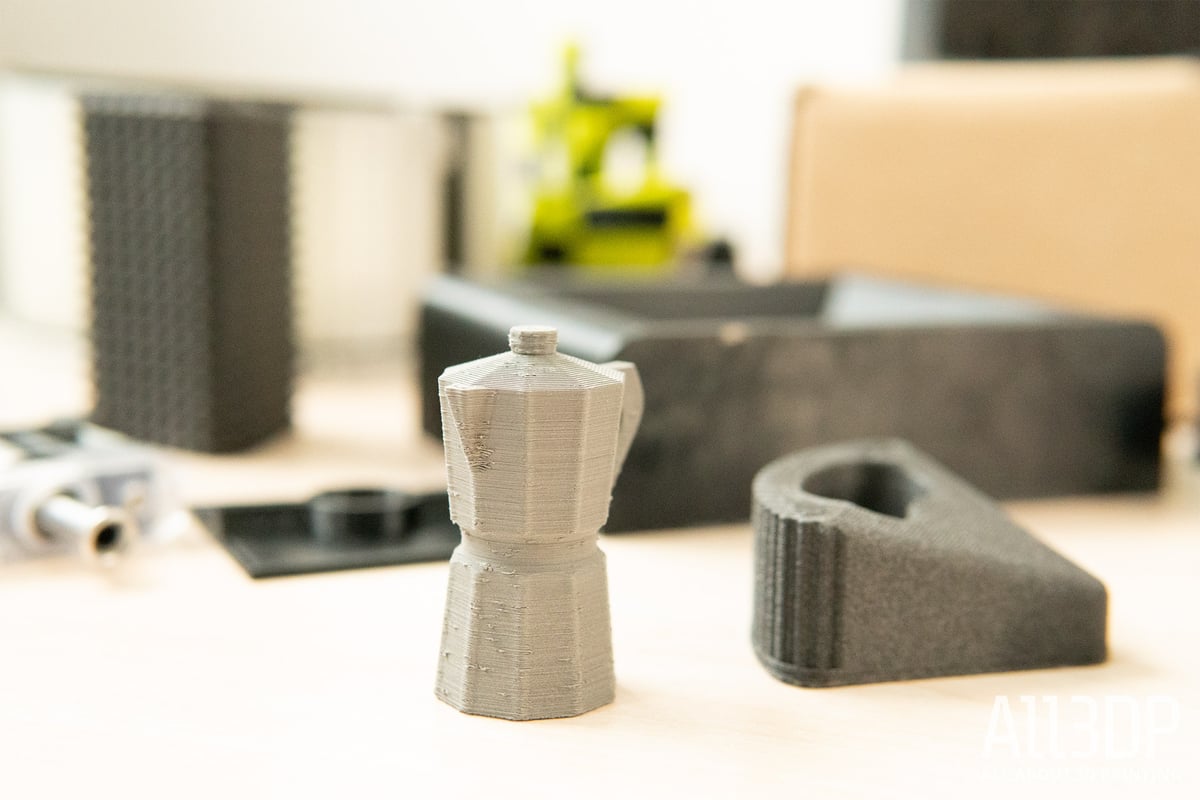

Building up and using the Ultimaker S5 Pro Bundle is a surprisingly straightforward experience that threw few curveballs our way during the introductory stages with the machine. It is a slick user-centric device that minimizes the inherent technicality of the process of additive manufacturing, giving a gentle onramp for the inexperienced and a powerful tool for the initiated. You can find sample imagery of our prints and details in the captions throughout this article.

Print quality generally remained high throughout our weeks putting the machine through constant printing. Ultimaker provides intent profiles for printing with its own materials, which give one of several outcomes for the print (prioritizing surface quality, tolerance, and so on.)

Though we expect different models, materials and printing conditions to push the printed dimensions around, we regularly found that prints kept within +/-0.2 mm in the X- and Y- axes, and almost always mere microns out in the Z-axis when using the default and draft profiles. The “Visual” intent profile sacrifices some dimensional accuracy for a nicer surface finish, while the “Engineering” print intent profile tightens things considerably to within +/-0.1 mm in the X- and Y- axes. The profiles provided by Ultimaker for its materials give you simple and quick control over print time and can nudge you closer to dimensionally better prints.

It must be said though that even the “Draft” print quality typically yielded prints with a decent finish, so you might not find yourself using the Visual profile all that much. Outside of Ultimaker-made materials, you will have to fine-tune your settings for the desired print effect. As is often the case with the S5 Pro Bundle, the more you throw yourself into the ecosystem (in this case, use Ultimaker’s materials) the easier time you’ll have.

It seems that print quality is most at peril from inappropriate material selection for the print at hand (user error) or the quality of the material in general. Diligence on the user’s part, obviously, matters here. The S5 Pro Bundle can’t tell you if you’re using the right material for the print you are attempting.

Some materials will need further fine-tuning, which is to be expected for applications that demand more specific results of the prints. We found that the default profiles for materials make print removal difficult and a risk to the part. This can be adjusted in the slicing settings.

Across a variety of prints ranging from small tooling fixtures to end-use parts for use in recreational activities, to design samples and “fun” prints, we saw a machine that reliably picks up tasks and automates much of the action that on other systems might require operator input. When the machine is correctly configured with materials, printing really is at the fingertips of the Cura or Digital Factory user.

Print Flops Happen

It must be said that the prints are not always perfect. Even using Ultimaker’s own well-versed combo of Tough PLA and PVA soluble support material, we found occasions where the support material strings into the object, leaving pits and pocks on the final part’s surface. Print quality and success are at the whim of the material and set up despite Ultimaker working to make both highly automated. The material and print profiles go a long way to take the pain out of printing, but print success is not assured, especially in our situation of diverse prints and materials. Manual abortions of prints have been necessary to take corrective action.

Which is perhaps more the point of a machine that pushes high uptime, such as the S5 Pro Bundle does. Finding your materials and settings and sticking to them will result in an exceptionally smooth and productive journey for your 3D printing.

We did encounter generic error codes, with the suggested course of action being to reboot the machine. We’ve experienced printer freeze-ups in the past, so to encounter a machine that knows something has gone wrong, even if not what exactly, is actually helpful. On the couple of occasions this happened, rebooting cleared the undetermined issue and the printer picked up where it left off, grabbing a print from the queue or waiting for one to be sent to it.

It’s difficult to place the generic errors into context since the reason for their being is unknown even to the machine, which generally does a decent job of monitoring itself – a note on this, the S5 printer will keep track of various usage milestones and prompt basic maintenance tasks such as lubricating its rods for better reliability in the long term.

Ecosystem, Subscriptions & Training

As we’ve already mentioned, there’s more to selecting the best professional 3D printers than the printer itself and the software. The full ecosystem around the machine – the support, training, service, warranties, and more – is vital to ensure that you get the most out of your investment.

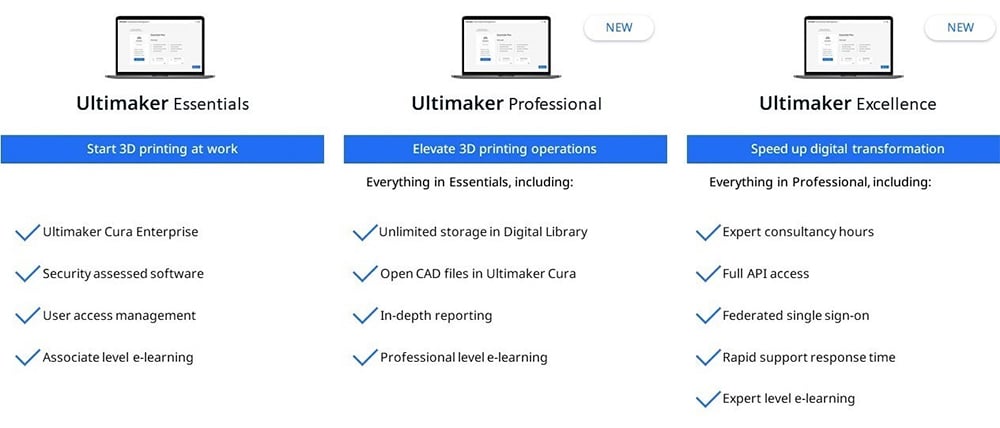

In 2021, Ultimaker beefed up its ecosystem to provide you with several tiers of support and services as a monthly subscription. All S5 printers come with Ultimaker Essentials, a free software-as-a-service subscription that includes Cura Enterprise slicing software; Digital Factory, an application to manage multiple printers anywhere; the Ultimaker Marketplace, which includes print profiles and verified plug-ins; plus professional-level e-learning and support.

With our S5, we upgraded to the Ultimaker Professional subscription, which includes everything in Essentials, plus unlimited storage in the Digital Library for shared part files and drafts, a reporting feature that gathers usage data on prints, printers, materials, and more that can potentially be used to calculate ROI and improve decision-making. This subscription level also includes what Ultimaker calls professional-level e-learning. The monthly price of the Professional subscription varies based on the number of Ultimaker printers you connect and the number of users accessing them in your organization.

- Ultimaker Professional monthly subscription: $600 (1 printer), $1,800 (2-5 printers), $6,000 (6-20 printers)

- Ultimaker Excellence monthly subscription: $12,000 (for 1-20) printers

You can access Ultimaker’s education materials, the Ultimaker Academy, via link out from your Ultimaker account dashboard. Here you’ll find Ultimaker-produced training and acclimatization courses that introduce and demonstrate best-practice use of its machines. Currently, course progress is linked to individual accounts. Organization admins can’t track the progress of team members through the various courses. The current nascent Academy offerings focus on application engineers and getting the newer Ultimaker machines working for you, although Ultimaker Excellence subscribers gain access to additional “expert” e-learning courses.

Buying, Warranties & Support

In your printer decision journey, you may work directly with Ultimaker at first, but the company only sells through local retailers, who will be your contact for purchase, installation (if necessary), some training, maintenance, warranties, and supplies.

As a professional, you know your relationship with your reseller is an important one and can greatly influence your success with any 3D printer. Ultimaker lists its certified resellers online by country. In the US, for example, there are nearly 30 to pick from and many resellers have physical showrooms where you can see the S5 in action.

Your reseller will be your first point of contact for questions and problems, so choose wisely. Don’t choose based on printer price because Ultimaker controls the prices, sales, and discounts. All resellers offer the same price and therefore compete on service. Large resellers, including Dynamism and Matterhackers, have large staff of support engineers and will involve Ultimaker only for complex issues.

Ultimaker says all of its printers come with “lifetime customer support – wherever you are, whenever you need it, and in your language,” which actually refers to their online FAQs, their community of 3D printing experts – an online support forum – and a “submit a request” support feature online.

If you want personal and rapid response from Ultimaker, that’s an option in the “Excellence” subscription, which is the top level of Ultimaker’s service plans. This level may be redundant if your reseller boasts quick response, yet could be an extra layer of protection for large enterprises.

The Excellence level also includes access to Ultimaker’s application engineers, IT and API architects, and data engineering experts. These folks are not trouble-shooting and support, like what your reseller will offer, they instead focus on customizing and integrating the Ultimaker ecosystem into your organization.

Disclosure: What We Can’t Review

We pushed the S5 to its limits and churned out a wide range of parts. We went through the company’s onboarding and peppered them with questions to give you the best impression of whether or not this machine is the best choice for your business. But there are always considerations no month-long review can answer, including durability over time and upgradeability or adaptability. Also, the parts we printed looked and felt as expected but, not being the end user of the part, we did not put them to use.

Although we can’t foresee what new materials or technology the S5 may need to adapt to in the future, we did reach out to one of the world’s largest Ultimaker resellers to talk about durability.

Dynamism has sold more than 10,000 Ultimakers printers and is the first stop for customer repair and maintenance. The reseller offers technical support for the lifetime of the ownership of the product, so they know the machines’ durability.

Douglas Krone, founder and CEO of Dynamism, says Ultimaker has an excellent track record for reliability. “The vast majority of issues we see, stem from Ultimaker being a workhorse printer that is used constantly, but customers may be not following all the maintenance guidelines.” As with any machine, parts wear out and need to be replaced. “So most repairs are simple procedures or part swaps.”

Enterprise customers who have been relying on the Ultimaker for five years or more, have tended to upgrade to the S5 to get all its expanded capabilities, says Krone. “But some educational customers continue to use older machines, and these machines continue to work well,” he adds.

Alternatives to the Ultimaker S5

By now, you should know all the advantages the S5 can deliver to your business. For our case study 3D printing service bureau, the printer was the ideal combination of ease-of-use, reliability, and network-ability, enabling a small staff to use the machine (or three or four of them synced up) efficiently and effectively.

Of course, no printer is one-size-fits-all. If you need to print very large parts, check out our guide to large professional printers:

If you need to use more industrial materials, such as PEEK, take a look at the collection of industrial FDM printers:

Stay tuned for our next Pro Printer Review by signing up for our Pro Newsletter debuting in the autumn of 2021.

Lead image source: The Ultimaker S5 Pro Bundle at the All3DP lab.

License: The text of "Ultimaker S5 Pro Bundle Review" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.