There’s no question that how something will be made influences its design. Additive manufacturing (AM) is giving engineers and industrial designers the freedom to reimagine parts and products, unconstrained by the limits of casting and machining metal, molding plastics, or assembling components. AM enables you to obtain objects with complex internal structures, un-moldable lattice geometries, unique material properties, and even mass customization. The results are lighter, more efficient parts that cost less and are faster to make.

Yet, despite the huge design freedom of additive manufacturing, it can be time-consuming and frustrating to generate and produce designs that fully exploit its potential while minimizing its drawbacks (e.g. supports, post-processing, etc.). This has lead to a growing number of software products that aim to guide and automate the process of design for additive manufacturing (DfAM).

Below we look at the top products that go beyond computer-aided design. They won’t replace your favorite CAD software, but rather apply all of the possible benefits of additive manufacturing to your CAD file. Some even talk to your printer and monitor the build quality in real-time. They offer tools to speed up the workflow of finding the optimal part or product design and getting it 3D printed. These tools include:

- topology optimization

- lattice pattern generation

- generative design

- automatic lightweighting

- automated part consolidation

- stress, heat, and impact simulation

- build failure prediction

The software options are created for designers and engineers who want to explore and experiment with new part forms, functions, and materials, as well as those ready to put them to use as final parts.

Before we dive into the software offerings, let’s define a few DfAM terms.

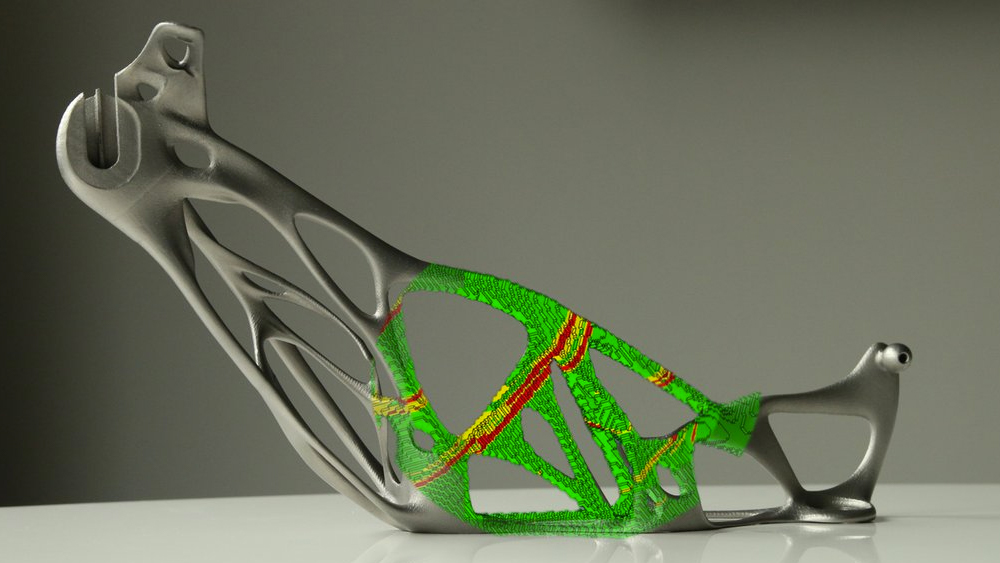

- Topology optimization is a method for, let’s say, streamlining a part by removing the material that isn’t needed for the part to function as required. For example, a solid metal table leg that’s topologically optimized may end up looking more like a scaffold structure because excess material has been removed, and remaining material maybe made more dense. Yet the ability for the leg to hold up the table is the same – or even better. The optimization process evaluates where the stresses are in a part and removes or alters material where needed.

- Generative design is a design exploration process centered around creating a part using the optimal amount and type of material, the ideal material density, shape, and orientation, plus other variables to achieve options for the most optimal design for a specific function. It also includes the use of simulation to impose stresses and mimic movements to further refine the design and present all the possible solutions. By using artificial intelligence, it tests and learns from each iteration. Because of the large amount of variables associated with generative design, powerful software is needed to make all of these calculations in a reasonable amount of time. Generative design is not exclusive to additive manufacturing, but it takes into consideration AM processes. There are shapes and forms that are impossible with traditional manufacturing methods, and the software will point that out.

- Simulation and validation enable you to predict part shape, distortion, and stresses before printing. Validate designs under a range of scenarios including both thermal and structural loading conditions to understand performance and durability. This can remove a lot of trial and error with additive manufacturing R&D and provide essential process documentation required for part certification in certain industries.

Because this niche of design software is still growing, there’s a wide range of options from robust engineering suites to advanced modules inside your favorite CAD programs. Let’s take a look!

| Name | Features | Price |

|---|---|---|

| nTopology’s nTop Platform | topology optimization, generative design, simulation, lattice design, design workflows, 3D packing | $7,500 per user, per year |

| Ansys Additive Suite | topology optimization, generative design, simulation, lattice design, design workflows, machine parameters | $3,260 per year |

| MSC Apex Generative Design | generative design, simulation, design validation, lattice design | contact reseller |

| Autodesk's Netfabb Ultimate | topology optimization, generative design, simulation, lattice design, design workflows, machine parameters, print failure prediction, 3D packing | ~$13,790 per year |

| 3D Systems' 3DXpert | topology optimization, simulation, lattice design, design workflows, machine parameters, print failure prediction, 3D packing | contact reseller |

| Gen3D Sulis | topology optimization, generative design, lattice generator, simulation | ~$2,000 per year |

| Altair Inspire Print3D & OptiStruct | topology optimization, generative design, simulation, lattice design, design workflows, 3D packing, manufacturing simulation | contact reseller |

| Fusion 360 | generative design, simulation | $495 per year |

| Materialise 3-matic | topology optimization, generative design, simulation, lattice design, design workflows, texture generator | contact reseller |

| Siemens NX | topology optimization, generative design, simulation, lattice design, design workflows, 3D packing, machine parameters, design validation | contact reseller |

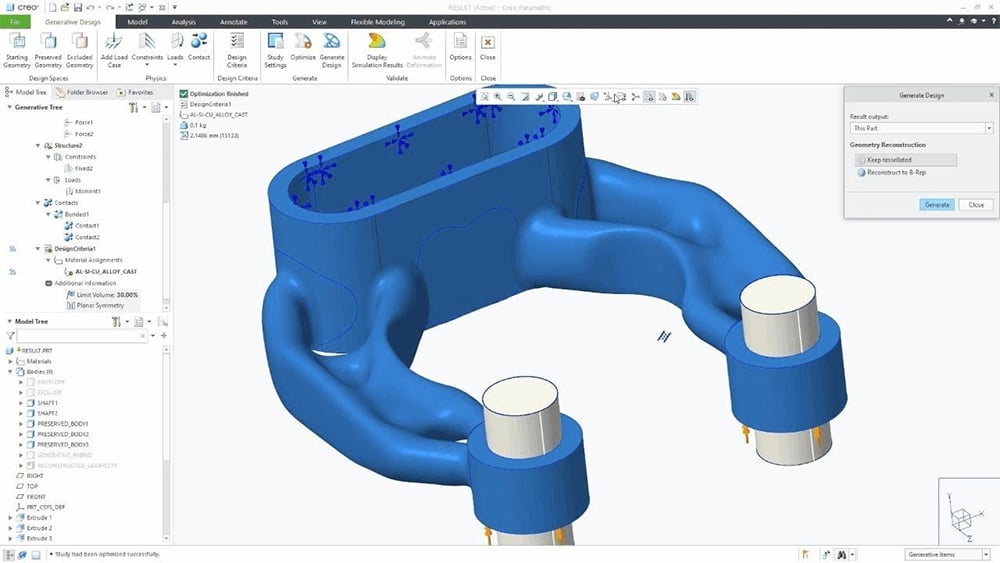

| Creo | topology optimization, simulation, lattice design, design workflows, 3D packing, machine parameters | $2,480 per year (without AM modules) |

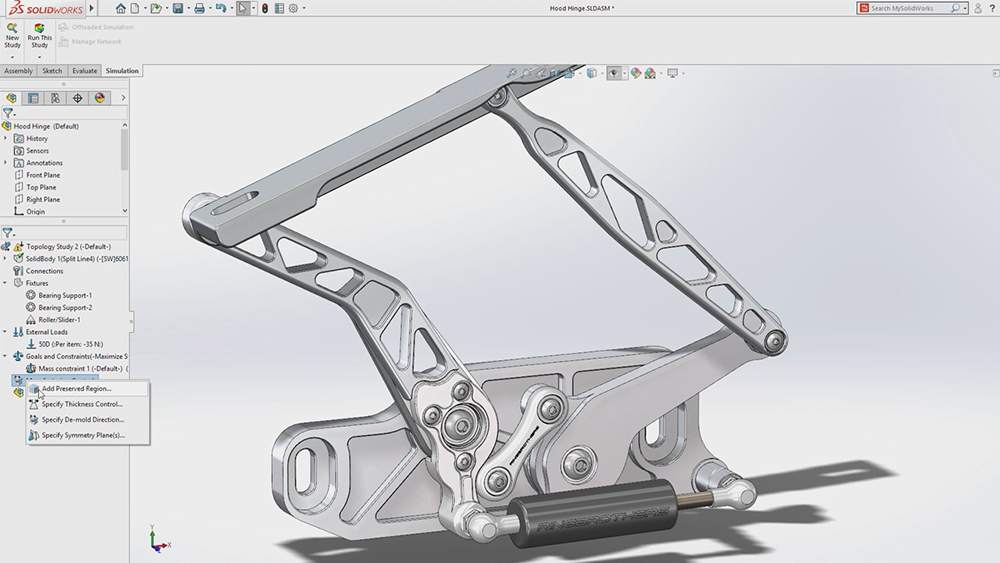

| Solidworks | topology optimization, generative design, simulation, lattice design, design workflows | contact reseller |

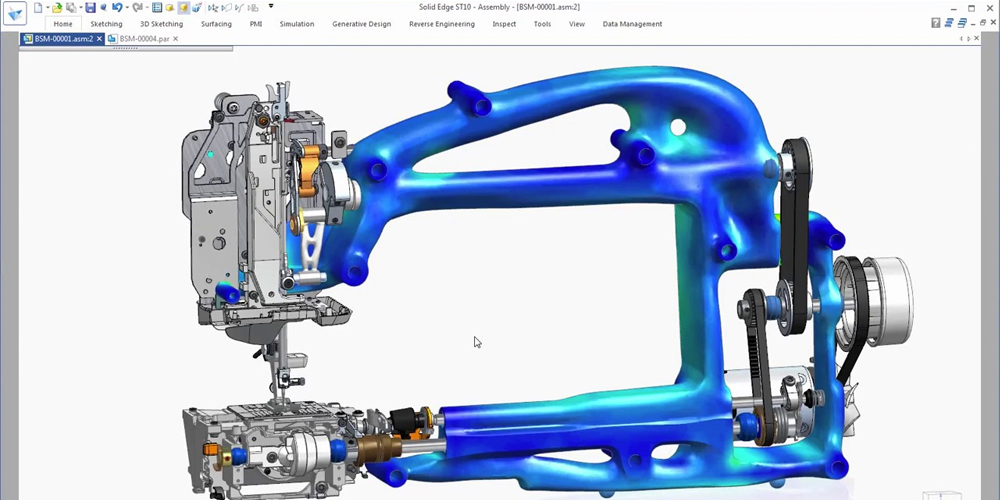

| Solid Edge | topology optimization, generative design, simulation | contact reseller |

nTopology’s nTop Platform

American software startup nTopology’s nTop Platform is a comprehensive modeling software suite for designers where they can either design a part for advanced manufacturing from scratch or import an existing digital design file for optimization. The platform helps engineers create lightweight and optimized parts with their functional requirements built in.

In addition to some of the tools you may be familiar with in CAD software, nTop offers toolkits, which are collections of predefined workflows that essentially automate a lot of what you want DfAM software to do. The toolkits include ones for lightweighting, design analysis, and topology optimization.

nTop Platform not only helps you prepare design data for additive manufacture but also lets you directly communicate with your 3D printers to ensure that your design intent is maintained throughout the process.

nTopology has been collaborating with printer manufacturer Stratasys to deliver essentially one-click processes for some of the most common additively manufactured products. Their FDM Fixture Generator automates about 90% of the design work required for additively manufacturing jigs and fixtures, while the Assembly Fixture Module, automates the design of kitting trays, storage cases, and other simple fixtures to support manufacturing operations.

Ansys Additive Suite

A comprehensive solution for AM designs and engineers, Ansys Additive Suite spans the entire workflow from DfAM through validation, print design, process simulation, and materials exploration.

Focusing exclusively on AM, the platform includes a range of tools for design (topology and lattice optimization) and simulation that’s specifically for AM build processes, such as metal powder bed fusion. The simulation and validation suites are designed to help you calculate for distortion and predict build failures.

In fact, Ansys’ main strength is its engineering simulation software, and its claim to fame is likely its speed. The GPU-enabled rapid modeling feature let you experiment with geometry and materials without taking hours to render, in order to quickly identify the optimal solution to an engineering problem.

The platform’s Additive Science module is a fascinating standalone application for the design-stage investigation of materials and optimal machine parameters. With this tool, you can explore how different materials affect the function of your part and tune your material setting to even predict the porosity and even the grain morphology.

Ansys Additive Suite is available as an add-on to the Ansys Mechanical Enterprise license and a wide range of third-party apps integrate with the system, include ones for mesh generation and lattice simulation.

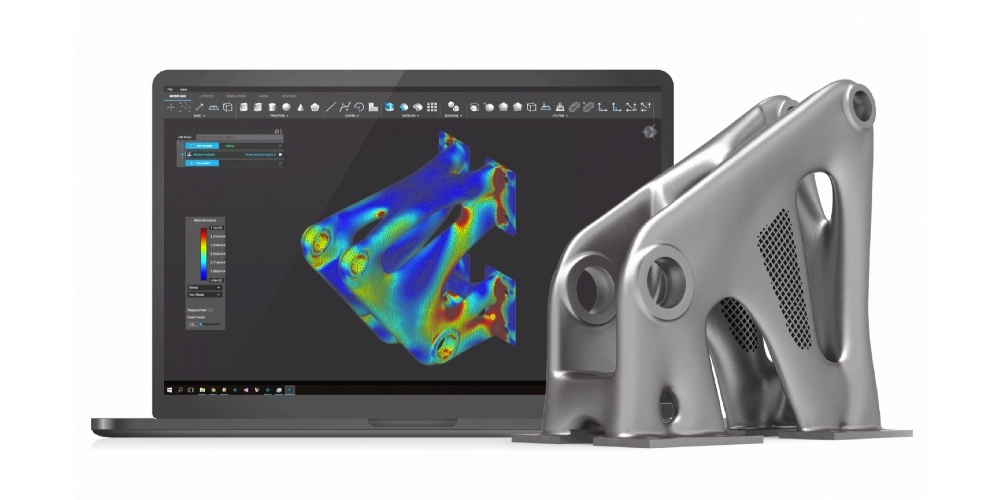

MSC Apex Generative Design

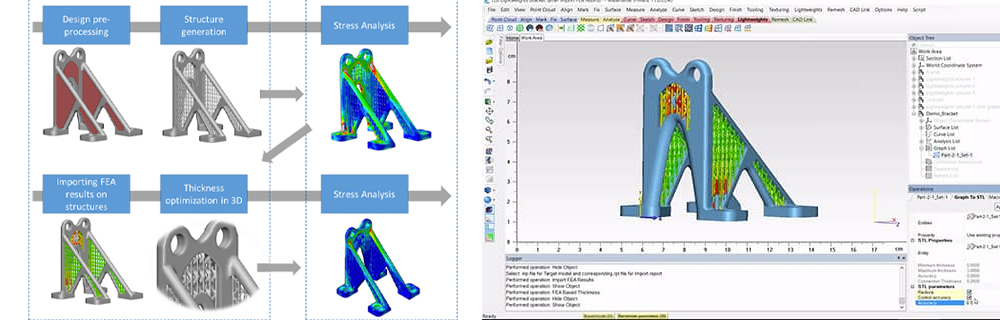

California-based MSC (a division of Hexagon Manufacturing Intelligence) produces a wide range of software solutions for engineers, but here we take a look at their Apex Generative Design product and AM simulation apps. Simufact and Digimat.

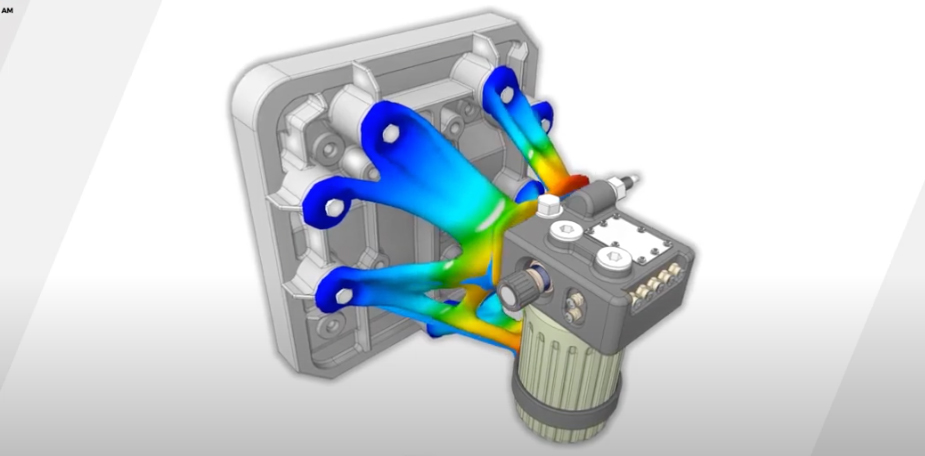

Apex Generative Design is an automated solution for optimizing technical parts that includes algorithms to generate complex, lightweight structures for additive manufacturing in a pretty short time. The aim of the software is to make generative design accessible to all types of engineers and Apex promises that the results can be sent straight to print.

Import your CAD file and almost automatically generate multiple design candidates that all satisfy the design criteria you’ve input while minimizing the weight. You can print the resulting files or import them into simulation engines, such as MSC’s Simufact Additive or Digimat AM to achieve “cost-efficient first-time-right results” for every part, MSC says.

Simufact Additive is MSC’s solution for metal additive manufacturing that focuses on build simulation and subsequent steps, including what will happens during heat treatment. You can also identify the best build orientation, determine and compensate for final metal part distortion automatically, predict the influence of several components in the build space, and identify potential manufacturing issues, such as cracks and layer offsets before they happen.

Digimat AM is MSC’s solution for polymer and composite AM providing more predictive simulation tools.

https://www.youtube.com/watch?v=TtiVnxVlRg4

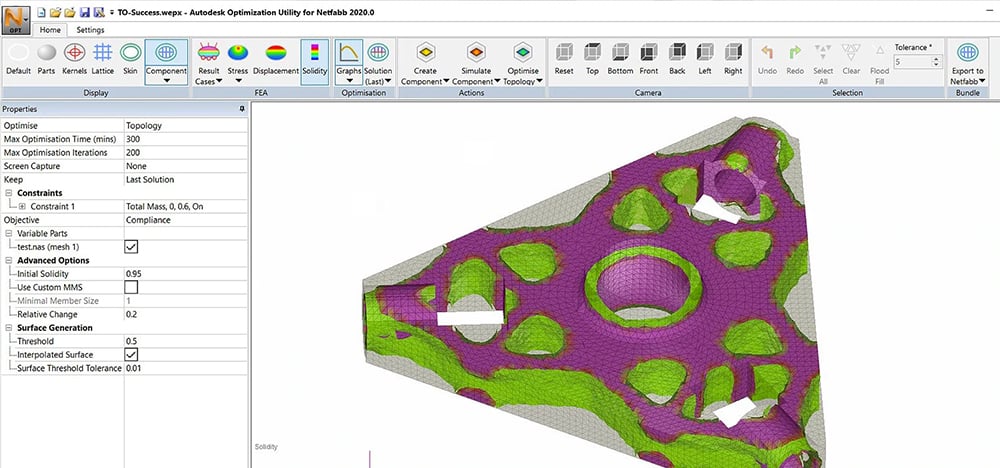

Autodesk's Netfabb Ultimate

Netfabb by Autodesk used to be one of these additive manufacturing software solutions that sat between your CAD and your 3D printer, but earlier this year Autodesk decided to bundle Netfabb with their CAD program Fusion 360. So, Netfabb users get Fusion 360 for an extra $30 a month, but Fusion 360 subscribers who want Netfabb Ultimate (full feature) will need to upgrade their subscription to $4,415 per year. There’s are also Netfabb Ultimate and Netfabb Simulation upgrades.

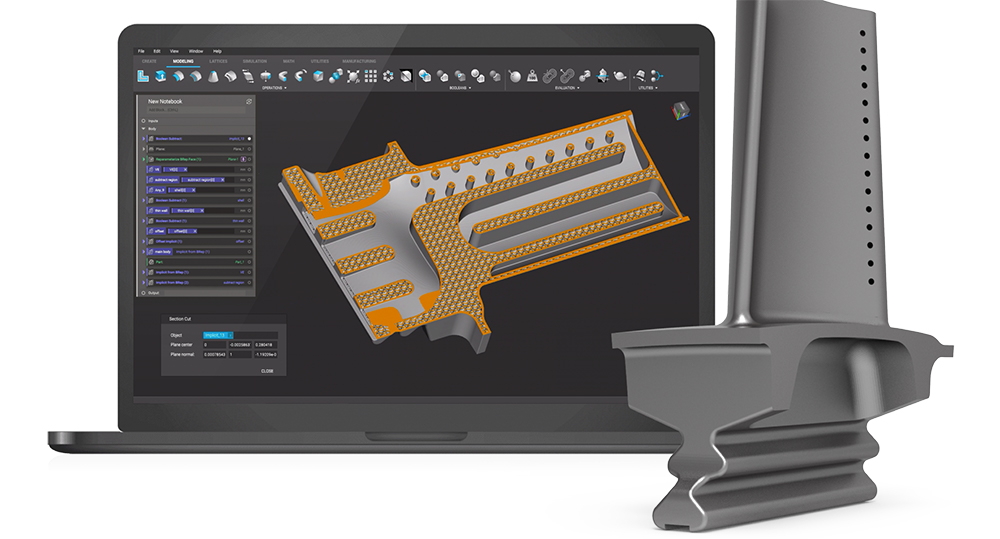

Netfabb is a build preparation software with tools for optimizing designs for additive manufacturing and simulating metal additive processes. Import models from a variety of CAD formats and use the design optimization for additive manufacturing tools to create internal lattice structures, automatically verify and optimize lattice and skin elements to meet load requirements and reduce weight, then generate forms that are optimized based on the loads and constraints of the parts.

But on top of those basic features sit a robust simulation environment that’s meant to streamline design and ensure that printed parts are printed right the first time. With the simulation capabilities, you can predict the thermomechanical response of additive parts during the metal powder bed fusion and directed energy deposition manufacturing processes.

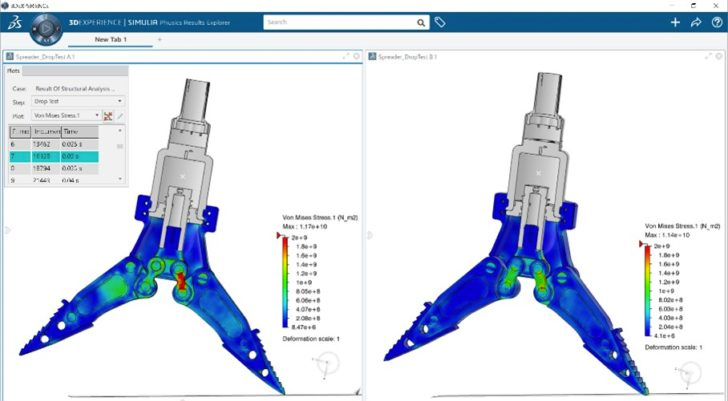

3D Systems' 3DXpert

3DXpert, published by printer manufacturer 3D Systems, was specifically created to prepare designs for metal additive manufacturing. It offers tools for everything from lightweighting and topology optimization to streaming your workflows and calculating manufacturing costs.

3DXpert is an AM-first software. Import your CAD file and take your part through topology optimization, lattice creation, support design, and simulate the printing and post-processing, then arrange the build platform and send it to print on any industrial printer (you don’t have to own a 3D Systems machine).

3DXpert comes in several modules that you can mix and match to your needs. There’s a basic package for automated 3D printing prep, a pro package with more advanced design tools, the Ultimate package for AM, and the AM designer package with the full set of DfAM tools. There’s also a separate module for dental and educational users.

Check it out via the company’s fully-functional free trial.

Gen3D Sulis

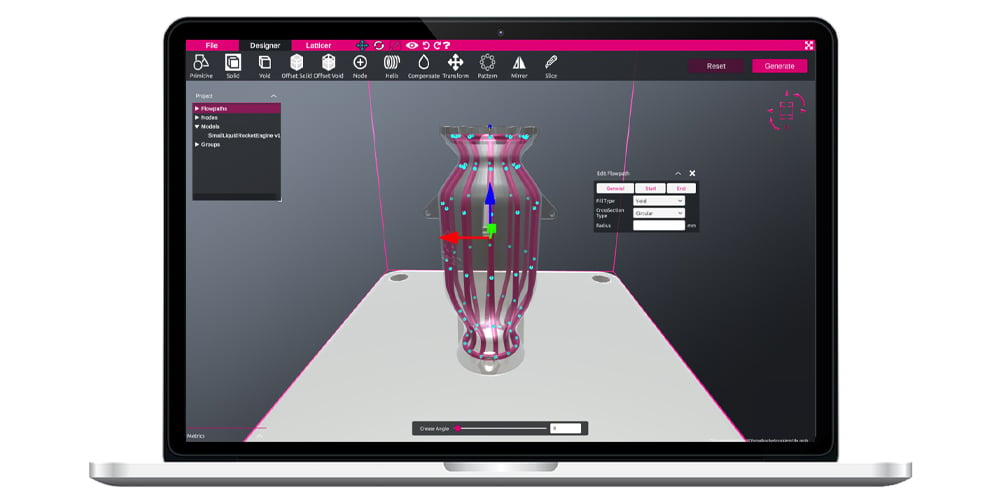

Founded in 2018, by academics at the University of Bath, Gen3D promises to let engineers “unleash their AM design potential.” The company offers additive manufacturing design software to rapidly create AM-appropriate geometry with “design accelerators” and generative design features.

WIth Gen3D you can define or change the layout of a concept in real-time using click-and-drag 3D editing tools. The manufacturing checks and compensation tools exploit the benefits of AM and reduce the risk of costly failures.

The lattice builder lets you choose between cartesian, cylindrical, or spherical coordinate systems to ensure lattices fit seamlessly within your CAD models.

https://www.youtube.com/watch?v=GZUjixidqFM

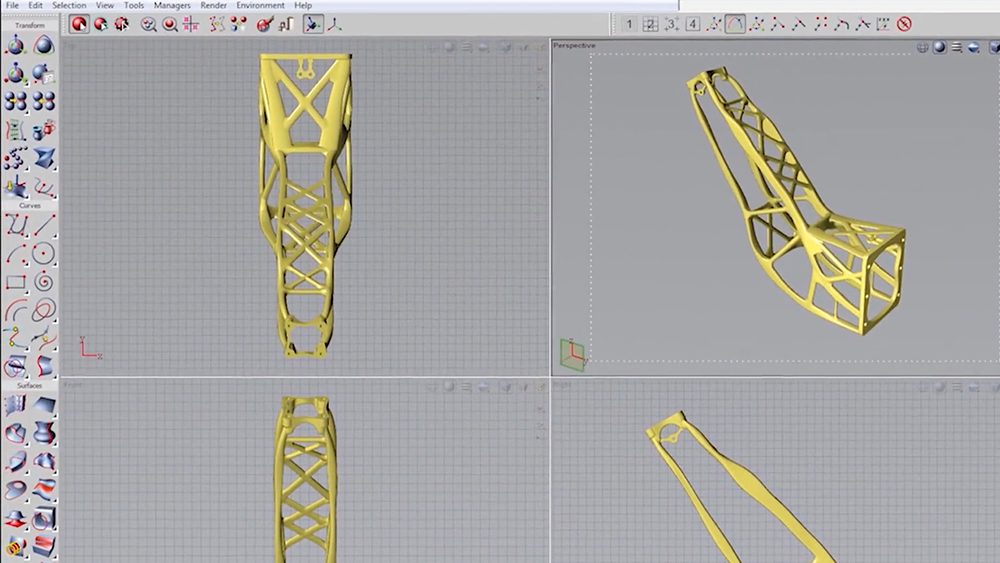

Altair Inspire Print3D & OptiStruct

American software publisher Altair provides solutions in the areas of simulation, high-performance computing, and artificial intelligence, with some pretty impressive topology optimization and DfAM tools.

The Altair OptiStruct is one of the earliest topology optimization structural design tools established decades ago to help designers and engineers rapidly develop lightweight and structurally efficient designs. Although not specific to additive manufacturing it does have DfAM features, including complex lattice structure generation. Lattice performance can be studied under tension, compression, shear, flexion, torsion, and fatigue life.

For Additive Manufacturing, Altair Inspire Print3D is designed to cut costs by reducing material usage, print times, and post-processing. It provides a fast and accurate toolset for the design and process simulation of selective laser melting (SLM) parts. Engineers can quickly understand changes to process or design that affect manufacturing efficiency, then export part and support structure geometry to major printer preparation software for printing. It also simplifies the identification and correction of potential deformation, delamination, and excessive heating issues before building a part.

Because Altair has simulation tools for all types of manufacturing it can help you shop to determine if something is better off manufactured with 3D printers or with a range of traditional methods.

DfAM Within Your Favorite CAD Programs

You may wonder why you need a separate piece of software when your favorite computer-aided design program offers a host of DfAM features, tools, plug-ins, and modules. Well, in many cases you don’t. Major software publishers are bringing DfAM tools into the CAD environment, but many of them lack the sophistication and especially the speed of the dedicated programs above because they have more broad design applications.

Yet, if you’re looking for a CAD program with good DfAM features, check out these options below.

Fusion 360

Autodesk has realized that if additive manufacturing methods aren’t included as options in its popular Fusion 360 CAD software, designers will need to make their build calculations elsewhere to avoid costly, late-stage redesigns. This is what’s behind the move to bundle the publisher’s Netfabb solution to Fusion 360, but if you won’t want the full Netfabb option (and pay the extra couple of thousand dollars) Fusion 360 offers some nice DfAM features on its own.

The program’s generative design module enables you to explore multiple manufacturing-ready outcomes that meet your design specifications while reducing weight, improving performance, and consolidating parts. Just plug in your criteria and 3D printing method and the module spits out a wide range of design options to choose from. You can even compare options side by side. Once you choose the best fit, import the optimized element into your design and continue to edit it.

Fusion 360 also comes packed with a pretty powerful simulation environment where you can expose your design to static and thermal stresses, structural buckling, and event simulation-like dropping. The module not only predicts these effects but solves them without pausing your work.

In addition to these included models, Fusion 360 also offers optional paid extensions, including a more advanced generative design option ($495 per year) and the Additive Build extension ($495 per year) for metal powder bed fusion machine AM processes. Additive Build enables you to select 3D print parameters, automatically orient parts, and generate fully associative support structures for efficient programming.

Materialise 3-matic

Materialise started nearly 30 years ago on data preparation software to take a digital model and make it 3D printable. Their Magics software began as a set of repair tools that automatically transforms your design into a watertight, 3D printable model, but as the industry has matured, so has Magics.

Today, there’s a lot more that can be done to optimize a design file on its way from CAD to printer, and Materialise has a huge suite of modules for enterprises that covers everything from auto-generating supports to communicating with a wide range of 3D printers to centralized management of your day-to-day AM operations, but here let’s take a closer look at their design optimization software, Materialise 3-matic.

Although not featuring a lot of the deep experimentation tools as others options, Materialise 3-matic is a versatile tool to make design modifications on the mesh level without disturbing the parts’ essential form. So it improves, but doesn’t reimagine. It can generate lattice designs and 3D textures, perforations, and patterns directly on the STL file. You can also develop and certify personalized porous medical devices with the new medical version of the grid structure module.

As more of an enterprise tool, say for 3D printing service bureaus, it can also script repetitive workflows for part optimization.

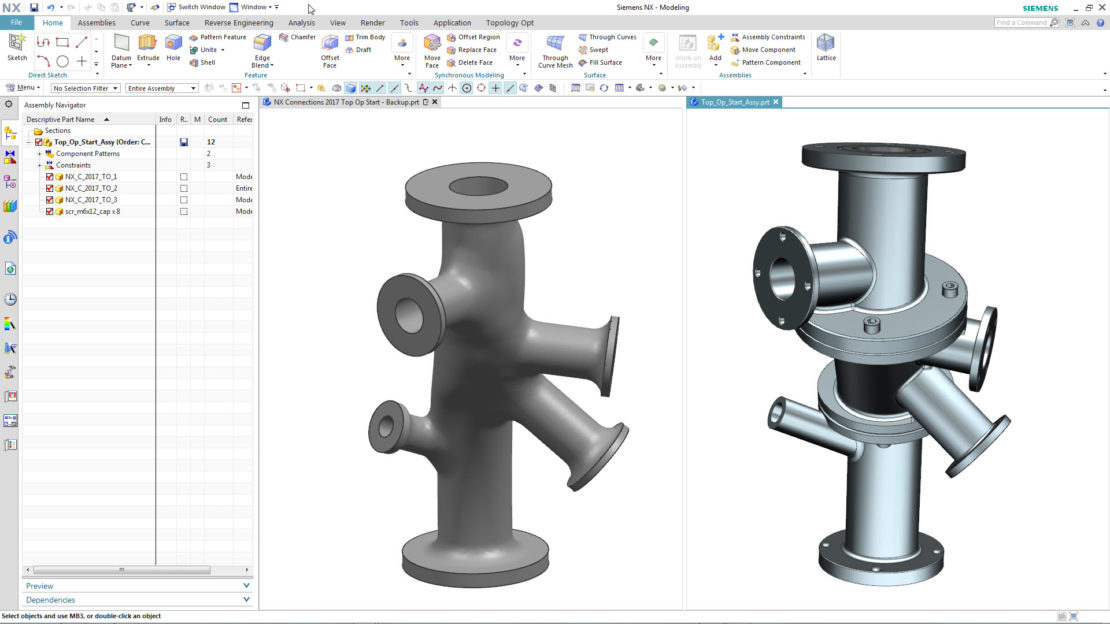

Siemens NX

Siemens NX software is one of the most complete platforms for CAD/CAM/CAE engineering design and manufacturing. Although not a solution specific to additive manufacturing, it incorporates a host of tools for automating many of the unique challenges of designing, optimizing, and building metal and plastic components using the latest additive manufacturing methods. It integrates with a wide range of additive manufacturing technologies and printers, and even offers a connection to a global supplier network of 3D printing services where you can get your parts printed if you don’t own your own machines.

Designed for companies where input on a product design is a collaboration, NX aims to streamline and accelerate the process with integrated data management, process automation, decision support, and other tools that help you refine your development processes.

Siemens says NX helps companies develop products “right the first time” by using virtual models and simulation to accurately evaluate product performance and manufacturability on a range of 3D printers, and by continuously validating designs for compliance with industry, company, and customer requirements.

NX’s tools specifically for additive manufacturing include generative design, topological optimization, nesting, automated support structure generation, and design validation.

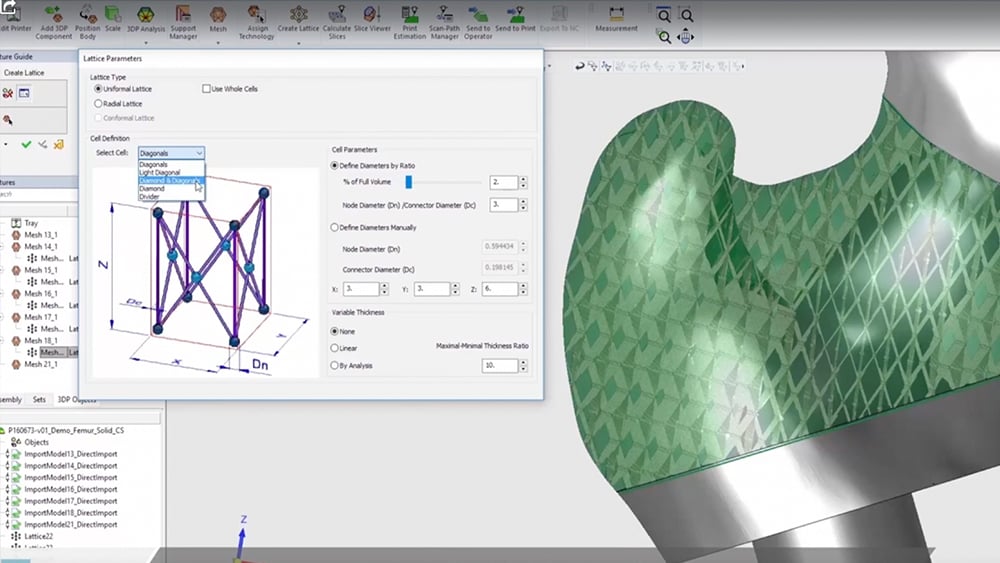

Creo

Creo by Parametric Technology Corporation (PTC) is another popular CAD software that’s upping its DfAM options. Now you can combine their easy-to-use design environment with new technologies, such as generative design, augmented reality, real-time simulation, and additive manufacturing.

In the latest version of Creo, you’ll notice expanded AI-drive generative design features that autonomously create designs from a set of criteria you specify, while new simulation tools guide and help validate your design decisions. Creo new Generative Topology Optimization (GTO) extension creates optimized product designs that enable you to simultaneously explore numerous innovative design options, with top options automatically highlighted. The cloud-based Generative Design Extension (GDX) helps you optimize product designs based on your constraints and requirements – including materials and manufacturing processes.

There are also new Creo features to help you simplify designs for additive manufacturing, including simulation-driven lattice design and improvements. Simulation results from CSL and Creo Simulate can now be used to optimize the variability of the lattices. This capability is accessible via the same lattice feature UI and workflow. Creo has partnered with Ansys (mentioned above) to provide simulation-driven design called Creo Ansys Simulation Live. It provides designers with a way to incorporate simulation early in the design process by using real-time structural, modal, thermal, and fluid flow analysis to iterate on and modify design.

Solidworks

If you’re a Solidworks (Dassault Systèmes) users there are a number of options and plug-ins for this CAD program along with integrations with other platforms from the same publisher. The expanded 3DExperience Works portfolio, from Solidworks, unites your entire ecosystem, allowing you to connect the people, applications, and real-time data from every aspect of your business. The portfolio provides not only 3D modeling, but simulation, data management, and manufacturing solutions.

Specific to DfAM, take a look at the Topology Study in Solidworks Simulation Professional module that lets you focus on validating the design function. The Topology Study takes your desired goals, constraints, and manufacturing options into account to guide your decisions on the component form. You can also incorporate simulation data from Solidworks’ Flow or Motion models to educate your options.

One add-in to the Solidworks platform called ParetoWorks enables you to generate early-stage concepts that balance constraints, objectives, product performance, resources, and time constraints. Its aim is to empower you to explore more designs in less time. ParetoWorks works inside SolidWorks on a desktop or laptop within your design process with no need to transfer data to the cloud.

Anther topology optimization modules that incorporate with Solidworks is Tosca Structure.

Solid Edge

Another Siemens product, Solid Edge is a popular CAD program with integrated DfAM features. The Solid Edge solution for topology optimization allows you to replace small assemblies with a single component and the generative design study can result in interesting new design ideas that can be incorporated into your traditional design process. Both of these features take additive manufacturing perimeters into consideration.

The Solid Edge Simulation module enables you to subject your design to all types of stresses and vibrations to pinpoint potential failures and fix them before you print.

Specialized DfAM Solutions

If your company only wants to optimize one product for additive manufacturing, you may not need a solution that will apply DfAM parameters to everything. That’s the thought behind specialized solutions below aimed and industries that produce a specific product that could greatly benefit from a redesign for 3D printing.

TOffeeAM

This UK startup offers design software that specializes in fluid-structure generative design, with applications in heat exchangers, valves, and complex coolant systems.

Shapeshift 3D

This start-up specializes in software solutions aimed at digitizing and automating the customization of high-performance medical and sports equipment, among other products. The software automatically fits a 3D product’s model to a client’s 3D scan while maintaining compliance to medical, manufacturing, functional, performance, and branding requirements.

Lead image source: Generative design module in Autodesk Fusion 360.

License: The text of "Top Design for Additive Manufacturing (DfAM) Software" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.