Prusa Research is a strange company. It was born of RepRap, remains loyal to the open-source ideals that underpinned the project, and is a huge success, quite possibly because of those ideals. But, where other passionate, commercialized, open-source 3D printing companies have fallen by the wayside, Prusa Research thrives.

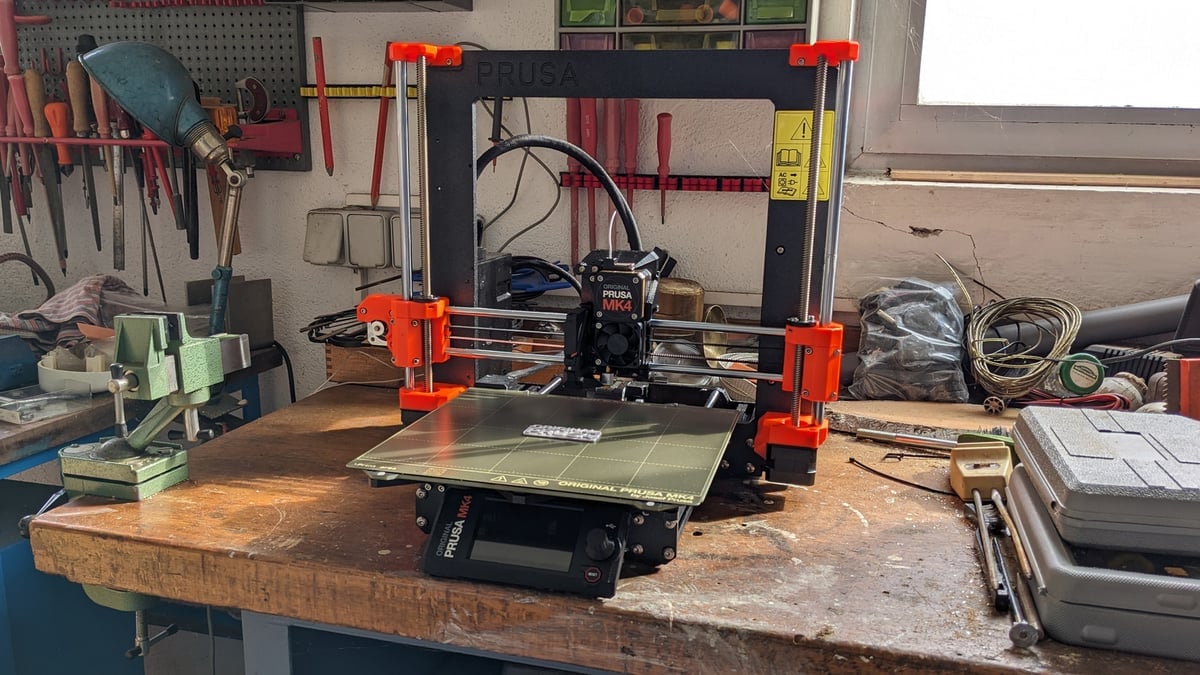

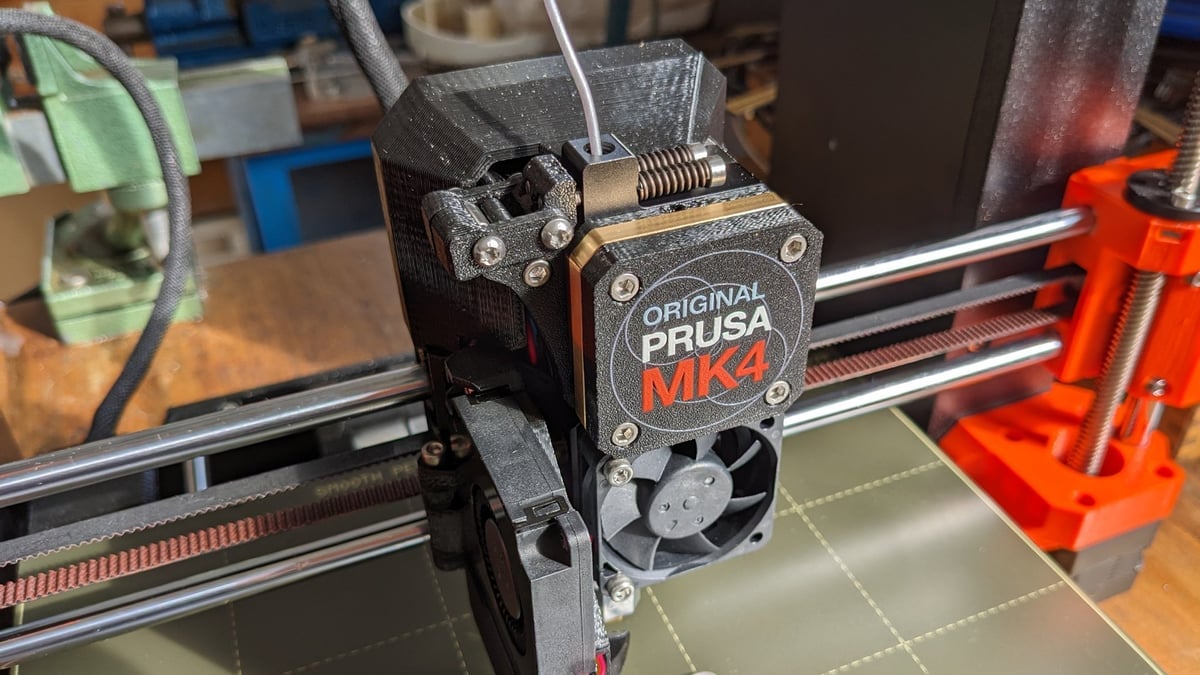

At its core, there is the “i3” model printer. A desktop workhorse, typically available in kit or fully-assembled versions, that has rowed through eight iterations to become the MK4 (not to mention countless updates between version releases), there’s always been a comfortable familiarity with Prusa’s releases.

The last model, the MK3S+, was highly recommended for a long time by All3DP and other publications. On reflection, this was because it offered near-peerless performance and reliability amidst a growing ecosystem that made desktop 3D printing easy. That, and the MK3S+ had few real rivals in quality at its price point.

The MK4, however, has several.

Verdict

Pros

- Superb printing performance

- Truly automatic bed leveling

- Brimming with minor QoL flourishes

- Connected out-of-the-box (kind of)

Cons

- Not so cost-competitive anymore

- Despite ~5 years of development, seems a bit rushed

- Not as “beautifully quiet” as claimed

Expectations were high for the MK4 and while it delivers almost everything we wanted of it – be in no doubt it’s an excellent 3D printer – it’s delivering on a wishlist that was created back when the MK3 was just starting to get a little stale. There are plenty of other equally capable printers turning heads nowadays, which dramatically dullens the impact of the MK4.

That is to say, you have a lot of choices in the current market. The MK4 is still a good choice, with the high print quality we expect of Prusa’s 3D printers, and it retains the dependability we’re used to from the brand. The MK4 is another decent step in the direction of making 3D printing hands-off – you really do get perfect first layers every time, and the UI is much nicer to interact with than the MK3S+ that came before it. Although we could do without the rotary encoder for control. (Just enable the touchscreen already!)

That said, it might not be the most innovative choice anymore. Its launch felt a little rushed, despite a long development, and even the further delayed input shaping had some odd hiccups during our testing. But for desktop 3D printing purists or those looking for a safe, dependable printer with provenance, there are few better choices.

At a Glance:

- Price: $799 (kit) $1,099 (assembled)

- Build Volume: 250 x 210 x 220 mm

- Max. Hot End/Heated Bed Temperatures: 300 °C / 120 °C

- Print Bed Material: PEI-coated spring steel sheet

- USP: Expect advanced features, high-quality prints, and reliability

- They say: “Always perfect first layer, high-speed printing with input shaper, 32-bit platform, Nextruder, MMU”

- We say: Love it or hate it, it’s a Prusa, and that still counts for something

The Tech

Users of previous Original Prusa i3 machines will be right at home with the MK4. Despite Prusa’s claim that 90% of the 3D printer’s parts changed, inside and out, it feels the same. Same form, same build area, same mechanics, same print capabilities. Same same same.

Interacting with it and seeing it come to life feels like slipping on a comfortable old pair of slippers. You know exactly what you’re getting, and you can relax. While a lot of the MK4 is, technically different, its characteristics are familiar.

It Can’t All Be the Same?

Okay so no, it’s not exactly the same. Despite its familiar feel, plenty has changed — though not all will be particularly apparent from looking at the MK4’s black and orange exterior.

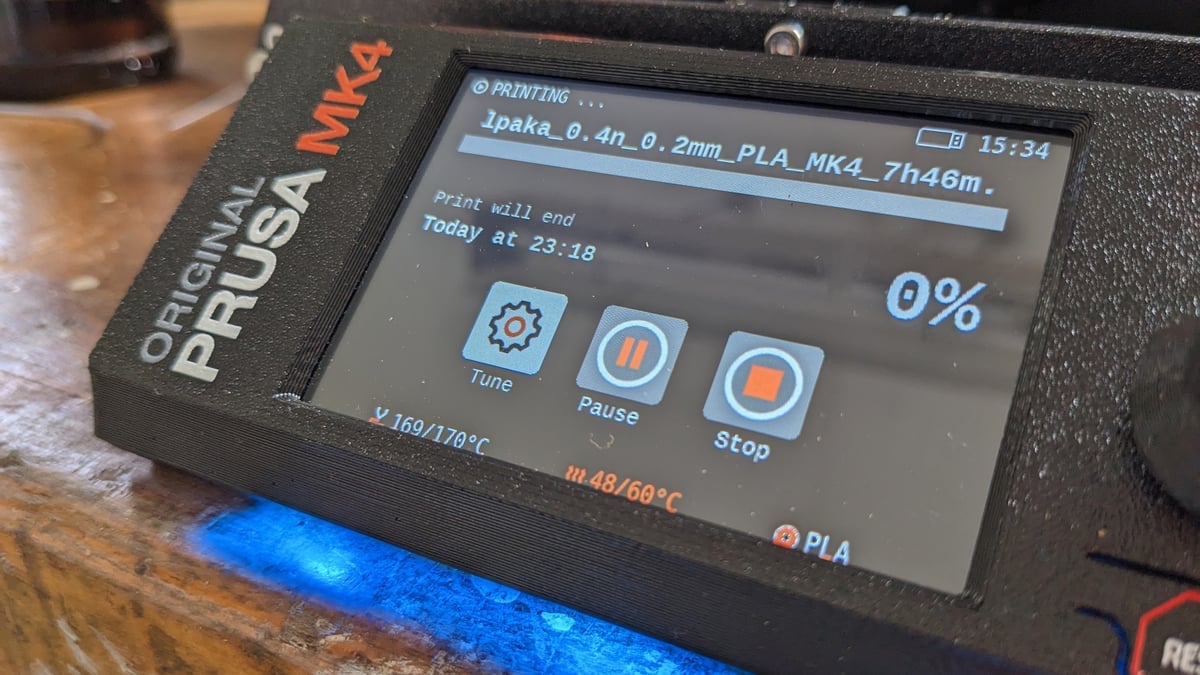

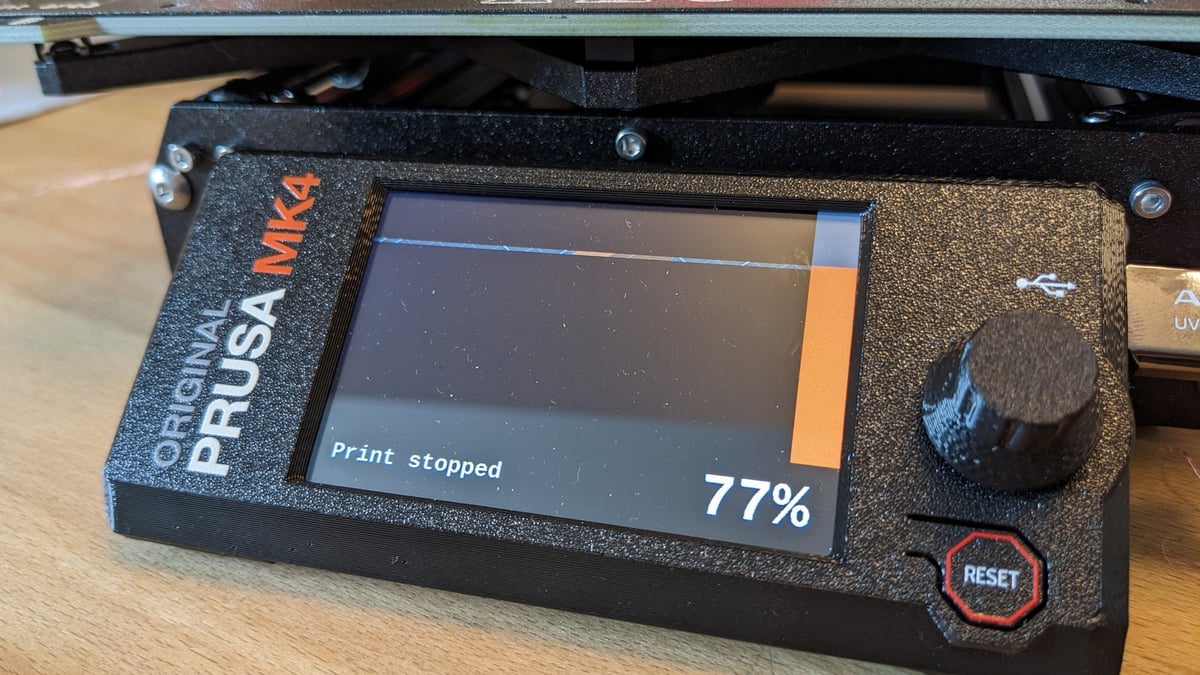

One thing that is noticeable, though, is the color display strapped to the front of the printer.

Carrying the large iconography introduced with the Prusa Mini, the MK4 also introduces a number of quality-of-life changes to the UI that make the printer feel nicer to use, including telling you the time. That is, on face value, trivial, yes. We know. But this plays into print time estimations. The MK4 doesn’t tell you how many hours and minutes until your print finishes – it tells you the exact time it will finish, instead.

Customizable quick icons let you place the information you care about most at your fingertips, too. Following through from the Mini (the MK4 shares the codebase with the Mini and XL printers — there is parity between the company’s machines now) is the system’s reading of media inserted into the printer. The last sliced file on the USB stick will automatically load for you to one-click print. It’s convenient.

Also convenient is the fact that when you load a material, telling the machine what it is in the process, the MK4 remembers this. When you go to unload that material later, it automatically knows the temperature it should heat to to appropriately unload the material. It’s small touches like this that elevate the experience of the MK4 over many other desktop 3D printers.

Besides the UI, the MK4 is a little smarter at detecting when something is off and triggering safety shutdowns, with the company’s new self-developed mainboard, plus a variety of thermistors, taking all manner of electrical readings and triggering safety shutdowns when things aren’t right. This isn’t something we have the tools to test thoroughly, but it is worthwhile noting the transparency around safety and the systems in place. It’s not always 100% clear in 3D printing and, while we won’t nanny folks about electrical safety, this is a plus in the MK4’s favor.

Kitted Out

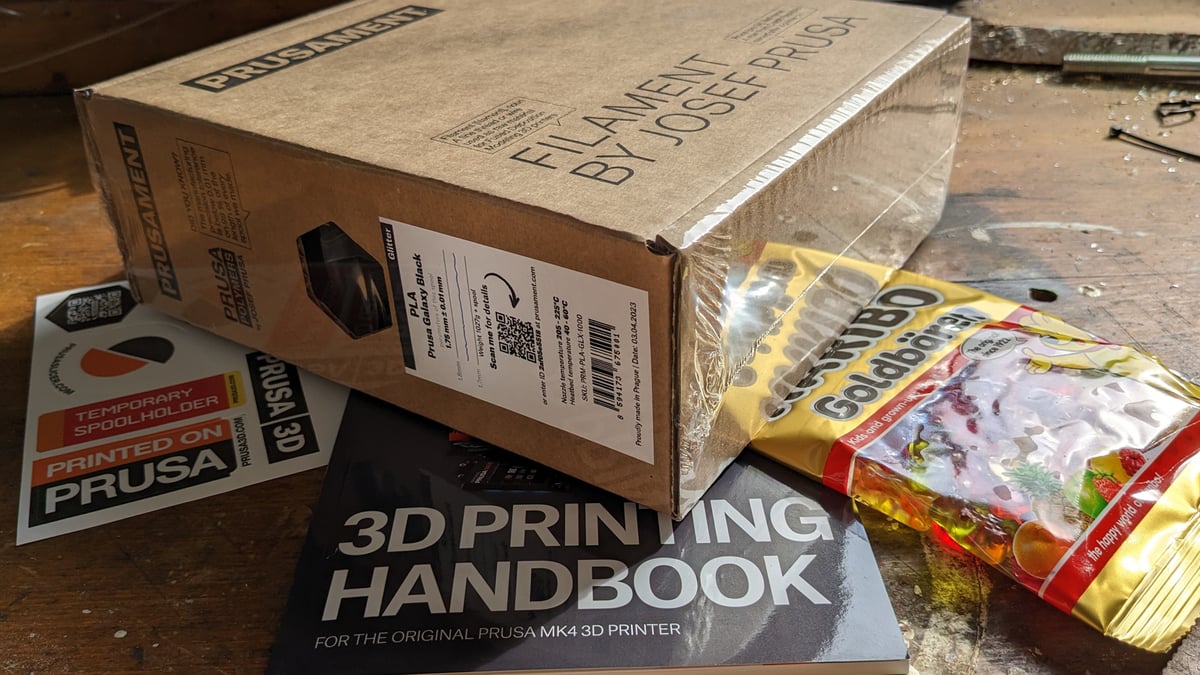

Something we’re very pleased has remained with the MK4 is Prusa’s less expensive kit offering. For $300 less than the pre-assembled version, you’ll get a well-organized box of MK4 parts and detailed assembly instructions – everything you need to put the printer together yourself. We’ve tested both versions of the MK4 for this review.

3D printer kits used to be the norm, but they’ve fallen out of vogue as the machines increasingly become plug-and-play consumer devices and less the hobby of electronics enthusiasts. Still, we stand by the recommendation that, if you’re just stepping into 3D printing, it’s an excellent idea to assemble a machine for yourself. There’s no better way to get intimate with the technology and begin to understand the workings of your 3D printer than by putting it together yourself – and Prusa’s above-and-beyond step-by-step instructions help this rewarding path also be a breeze. The assembly guide is meticulous, as is Prusa’s parts labeling.

Though the process of assembling your own 3D printer may be lengthy and somewhat daunting, you can be confident at every step following Prusa’s guide (and munching on your included bag of Haribo).

Maintenance & Modularity

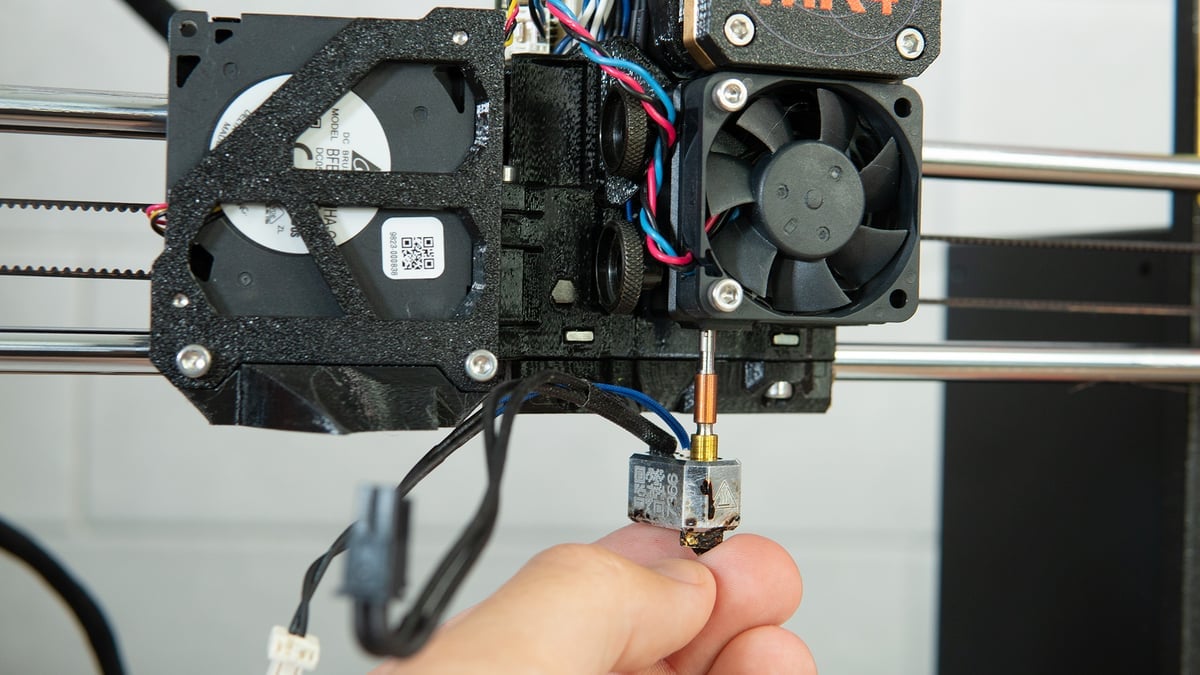

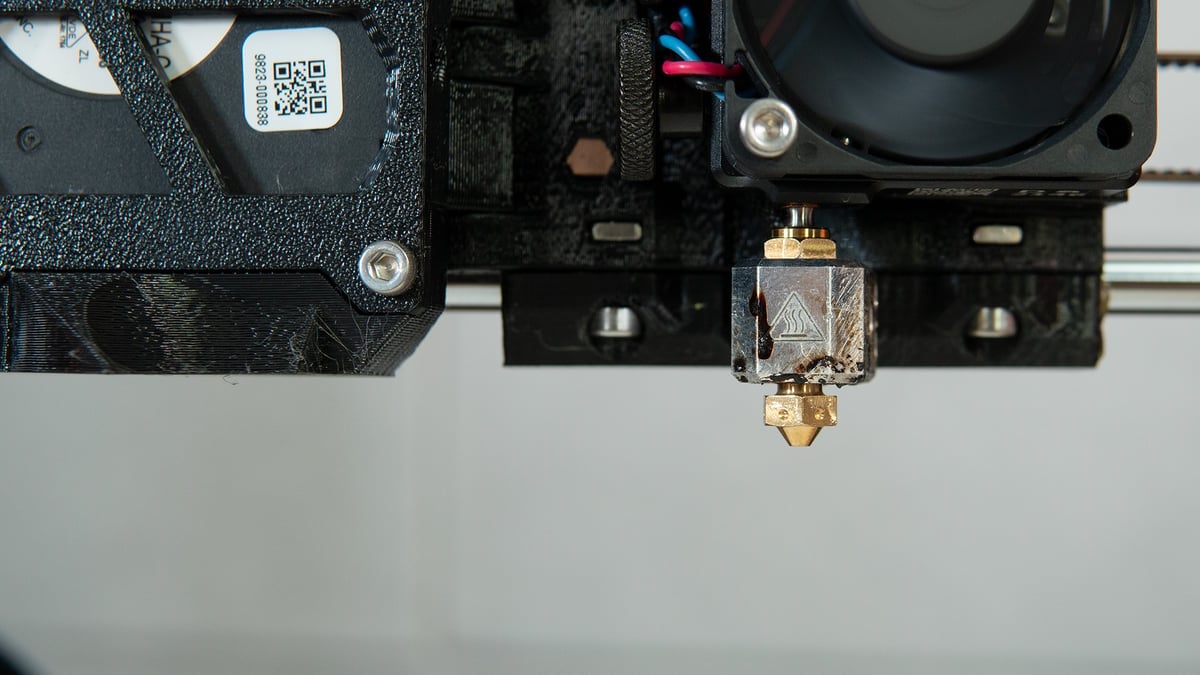

Improvements to the modularity of the MK4 make it easier to maintain in the long term – the print head isn’t as fiendish to dismantle as the MK3’s was. Likewise, nozzle swaps are simpler, with the hinged print cooling fan swinging out of the way to reveal the two integrated nozzle-heatbreak release thumbscrews.

Dedicated ports for accessories and add-ons, such as an ESP Wi-Fi module (included) and Prusa’s upcoming MMU3 multi-material system, dramatically simplify expanding the MK4 compared to the previous generation machine. There’s no real need to open up the control box and tinker with the mainboard anymore; an improvement to both the usability and longevity of the system, we’re sure.

Connected

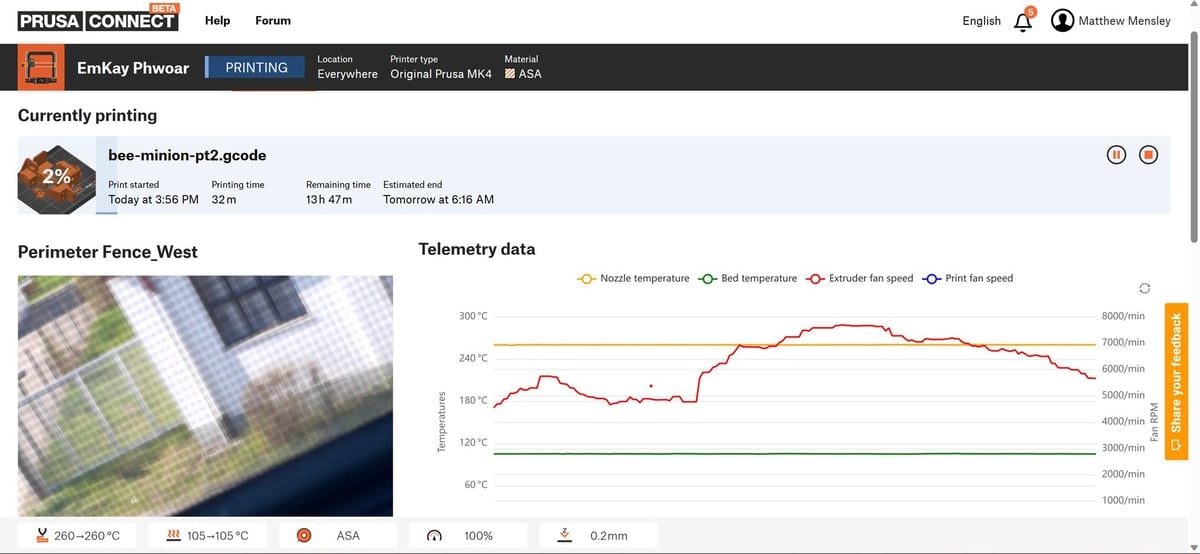

While not strictly an integrated part of the printer, the MK4 ships with its optional ESP Wi-Fi board attached. Hidden away behind a small 3D printed shroud on the rear of the machine, this small chip lets you hook your MK4 up to your Wi-Fi network for remote monitoring and control via the PrusaConnect web browser interface.

The process for setting your printer up on your network is needlessly complicated, requiring you to first create a configuration file on a USB thumb drive using the printer, then update it with a text editor on your computer before reinserting it into the printer. Once you’ve jumped through those hoops, you have to wait “5 to 8 minutes” for the connection to establish, during which time you seemingly can’t add the printer to your account. As far as experiences go with connected devices, it’s not particularly elegant.

Once connected, though, you gain access to telemetry about your printer of the nerdy kind we’re accustomed to from the company (buy a spool of their filament and you’ll see what we mean), as well as the ability to remotely manage and operate the machine and, possibly the coolest trick of it all, connect a (presumably old and disused) smartphone to use its camera for monitoring and timelapse function.

Bit of a tangent, this, but if you have a drawer full of old phones, it seems like you could set up a wireless home security setup using the PrusaConnect old-camera-webcam system. Paranoid.

The data aspect is likely of limited use to most folks, particularly since the printer will wave a flag if something is wrong, but device and print queue management, plus the smartphone thing, sum up as a pretty robust, if a little fiddly to set up, out-of-the-box, wireless solution.

Alternatively, there is an Ethernet port for a wired connection to the MK4.

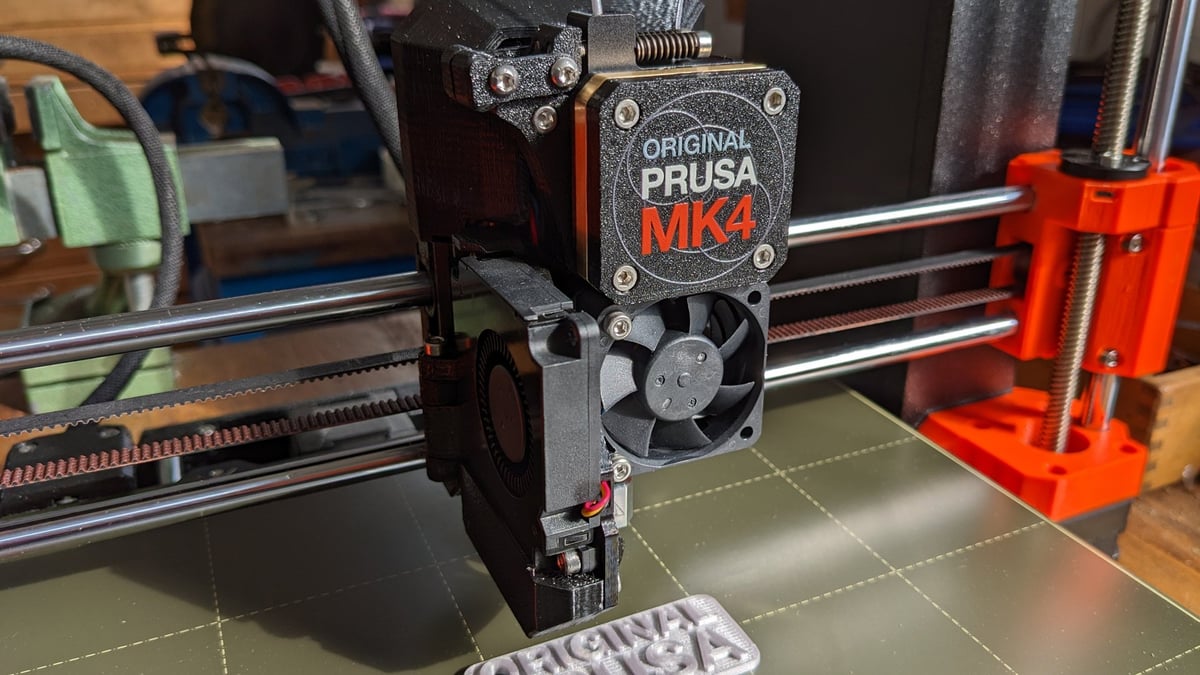

Nextruder

A lot has been said about Prusa’s Nextruder, not least of all by us. The all-new extruder setup for the company’s long-awaited XL 3D printer puts an appearance in here, albeit in a slightly stripped-back form.

Of particular note is the new nozzle system, which uses an integrated metal heatbreak and guiding tube. This is to the effect of safer high-temp printing and, typical of all-metal hot ends, more precise control of the melt zone.

An adapter for V6-style nozzles is available, too, meaning any past investment in additional or special nozzles isn’t wasted. And, given the MK4’s use of load cells for its bed probing, the nozzle’s height isn’t a factor. No offsets are needed as it compensates automatically.

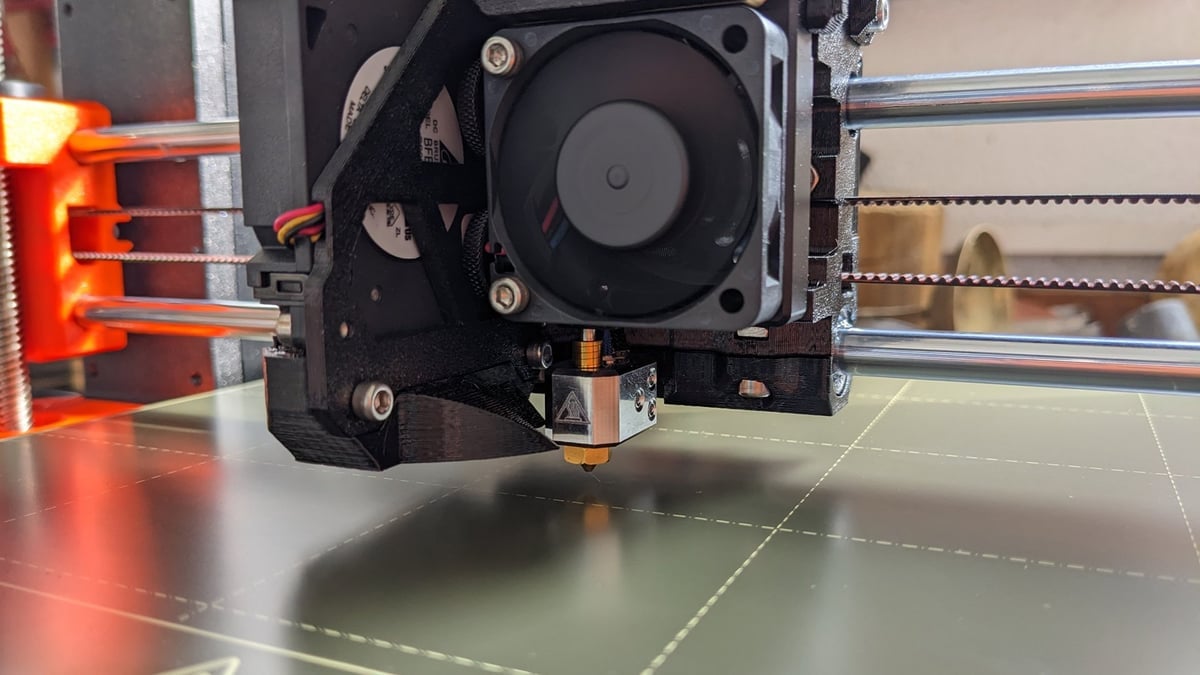

Printing

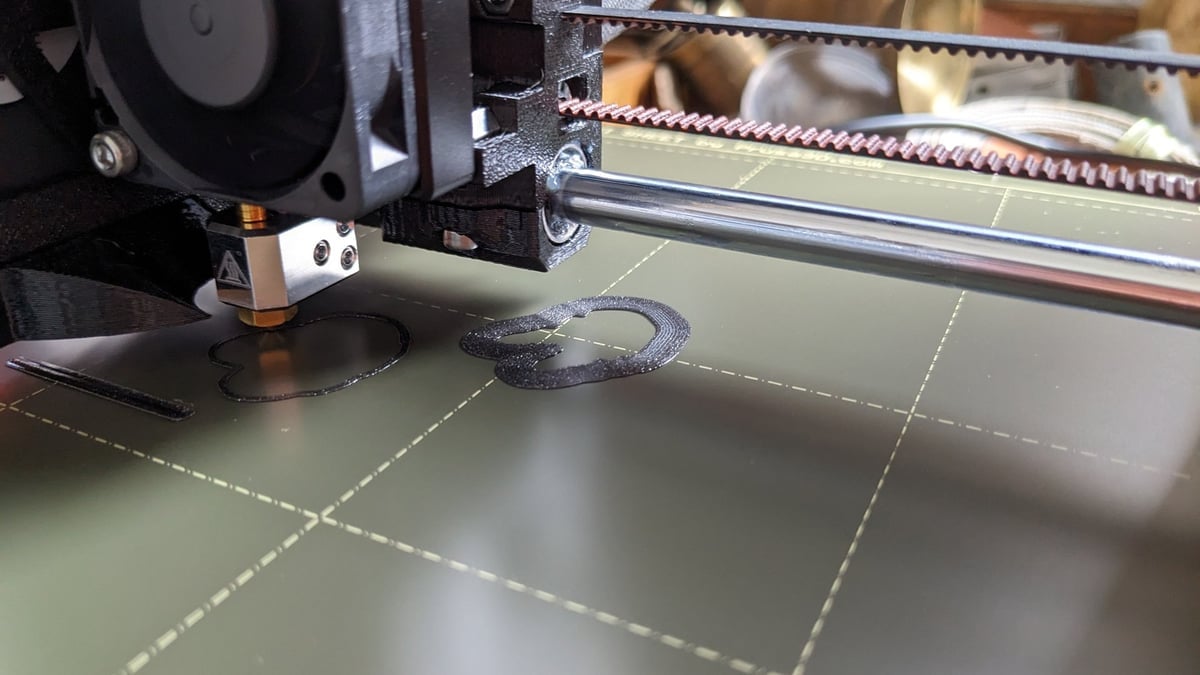

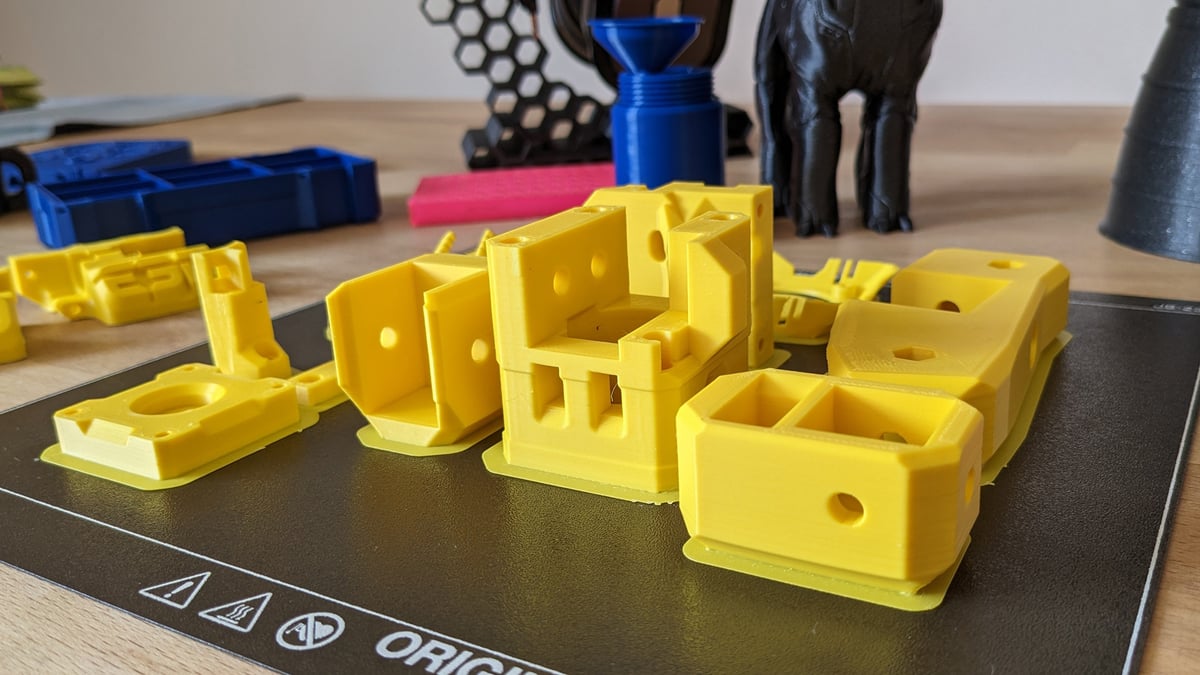

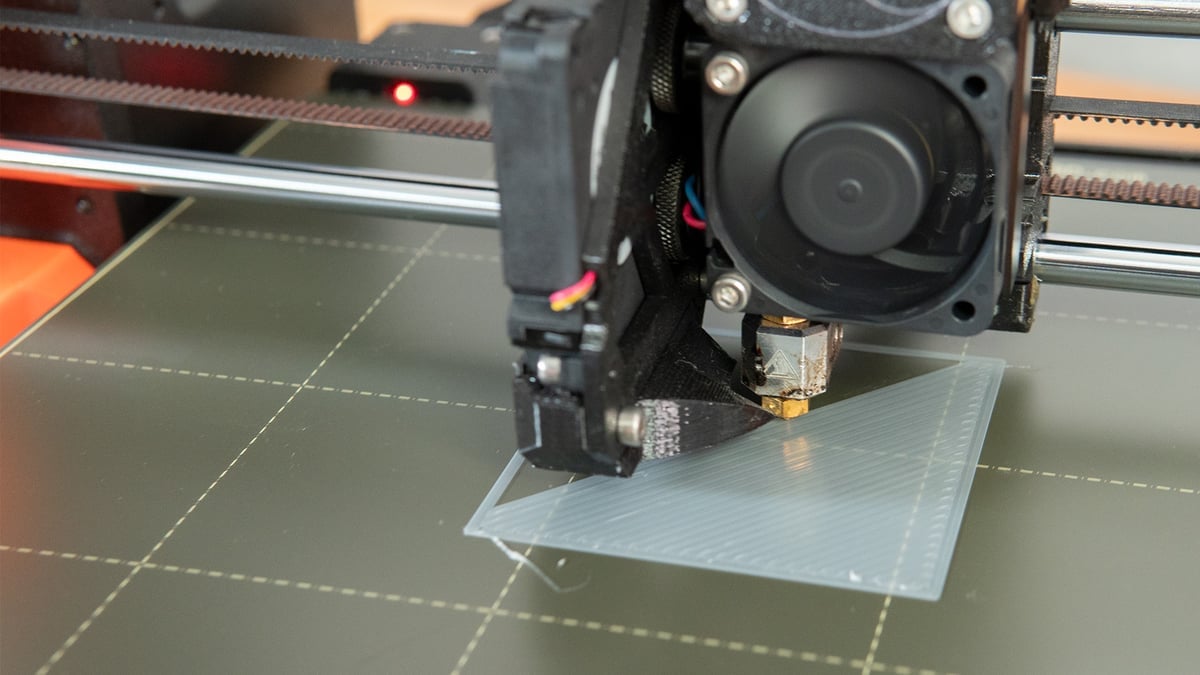

The Original Prusa MK4 outputs sublime prints. As with past iterations, the hardware really does sing, and prints are put down on the bed in an almost painterly-like fashion. In our short time with it, we’ve run the gamut of “standard” materials, including PLA, ASA, and TPU95, through the MK4, and it has handled all without issue.

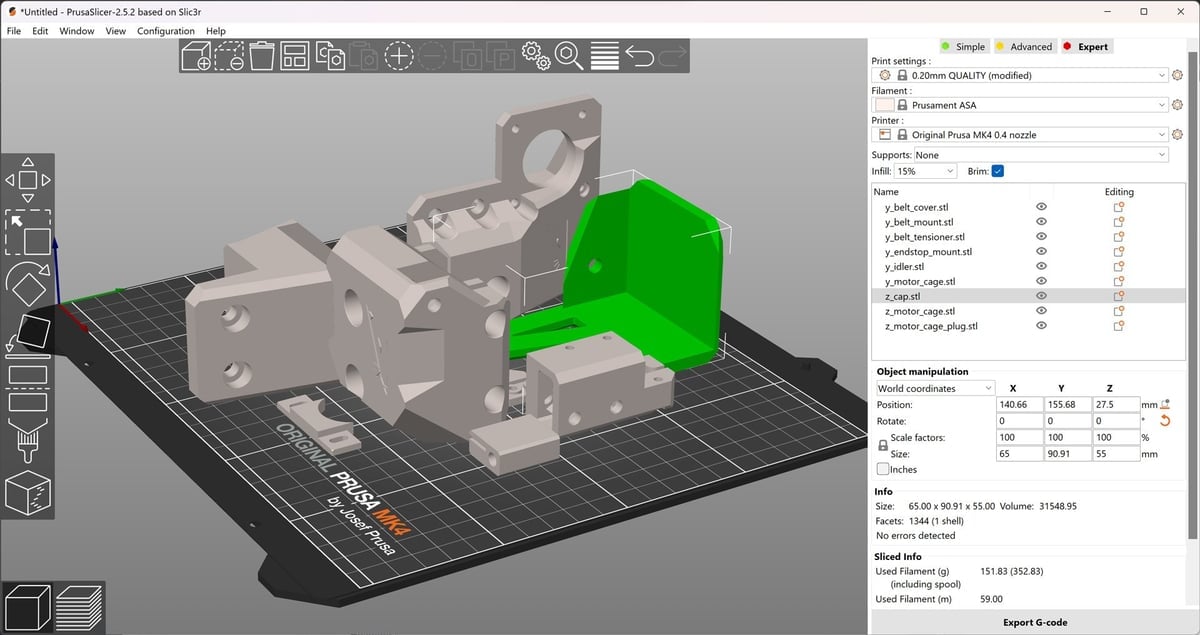

Print preparation using the company’s open-source slicing software, PrusaSlicer, is at its easiest when you’re using one of the company’s own machines, and the MK4 is no exception. There’s a wide variety of print quality options available to you and a broad material profile section, too. You can, generally, get by without having to dive into any deeper settings by using these quality profiles with the generic materials profiles alone.

Digging deeper for fine control over your prints is, of course, present, although we’ll note that PrusaSlicer feels a little opaque with print settings behind a separate tabbed page rather than filtered into view alongside the preview of your model.

Optimizations

Getting a print going is a speedy sequence of events, with the hot end and bed both heating quickly and, new for the MK4, print-zone-specific mesh bed leveling. Rather than probe the entire bed for readings that then influence the printer’s first few layers to compensate for unevenness, the MK4 will instead measure only the area of the print it’s about to do. This saves quite a chunk of time, particularly when you’re printing only narrow or small objects.

Where the MK4 adds in many areas, it seems that some things have been left out. We noticed in testing that crash detection is absent in the MK4, meaning the printer will not detect any stalls and skips.

Also, despite the claim that the printer is “beautifully quiet”, we wouldn’t say it’s remarkably quiet compared to the gamut of bed-slinging desktop printers today. If anything, there’s a distinctive note to the MK4’s bearing and rod setup that is more noticeable compared to the amorphous fan-based white noise you get from many bed-slingers of the same size. Despite technically being as quiet as the likes of an Elegoo Neptune 3 Pro (which we ran alongside the MK4 to check we weren’t imagining things), the MK4 seems louder. It’s still a country mile quieter than current high-speed CoreXY printers like those from Bambu Labs, but then those machines aren’t sold on the promise of being quiet.

It’s worth noting that our review sample shipped with X- and Y- axis motors that had been identified as part of a faulty batch after our initial publication of this review. While these motors caused excessive noise, after fixing our unit with new motors, we’re still of the opinion that quietness isn’t a noteworthy feature of the MK4. Handily, this situation gave us first-hand contact with the company’s exceptionally helpful support chat, which identified the issue and, following a couple of tests to confirm things, quickly shipped new motors out (an option extended to all affected by the bad batch).

Elsewhere, the occasional bug in the UI pulls you out of the MK4’s nicely managed presentation, but knowing the company’s excellent record for updates and bug fixing, we don’t expect this kind of software issue to be around for long.

Further contributing to a sense of things being a little rushed with this printer is its display actually being a touchscreen – you just can’t use it. It’s not enabled by default, and there’s no indication of when, or even if, it will be.

Reps for the company have said that the less you have to interact with the printer, the less you really need an interface like a touchscreen, which smells a little evasive when you acknowledge the printer has the tech and could be touch interactive but isn’t.

Should You Buy One?

If you own any of Prusa’s other printers and enjoy the ecosystem, then the MK4 is an easy recommendation to expand on or replace the machines in your lineup. The MK4 improves many of the dated elements of the MK3 and then some.

It’s more forgiving, prints are even less likely to fail, and the print performance is above average. The small flourishes remind you that it’s a machine on a level above most others in the desktop 3D printing market, and out-of-the-box compatibility with PrusaConnect elevates the experience quite nicely.

There’s no denying that it’s a pricey machine, though. But, no one ever bought a Prusa because it was the budget option – you’re paying for a meticulously designed product built in Europe with a well-developed support ecosystem.

We picked up on a lot of tribal pitchfork-waving after the MK4 announcement, proclaiming it dead in the water, or words to that effect, in the wake of the Bambu Lab X1 Carbon, which is just stupid fandom noise. Buy what makes you happy. The MK4 is a good, competitive 3D printer.

We have to put a star rating on this review, or the All3DP SEO overlords will roll up a newspaper and start bopping us on our collective head. So we’ve settled on a four out of five. It’s great but, by the ever-shifting standards of today, not perfect.

Update – Nozzle Knowledge

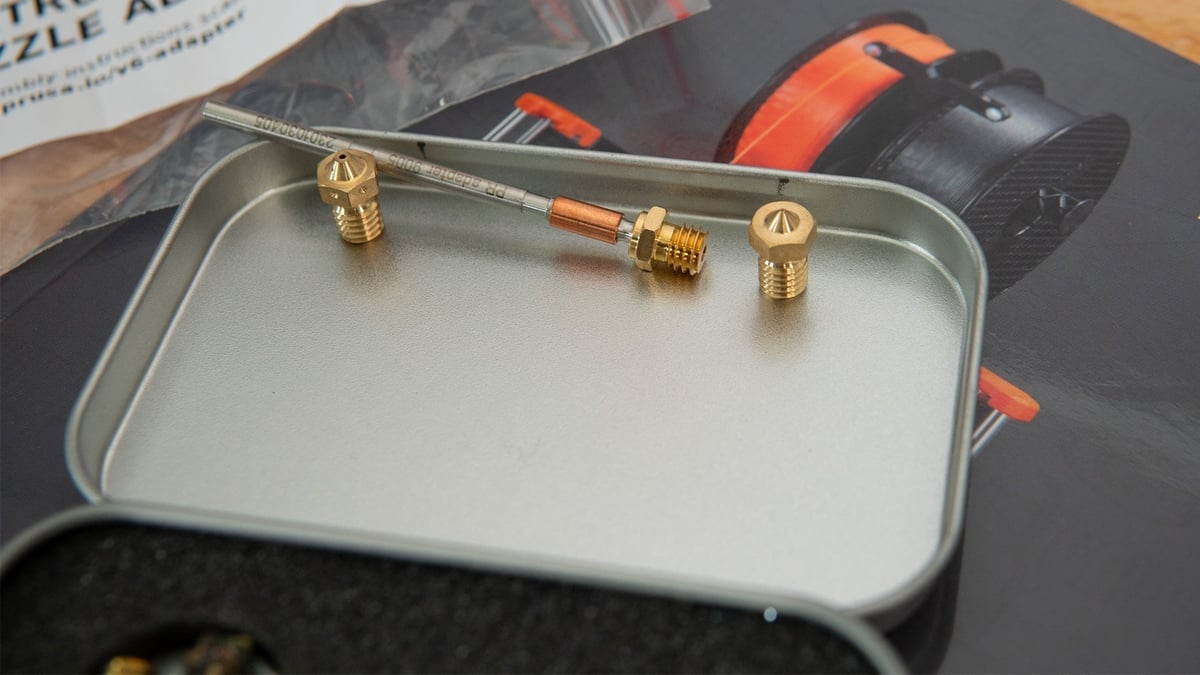

June 28, 2023 – Matt Mensley | Time constraints kept us from going too deep on the MK4’s new nozzle system, which is more or less a direct lift from the XL-introduced Nextruder. Shifting to a nozzle-agnostic leveling system, as found with the Nextruder’s use of load cells, meant the company could redesign the filament path through the hot end.

The result is an exceedingly long filament guide tube that integrates directly with the nozzle. They are a single piece and, upon quick release from the print head, withdraw through the entire hot side of the extruder’s pinch on the filament.

There’s one strong advantage to what Prusa Research has done with this, which is discerning control over the filament after the extruder motors input. Typically there are dead zones in the filaments path where the filament could buckle – this is particularly true of printers with Bowden extruders, which have a long filament path after the extruder. The filament can bend and wiggle – some more than others. This is a particularly difficult situation for flexible filaments, which buckle and flex under little force.

The MK4’s (and, by extension, XL’s) solution eliminates this, offering an all-metal guide that can effectively constrain the entirety of the filament path. One neat result is that prints using flexible filaments can be accomplished as quickly as they would with PLA.

Choice, Choices

Interestingly, an adapter for V6-style nozzles is available for the MK4, which effectively opens the printer up to the world of aftermarket nozzles that have steadily released over the years, including newer types such as Bondtech’s CHT, the Olsson Ruby, plus E3D’s recently released ObXidian, despite the Nextruder’s custom metalwork.

While this review strikes a softly critical note about the MK4, we can’t deny that there are few (if any) manufacturers that would take this extra step. There’s nothing in it for them, except perhaps for reputation – custom nozzles aren’t its style, and pitchforks would be raised if such a part was placed in a walled garden.

While we have it on good authority that more nozzles are coming for the new extruder, we’ve thrown some plain brass E3D V6 nozzles of a multitude of sizes at the MK4 to snap some pics of the system in action and how easy the nozzle setup can be.

Installing the V6 Nozzle Adapter

It’s worth noting that using the V6 adapter initially doubles the work you must do to change a nozzle. Installation of the adapter means following a handful of steps, including unplugging and removing the hot end, some minorly finicky cable routing, and then installing your old V6-style nozzle. The procedure requires you to heat the printer and let it cool down several times.

It’s somewhat similar to E3D’s (ultimately, more convenient) Rapidchange Revo system (we installed one on an Ender 3), which also features integrated heatbreaks but can be switched out cold and completely toollessly.

Overall, the initial setup is a time-consuming but trivial installation. For extending the life of nozzles you have sitting around or, more likely, hitting the ground running with the MK4 and years of developed V6-size metal, it does the trick. And all without you needing to rerun bed-leveling routines.

Correction – July 07, 2023: An older version of this article stated the V6 Nozzle Adapter was included as standard with the MK4. This is not the case, and the text has been updated to clarify this.

Update - Input Shaping

November 14 – Shawn Frey | It took about six months from the Original Prusa MK4’s initial announcement and release – where the feature was first advertised – but Prusa’s latest bed slinger now has input shaping. It’s pretty impressive what Prusa has achieved with generalized input shaping settings, but it doesn’t quite meet the expectations set up by competing (and cheaper) fast printers.

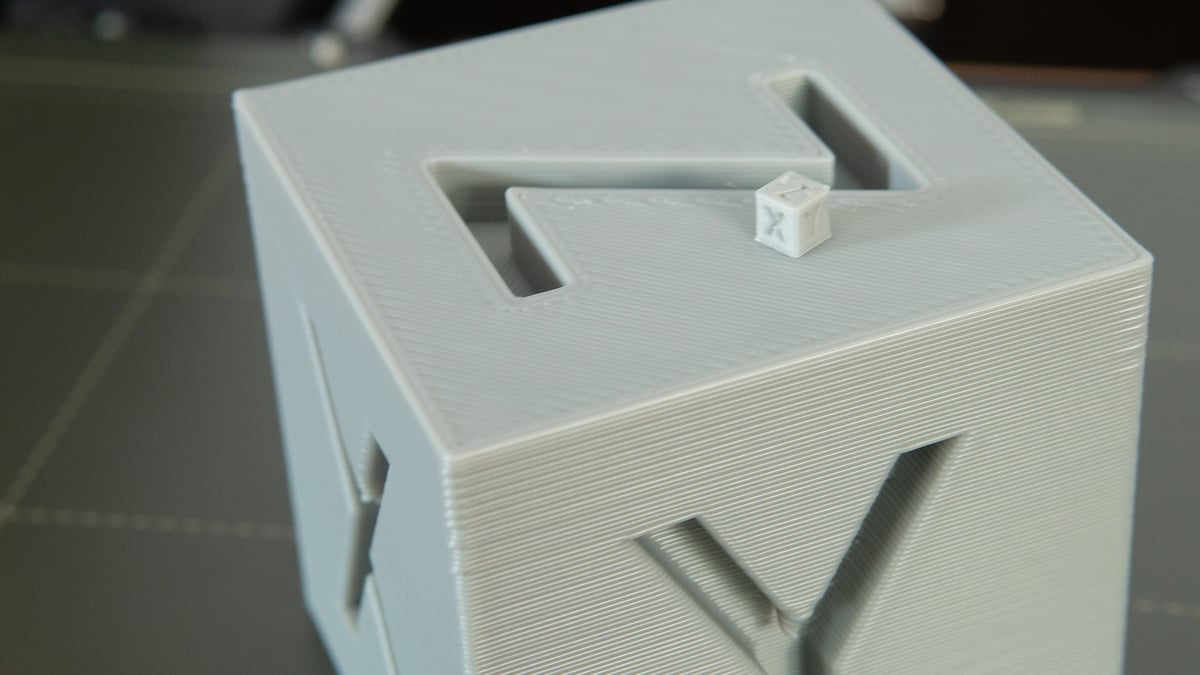

In our testing, the MK4’s new input shaping-enabled profile sped things up substantially and usually reduced print artifacts like ringing noticeably without loss in quality – but there were exceptions – without using an accelerometer or relying on user input.

What is Input Shaping?

If you’ve been paying attention the last year or two, you’ve probably noticed Klipper’s sharp rise to prominence. The firmware has become a major feature of a growing number of new 3D printers of varying kinematics touting high printing speeds that would have seemed ludicrous just a couple of years ago. Klipper managed to achieve such high speeds thanks, in large part, to its early implementation of input shaping – also known as resonance compensation.

Marlin now has its own implementation of input shaping, but Prusa’s custom solution lagged until now.

Accelerometer Need Not Apply

Setting up input shaping usually requires some sort of calibration, either by measuring the ringing effect on a benchmark print and plugging the results into an equation, or by automating the process with an accelerometer. The MK4 is interesting because it neither has an accelerometer in its print head – a difference from the Original Prusa XL’s Nextruder, which does – nor does it require any user input. Prusa’s input shaping algorithm simply attempts to hit the sweet spot by a factory setting frequency: 50 Hz on the X-axis, 40 Hz on the Y. All the user needs to do is switch to the new Prusa MK4 Input Shaper PrusaSlicer profile, which includes a bit of start G-code to enable the feature.

If you’re particular and want to tweak your frequencies to be the best they can be, the input shaper’s setting can be edited in the MK4’s menu or by adding the M593 command to your start G-code.

The Results

We used the ringing tower provided in Klipper’s documentation to test the results of Prusa’s input shaper algorithm, removing the top layers and infill, setting speed as instructed (100 mm/s), and disabling dynamic acceleration (by setting the options to 0 in PrusaSlicer), then sliced and printed the file once with the MK4’s previous firmware installed (V4.7.2) and once with the input shaping-enabled V5.0.0 firmware and PrusaSlicer input shaper profile. We repeated the procedure twice, changing print speeds to 250 mm/s and 500 mm/s to push the results.

The results are clear, with input shaping providing a noticeable reduction of ringing across the board and noticeably sharper corners to boot.

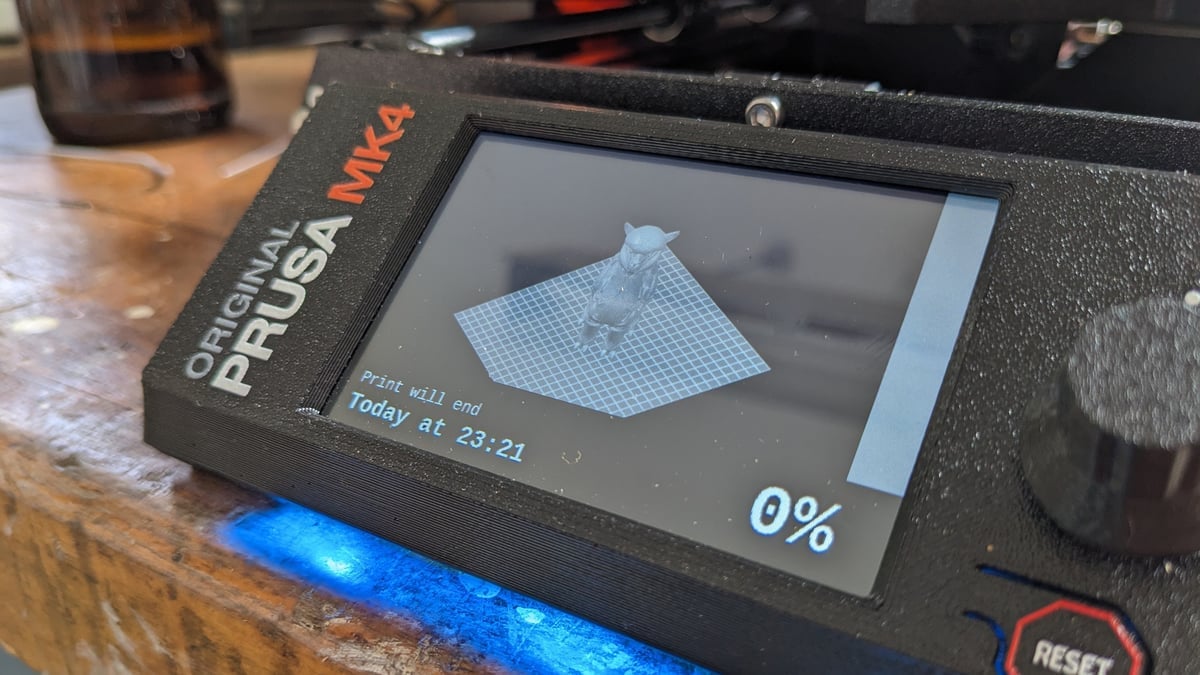

So, the reduction of artifacts is achieved, but how is Prusa’s new profile performing otherwise? To check, we compared Benchies and a more detailed gargoyle model with both the previous V4.2.7 firmware and new input shaping firmware and profile, with all settings at default.

The results are a bit of a mixed bag. With our initial testing material, the previous firmware’s Benchy doesn’t show ringing at the porthole but, with input shaping enabled, it did – in addition to cooling issues that affected our hull. However, these issues weren’t present when we swapped out materials. Perhaps our testing material just needed a bit more cooling than others, but it’s worth noting that a Benchy printed in the same material with Bambu Lab’s default generic PLA profile on the P1S with the auxiliary fan disabled printed in the same amount of time without ringing or poor overhangs. A rare blip in the MK4’s performance that we can’t explain nor deny happened.

Benchies were produced significantly faster at 40 minutes with input shaping enabled compared to the 1:04 clocked without. Our gargoyle print didn’t show any serious changes, except perhaps slightly worse overhangs in some areas, but input shaping did have a much larger impact on this model’s print time; nearly halving it cutting about an hour of print time for the ~70 mm tall model.

Overall, the speed benefits are certainly substantial. In fringe cases, you may need to spend some extra time dialing in the settings for your material. Ultimately, the MK4’s input shaping is a welcome option, but we didn’t find it to close the gap between fast printing on other popular devices in our testing.

Alternatives

The MK3 may have been the top dog for years, but things have changed lately. Some of the race-to-the-bottom companies, that you could argue created more customers for Prusa than stole, are now punching up. That and innovators like Bambu Lab have released hyper-competitive alternatives to what the MK-series has always been — a desktop workhorse.

All this is to say, you have more choices now than ever.

If you’ve got MK4-kind of money to spend, consider the Bambu Lab X1 Carbon. It’s fully enclosed, faster, and has a nicer UI with easier wireless capabilities, including OTA firmware upgrades. Not to mention lidar-based bed leveling and print-failure detection. It’s not so welcoming of tinkering, though — but we’d argue that a printer like that is bought for printing, not modifying.

Elsewhere, Creality is upping its game with the Bambu Lab-esque K1 Max. For similar money to the MK4, it offers Bambu Lab X1 Carbon-like features and connectivity, with a larger 300 x 300 x 300 mm build volume. The jury is still out on whether Creality has a winning formula on its hands with the K1-series, though. It was only just announced, and won’t ship for a while yet.

Where price is a concern, the lower end of the market offers no shortage of solid bed-slinging alternatives. The Sovol SV06 is a popular low-cost 3D printer that takes heavy cues from the MK3, while the Elegoo Neptune 3 Pro and Creality Ender 3 S1 Pro both offer similar printing capabilities, albeit without the sophistication present on the MK4 and Bambu Lab machines.

Tech Specs

- Technology: Fused deposition modeling (FDM)

- Year: 2023

- Assembly: Fully-assembled – plug and play; kit – medium difficulty (comfortably doable for a newbie with time and patience)

- Mechanical arrangement: Cartesian-XZ-head

- Build volume: 250 x 210 x 220 mm

- Feeder system: Direct, planetary geared

- Nozzle: 0.4 mm brass

- Max. hot end temperature: 300 °C

- Max. heated bed temperature: 120 °C

- Print bed material: PEI-coated spring steel sheet

- Bed leveling: Nozzle-based auto-bed leveling, mesh (local to the specific print area)

- Connectivity: Wi-Fi, Ethernet, USB

- Filament sensor: Yes

- Filament diameter: 1.75 mm

- Frame dimensions: 500 x 550 x 400 mm

Featured Prints

A tip of the hat to the talented folks that designed the models featured in this review.

- RatRig V-Minion printable parts, by RatRig via GitHub

- 3DNA Penny Board, by Simone Fontana via Youmagine

- Planetary Compartment Container, by 3DPrintingWorld via Thangs

- Prusa Mini+ Upgrade (Edition 2) Revo Micro, by E3D via Printables

- Slim TPU Wallet, by 3D Print Project Athens via MyMiniFactory

- Robo Alpaka, by Prusa Research via Printables

- Rocket Engine – MK4 Sample Model, by Prusa Research via Printables

Headphone Stand, by Str8_3D via Printables

What's Changed?

If some of the comments look like they don’t belong, that’s because this article was adapted from a previous Original Prusa MK4 speculation piece. It was fun to write, and more fun to score. We got a lot right, but are maybe a little sour that linear rails didn’t make an appearance. Six out of seven of our “definitely” predictions isn’t bad, though. Right? Right.

Update – April 24, 2023: We’ve been printing with the MK4 for a couple of weeks and have furiously scribbled our thoughts into a full review. Expect updates to follow, as we eagerly await a speed boost from the expected input shaping firmware update.

License: The text of "Original Prusa MK4 Review: Good Changes, but Too Late" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.