Manufacturing a machine with three mechanically-similar functions in one may seem simple on paper, but the fact that there are so few companies that do it shows the true complexity (or folly) of the task. The Snapmaker Artisan is Snapmakers’ third crack at the 3-in-1 space – and it brings a lot to the creative table.

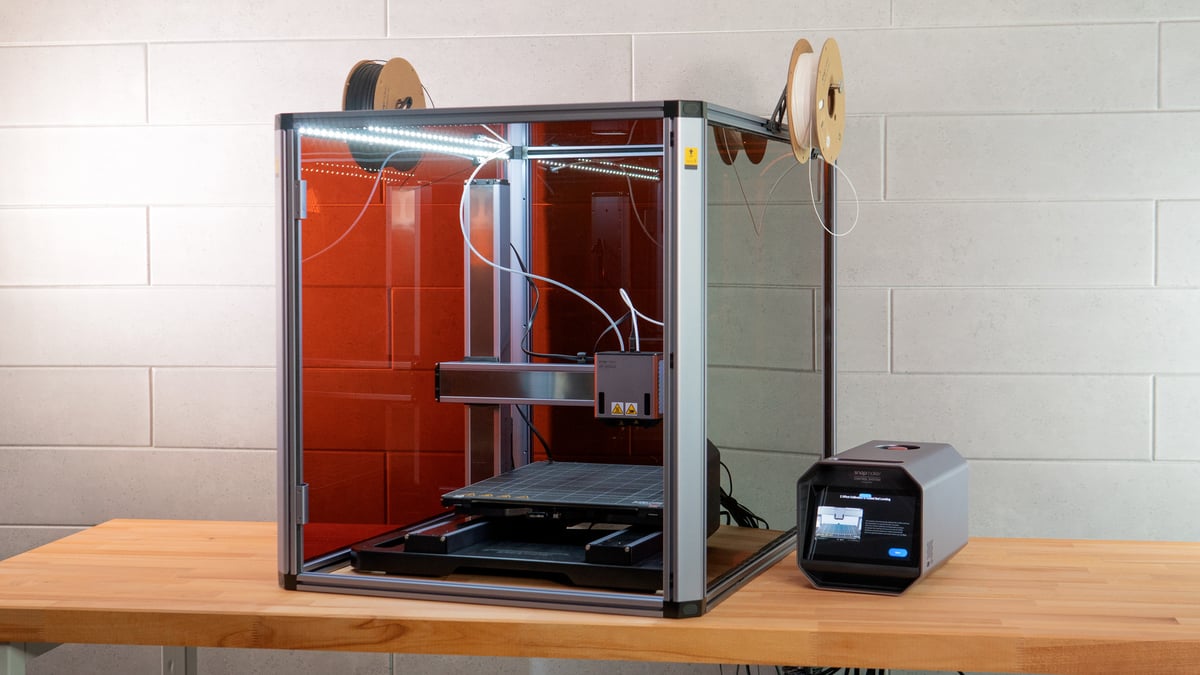

It also takes up a lot of said table – the Snapmaker Artisan is massive. Encased in an enclosure that has a few tricks of its own, the Artisan offers dual-extrusion 3D printing, laser cutting and engraving courtesy of a 10W dual-diode laser, and CNC cutting and carving powered by a 10W spindle with ER11 collet. Within its monolithic orange box, the Artisan offers up to a whopping 400 x 400 x 400 mm of build volume, and sprawls to a monstrous ~1,000 x 1,000 x 900 mm footprint.

Unlike previous Snapmaker machines, the Artisan wasn’t funded via a Kickstarter campaign. So the expectation should be that it’s a slick, finished product shipping out rather than a glorified beta test unit, shouldn’t it? Shouldn’t it?!

Oh dear.

Verdict

Pros

- Three creative tech tools in the footprint of one

- The overall presentation of the Artisan is premium

- Decent dual extrusion printing experience

Cons

- It takes up an absurd amount of space

- Some wrinkles to iron out in the system

- CNC experience too dense for beginners

- Fiddly enclosure setup

The Snapmaker Artisan makes a clear evolutionary step up from its predecessor, the Snapmaker 2.0. A stronger motion system, stronger CNC spindle, stronger laser, expanded 3D printing capabilities, and a perfected module swap mechanism make sure of that.

Despite being better, it’s still a jack-of-all-trades, master of none. The Artisan’s sole advantage over dedicated systems is that you’re getting three functions in one machine, instead of requiring the space for them individually. That argument weakens a little when the enclosure and control box together (plus accessories and tools) require a comically absurd amount of desk space.

And there are still software issues to iron out, too. Wi-Fi connectivity isn’t an option if your network password is longer than 16 characters (or, in a word, secure) plus the odd freeze-up and individual issues with 3D printing points to Snapmaker playing catchup with updates for the Artisan. It is not yet the buttery smooth experience its overall presentation suggests it should be.

A needed update on the Snapmaker 2.0 for power users (which, in the small world of 3-in-1 3D printers, laser engravers, and CNC machines, makes it our top recommendation). But for the rest of us, one to watch for now.

At a Glance

- Price: $2,999

- Build Volume: 400 x 400 x 400 mm

- Max. Hot End/Heated Bed Temperatures: 300 °C / 110 °C

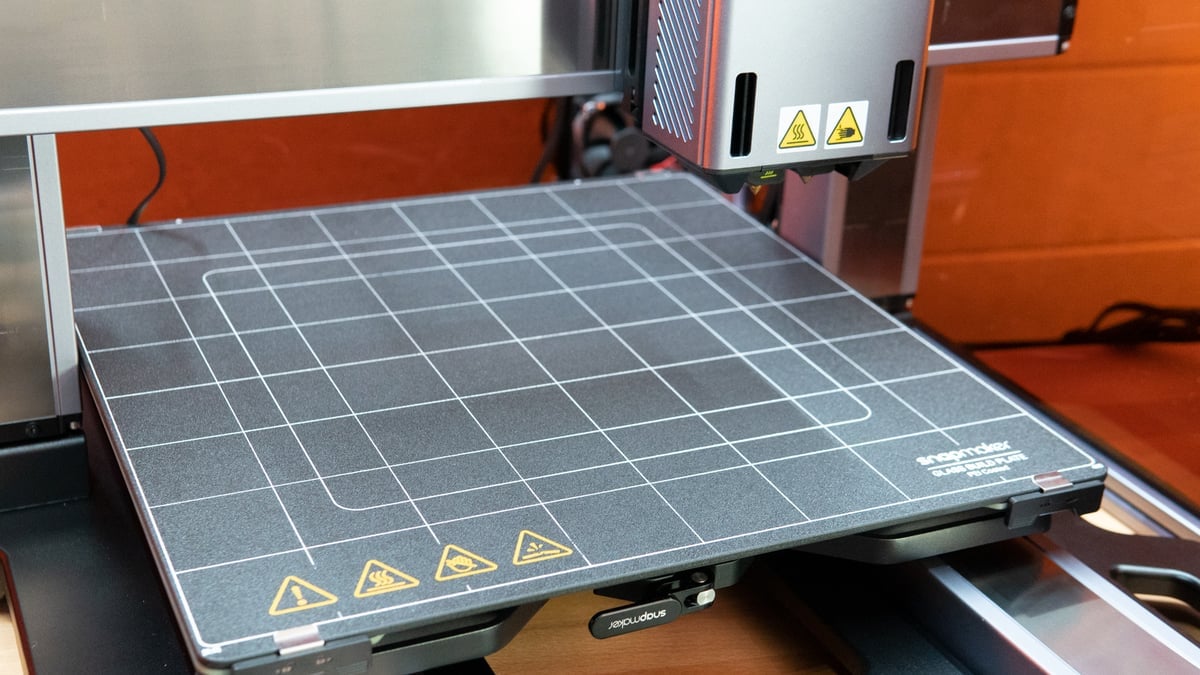

- Print Bed Material: PEI-coated glass, removable

- USP: Stylish multifunctional making machine

- They say: “Turn your desktop into your workshop.”

- We say: “Apply for a zoning permit before buying.”

The Tech

If you hadn’t gathered by this point, the Snapmaker Artisan is a multi-functional making machine. It offers 3D printing (dual extrusion 3D printing, to be precise), alongside laser engraving and cutting, plus CNC engraving and cutting. A rotary module is available separately for 4-axis laser and CNC engraving.

Not to over-egg the pudding, but the Artisan is a big machine. No one should go into buying one expecting it to take up a modest corner of their workspace. The enclosure is huge, and you need space next to this for the control box; almost a meter cubed in all.

Thankfully, it all looks pretty snazzy, which consequently lowers your guard against giving up so much of your personal space to the machine. At least it looks good.

3D Printing

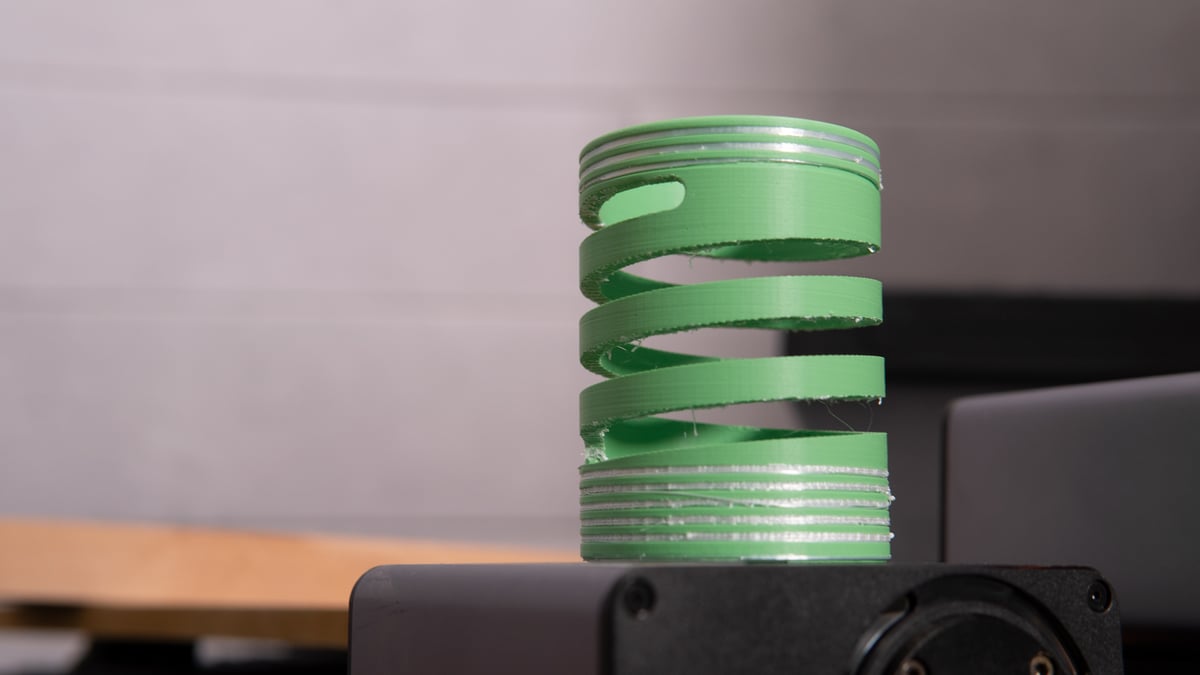

We’re pleased to report that the 3D printing experience of the Artisan is much nicer than that of the Snapmaker 2.0. Where before it was passable, now it’s pretty okay. (A glowing endorsement, we know.) Despite a sprightly boost in speed over its predecessor, it’s not the fastest – hardly surprising, given the sheer mass of moving parts. We flag this because print speed is a hot topic in desktop 3D printing right now thanks to the likes of Bambu Lab going scorched earth on everyone else – the Bambu Lab P1P absolutely smokes the Artisan, and you could buy four of them (with change) for the Artisan’s $2,999.

The Artisan will always be limited somewhat by its components having to be heavy-duty to withstand the stresses of CNC machining. That forces it to be slower. Realistically, given this slowness, there’s no excuse for the Snapmaker print quality to be anything less than perfect, but it’s not. Through all our testing, we rarely found the prints to be display-worthy without touching up and post-processing. Imperfect, if that’s all, is mostly fine, but our multiple attempts at large volume-spanning prints all encountered layer shifting, too, which isn’t so forgivable.

A saving grace, perhaps, is that dual extrusion performance is decent. The new print core system has a lot of potential, with different sizes and types available to combine and achieve smarter print strategies. It’s disappointing only to see 0.4 mm cores come in the box, given the Artisan’s sprawling 400 x 400 x 400 mm build volume. In its stock configuration, large prints take days, which is way too long.

Kudos to Snapmaker for making the Artisan’s heated print bed zonal, meaning you can print smaller objects quicker (and presumably more energy efficiently) by only heating the middle of the print bed.

Heating to 300 °C, both hot ends are capable of printing trickier, high-temp materials, something helped by the Artisan’s enclosure trapping heat well. The provided nozzles are brass, though, so abrasives are a no-go unless you plan on replacing the nozzle. (The nozzles seem to be standard MK8-style, so you could just swap out the metal without having to buy a new print core as Snapmaker seems to want you to, judging by the $55 hardened-nozzle print cores listed on its accessories page.)

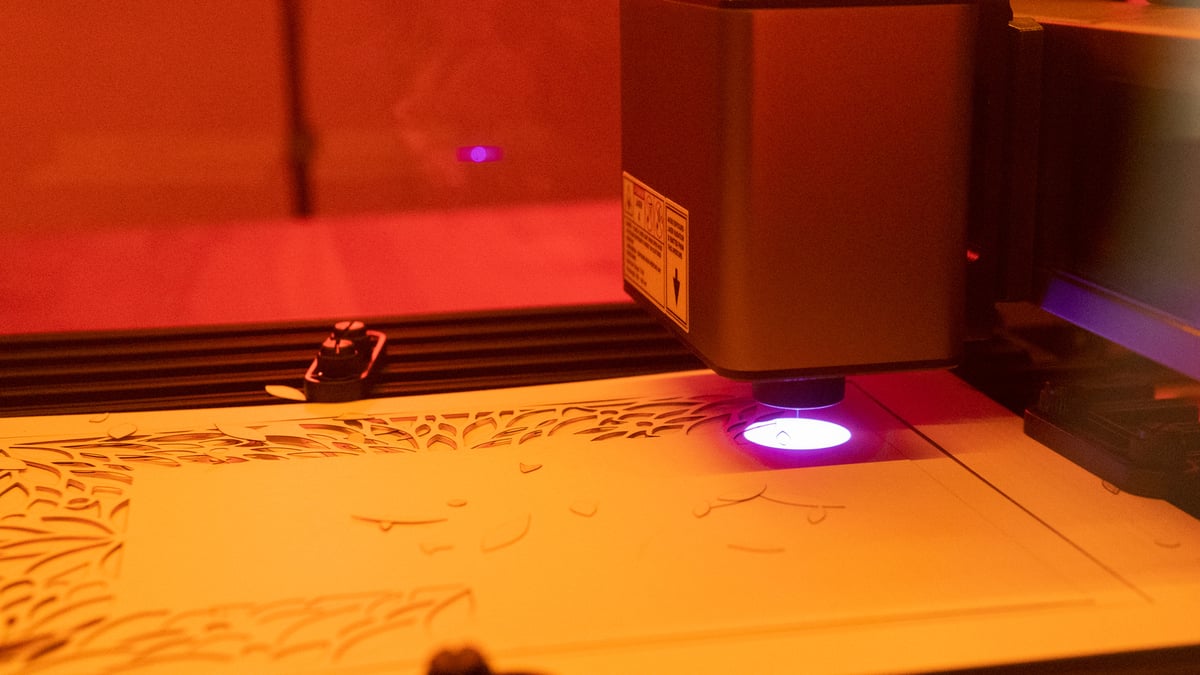

Laser Engraving/Cutting

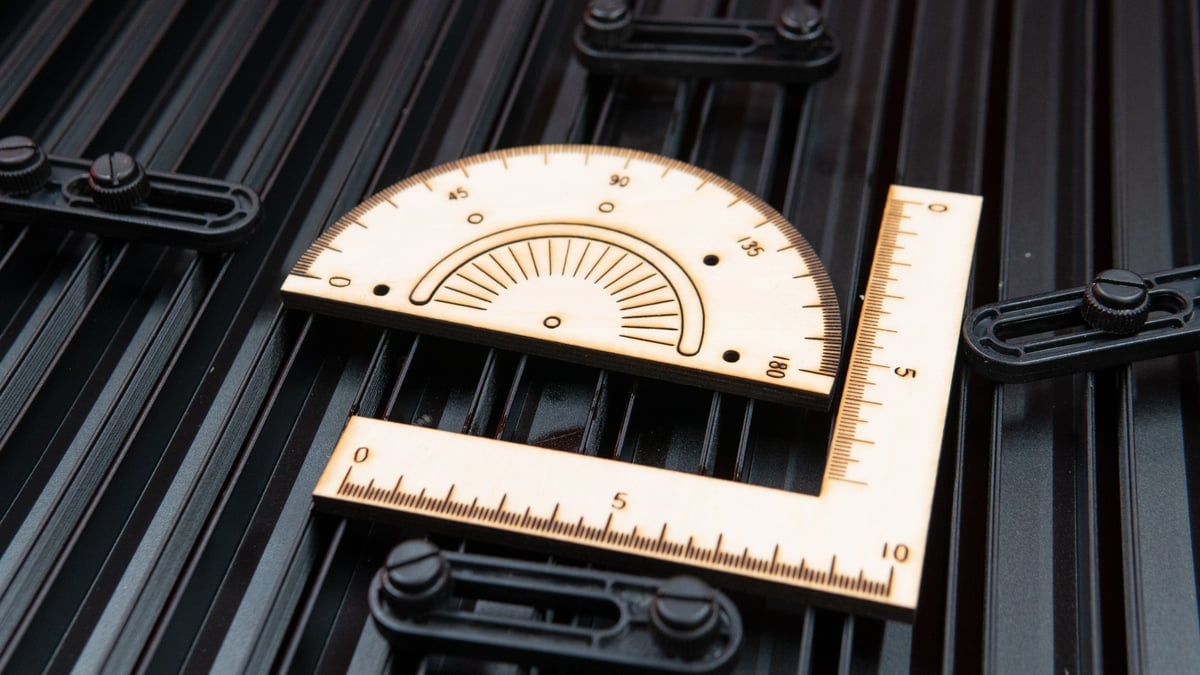

Snapmaker’s new 10W laser module for the Artisan combines two 5W laser diodes to pack some punch. The cutting performance is good enough for single-pass cuts of some woods up to 8 mm thick, plus simpler materials like leather and acrylics.

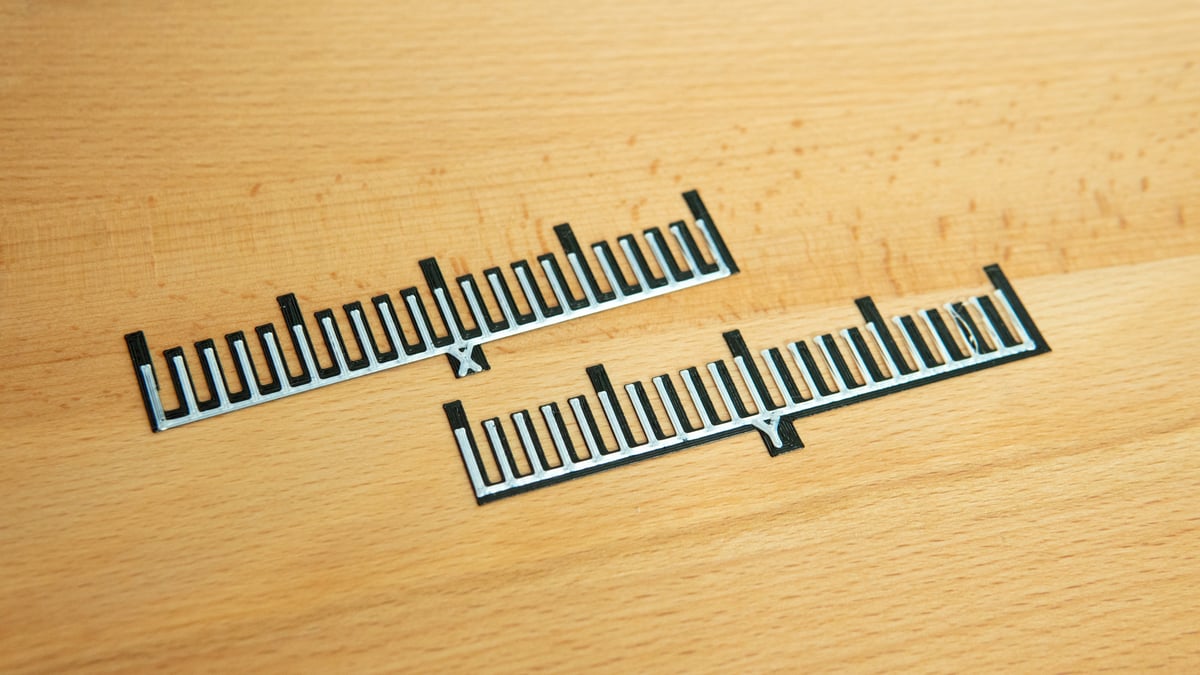

Using the test file Snapmaker provides – some kind of ruler and set square – shows inconsistent spacing between millimeter marks and charring. It’s not a particularly convincing test, but going off-piste with our own laser jobs we saw better results. Certainly, the convenience of setting the Artisan’s laser using the provided calibration plate is welcome.

You’re provided with a versatile baseplate to fix materials to, too, and a camera-assist mode lets you line up jobs with relative ease. There’s some manual finagling required to square the camera preview, but you get a quick and dirty approximation for lining your work up.

Of all the modules, the laser is the simplest to use, and quickest to pay off with regard to productivity. You can choose materials from a dropdown menu and quickly configure vector-based toolpaths or the more time-consuming bitmap-based relief work.

CNC Engraving/Cutting

As with past Snapmaker models, the CNC mode feels the most neglected for any beginners getting to grips with the machine. In the provided Luban software, you aren’t given much assistance with job setup. You have the controls but no buffers to nudge things in the correct direction. We often overheated the spindle, causing the machine to fail mid-way through jobs, just from using the default settings (not an unreasonable thing to do in the absence of any guidance on what to change).

Of course, the reality is that CNC cutting is far more nuanced than first meets the eye: feeds, speeds, chipload, and all manner of considerations must be taken into account for optimal CNC work. You get none of this from Luban and the Artisan’s workflow. Turning to Snapmaker’s support webpages, you will find in-depth guides explaining elements of the CNC workflow and tooling, but very little is translated to Luban and the machine you have in front of you. If you don’t already know how to handle CNC equipment in the likes of Fusion 360 or Carveco, expect to spend a lot of time outside of Snapmaker’s ecosystem learning it.

Included in the box are a V-shape carving endmill and two flat endmills (single and double flute). No ball nose, as with past Snapmaker machines. It’s weird – Snapmaker is in a position to make CNC as easy and accessible as 3D printing, but three generations in, we see barely any progress.

On the plus side, when things go wrong, you’ve got a magnificently satisfying big red button to slap that brings things to a halt. The machine slams to a stop, and a siren sounds. Give it a quick twist to reset, and you’re good to continue. This big red button functions across all of the Artisan’s work modes.

Enclosure

A standard feature of the Artisan is its enclosure, which fixes to the machine’s baseplate. You have to assemble it yourself, including stuffing some desperately fiddly padding in the frame. This part of the build is not enjoyable, but it’s worth it when you set the CNC function working and the large acrylic panels don’t rattle.

The Artisan’s laser module carries a class 4 laser. The enclosure’s light-blocking walls reduce what you can see from outside the enclosure down to a class 1 laser. It’s generally safe to be around. (Just don’t look at it through binoculars.) Caution is recommended even despite the safety features; it’s too easy to become complacent around such machines.

Door detection will pause any running operation, with the option to resume the job just a tap on the huge touchscreen control panel away. This can be disabled in the settings. A single large fan at the rear of the enclosure expels air through a duct, should you wish, and can be hooked up to a filtration unit (sold separately). The entire enclosure lacks a floor, so for it to work effectively, you need a desk deep enough to complete the enclosure and seal the chamber off from the room.

Making

For a device that combines functions for space-saving frugality, building the Artisan is anything but. Coming in two massive boxes, the build requires you to stop halfway through putting together the printer to build the enclosure – which results in a room-blocking mess of packaging, half-built machinery, and stress. To Snapmaker’s credit, everything is rigorously labeled, and you’re left in no doubt about what’s needed next.

UI

Snapmaker has stepped away from the Snapmaker 2.0’s app-like interface for a much cleaner look that focuses the machine on the equipped module. It’s logical, looks great, and all the necessary tools are at your fingertips.

The muscle memory acquired for one function carries to the others – calibration routines are in the same place, likewise module swapping, module controls, plus general settings. The register of tapping isn’t as snappy as we’d like it to be, but it’s a minor mark against a nicely presented UI.

Module Swaps

Something the Snapmaker Artisan absolutely nails is module swapping. Now completely toolless, all you have to do is activate the module swap routine. This will put the machine’s mainboard offline but not the control box – which stays awake for you to confirm the swap is complete. The new friction-lock levers quickly release the currently equipped hardware, and everything slides out and into place; hit “okay”, and the machine reboots in the correct state for the newly equipped modules.

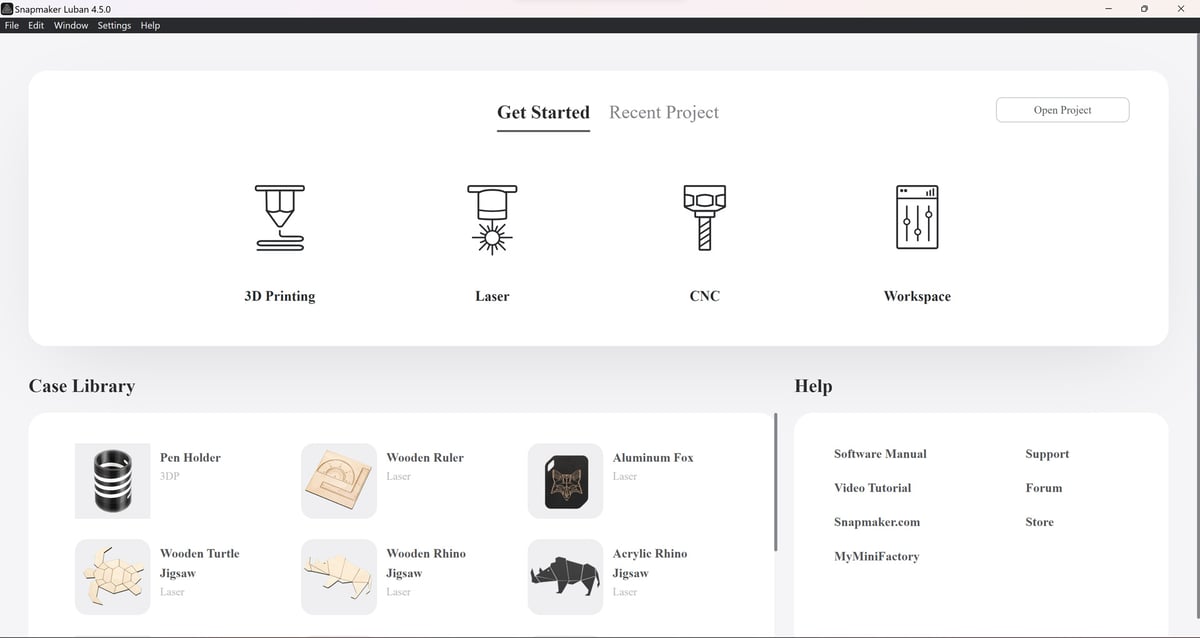

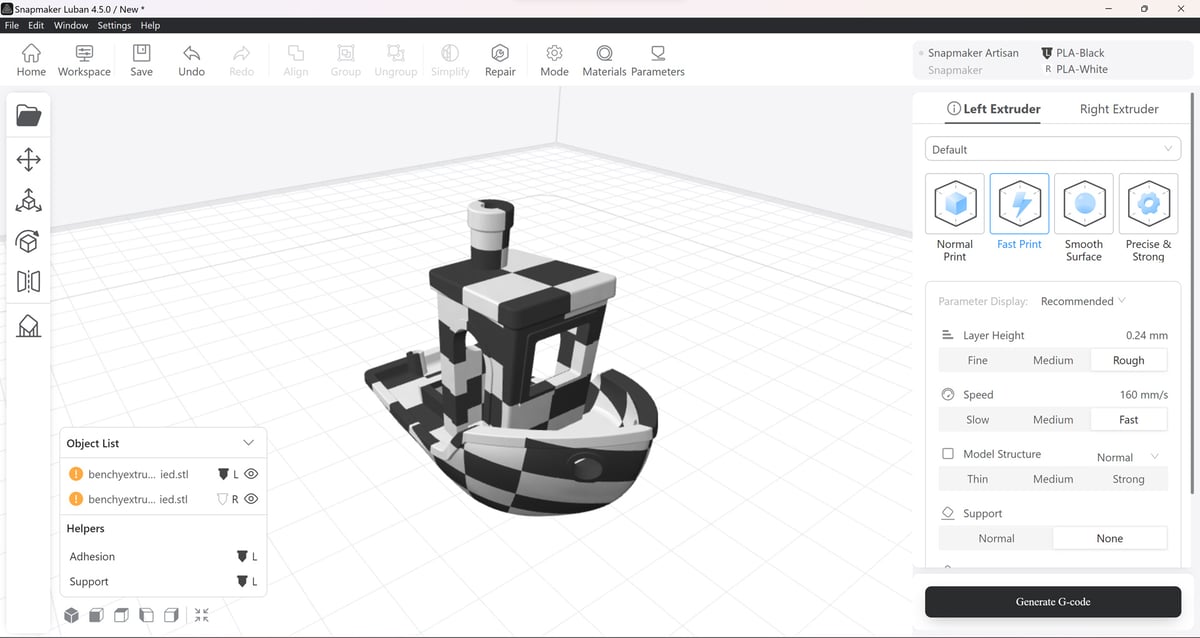

Software

The bare minimum for the Artisan’s software, Luban, to accomplish is to handle the three modes well enough for you not to hate it. Fortunately for Snapmaker, that is just about the case here.

A basic home screen lets you jump into work prep for one of the Artisan’s functions. Alternatively, you can pick up where you left off with a saved project or tap into your machine directly for some G-code sending or mid-job monitoring.

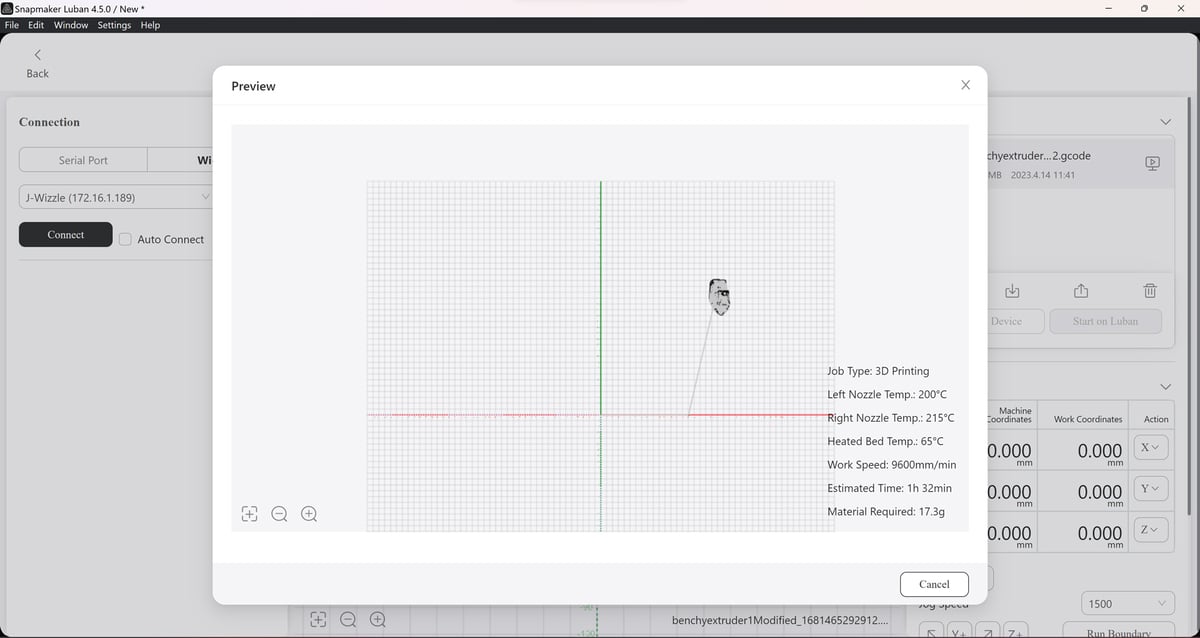

Luban deftly handles 3D printing, with a relatively solid user experience for the machine’s new dual extrusion ability. You have default “simple” control options that let you prefer strength over presentation, speed, and vice versa. Deeper control on print settings allows advanced users to tinker if they need, and it’s simple enough to create your own print and material profiles. It’s not a patch on a dedicated open-source slicer like Cura or PrusaSlicer, but it’s enough.

Sending jobs wirelessly (using a smartphone hotspot instead of the office Wi-Fi) functions, but the presentation is a little rough. The labeling of buttons and general layout don’t give you a great sense of where to go and what to click to port your job to the machine. Snapmaker’s solution for circumventing having to confirm a file-send directly on the machine (an issue early on with the Snapmaker 2.0) is janky, triggering a popup asking you to verify on the device before automatically dismissing it for you in anycase. It’s a bit of a mess.

Putting our snobby design hat on, the presentation of Luban is a departure from the colorful slickness of the Artisan’s UI, too. It looks and feels rough around the edges, particularly in the laser and CNC branches. Previewing Luban’s simulation of CNC can be hit or miss, with the program disregarding your specified workpiece for a full build area representation instead, but that’s a minor grumble against the system’s generally solid functionality.

Should You Buy One?

The Snapmaker Artisan sits in a very specific niche, offering three creative technologies in one. It does this well enough that if maximizing the space available to you is absolutely critical, then yes, the Snapmaker Artisan is a comfortable purchase. It’s a step up on the Snapmaker 2.0 in many ways, with more powerful modules letting you achieve your work faster.

This is still us comparing jack-of-all-trades against another jack-of-all-trades, though. The Artisan’s near $3,000 price tag is considerable, particularly when there are wrinkles that have yet to be ironed out. So, if you do have the space for dedicated machines, you have better options available to you. Just like amphibious (or flying) cars aren’t necessarily good cars or boats (or planes), the Artisan isn’t necessarily faster, or better, than a single machine dedicated to a single of those technologies.

The Artisan makes complete sense as the machine for power users that fit in the niche we mention above. It has convenience and speed on its side, but only users putting it through the ringer making frequent mode changes will likely get their money’s worth.

If you don’t think you’ll be using it all that often, then the savings on the severely cheaper Snapmaker 2.0 A350T are pretty attractive. Right now, you can buy the machine and retrofit it with the dual extrusion print head and 10W laser tool head for a little over two-thirds the price of the Artisan (while carrying the advantage of several years’ updates and bugfixes).

If space isn’t your concern and you’re still reading this, then you must be a Snapmaker 2.0 owner.

Snapmaker seems set on providing an upgrade path to bring the Snapmaker 2.0 pretty close to the Artisan’s new capabilities. Certainly, you can spend upwards of ~$1,300 upgrading your machine with the dual extrusion module ($429), a 10W laser module ($413), an emergency stop button ($50), CAN hub ($50), and enclosure ($440), to bring your machine into the same ballpark as the Artisan. While this leaves aside heated bed and module swap mechanism upgrades, it’s a handful of reasons not to ditch the 2.0 just yet.

Granted it won’t be as fast, or quiet, and the print bed will still take an age to warm up, but capability-wise, it’d be a step up. Unlike the transition from the Snapmaker Original to Snapmaker 2.0, those who’ve bought into Snapmaker’s ecosystem aren’t left quite so high and dry this time.

Alternatives

There aren’t many alternatives that offer what the Snapmaker Artisan offers. One clear option, though, is the ZMorph Fab. Available in 2-in-1 and 5-in-1 configurations, the 5-in-1 offers the closest feature parity to the Artisan but, at $5,999, costs twice as much. That said, it’s smaller, occupying a much tidier footprint, and offers superior software for complex job setup.

Besides the Fab, the only viable multi-function machine is the Snapmaker 2.0, which often goes on sale for close to ~$1,000. You only get single-extrusion 3D printing, and the standard laser and CNC spindle are weaker than the Artisan’s, but the 2.0 is still a capable machine for multifaceted making.

If we were to take the $2,999 the Artisan costs and put it towards three specific single-function machines instead, here’s one lineup that could work:

- 3D printing: Bambu Lab P1P + AMS // ~$1,000 // multi-material printing, very fast

- Laser cutting/engraving: XTool D1 Pro 10W // ~$699 // work area, more powerful

- CNC cutting/engraving: SainSmart Genmitsu 4030 ProverXL // ~$999 // more powerful

You’d lose out on print volume with the Bambu Lab P1P, but for how fast it prints, it’d handle multiple parts of a chopped-up print before the Artisan has put its shoes on. The XTool D1 Pro offers a larger work area and similar power, while the SainSmart Genmitsu PROVer 4030XL offers a slightly smaller work volume but has a more powerful spindle. It’s a push-pull package of machines that is stronger in some areas and weaker in others, but saves you $300.

Tech Specs

- Technology: FDM / Laser / CNC Machine

- Year: 2023

- Assembly: Medium (comfortably doable for a newbie with time and patience)

- Mechanical arrangement: Cartesian-XZ-head

- Build volume: 400 x 400 x 400 mm

- Feeder system: Direct, dual-geared

- Nozzle: Brass, 0.4 mm

- Max. hot end temperature: 300 °C

- Max. heated bed temperature: 110 °C

- Print bed material: Removable, PEI-coated glass

- Bed leveling: Auto-bed leveling (nozzle probed, mesh, 25-point)

- Connectivity: Wi-Fi, USB

- Filament sensor: Yes

- Filament diameter: 1.75 mm

- Laser power: 10 W

- Laser cutting depth: 8 mm (paulownia)

- CNC power: 200 W

- Max. spindle speed: 18,000 rpm

- Frame dimensions: ~1000 x 1000 x 900 mm (incl. control box, spool holders)

License: The text of "Snapmaker Artisan Review: Big Potential" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.